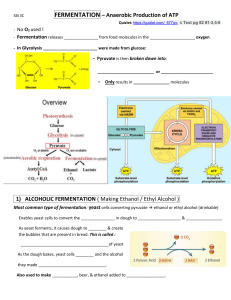

ANALYSIS OF FERMENTATION PROCESS USING PLANT EXTRACT AJUGA REMOTA PROJECT PROPOSAL SUBMITTED TO MASINDE MULIRO UNIVERSITY OF SCIENCE AND TECHNOLOGY In partial fulfillment of Bachelor’s Degree in Industrial Chemistry By JOSEPH WAMBUA NJOROGE SIC/B/01-00016/2019 ii DECLARATIONS I declare that this project “analysis of fermentation using plant extract Ajuga Remota” is an original work done by me under the supervision of Prof. Duston B Lilechi Faculty of Pure and Applied Chemistry, University of Masinde Muliro of Science and Technology. JOSEPH WAMBUA NJOROGE SIC/B/01-00016/2019 SIGNATURE DATE Supervisor approval This project proposal has been submitted for examination with my approval. SIGNATURE DATE iii ACKNOWLEDGEMENT I thank the almighty God for giving me knowledge, wisdom, mercy, and grace throughout the period of the program. I sincerely appreciate my supervisor Prof. Duston B Lilechi for offering assistance that led me through the various stages of this project. I give thanks to my parent, my siblings, and my friends for their unquantifiable love and financial assistance during this period, may you live long to see my success and enjoy the fruit of your work. iv ABSTRACT Most commercial alcohols are produced through the fermentation process, it’s usually affected by two types of wild bacteria that is Lactobacillus Fermentum and Dekkera Bruxellensis which are mutated from Saccharomyces Cerevisiae fermentation yeast. Wild yeast bacteria affect the productivity of fermentation by contaminating the process; thus, pretreatment is highly required. Most industries use sulphuric acid to regulate the growth of bacteria but these wild bacteria are tolerant to acid treatment and the low pH of the mush. Different plants extract which have antimicrobial properties can be employed to combat the growth of this wild yeast bacteria during the fermentation process which can lead to increased productivity of the process. In this project juice extract from Ajuga Remota a spice of Ajuga Australis will be used, it is suspected to have some antimicrobial properties, thus threefermentation experiment will be carried out; one with my plant extract (Must 3), the other with one in acidified water of pH 2.0 (Must 2), and lastly one without any treatment to control the experiment (Must 1). The fermentation will run for five days, after which alcohol concentration of each fermentation will be determined using an alcohol meter and 1000ml of the fermented mush will be subjected to distillation process to obtain ethanol with will be analyzed using GC-MS to know the quality of ethanol produced from the three different fermentation experiment. v Table of content DECLARATIONS .....................................................................................................................ii ACKNOWLEDGEMENT ....................................................................................................... iii ABSTRACT .............................................................................................................................. iv 1 2 3 INTRODUCTION .............................................................................................................. 1 1.1 BACKGROUND ......................................................................................................... 1 1.2 STATEMENT OF PROBLEM ................................................................................... 2 1.3 OBJECTIVE................................................................................................................ 2 1.3.1 specific objective ................................................................................................. 2 1.3.2 Significance of the study and the anticipated outcome ........................................ 2 LITERATURE REVIEW ................................................................................................... 3 2.1 FERMENTAION PROCESS ...................................................................................... 3 2.2 DISTILLATION PROCESS ....................................................................................... 3 2.3 ETHANOL ANALYSIS ............................................................................................. 4 2.4 BACTERIA L. FERMENTUM AND D. BRUXELLENSIS ..................................... 4 2.5 AJUGA REMOTA ...................................................................................................... 5 METHODOLOGY ............................................................................................................. 6 3.1 SAMPLING SITE ....................................................................................................... 6 3.1.1 Plant material sampling........................................................................................ 6 3.2 PLANT PROCESSING .............................................................................................. 7 3.3 STRAIN ...................................................................................................................... 7 3.4 FERMENTATION EXPERIMENT SECTION ......................................................... 7 3.4.1 Fermentation materials and apparatus ................................................................. 7 3.4.2 Fermentation Process ........................................................................................... 7 3.5 Distillation and Analysis method ................................................................................ 8 REFERENCES .......................................................................................................................... 9 1 CHAPTER ONE 1 1.1 INTRODUCTION BACKGROUND Ethanol belongs to an important class of organic compounds with the general name ‘Alcohols’. In the early day’s ethanol was used as a constituent of alcoholic beverages, through advancements in technological science and civilization benefits extracted from ethanol have multiplied continuously which include solvent, germicides, antifreeze, fuel, and versatile intermediate for other organic chemicals. Because of these advantages, research and investigation have been geared toward the production of ethanol from different raw materials (Feedstock). However, the environmental destruction resulting from the overconsumption of petroleum-derived products, particularly the fuels consumed in the transport industry is threatening the sustainability of human society (Bai et 2008). High consumption of fossil fuels especially in large urban areas has resulted in high levels of pollution during the last decades. Agriculture wastes that are dependent on fossil fuels can be used and reduced, in particular, molasses, a byproduct generated in the process of sugar cane refining. Molasses can be used as bioethanol raw material as it contains 50%-60% sugar, amino acids, and minerals such as potassium 300-1200 mg/L, calcium 150-2000 mg/L, and magnesium 80-3900mg/L. Ethanol production using has gained more interest because its high rich in sucrose, has low cost, and does not require pre-treatment before fermentation. Bioethanol fermentation can be carried out using various microorganisms such as yeast, fungi, and bacteria. The yeast strain saccharomyces cerevisiae is the most useful microorganism for ethanol production by fermentation of various raw materials rich in sugar. The sugars in fermentation broth are metabolized y saccharomyces cerevisiae in the absence of oxygen, producing ethanol and carbon dioxide as shown in the equation below. C6H12O 2CH3CH2OH + 2CO2 Over the years, ethanol production processes have improved considerably, initially annexed distilleries were used to process molasses from the sugar industries, but with the increasing ethanol importance in the 1980s, mills began to run as autonomous distilleries which only produced ethanol. 2 To monitor the process productivity High-performance liquid chromatography and Gas chromatography are used to quantify the components present in the fermentation broth. However, the separation and quantification of all the different components in the fermentation broth have not been successfully achieved using only one of these two instruments. Using simultaneously both instruments increase the capital cost and time required to perform an analysis. 1.2 STATEMENT OF PROBLEM The fermentation process is affected by wild yeast species of the genus Lactobacillus fermentum and Dekkera Bruxellensis which are indigenous yeast from Saccharomyces Cerevisiae. This wild yeast causes contamination of the mush hence low production of ethanol. Most industries employ the pre-treatment stage in the fermentation by acidification of the mush using sulphuric acid to combat the growth of bacteria but most bacteria are tolerant to acid and high-temperature treatment thus this method is not very effective and other ways should be developed to protect this process. Acid treatment during the fermentation cycle can result in increased cost and environmental pollution. 1.3 OBJECTIVE 1.3.1 specific objective I. II. To control bacteria growth in fermentation using Ajuga remota To test whether there is a significantly different between the plant extract and acid treatment through a comparison of their activity. 1.3.2 Significance of the study and the anticipated outcome To come out with a new way of dealing with contamination caused by different bacteria the fermentation process by use of plant extract that has antimicrobial properties and to propose further research and screening to exploit this plant commercially. Also, ethanol-producing industries will use this knowledge to reduce the cost associated with using sulphuric acid in the pre-treatment stage and manufacture quality ethanol beverages with some medicinal properties, and come out with a new alcoholic brand. 3 CHAPTER 2 2 2.1 LITERATURE REVIEW FERMENTAION PROCESS Sugar is fermented to ethanol by yeast, fermentation starts by mixing jaggery, molasses, or sugarcane juice which contains 18%-22%(W/W) total reducing sugars to the yeast cell suspension. However, the growth of yeast cells depends on a few parameters, the most important one is the acidification of the mush to protect the fermentation process against bacterial contamination of the genus Dekkera Bruxellensis and Lactobacillus fermentum, to control this the industries apply sulfuric acid which is water diluted adjusted to pH 2.0-2.5 between the fermentation cycles. This treatment is not always effective to hinder bacterial contamination. Fed-batch process among batch and continuous process is commonly used in 1G ethanol production, feeding time usually takes 4-6 hours and fermentation takes 6-10 hours depending on conditions employed. Before fermentation starts the fermentation, the vat is loaded with carbon dioxide gas before the addition of yeast (Saccharomyces Cerevisiae). During fermentation, yeast converts sucrose into reduced sugars by the use of the enzyme invertase. Since molasses calcium ions affect fermentation by inhibiting the enzyme activity of invertase, decalcification using sulfuric acid is normally used. In the fermentation broth, several products are present including acetone, butanol, ethanol, acetic acid, butyric acid, and sugars (glucose and xylose). To be able to characterize the fermentation process (yield productivity and concentration of the products and each of the byproducts) precise quantification of all components is required. 2.2 DISTILLATION PROCESS Distillation is the most dominant and recognized industrial purification technique of ethanol. It utilizes the differences of volatilities of components in a mixture. The basic principle is that by heating a mixture, low boiling point components are concentrated in the vapor phase. By condensing this vapor, more concentrated less volatile compounds is obtained in liquid phase. Distillation is one of the most efficient separation techniques. However, it contains several problems. One is separation of volatile compounds. In ethanol production, a distillation tower is designed to separate water and ethanol effectively. Water is obtained from the bottom of the tower and ethanol is obtained from the top of the tower. It is expected that impurities with 4 similar boiling points to ethanol lodges in ethanol even after distillation. Second is its cost. Distillation is a repetition of vaporization and condensation. Therefore, it costs a lot. 2.3 ETHANOL ANALYSIS Gas chromatography (GC) is an analytical technique for volatile and semi-volatile compounds. Many ethanol analyses have done with GC since impurities in ethanol are basically volatile as well as ethanol itself (Hide et al., 2001, Campo et al., 2007, Rodrigues et al., 2008). A sample is vaporized at an injection port by heat. The sample vapor is sent to column packed with adsorbent or absorbent. Inside column, each component in sample is separated depending on its physical and chemical property. The end of column the concentration of each compound is measured by a detector. There are many kinds of coatings for column. A coating should be chosen depending on the target compounds. Also, there are many kinds of detectors. Each detector has advantages and disadvantages. Thus, a detector should also be chosen carefully to detect target compounds. Gas chromatography-mass spectrometry (GC-MS) is an integrated system of two analytical equipments. Gas chromatography separates analytes and mass spectrometry identifies them. GC-MS accelerates ethanol analysis with its simultaneous separation and identification capacities. 2.4 BACTERIA L. FERMENTUM AND D. BRUXELLENSIS Lactic acid bacteria (LAB) are one of the main contaminant groups in industrial fermentation using yeast and several species have been identified and isolated from this process. Lactobacillus fermentum and Lactobacillus Brevis are the most common contaminants in ethanol production. Due to the high growth rate, resistance to high concentrations of ethanol, tolerance to low acid pH 2.0–2.5, and high temperature, LAB can compete directly with fermentation yeast for sugar substrate, and can improve the fermentation process through the production of organic acids, mainly lactic acid. Bacterium Lactobacillus vini isolated from several ethanol productions (fermentation broth) that reacts with yeasts and is associated with the presence of Dekkera Bruxellensis. D. Bruxellensis is an unconventional yeast that has supplanted the traditionally used Saccharomyces Cerevisiae in several ethanol production plants using continuous cell fermentation and imparts some aromatic properties to some red wines and adds flavor to some beers. Although D. Bruxellensis is usually considered a contaminant in bioethanol production, D. Bruxellensis has similar or higher ethanol 5 production than S. Cerevisiae and has low glycerol formation, high tolerance to ethanol, high biomass yield, high temperature, and high pH Tolerance, but on the other hand it has lower specific ethanol production and growth rates than S. cerevisiae and can be competitive in batch fermentation. 2.5 AJUGA REMOTA The genus of Ajuga belongs to the family Lamiaceae and contains at least 301 species. Many of these plants have been used in traditional medicine. Ajuga remota in particular is traditionally used as a herbal remedy for fever and infections, and is prescribed for malaria by 66% of the Kenyan herbalists. A large number of compounds have already been isolated from A. remota, including ergosterol-5,8-endoperoxide (6), ajugarin-I (1), 8-O-acetylharpagide (5) and several phytoecdysteroids. In vitro pharmacological studies have been conducted on constituents of A. remota of which some of them displayed a concentration-dependent inhibition of chloroquine-sensitive and -resistant Plasmodium falciparum and Mycobacterium tuberculosis. the aerial part of Ajuga remota Benth is used in the treatment of diarrhea. There is a continuous and urgent need to discover new antidiarrheal compounds with diverse chemical structures and novel mechanisms of action. Therefore, researchers are increasingly turning their attention to folk medicine, looking for new leads to develop better drugs against diarrheal diseases. Ajuga remota is an erect rhizomatous pubescent herb found growing in the grasslands and other geographic parts of East Africa especially in Kenya and Ethiopia. In Ethiopia, one of the vernacular names of A. remota is Armagusa (oromiffa), the name given by the community that uses this plant for the management of diarrhea. The herb is not eaten by animals, birds or insects. This is probably due to the very bitter taste of almost all its parts. The species A. remota is also known by other names such as A. integrifolia Buch. -Ham, and A. bracteosa Wall.ex. Benth. Several studies are conducted on many species of the genus Ajuga and their active compounds have been identified. These efforts have led to the isolation of a number of compounds, including phytoecdysteroids, neo-clerodane diterpenes, diterpenoids (ajugarin I, II, III, IV &V, and others), triterpenes, specific-sterols like beta-sitosterol, gamma-sitosterol, ceryl alcohol, anthocyanidin-glucosides, iridoid glycosides, flavanol glycosides, quinolones, withanolides, flavonoids, tannins, triglycerides and essential oils. 6 In East Africa, plants of the genus Ajuga have been used as a remedy for fever, toothache, severe stomachache, dysentery, high blood pressure, malaria, edema, pneumonia and liver problems. In North Africa, plants of the genus Ajuga are used to treat diabetes and hypertension, as a panacea (cure-all), specifically for gastrointestinal disorders, and as an anthelmintic. In traditional Chinese pharmacopoeia, plants of the genus Ajuga are known to produce a diuretic effect. Other ethnobotanical claims of the plant include treatment of diarrhea, gout, jaundice, amenorrhea, yellow fever, and as antiinfective. Pharmacological studies have been carried out with A. remota since 1976 and it has been reported that A. remota possesses antimalarial activity, analgesic activity, anti-Human Immunodeficiency Virus Type 1 (HIV-1) and Type 2 (HIV-2) activity, antioxidant /oxygen scavenging activity, diuretic activity, antibacterial activity as well as anthelmintic activity. There are different mechanisms by which A. remota may have antidiarrheal effect. Some of the possible mechanisms are through its anthelmintic and antibacterial activities. CHAPTER THREE 3 3.1 METHODOLOGY SAMPLING SITE 3.1.1 Plant material sampling A. remota was collected in January 10th 2023 from Makadara constituency, Nairobi County based on ethnopharmacological use through interview with different communities who know the plant. Information gathered include vernacular names and the active sites of the plant used in preparation of herbal antibacterial remedies. The plant was identified by Mr. Seth 7 Omuse undergraduate student of the Pure and Applied Chemistry who knew the plant very well. 3.2 PREPARATION OF PLANT EXTRACT Plant aerial parts were chopped into small pieces, sun dried for one week. 33.6g of the dried plant sample was soaked in 700ml water and heated until the water boiled to dissolve the active compounds from the plant, the mixture was filtered to obtain 500ml of the filtrate which was used in fermentation. 3.3 STRAIN Saccharomyces cerevisiae strain will be purchased from Kakamega shopping Centre Khetia’s supermarket where it’s available. 3.4 FERMENTATION EXPERIMENT SECTION 3.4.1 Fermentation materials and apparatus Jaggery, Yeast, Sugar, juice extract from Ajuga Remota, sulphuric acid, Acidified water with pH 0.2, 5L plastic bottles, distilled water, saline water, clear 1000ml glass jar. 3.4.2 Fermentation process 1 kg of jaggery will be blended with saline water (9kg of salt per liter) then added to a mixture of 2L distilled water and 110g of yeast repeated in three cycles to make up the fermentation experiments referred as Musts. The three musts will have distinctly different fermenting characteristics, must 1 will contain no treatment, must 2 will contain acidic treatment and must 3 will contain plant extract treatment limiting the growth of spoilage microorganism. The fermentation process will be initiated at ambient temperature with saccharomyces cerevisiae yeast in a plastic 5L bottles stored in the dark away from direct sunlight for five days. 8 Fig 1.0 FERMENTATION EXPERIMENTS 3.5 DISTILLATION AND ANALYSIS METHOD After 5 days of fermentation one liter from each must will be distilled to obtain ethanol and of the sample will be taken for analysis using GC-MS to know the concentration and purity of ethanol produced from the three fermentation experiments. 3.6 RESULTS AND DISCUSION 9 REFERENCES El-Gendy, Nour Sh, Hekmat R. Madian, and Salem S. Abu Amr. "Design and optimization of a process for sugarcane molasses fermentation by Saccharomyces cerevisiae using response surface methodology." International Journal of Microbiology 2013 (2013). Tripathi, Abhishek Dutt, et al. "Utilizing of sugar refinery waste (cane molasses) for production of bio-plastic under submerged fermentation process." Journal of Polymers and the Environment 20.2 (2012): 446-453. Tang, Y. Q., An, M. Z., Zhong, Y. L., Shigeru, M., Wu, X. L., & Kida, K. (2010). Continuous ethanol fermentation from non-sulfuric acid-washed molasses using traditional stirred tank reactors and the flocculating yeast strain KF-7. Journal of bioscience and bioengineering, 109(1), 41-46. Gasmalla, M. A. A., Yang, R., Nikoo, M., & Man, S. (2012). Production of ethanol from Sudanese sugar cane molasses and evaluation of its quality. J Food Process Technol, 3(7), 163-165. Khanna, P. S., & Kocher, G. S. (2016). Enhanced ethanol production through salt preconditioning of S. cerevisiae MTCC 11815. International Journal of Food and Fermentation Technology, 6(2), 289. Steensels, J. and Verstrepen, K.J., 2014. Taming wild yeast: potential of conventional and nonconventional yeasts in industrial fermentations. Annu Rev Microbiol, 68(1), pp.61-80. Bassi, Ana Paula Guarnieri, et al. "Interaction of Saccharomyces cerevisiae–Lactobacillus fermentum–Dekkera bruxellensis and feedstock on fuel ethanol fermentation." Antonie Van Leeuwenhoek 111.9 (2018): 1661-1672. de Souza, Rafael Barros, et al. "The consequences of Lactobacillus vini and Dekkera bruxellensis as contaminants of the sugarcane-based ethanol fermentation." Journal of Industrial Microbiology and Biotechnology 39.11 (2012): 1645-1650. Maria, C., et al. "Neo-clerodane diterpenoids from Ajuga australis and A. orientalis." Phytochemistry 45.1 (1997): 121-123. Ramazanov, N. Sh. "Phytoecdysteroids and Other Biologically Active Compounds from Plants of the Genus Ajuga." Chemistry of Natural Compounds 41.4 (2005). Young, Jinchuan, Peter J. Lee, and A. Di Gioia. "Fast HPLC analysis for fermentation ethanol processes." Waters Corporation, Milford, MA (2006). 10