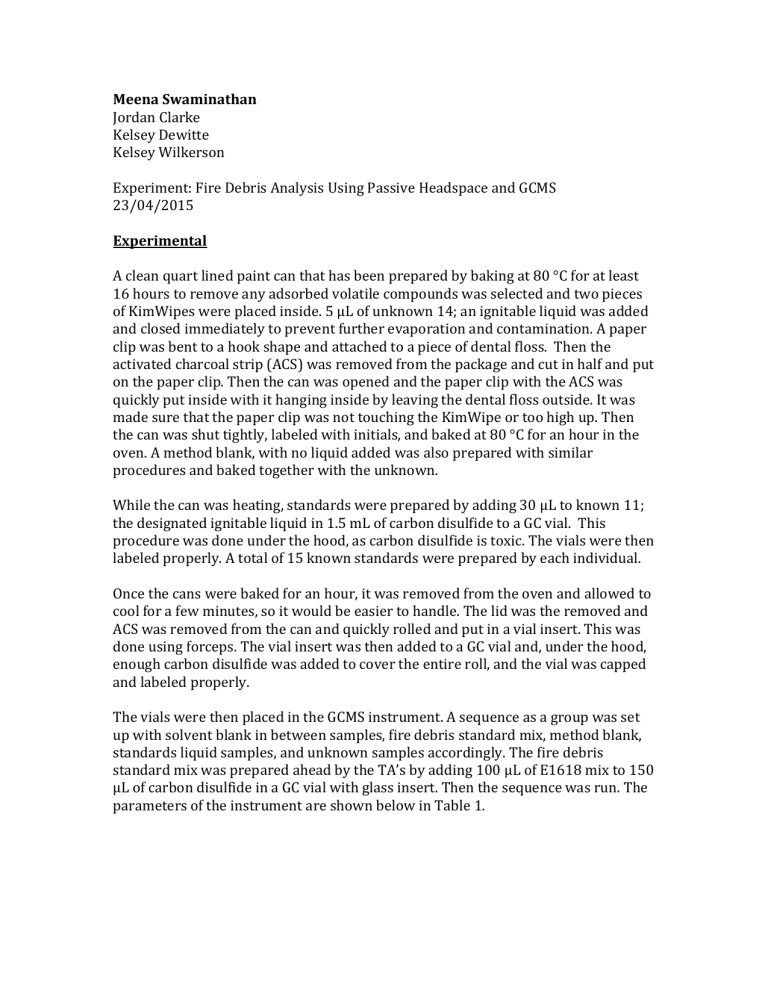

Meena Swaminathan Jordan Clarke Kelsey Dewitte Kelsey Wilkerson Experiment: Fire Debris Analysis Using Passive Headspace and GCMS 23/04/2015 Experimental A clean quart lined paint can that has been prepared by baking at 80 °C for at least 16 hours to remove any adsorbed volatile compounds was selected and two pieces of KimWipes were placed inside. 5 μL of unknown 14; an ignitable liquid was added and closed immediately to prevent further evaporation and contamination. A paper clip was bent to a hook shape and attached to a piece of dental floss. Then the activated charcoal strip (ACS) was removed from the package and cut in half and put on the paper clip. Then the can was opened and the paper clip with the ACS was quickly put inside with it hanging inside by leaving the dental floss outside. It was made sure that the paper clip was not touching the KimWipe or too high up. Then the can was shut tightly, labeled with initials, and baked at 80 °C for an hour in the oven. A method blank, with no liquid added was also prepared with similar procedures and baked together with the unknown. While the can was heating, standards were prepared by adding 30 μL to known 11; the designated ignitable liquid in 1.5 mL of carbon disulfide to a GC vial. This procedure was done under the hood, as carbon disulfide is toxic. The vials were then labeled properly. A total of 15 known standards were prepared by each individual. Once the cans were baked for an hour, it was removed from the oven and allowed to cool for a few minutes, so it would be easier to handle. The lid was the removed and ACS was removed from the can and quickly rolled and put in a vial insert. This was done using forceps. The vial insert was then added to a GC vial and, under the hood, enough carbon disulfide was added to cover the entire roll, and the vial was capped and labeled properly. The vials were then placed in the GCMS instrument. A sequence as a group was set up with solvent blank in between samples, fire debris standard mix, method blank, standards liquid samples, and unknown samples accordingly. The fire debris standard mix was prepared ahead by the TA’s by adding 100 μL of E1618 mix to 150 μL of carbon disulfide in a GC vial with glass insert. Then the sequence was run. The parameters of the instrument are shown below in Table 1. Table 1: GCMS Parameters Oven Temp and time Ramps Run Time Inlet mode Inlet initial temp & pressure Split ratio Split flow Total flow Gas Type Column Type Column max. temp Column Length Column diameter Injector Volume Solvent Delay Initial temp: 60 °C & Initial time: 2.00 min Rate: 10.00 Final Temp: 300 °C 26.00 min Split 250 °C & 8.19 psi 20:1 19.9 mL/min 23.8 mL/min He Restek Rxi-5ms DB5 350 °C 30.0 m 250 μm 1.00 μL 3.0 min Results and Discussion The total ion chromatogram and extracted ion chromatogram of unknown 14 is attached to the back of this report, and are labeled accordingly. From the chromatograms it can be seen that the carbon range is between around C4 to C10; and this would be considered a light product. Looking at unknown 14’s total and extracted ion chromatograms and comparing them with the 15 known total and extracted ion chromatograms; it seemed that unknown 14 was the most similar to known 11; which was Klean strip, a lacquer thinner. This would mean that unknown 14 would be an oxygenated product under the ASTM E1618 classification. The major peaks of unknown 14 chromatogram are clearly defined and spaced. The abundance for the chromatograms for the peaks is different; thus the peak sizes are smaller in unknown 14 than in known 11. However, upon closely comparing the extracted ion chromatogram, the retention times of the peaks in the alkanes, beginning of the aromatics and cycloalkane/alkene are similar. For example, in unknown 14 in the alkanes, the retention times are around a little after 4.00, a little before 6.00, about 7.50, and a little before 10.0. This matches the retention times in known 11 alkanes. Also in aromatics there are two peaks beside each other around 3.00 and a little after in unknown 14, and this is the same in known 11. Unknown 14 was first identified to be similar to known 2, which was America’s Original Drygas Brand, a fuel injection and carb cleaner. This was due to the fact that the total ion chromatogram looked similar. However, upon looking closely the peaks in known 2’s total ion chromatogram had more “hash and trash,” and there were not much single distinct peaks, and the overall shape was different. Also the extracted ion chromatogram was different as well. Thus, in the end it was excluded as a possibility. Conclusions Fire debris analysis using passive headspace, with activated charcoal strips, and GCMS analysis was performed on an unknown liquid, unknown 14. Known standards were also prepared and analysed by GCMS. The total ion chromatograms and extracted ion chromatograms of unknown 14 and known were compared, and known 11, which was Klean strip, a lacquer thinner. Unknown 14 had a carbon range of around C4 to C10, which indicated that unknown 14 was a light product. Also the peaks were clearly defined and spaced; there were higher than the baseline and not really connected to the baseline. From this and extracted ion chromatogram, unknown 14 was classified to be an oxygenated product under the ASTM E1618 classification. This information matched as known 11 was also a light oxygenated product. Thus, it was concluded that unknown 14 was most probably known 11, the Klean strip, a lacquer thinner.