A.A.I.T

Center of Energy Technology

Graduate Program in Energy Technology

Subject: Photovoltaic Systems Engineering

Course no. ECEG - 6442

Submited Assignment #1.

Question #1. Review on PV manufacturing technology

#2. PV System Design Illustrating Typical Methodology.

By: EFREM NEGUSSIE

Id No GSR/2911/11

May, 2019

#1. A Review on PV Manufacturing Technologies including Cost &

Performance.

Elemental silicon is used in photovoltaics as the main semiconductor material

converting light to electricity.

Solar cells called photovoltaics made from thin slices of crystalline silicon,

gallium arsenide, or other semiconductor materials convert solar radiation

directly into electricity.

PV modules are made by connecting several cells (usually 36) in series and

parallel to achieve useful levels of voltage and current, and putting them in a

sturdy frame complete with a glass cover and positive and negative terminals

on the back.

Photovoltaics as energy source which material and which natural

resources are critical to secure long term sustainability of the energy

source.

Silicon

The element silicon is one of the most abundant elements in Earth’s crust, second only to

oxygen. Most rocks consist of silicon in combination with other elements.

Source:[Charles D. Winters/Photo Researchers, Inc. Microsoft ® Encarta ® 2009. ]

According to survey of commercial & organizations multicrystal silicon has

huge share of market of photovoltaic.

Silicon is a semiconductor, in which the resistivity to the flow of electricity at

room temperature is in the range between that of metals and that of insulators.

The conductivity of silicon can be controlled by adding small amounts of

impurities, called dopant like Boron. The ability to control the electrical

properties of silicon, and its abundance in nature, have made possible the

development and widespread application.

Validity for semiconductor material whose band-gap has to perform

the efficient conversion of sunlight to electricity.

Commercial silicon bulk material is of two types:

• The metallurgical grade,• The semiconductor grade,

Our interest is in the The semiconductor grade,

Manufacturing Technologies

The atomic number of silicon is 14 so with 4 electron in the outer shell

configuration it is a group IV of the periodic table

-First isolated from its compounds in 1823 by the Swedish chemist Baron Jöns

Jakob Berzelius. The element’s name comes from the Latin word for flint, a

mineral that contains silicon. The raw material, from which silicon is made,

quartz or quartzite.

-Glass made of silicate dated back to 12 000B.C.

- Elemental silicon was prepared for the first time in 1824 by Berzelius,

passing silicon tetrachloride over heated potassium.

- Silicon tetrachloride could be prepared by chlorinating silicate/silica

- The first crystalline silicon was made accidentally in 1854by Sainte-Claire

Deville working on aluminium electrolysis.

The first preparation of silicon/silicon rich alloys in an electric arc furnace

was performed by Moisan in 1895 and the industrial production was by Bozel

and Rathenau independently from 1897 to 1898. . [Ref #1. Handbook of Photovoltaics

Science and Engineering, Wiley2003,Chapter 5]

-silicon-based technologies and their characteristics

(Semiconductor

application)

1. Crystallline

2. Thin Film

3. From Groupiii-iV cells

1. Crystallline

Single, Multi or Poly

Manufacturing silicon PV systems.

First, polysilicon is processed from mined quartz until it is very pure (semiconductor grade). This is melted down when small amounts of boron, a

group III element, are added to make a p-type semiconductor rich in electron

holes. Typically using a seed crystal, an ingot of this solution is grown from

the liquid polycrystalline. Wafers of this semiconductor material are cut

from the bulk material with wire saws, and then go through surface etching

before being cleaned. Next, the wafers are placed into a phosphorus vapor

deposition furnace which lays a very thin layer of phosphorus, a group V

element, which creates an n-type semiconducting surface. To reduce energy

losses, an anti-reflective coating is added to the surface, along with electrical

contacts. After finishing the cell, cells are connected via electrical circuit

according to the specific application and prepared for shipping and

installation. [Ref#2 Wikepedia,]

Single Crystal

Czochralski method: itfollows melting pure Si: under vacuum: Deeping seed

crystal: Seed crystal for molten crystal crystallizes to the seed[rod spinning]

Formed controlled by the temperature, rotation of the road, pull rate] Ingot

cut, thinned to wafer which is equivalent to solar cell

Float zone method : where Cylindrical poly silicon rod is used, with seed

crystal in its lower end;

Melting by inductive heating; by pulling action on the molten zone;

solidified single crystal formation at with impurities in molten zone

Multi crystal; Ribbon silicon technique

• Crucible molten silicon and 2 graphite filaments, growing molten silicon

horizontally through capillary action along filaments, forming long wafer,

ribbon like sheet of multi crystalline Si, thickness controlled by filament

width & pull speed

Poly – multi crystalline method:

• Silicon wafer in the form of either single crystal or multi crystal also called

multicrystal, Silicon source in large crucible and directional cooling action,

impurities drifted to edges then sawn in to thin wafers.

2. THIN FILM

Thin semiconductor on glass taking advantage of cheap glass material:

Amorphous type, P& n type.

Amorphous silicon, Monosilane (SiH4) is the source of silicon required for

the deposition of silicon amorphous thin film in a glow discharge or low

temperature plasma.

Thin-film PV, are manufactured by depositing semiconducting layers on

substrate in vacuum. The substrate is often glass or stainless-steel, and these

semiconducting layers are made of many types of materials such as

cadmium telluride (CdTe), copper indium diselenide (CIS), copper indium

gallium diselenide (CIGS), and amorphous silicon (a-Si). After being

deposited onto the substrate the semiconducting layers are separated and

connected by electrical circuit by laser-scribing.

organic photovoltaics, OPVs fall into the thin-film category of

manufacturing.

3. Group III- Iv cells:

Other emerging PV technologies include organic, dye-sensitized, quantumdot, and Perovskite photovoltaic .

Polysilicon routes:

-Preparation

- Purification

- Recycling of by product

o Thermal decomposition of trichlorosiliane at high temperature on a

heated silicon rod placed inside a deposition chamber; called Siemens

Process ( fully developed around 1960)

o LLC company; Advanced Silicon Material; Monosilane Si H4

decomposition to Si and 2 H2

o MEMC corporation: use fluidized bed of heated silicon partition

rather than heated silicon rod of the closed chamber [Ref #1,

Wiley2003,Chapter 5]

ROUTES to solar grade:

1. Crystallisation is generally an effective purification technique.

Crystallization is also a necessary step to produce the silicon device.

Predicted by the segregation or the distribution coefficient of each impurity

element b/n the solid and liquid phases of silicon. Crystallization as

such cannot be satisfactory without prior treatments,

2. Upgrading the purity of metallurgical silicon is a technique with the

potential to produce enough amount for feed stock demand.

Purity at acceptable cost. The use of pure linings in the furnaces and the

intermediate vessels containing the liquid silicon was a first approach.

3. The polysilicon process involving the synthesis, the purification and the

decomposition to elemental silicon of volatile silicon hydrides .

4. Electrolysis, electrolytic methods, metallic reduction of silicon. The

aluminothermic reduction of silica, The electrolytic transfer of silicon

from an anode made partly of metallurgical grade silicon alloyed with Cu

Cost versus Performance

According to studies demand is the primary criteria for the process design. Capital

expenditure and energy consumption were considered secondary criteria. While

large production quantities of ultra-pure polysilicon were available at acceptable

prices for semiconductors, this price was too expensive for the development of

low-cost solar systems. For solar cells, a process with reduced costs, reduced

energy consumption and increased production rates, with purity levels not as

important, is predicted as necessity.

For this review and re-evaluation of the silicon chemistry of these a

process is suggested one development.

Cost reduction by selecting: Rejects from crystal growth: Crystal growth,

particularly by the CZ method, generates significant amounts of unusable

siliconasfollows:

• The head (or top) as well as the bottom (or tail) of the single crystal (also

called ingot or boule) Ingots from aborted runs, for example, because of

electrical

power

failure

during

crystal

pulling.

• Ingots or ingot sections that fail to meet the specifications of crystal

structure, electrical characteristics or carbon (C) and oxygen (O) content.

• Crucible leavings or pot scrap

Rejects from polysilicon: Four to five percent of polysilicon produced is also

rejected

for

quality

reasons.

These

are

• chunks and rods from aborted runs (failure under operation);

• broken or imperfect seed rods;

Recent development involves the makeup of solar cells states that a material called

as Perovskite is inexpensive material compared to the expensive crystalline silicon

which is still part of a standard PV cell build to this day.

(Ref # 2 Wikepedia,Michael

Graetzel, EPFL ]

Solar cell efficiencies vary from 6% for amorphous silicon-based solar cells

to 44.0% with multiple-junction concentrated photovoltaics. Solar cell

energy conversion efficiencies for commercially available photovoltaics are

around 14–22%.

Generally photovoltaic 10 -20 percent efficient in converting sunlight,

design

lifetimes

of

over

10

years

price Si 35 to 55 US$/kg

Silicon is one of the main, if not the largest, cost drivers of the installed PV

system. It accounts for approximately 25% of the wafer cost and 15% of the

cell cost.

Amorphous silicon has less production cost

Of 100 000 silicon crystals every year bulk monocrystalline material is

either by the Czochralski technique (80%) or the floating-zone technique

(20%).

The semiconductor grade, global annual output: 20 000 to 25 000 MT, price

35 to 55 US$/kg

Crystalline silicon modules are the most commonly used. Mono-crystalline

silicon photovoltaic systems (mono-si) have an average efficiency of 14.0%.

Techniques to produce multi-crystalline silicon (multi-si) photovoltaic cells

are simpler and cheaper than mono-si, however tend to make less efficient

cells, an average of 13.2%.

Multijunction cells have (materials with varying spectral response) have

been constructed that have efficiencies of more than 30 % absorbing highenergy photons multi-junction concentrator solar cell with an efficiency of

46.0% produced by Fraunhofer ISE in December 2014. The highest

efficiencies achieved without concentration include a material by Sharp

Corporation at 35.8% using a proprietary triple-junction manufacturing

technology in 2009, and Boeing Spectrolab (40.7% also using a triple-layer

design). The US company SunPower produces cells that have an efficiency

of 21.5%, well above the market average of 12–18%.

Ultrahigh-efficiency devices (η>30%)[31] are made by using GaAs and

GaInP2 semiconductors with multijunction tandem cells. High-quality,

single-crystal silicon materials are used to achieve high-efficiency, low cost

cells (η>20%).

Organic photovoltaic cells (OPVs) have made significant advancements in

power conversion efficiency from 3% to over 15% since their introduction in

the 1980s. To date, the highest reported power conversion efficiency ranges

from 6.7% to 8.94% for small molecule, 8.4%–10.6% for polymer OPVs,

and 7% to 21% for perovskite OPVs

Cadmium telluride (CdTe) thin film based solar cells. This new thin film

device also shares similar performance restrictions (Shockley-Queisser

efficiency limit) as conventional Si devices but promises to lower the cost of

each device by both reducing material and energy consumption during

manufacturing. This technology’s highest power conversion efficiency is

21%.[61]

Purity versus cost guiding number should remain less than 10 US$/kg

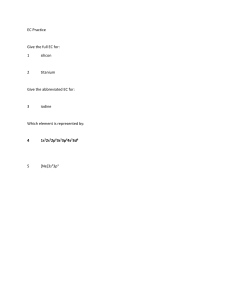

The comparative and here pasted diagrammatic expression taken from “Wikepedia Photovoltaics

section “shows trend of Conversion efficiencies of best research solar cells worldwide for various

photovoltaic technologies since 1976up to forecasted 2020.

Multi-junction cells: Concentrator PV, Solar panels on spacecraft, Gallium Arsenide (GaAs)

Crystalline Si Cells: Single crystal, Multicrystalline

Thin-Film Technologies: CdTe, CIGS, Amorphous Si

Emerging PV: Dye-sensitized solar cells, Perovskite solar cells, Organic solar cells, CZTSSe,

Quantum dot solar cells

References:

1 Handbook of Photovoltaics Science and Engineering, Wiley 2003,

Edited Antonio Luck, Steven Hegedus.

2 Wikepedia, Photovoltaics (Browsed May 2019)

#2.

PV System Design Illustrating Typical Methodology.

A home solar system for back up application in case of outage of usual electric power

supply uses a photovoltaic energy source for the following loads.

Appliance

quantity Rating,

each

LCD

1

Television

Radio

Operating Corresponding Maximum

Hours/day Ampere

Power

Hours.

consumption

4 hrs

12Ahr

240W hr

20V,

3A

1

2 hrs

1Ahr

12W hr

3 hrs

31.5Ahr

157.5W hr

4 hrs

40Ahr

600W hr

10 hrs

10Ahr

100W hr

4 hrs

14Ahr

266W hr

100.5A hr

1375W hr

12V,

0.5 A

Cell

Phone

3

Lamp

,CFL

5

LAMP,

LED

2

Laptop

1

15 V,

3.5A

15V,

2A

10V,

0.5A

19V,

3.5A

SUM

Maximum operating voltage from each appliance is 20V.

Let select 24 V as a system voltage.

Peak power needed is 1.375 KWhr [from table]

Corresponding Ampere hour required with respect to system voltage.

Ampere hour = Peak power/ System Voltage = 1.375 KWhr/24V = 58Ahr.

Solar Array size: 58 Ahr * 1.3 { where 1.3 is a multiplier considering losses)

Solar Array = 76Ahr; 24 V

Storage Battery Sizing: 58 * 6 = 348 Ahr{ where 6 is a multiplier for better storage

capacity}

Selecting a module with 36 cells, {rated for 6.75 A and 17 V,}

If one string contains 4 modules

From 4 modules rated 6.75 A we get [ 6.75* 4 = 27 Ahr]

For the required 76 Ahr consumption {Solar array capacity required; calculated}

Number of strings required: Number of Strings = 76 Ahr/ 27Ahr = 3.8 =4 Strings

{576 cell==16 modules == 4 Strings}

Power Output from Single module [6.75 A * 17V = 114.75 W]

Total Power from Solar Array at any time [ 16 modules * 114.75 W = 1836W}

Peak power needed is 1.375 KWhr.

Therefore the selected 4 string of solar array 36 cell module rated for 6.75

A and 17 V, seen here has capacity higher than the peak power implies

covering wiring and other losses is selected well.

And the battery storage size with 348 A hr is to accommodate the loads when the

direct solar power is unavailable as it is durational.