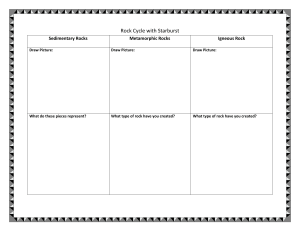

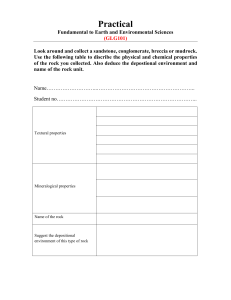

PLOS ONE Comprehensive evaluation method of stope stability and its application in deep metal mine --Manuscript Draft-Manuscript Number: Article Type: Research Article Full Title: Comprehensive evaluation method of stope stability and its application in deep metal mine Short Title: Comprehensive evaluation method of stope stability Corresponding Author: Hong Zhou Northeastern University Key Laboratory of Safe Mining of Deep Metal Mines Ministry of Education Shenyang, CHINA Keywords: stope structural parameters; rock mass quality classification; stope stability; support design Abstract: The problem of high stress condition is a critical challenge for mining activity in deep metal mine, and the difficulty and economic cost of maintaining the stability of surrounding rock also increase. In order to ensure the stability of surround rock mass in the mining process, it is necessary to evaluate the stability of surround rock for a more stable stope structure. However, there are many kinds of methods for the rock stability assessment, most of them are based on the empirical and analytical methods, which lead to an uncertain result. In this paper, a comprehensive evaluation method including factors of stope stability, self-stabilization time, maximum safety span and support measure is determined, this assessment method is more likely to provide a comprehensive result. Finally, it was verified by the field application in Jiaojia Gold Mine. Results show that it can accurately evaluate the stability of the surrounding rock of the stope from different aspects compared with the traditional single evaluation method, and it leads to a more comprehensive and reliable result. Order of Authors: Zhaojun Qi Huanxin Liu Zhihai An Yantian Yin Zhen Liu Mingde Zhu Yunsen Wang Hong Zhou Opposed Reviewers: Additional Information: Question Response Financial Disclosure This work was funded by National Key R&D Programme of China (2021YFC3001304) and the Fundamental Research Funds for the Central Universities(N2101044). Enter a financial disclosure statement that describes the sources of funding for the The funders had no role in study design, data collection and analysis, decision to work included in this submission. Review publish, or preparation of the manuscript. the submission guidelines for detailed requirements. View published research articles from PLOS ONE for specific examples. Powered by Editorial Manager® and ProduXion Manager® from Aries Systems Corporation This statement is required for submission and will appear in the published article if the submission is accepted. Please make sure it is accurate. Unfunded studies Enter: The author(s) received no specific funding for this work. Funded studies Enter a statement with the following details: • Initials of the authors who received each award • Grant numbers awarded to each author • The full name of each funder • URL of each funder website • Did the sponsors or funders play any role in the study design, data collection and analysis, decision to publish, or preparation of the manuscript? • NO - Include this sentence at the end of your statement: The funders had no role in study design, data collection and analysis, decision to publish, or preparation of the manuscript. • YES - Specify the role(s) played. * typeset Competing Interests The authors have declared that no competing interests exist. Use the instructions below to enter a competing interest statement for this submission. On behalf of all authors, disclose any competing interests that could be perceived to bias this work—acknowledging all financial support and any other relevant financial or nonfinancial competing interests. This statement is required for submission and will appear in the published article if the submission is accepted. Please make sure it is accurate and that any funding sources listed in your Funding Information later in the submission form are also declared in your Financial Disclosure statement. View published research articles from Powered by Editorial Manager® and ProduXion Manager® from Aries Systems Corporation PLOS ONE for specific examples. NO authors have competing interests Enter: The authors have declared that no competing interests exist. Authors with competing interests Enter competing interest details beginning with this statement: I have read the journal's policy and the authors of this manuscript have the following competing interests: [insert competing interests here] * typeset Ethics Statement N/A Enter an ethics statement for this submission. This statement is required if the study involved: • • • • • Human participants Human specimens or tissue Vertebrate animals or cephalopods Vertebrate embryos or tissues Field research Write "N/A" if the submission does not require an ethics statement. General guidance is provided below. Consult the submission guidelines for detailed instructions. Make sure that all information entered here is included in the Methods section of the manuscript. Powered by Editorial Manager® and ProduXion Manager® from Aries Systems Corporation Format for specific study types Human Subject Research (involving human participants and/or tissue) • Give the name of the institutional review board or ethics committee that approved the study • Include the approval number and/or a statement indicating approval of this research • Indicate the form of consent obtained (written/oral) or the reason that consent was not obtained (e.g. the data were analyzed anonymously) Animal Research (involving vertebrate animals, embryos or tissues) • Provide the name of the Institutional Animal Care and Use Committee (IACUC) or other relevant ethics board that reviewed the study protocol, and indicate whether they approved this research or granted a formal waiver of ethical approval • Include an approval number if one was obtained • If the study involved non-human primates, add additional details about animal welfare and steps taken to ameliorate suffering • If anesthesia, euthanasia, or any kind of animal sacrifice is part of the study, include briefly which substances and/or methods were applied Field Research Include the following details if this study involves the collection of plant, animal, or other materials from a natural setting: • Field permit number • Name of the institution or relevant body that granted permission Data Availability Yes - all data are fully available without restriction Authors are required to make all data underlying the findings described fully available, without restriction, and from the time of publication. PLOS allows rare exceptions to address legal and ethical concerns. See the PLOS Data Policy and FAQ for detailed information. Powered by Editorial Manager® and ProduXion Manager® from Aries Systems Corporation A Data Availability Statement describing where the data can be found is required at submission. Your answers to this question constitute the Data Availability Statement and will be published in the article, if accepted. Important: Stating ‘data available on request from the author’ is not sufficient. If your data are only available upon request, select ‘No’ for the first question and explain your exceptional situation in the text box. Do the authors confirm that all data underlying the findings described in their manuscript are fully available without restriction? Describe where the data may be found in All relevant data are within the manuscript and its Supporting Information files. full sentences. If you are copying our sample text, replace any instances of XXX with the appropriate details. • If the data are held or will be held in a public repository, include URLs, accession numbers or DOIs. If this information will only be available after acceptance, indicate this by ticking the box below. For example: All XXX files are available from the XXX database (accession number(s) XXX, XXX.). • If the data are all contained within the manuscript and/or Supporting Information files, enter the following: All relevant data are within the manuscript and its Supporting Information files. • If neither of these applies but you are able to provide details of access elsewhere, with or without limitations, please do so. For example: Data cannot be shared publicly because of [XXX]. Data are available from the XXX Institutional Data Access / Ethics Committee (contact via XXX) for researchers who meet the criteria for access to confidential data. The data underlying the results presented in the study are available from (include the name of the third party Powered by Editorial Manager® and ProduXion Manager® from Aries Systems Corporation and contact information or URL). • This text is appropriate if the data are owned by a third party and authors do not have permission to share the data. * typeset Additional data availability information: Powered by Editorial Manager® and ProduXion Manager® from Aries Systems Corporation Cover Letter Dear Editors: We would like to submit the enclosed manuscript entitled “Comprehensive evaluation method of stope stability and its application in deep metal mine”, which is a research article, and we wish to be considered for publication in “PLOS ONE”. No conflict of interest exits in the submission of this manuscript, and manuscript is approved by all authors for publication. I would like to declare on behalf of my co-authors that the work described was original research that has not been published previously, and not under consideration for publication elsewhere, in whole or in part. All the authors listed have approved the manuscript that is enclosed. In this work, we found the evaluation of stope stability is extremely important in the process of metal mining, but there is no unified evaluation method at present, so we proposed a comprehensive evaluation method according to the common evaluation methods in engineering, which is more likely to provide a comprehensive result. In addition, I have read some research articles related to rock mechanics and mining in “PLOS ONE”, and hope this paper is also suitable for your journal. We deeply appreciate your consideration of our manuscript, and we look forward to receiving comments from the reviewers. Thank you and best regards. Yours sincerely, Hong Zhou E-mail: 2110404@stu.neu.edu.cn Manuscipt Click here to access/download;Manuscript;Manuscript.docx 1 Comprehensive evaluation method of stope stability and its application in deep metal 2 mine 3 Zhaojun Qi1, Huanxin Liu1, Zhihai An1, Yantian Yin1, Zhen Liu1, Mingde Zhu1, Yunsen Wang2,*, 4 Hong Zhou2 5 6 1 Deep 7 2 8 University, Shenyang, China. Mining Laboratory of Shandong Gold Group Co., Ltd., Jinan, China Key Laboratory of Ministry of Education on Safe Mining of Deep Metal Mines, Northeastern 9 10 *Corresponding 11 E-mail: wangyunsen@mail.neu.edu.cn(YW) author 12 1 13 Abstract: 14 The problem of high stress condition is a critical challenge for mining activity in deep metal 15 mine, and the difficulty and economic cost of maintaining the stability of surrounding rock also 16 increase. In order to ensure the stability of surround rock mass in the mining process, it is 17 necessary to evaluate the stability of surround rock for a more stable stope structure. However, 18 there are many kinds of methods for the rock stability assessment, most of them are based on the 19 empirical and analytical methods, which lead to an uncertain result. In this paper, a comprehensive 20 evaluation method including factors of stope stability, self-stabilization time, maximum safety 21 span and support measure is determined, this assessment method is more likely to provide a 22 comprehensive result. Finally, it was verified by the field application in Jiaojia Gold Mine. Results 23 show that it can accurately evaluate the stability of the surrounding rock of the stope from 24 different aspects compared with the traditional single evaluation method, and it leads to a more 25 comprehensive and reliable result. 26 Key words: stope structural parameters; rock mass quality classification; stope stability; support 27 design 28 1 Introduction 29 Mining industry supports the sustainable development of the national economy. With the 30 reduction and depletion of shallow mineral resources, it has become an inevitable trend among the 31 world mining industry to utilizing deep resources. More than 80 metal mines, mostly in South 32 Africa, are over 1000 meters deep, such as TauTona Gold Mine in Witwatersrand (3910m), East 2 33 Rand Gold Mine (3585m), Mponeng Gold Mine (4500m), Anglogold Gold Mine (3700) and the 34 deepest platinum palladium mine in South Africa (2200m). Moreover, there are 16 metal mines 35 with a mining depth over 1000m in China. In the future, with the development of exploration 36 technology and equipment, it is entirely possible to find a large number of metal deposits in the 37 depth of 3000~5000m. 38 With the mining activity going deeper, the ground stress increases, the mining technical 39 conditions and environment deteriorate seriously, and the mining cost increases sharply. The 40 premise of mining is to ensure the stability of rock mass during the mining activity, so it is 41 necessary to design a reasonable stope structure parameter, which could ensure its stability. From 42 the actual production situation of mining site, the structural parameters of the underground stope 43 occupies a decisive role in its stability. Meanwhile, it affect the economic benefits of mining. 44 When this parameter is too large, it will lead to instability and caving of surround rock, which also 45 increase the dilution and risk of operation. When it goes too small, resulting in a large mining 46 volume, low ore recovery rate and economic efficiency(1, 2). Therefore, stope stability is an 47 important index to evaluate the rationality of stope structure parameters. Stope instability directly 48 affects ore loss and dilution, reduces mine economic benefits and even affects mine safety 49 production. 50 Many scholars have done lots of researches on stope stability. Mathews et al. First proposed 51 the stability diagram method in 1981(3), which is an empirical formula summarizing from a large 52 number of engineering examples. In 1988, Potvin revised Mathews stability chart by analyzing 53 242 cases and redefining some adjustment factors(4). In 1992, Potvin and Nickson et al. verified 54 the rationality of this method and proposed amendments by collecting more deep mining field data 3 55 (5). In 2000, Trueman et al. based on a large number of new examples of data, using the method of 56 logarithmic regression to redefine the stable area and serious damage area (6). Moreover, 57 Mawdeskey et al. gave the determined the equal probability diagram of these two areas in 2001 58 (7). The general step of using Mathews stability diagram method to evaluate the stope is to 59 calculate the stability number N’ and hydraulic radius HR on the basis of numerical simulation, 60 draw those parameters on the diagram, and evaluate stope stability according to the diagram area 61 where the intersection is located. 62 With the revolution of computer technology, the application of numerical analysis method of 63 rock mass engineering has become more extensive and necessary for studying the stability of 64 underground rock mass. Elrawy Abdellah et al.(8)used RS2D to study the depth of stope failure. 65 The stability of stope is evaluated according to the failure depth of plastic zone, the range of yield 66 or plastic zone and deformation profile. 67 Aiming at the problem that the goaf area is very dangerous, Wu et al.(9)used Hoek-Brown 68 strength criterion to establish the limit equation of pillar in this area under steady state and 69 introduced interval theory. The overlying strata weight, rock uniaxial compressive strength and 70 rock damage degree of interval variable value range as the condition to calculate the reliability and 71 then analyze the damage degree of rock mass, to evaluate the stability of goaf. 72 With the assistance of acoustic, optical or electrical sensors and equipment, the acoustic 73 signals of surrounding rock displacement, stress and rock fracture are collected and analyzed to 74 evaluate the stability of stope. At present, the main technology of goaf stability monitoring in 75 China are micro-seismic monitoring method, photo-elastic stress meter meter method, acoustic 76 emission monitoring method, three-dimensional laser scanning method, etc. In the process of 4 77 studying the stability of goaf in a gold mine, Zhao Kui et al.(10) used a long-term photo-elastic 78 stress meter to monitor the stress change in the mining activity, and carried out cluster analysis on 79 the monitoring results. On this basis, the stability of goaf is divided into three levels and pillars 80 that play a key role in it are identified. 81 However, there is no unified evaluation method for stope stability. According to the common 82 method in engineering, a comprehensive way is proposed in this paper. Firstly, the geomechanical 83 data is investigated, and then the RMR and Q values are calculated. Survey and calculation results 84 are input into the database. RMR, Q value and other information of the field point are calculated 85 by inverse distance weighted average method, Chinese national standard recommendation method, 86 self-stabilization time judgment method and Barton stope width empirical formula are used to 87 evaluate the stability of stope. At the same time, the support parameters are calculated by using the 88 support recommendation formula, Chinese national standard recommendation method and Q 89 grading support chart theory. These stability evaluation results and support parameters are 90 compiled into a table. Through the mutual confirmation of each result, a multi-dimensional 91 comprehensive evaluation system is formed from the aspects of stope stability, self-stabilization 92 time, safety span and support measures. In order to be quickly applied on site, the stability 93 evaluation system was developed by python and applied in Sizhuang mining area of Jiaojia gold 94 mine. Results show that the method and system provided in this paper can quickly evaluate the 95 stability of the designed stope, and the evaluation results are basically consistent with the actual 96 monitoring results. 5 97 2 Methodology 98 Through the investigation of rock mechanics parameters on site, using the results of rock 99 mass quality classification, combined with Mathews stability chart, limit span method for span, 100 Chinese national standard recommendation method, self-stability time judgment method and other 101 methods, the comprehensive evaluation of stope stability is carried out. At the same time, the 102 evaluation results are output into Excel table. This paper proposes a specific flow chart of 103 comprehensive evaluation method as shown in Fig 1. 104 105 Fig 1. Flow chart of comprehensive evaluation method 106 2.1 RMR and Q value calculation 107 Rock mass quality evaluation and classification are the basic work to evaluate the stability of 108 rock mass. Whereas the RMR and Q system are more familiar, and most of the stability evaluation 109 methods use index values of these two classification methods, so it is necessary to measure. 110 Rock mass rating is proposed by Bieniawski from CSRI of South Africa(11, 12). It consists 111 of five indexes: rock fragmentation, RQD, joint spacing, joint condition and groundwater. Each 112 value is scored according to the established criteria, and the RMR can be obtained by adding these 113 values. 114 𝑅𝑀𝑅 = 𝑅1 + 𝑅2 + 𝑅3 + 𝑅4 + 𝑅5 + 𝑅6 115 In the formula: R1 is the rock mass strength (point load strength or uniaxial compressive 116 strength); R2 stands for the core quality index RQD value; R3 represent for the joint spacing score 6 (1) 117 value; R4 is the joint condition score value; R5 is the groundwater condition value; R6 is the 118 modified parameter scoring system. 119 The Q system classification method was proposed by Barton of the Norwegian Institute of 120 Geotechnical Engineering in 1974(13). It is calculated by six indexes including rock mass quality 121 index, joint group number, roughness system, joint alteration coefficient, fissure water reduction 122 coefficient and in-situ stress conditions. Similar to the calculation of RMR, the above six indexes 123 are scored, and then the score value is substituted into the following formula to calculate the Q 124 value (14): 𝑄= 125 𝑅𝑄𝐷 𝐽𝑛 𝐽 𝐽 𝜔 ∙ 𝐽𝑟 ∙ 𝑆𝐹𝑅 𝑎 (2) 126 Where 𝑅𝑄𝐷 is the rock mass quality index, 𝐽𝑛 is the number of joint group, 𝐽𝑟 is the 127 roughness system, 𝐽𝑎 is the joint alteration coefficient, 𝐽𝜔 is the fracture water reduction 128 coefficient, 𝑆𝑅𝐹 is the stress reduction coefficient. 129 2.2 Inverse Distance Weight Method 130 The investigation of rock mechanics parameters is a sampling survey in the stope or 131 development roadway. These survey data generally reflect the surrounding rock state of the 132 corresponding mining area, and cannot be specific to each point. The inverse distance weight 133 could be utilized to identifies the mechanical parameter in a specific point. 134 Inverse Distance Weight (IDW) is a spatially weighted average interpolation method can be 135 exact or smooth interpolation(15). It is used to calculate the attribute value of the unsampled point, 136 assuming that the value is a weighted average of the known values in the neighborhood(16). The 137 calculation method is as follows: 7 138 𝑃𝑖 = ∑𝑛𝑗=1 𝜆𝑗 𝑃𝑗 139 𝜆𝑖 = (3) 𝑑𝑖𝑗 −𝛼 𝑛 ∑𝑗=1 𝑑𝑖𝑗 −𝛼 (4) 140 ∑𝑛𝑗=1 𝜆𝑗 = 1 (5) 141 Where 𝑃𝑖 is Parameter values of points to be solved; 𝑃𝑗 is Parameter values of known points in 142 the region 𝜆𝑖 is Weight of Known Points in Region 𝑛 is Number of known points in a region; 143 𝑑𝑖𝑗 is Distance from the point i to the point j; 𝛼 is Weight power function. 144 2.3 Stope Stability Calculation 145 2.3.1 Mathew Stability Chart Method 146 The Mathews stability diagram method proposed by Mathews et al.(17) is based on the 147 calculation of stability coefficient N and hydraulic radius S, and combines the stability diagram to 148 evaluate the stability of underground stope under supporting and non-supporting conditions. Then 149 Potvin(4) made improvements, and the expression of the stability coefficient is as follows : 𝑁= 150 𝑅𝑄𝐷 𝐽𝑛 ∙ 𝐽𝑟 𝐽𝑎 ∙𝐴·𝐵∙𝐶 (6) 151 Where N is the stability coefficient; A is the rock stress coefficient; b is the correction coefficient 152 of joint orientation; c is the gravity adjustment coefficient of the designed exposed face; and other 153 symbols are the same as above. 154 Hydraulic radius HR reflects the size and shape of the stope. The hydraulic radius is the ratio 155 of the excavation surface to the perimeter of the exposed surface, which can be determined by the 156 following method shown in Fig 2, the hydraulic radius of the hanging wall is equal to the area 157 divided by perimeter. 8 158 Fig 2. Hydraulic radius determination method diagram 159 The calculation method of hydraulic radius S is : 𝑆= 160 161 162 163 𝐿×𝐻 2×(L+H) (7) Where L and H are the length and width of the exposed surface respectively. After obtaining the stability coefficient and hydraulic radius, the stability of the stope under the current structural parameters is judged according to Fig 3. 164 165 Fig 3. Mathews stability chart 166 2.3.2 Limit Span Method 167 The research team of UBC University in Canada obtained the relationship between rock mass 168 quality RMR and the limit span of the stope by analyzing 292 examples of stope roof stability 169 situation mined by different layered filling methods in Canada(18), and established the limit span 170 curve, as shown in Fig 4(19). It can be seen from Figure 2.3 that the limit span curve divides the 171 surveyed observation points into three regions: stable, potential unstable (fluctuation) and unstable. 172 Based on this, the stope span can be designed or the stability of the surrounding rock under a 173 certain span can be evaluated. It should be noted that the limit span in this method is defined as the 174 diameter of the maximum inscribed circle within the exposed roof boundary, and its determination 175 method is shown in Fig 5. 176 177 Fig 4. Limit Span Method (Under the condition of no support or local support) 178 Fig 5. Determination of limit span of stope 9 179 In addition, since the limit span method is based on the RMR evaluation method, when there 180 are obvious gently inclined joints (joint dip angle is less than 30 degree), the RMR value in this 181 area needs to be further reduced by 10. 182 2.4 Stope self-stabilization time calculation 183 2.4.1 Self-stabilizing time evaluation (based on RMR classification) 184 The stability time of surrounding rock is also an important index to evaluate the stability of 185 surrounding rock. Its value can not only reflect the quality of surrounding rock in stope, but also 186 provide suggestions for the selection of excavation and support method. In the study of 187 self-stabilizing time, Bieniawski(20) summarized the relationship between the structural 188 parameters of the unsupported stope (exposed surface span) and its self-stabilizing time in 1993 189 based on the RMR classification of rocks, as shown in Fig 6 The self-stabilizing time can be 190 estimated according to the RMR value of the surrounding rock and the unsupported span, and the 191 larger the RMR value and the smaller the span design, the longer the self-stabilizing time of the 192 surrounding rock. 193 Fig 6. Self-stabilization time judgment based on RMR classification 194 2.4.2 Chinese national standard recommendation method 195 The above self-stabilizing time assessment method only obtains the self-stabilizing time 196 according to RMR and span, which result is slightly rough. Based on this, China’s national 197 standard “Technical Code for Rock and Soil Anchor and Shotcrete Support Engineering” (GB 10 198 50086-2015)(21) determined the provisions on the level of surrounding rock of tunnel caverns, 199 which makes the evaluation from the aspects of rock mass structure, rock strength, rock mass 200 acoustic wave and rock mass stress ratio, and uses multiple indicators to judge the stability of 201 stope or tunnel without support. Those results not only estimate the self-stabilization time, but also 202 give the failure form of surrounding rock. 203 Rock mass integrity index Kv can be calculated as follows : 𝐾𝑣 = ( 204 𝑉𝑝𝑚 2 ) 𝑉𝑝𝑟 (8) 205 Where 𝑉𝑝𝑚 is Measured Longitudinal Wave Intensity of Tunnel Rock (km/s); 𝑉𝑝𝑟 is Measured 206 longitudinal wave velocity of tunnel rock (km/s). 207 208 209 210 211 When the acoustic wave is measured unconditionally, the volumetric joint count Jv of rock mass can also be used to determine the Kv value according to Table 3.2. Rock mass strength stress ratio in surrounding rock classification table should be calculated according to the following formula: (1) When there is a measured number of ground stress : 𝐾𝑣 𝑓𝑟 212 𝑆𝑚 = 213 Where 𝑆𝑚 is Rock mass strength stress ratio; 𝑓𝑟 is Saturated uniaxial compression strength of 214 rock (kPa); 𝐾𝑣 is Integrity coefficient of rock mass; 𝜎1 is The maximum principal stress of 215 vertical hole axis (kN/m2). 216 217 218 219 𝜎1 (9) (2) When there is no in-situ stress measured data, 𝜎1 can be determined by the following formula or by displacement back analysis data: 𝜎1 = 𝛾𝐻 (10) Where 𝛾 is Gravity density of rock mass (kN/m3); 𝐻 is Thickness of tunnel roof overburden 11 220 (m). 221 2.5 Calculation of Maximum Safety Span of Stope 222 The reasonable design span is an important factor to ensure the stability of the stope. 223 Therefore, determining the maximum safety span of the stope is also one of the indexes to 224 evaluate the stability of the stope. For the calculation of stope safety span, Barton et al.(22) 225 suggested the following empirical formula to determine the engineering span through field 226 investigation 227 𝑊 = 2 ∙ 𝐸𝑆𝑅 ∙ 𝑄 0.4 228 Where W is the maximum safety span of no support system, Q is rock mass quality index, ESR is 229 the support ratio, which is generally valued according to Table 1. In mining activity, the ESR value 230 is generally selected as 3 according to experience. 231 (11) Table 1. ESR value Project Type A. Temporary engineering ESR 2~5 B. Permanent mining roadways, water tunnels, auxiliary tunnels, roadways and 1.6~2 chambers C. Storage chambers, water treatment works Small road and railway tunnels 1.2~1.3 D. Power stations, main road and railway tunnels, etc. 0.9~1.1 E. Underground nuclear engineering base, station, public place, factory or major gas 0.5~0.8 supply tunnel 12 232 2.6 Stope Support Parameter Calculation 233 The calculation of stope support parameters is also an important content to evaluate the 234 stability of stope and roadway. On the one hand, it provides reasonable suggestions for stope 235 support, on the other hand, it can check the rationality of the supported stope. This comprehensive 236 evaluation method uses empirical formula, national standard recommended method and Q grading 237 support chart theory to calculate support parameters. 238 2.6.1 Empirical formula (bolt spacing and length) 239 According to the existing experience and examples of bolting and shotcreting support, the 240 following empirical formula can be used to determine the bolt parameters for mining projects with 241 a span of less than 10 m : 242 (1) Bolt length L: 𝐿 = 𝑛(1.1 + 243 𝐿 > 2𝑆 244 𝐵 10 ) (12) (13) 245 Where B is the roadway span. N is the stability parameters of surrounding rock. For the 246 surrounding rock with good stability, N is 1.0, for the surrounding rock with poor stability, N is 247 1.1, for unstable surrounding rock, N is 1.2. S is the joint spacing in surrounding rock. L is the 248 length of bolt. Bolt length takes the larger value according to the above calculation. In domestic 249 roadway engineering, the length of bolt is generally from 1.5m to 2.0m, whereas 2m to 3m in 250 stope and 2m to 5m in large chamber engineering. 251 (2) Bolt spacing D 13 252 𝐷 < 0.5𝐿 (14) 253 𝐷 > 3𝑆 (15) 254 The fracture spacing S is an important factor to determine the bolt spacing. Domestic 255 roadway engineering, bolt spacing is generally 0.8m to 1.0m, the longest not more than 1.5m. 256 (3) Bolt diameter d 257 Bolt diameter depends mainly on the type of anchor and anchorage force: 𝑑≈ 258 𝐿 110 (16) 259 If the bolt length is 2200 mm, the diameter d equals to 20 mm. 260 However, the above empirical formulas and data ignore the anchoring force of the bolt. The 261 parameters selected by empirical formula, especially the anchorage force, must be tested by 262 theoretical calculation. 263 2.6.2 China national standard recommended method (anchor spray 264 support) 265 China national standard “Technical code for engineering of ground anchorages and shotcrete 266 support” (GB 50086-2015)(21) provides a “Design parameter chart of anchor spray support in 267 slant hole and tunnel”. It demonstrates detailed suggestions for the selection of support parameters 268 of excavation cavern in combination with surrounding rock grade and excavation span. In the 269 process of selecting support parameters, the type and parameters of bolting and shotcrete support 270 are initially selected according to this chart, and then the mining parameters are modified 271 according to the actual engineering. In addition, when the cavern excavation span is greater than 272 20m and the height-span ratio H/B is greater than 1.2, the sidewall supporting parameters should 14 273 be strengthened according to the specific circumstances of the project. When the height-span ratio 274 H/B of the cavern is greater than 2.0, the sidewall support should be strengthened by pre-stressed 275 anchor group support with a length not less than 0.3 times the height of the side wall. The rock 276 pillars between caverns are strengthened according to their thickness or supported by through-type 277 pre-stressed anchor bolts. 278 2.6.3 Q classification support chart theory 279 The Barton rock mass quality classification Q system links the rock mass quality with the 280 type of support, and the recommendation of support type is very detailed. According to the Q 281 value, the support design can be divided into 9 categories, as shown in Figure 7(23). It shows the 282 latest classification and support charts (based on the statistical results of 2000 tunnels) in the 283 “Norwegian Tunnel and Underground Engineering 2004 Annual Report” published in 2004. It is a 284 series of De-Q value curves from which the required support types can be determined. 285 286 287 The De in the figure is the equivalent size, which is the ratio of the engineering span to the excavation support ratio. The calculation formula is as follows : 𝐷𝑒 = Excavation space span ESR (17) 288 289 Fig 7. Q system rock classification and support chart 290 2.7 Comprehensive Evaluation of Stope Stability 291 The information of rock mechanics parameters investigated is input into a special database. 292 At the same time, in order to better and faster realize the field application, a comprehensive 15 293 evaluation system of stope stability is compiled by python to realize the comprehensive evaluation 294 of the above various evaluation methods. For the graph curve involved, getdata and origin are 295 used to get the curve information and fit it. 296 In the process of evaluation, the information such as the middle section name, coordinate 297 value and mining parameters of the point that needs to be judged for stability is input to the 298 comprehensive evaluation system of stope stability. The system will find the database to find the 299 parameters of the same middle section according to the input parameters, and then use the inverse 300 distance weight difference method to calculate the parameter information of the input point, so as 301 to evaluate the stability, and output the evaluation results of multiple methods to a result report. 302 The generated result report shows the stability evaluation results of four aspects: surrounding rock 303 stability, self-stabilization time of exposed surface, maximum safety span, support parameters and 304 measures. 305 (1) Stability evaluation: 306 The Mathews stability chart method and the UBC limit span method are used to evaluate the 307 stability of the input mining parameters at the current evaluation point. The Mathews stability 308 chart method gives three evaluation levels: stability, destruction, and caving. The UBC limit span 309 method gives three evaluation levels: stability, fluctuation, and instability. The two evaluation 310 results confirm each other and get more accurate stability evaluation. 311 (2) Self-stabilizing time evaluation : 312 The self-stabilization time judgment method based on RMR classification obtains its span 313 through the output mining parameters, and then combines the RMR value of the mining point to 314 determine the self-stabilization time of the surrounding rock ( in hours ), while the Chinese 16 315 national standard recommendation method is based on the self-stabilization time evaluation from 316 the aspects of rock mass structure, rock strength, rock mass acoustic wave, rock mass stress ratio, 317 etc., and outputs the self-stabilization time and failure form of the mining point in the span of 318 5-10m or below 5m. The two judgment results can confirm each other. If the difference is large, it 319 is necessary to check the rationality of the data in the database and re-evaluate. If the difference is 320 small, it is considered that the judgment result is reasonable, and the smaller value is taken as the 321 self-stabilizing time evaluation value of the evaluation point. 322 (3) Maximum safety span 323 The stability evaluation system obtains the Q value of the judgment point in the database, 324 takes ESR value as 3, and then uses the empirical formula to calculate and output the maximum 325 safety span of the judgment point. In addition, combined with the evaluation results of the UBC 326 limit span method, the rationality of the evaluation is tested. If the two values differ greatly, it is 327 necessary to check the validity of the data. If the difference is not large, a smaller value can be 328 taken as the evaluation result of the maximum safety span. 329 (4) Support parameter calculation 330 The empirical formula gives the bolt support suggestion of the judgment point under the 331 input mining parameters, the national standard recommendation method gives the bolt-shotcrete 332 support type and parameter suggestion, and the Q classification support chart theory gives the 333 support parameter design suggestion. The specific implementation of supporting measures has 334 certain subjectivity. The above evaluation methods provide recommended values for the design or 335 optimization of supporting parameters of stope or roadway. The final supporting parameters need 336 to be corrected by mine workers or designers according to the field situation. 17 337 3 Field application example 338 3.1 Engineering background overview 339 Jiaojia Gold Mine is the core enterprise of Shandong Gold Mining Co., Ltd. It has three 340 mining areas: Jiaojia, Wangershan and Sizhuang mining area. Among them, the ore-controlling 341 structure of Jiaojia mining area is the main fault of Jiaojia type in the hanging wall, and the ore 342 body occurs in the footwall alteration zone of the main fault. The overall trend of ore body is 343 NE54°, tendency NW, dip angle of about 27°. The horizontal thickness of the ore body is about 344 2m to 70m, the thickest is about 70m near the 104 line, and the two wings gradually become 345 thinner to less than 10m. The ore body belongs to gold-bearing pyritization, yellow iron sericite 346 quartzite broken altered rock type, the hanging wall of ore body and the surrounding rock are fault 347 contact relationship, the boundary is obvious ; the footwall of the ore body has a gradual transition 348 relationship with the surrounding rock, and there is no obvious boundary. The hanging wall rock 349 of ore body is amphibolite with poor stability, large exposed area or long residence time, which is 350 prone to collapse. The footwall of the ore body is sericitization, silicification and potassic granite, 351 and there are also interlaced fracture joints in it, resulting in local surrounding rock fragmentation. 352 The main mining methods include downward drift cemented filling mining method, upward 353 horizontal drift cemented filling mining method and medium-deep hole double-amplitude 354 sub-section subsequent filling method. 355 356 357 Fig 8. Location of Jiaojia Gold Mine At present, the mining method of Jiaojia Gold Mine mainly has the following problems : 18 358 (1) The mining method of upward horizontal entry cemented filling has been used for many 359 years in the middle production stage of Jiaojia Gold Mine. The entry section size of most stopes is 360 controlled to 3.5m × 3.5m. The small entry section is beneficial to the safe mining operation, but 361 there are also some problems such as small stope size, small production capacity of single stope, 362 low production efficiency, high production cost and complex construction organization. The 363 production task of Jiaojia Gold Mine in 2021 is 7.6 tons of gold. The mine faces great pressure to 364 successfully complete the production task. It is difficult to successfully complete the heavy 365 production task by continuing to adopt the small-size mining design. 366 (2) The current supporting means of Jiaojia Gold Mine mainly include : pipe seam anchor 367 support, anchor net support, anchor net spray support and U-shaped steel arch support. Especially 368 in the stope, the roof joint fissure development, part of the existence of two groups or even 369 multiple groups of joint staggered distribution phenomenon, only through the 1.8 m pipe joint bolt 370 and through the belt to support, often can not meet the requirements of maintaining roof safety. 371 In summary, it is urgent to count the distribution of joints and fissures in Jiaojia gold mine, 372 classify the stability of ore bodies exposed in different stopes, and optimize the industrial test of 373 upward horizontal approach filling method parameters according to the classification results of ore 374 rock stability, so as to realize efficient mining and successfully complete the production 375 connection task of Jiaojia mining area. 376 This research mainly aims at the rock mechanics data collection of -570m main production 377 middle section of the mine, and carries on the experimental design stope stability appraisal 378 according to the rock mechanics data and the mine reality. 379 19 380 Fig 9. Experimental evaluation of stope design 381 3.2 Rock Mechanics Parameters Acquisition 382 3.2.1Investigation of Rock Mass Structural Plane 383 In practical engineering, these small and numerous structural planes are likely to cause 384 large-scale rock engineering problems, that is, rock mass instability. Therefore, in order to explore 385 the failure mechanism of the surrounding rock of the roadway with more developed joints, it is 386 necessary to analyze the characteristics of joint development, such as distribution law, surface 387 characteristics and spatial combination form. In this study, the Sirovision rock mass telemetry and 388 structural analysis system was selected to scan the structural planes of the three-layer and 389 four-layer approach stopes of a sub-lane in the level of-570 m in the Sizhuang mining area of 390 Jiaojia Gold Mine, and the development of joints and fissures in the area was obtained by software 391 splicing. Combined with Dips6.0 software, the joint measurement results are grouped and counted, 392 and the joint Schmidt diagram and joint rose diagram are drawn. The results are shown in Fig 11. 393 The information of -570m level approach structural plane in Sizhuang mining area of Jiaojia Gold 394 Mine is summarized in Table 3. Based on this, Q system and RMR rock mass quality evaluation 395 system are used to classify the rock quality of the surrounding rock in the above area, which 396 provides data basis for the optimization of roadway support and the selection of stope span 397 parameters in this area. 398 Fig 10. Drawing of rock mass structural plane of measuring point in -570m level by 399 Sirovision 20 400 Fig 11. Schmitt diagram and rose diagram of joint in -570m level (a) Schmitt diagram; (b) rose 401 diagram 402 Table 2. Structural plane information in -570m level Joint Joint Location Dip Group Number (o) Joint Volume Spacing Joint (cm) Number Dip Angle Condition of Joint Structural Plane (o) Number One lane 1 302.7 55.2 16 Three layers The joint fissures of rock mass are 2 11.08 -570m level relatively developed, and the joints 2 89.2 80.3 74 (9360,9120,-570) are mostly wavy or rough and One lane irregular. There are fillers between 1 308.5 59.6 22 some joints, and the structural plane Four layers 2 20.93 is relatively wet. -570m level 2 90.7 53.0 27 (9350,9130,-570) 403 3.2.2 Rock Mechanics Experiment 404 The strength of rock mass has engineering guiding significance for the implementation of ore 405 mining. However, some basic physical and mechanical parameters of rock are needed to calculate 406 the strength of rock mass, so these parameters are the basis of the calculation of the whole stress 407 field. At the same time, the different properties of rock under different conditions have certain 408 reference value for the methods and strategies of field construction. 409 The sources of the indoor test samples are mainly roadway sampling and stope sampling. The 21 410 test rock is mainly granite rock samples. The ZTR-276 rock triaxial test machine is used, and the 411 maximum load is 2000 kN. This includes a loading system, a test system and a control system, as 412 shown in Fig 12. The device has different control modes such as axial stress control, axial stroke 413 control, axial strain control and cyclic strain control, which can meet the requirements of various 414 experimental designs. 415 416 Fig 12. ZTR-276 rock triaxial test system 417 During the experiment, the loading is controlled by longitudinal strain, and the loading 418 control rate is (1~5)×10-6mm/s. The computer automatically records the original data such as 419 displacement and load of the experiment, and then the stress-strain relationship curve can be 420 drawn after secondary processing. Fig 13 shows the whole process curve of loading and unloading 421 stress-strain of some samples in the middle section of -570m. 422 423 Fig 13. Process curve of rock uniaxial compression in -570m level of Sizhuang Mining Area 424 The uniaxial loading experiment was carried out on the rock in -570m level of Sizhuang 425 Mining Area, and the stress-strain curve was drawn by the experimental data. It can be seen from 426 the figure that the early curve of rock compressive strength is not smooth, indicating that the rock 427 has joint cracks. During the loading process, the joint cracks weaken the bearing capacity of the 428 rock, and the cement in the rock joint cracks affects the bearing capacity of the rock. There is a 429 small peak curve before the peak strength of the stress-strain curve of the rock sample SZY-008, 430 indicating that there are joints in the rock sample, and its failure strength cannot truly reflect the 431 compressive strength of the rock itself. Therefore, the compressive strength of the rock is 140 22 432 MPa. There are many post-peak curves of SZY-012 sample, and it has obvious characteristic 433 curves. After the sample passes the peak stress, its internal structure is destroyed, and the single 434 sample basically maintains the whole shape. In the post-failure stage, the fractures develop rapidly, 435 intersect and combine with each other to form macroscopic fracture surfaces. Since then, the 436 deformation of the rock sample is mainly manifested as the block slip along the macroscopic 437 fracture surface. The bearing capacity of the sample decreases sharply with the increase of 438 deformation, but it does not drop to zero, indicating that the rock sample still has a certain bearing 439 capacity after fracture, but maintains a small value. The strength relative to the final point is called 440 residual strength. With the increase of load until failure, the volume of rock sample increases 441 rather than decreases. This phenomenon is called dilation. The failure of rock sample undergoes a 442 dilation stage, so dilation is often a precursor of rock failure. The results of uniaxial compression 443 test are shown in Table 3. 444 Table 3. Uniaxial compression test results of -570m level rock Sample Size (mm) Average Compressive Compressive Location Lithology Strength Diameter Height Strength (Mpa) (Mpa) One lane Three layers Sericite -570m level Rock (9360,9120,-570) One lane Sericite Four layers granite 49.80 99.80 63.07 49.60 99.60 136.69 49.70 99.90 129.42 49.60 99.66 144.75 133.05 134.10 49.62 99.75 23 120.27 -570m level 49.76 100.00 137.28 (9350,9130,-570) 445 3.3 Calculation of RMR and Q Value 446 Through the investigation of the surrounding rock in the -570m level in Sizhuang mining area of 447 Jiaojia Gold Mine and the rock mechanics experiment, the rock quality classification of the 448 surrounding rock in the above area is carried out by using Q system and RMR evaluation system, 449 and the classification results are shown in Table 4. 450 Table 4. Rock classification summary Q RMR Location Value Description Value Grade Description 29.42 Good 71 Ⅱ Good 8.61 General 55 III General One lane Three layers -570m level (9360,9120,-570) One lane Four layers -570m level (9350,9130,-570) 451 3.4 Stability Evaluation 452 The investigated rock mechanics parameter information and rock quality classification results 453 will be input into the rock mechanics parameter database associated with the comprehensive 454 evaluation system of the stope. After inputting the location information and mining parameters of 24 455 the proposed optimization stope or roadway, the system will extract and calculate the 456 corresponding parameters, and evaluate the stability of the area where the point is located. At the 457 same time, it provides suggestions for support optimization and stope span parameter selection. 458 In this study, the point (9360,9120,-570) at the three-layer mining and the four-layer 459 (9350,9130,-570) in the Sizhuang mining area of Jiaojia Gold Mine were selected for evaluation. 460 Among them, the stope in three-layer is 59.84 m long, 5.16m wide and 4.01m high, compared 461 with the stope in four-layer is 31.87m long, 3.5m wide and 3.49m high. Input these information 462 into the stope comprehensive evaluation system, the system will automatically output the results 463 report in the form of excel after calculation. 464 3.5 Stability Evaluation Results and Discussion 465 466 For the evaluation points selected in Section 3.4, the main evaluation results of the output report of the stope comprehensive evaluation system are shown in Table 5 and Table 6. 467 Table 5. Results of three-layer Stope Jiao Jia Gold Mine, -570m level, One lane, Three layer Coordinate (9360,9120,-570) Proposed design Stope parameters Length: 8m, Width: 5m, Height: 4m Rock Classification RMR 71 Q 29.42 Stope stability UBC limit span method Scheme in stable area, limit span is 26.95 meters evaluation Mathews stability chart method When the span is 5m to 10m, rock can be stable China national standard Self-stabilizing for a long time (months to years), only a small part recommendation method of it falls off time judgment Self-stabilizing time judgment Maximum safety span without Scheme in stable area Barton stope width empirical formula 25 The self-stabilizing time without support after mining exposure is estimated to be 42137.59 hours The maximum safety span of unsupported area is 23.21m support Bolt support length 1.76m, Empirical formula Bolt spacing less than 0.88m, Bolt diameter 16m Support measures and parameters China national standard Shotcreteδ=50 recommendation method Q classification support chart theory 468 No support required Table 6. Results of four-layer Stope Jiao Jia Gold Mine, -570m level, One lane, Four layer Coordinate (9350,9130,-570) Proposed design Stope parameters Length: 8m, Width: 5m, Height: 4m Rock UBC limit span method 55 Classification Mathews stability chart method 8.61 Stope stability evaluation Self-stabilizing time judgment Maximum safety span without support China national standard Scheme in stable area, limit span is 16.33 meters recommendation method Self-stabilizing time judgment Scheme in stable area Barton stope width empirical When the span is 5m, the stability time of surrounding formula Empirical formula China national standard recommendation method rock is very short, about hours to days Self-stabilizing time without support after mining exposure is estimated to be 2454.09 hours Maximum safety span of non-supporting area is 14.20m Bolt support length 1.74m, Q classification support chart Bolt spacing less than 0.87m, theory Bolt diameter 15.42m Support measures and parameters 1. Shotcreteδ=80~100 UBC limit span method 2. Shotcreteδ=50, Bolt length 1.5~2.0m, @0.75~1.0 Mathews stability chart method No support required 469 From Table 5, it can be seen that the surrounding rock quality grade of the three-layer is good. 470 Under the proposed mining parameters, the Mathews chart method and the UBC limit span 471 method are evaluated in the stable area, and the stope is in a stable state. At the same time, under 472 the proposed mining parameters, the national standard recommended method predicts that the 473 surrounding rock of the stope can maintain stability for a long time (months to years), which is 474 also consistent with the 42137.59 hours (about 4 years and 10 months) given by the 26 475 self-stabilization time judgment. In addition, the maximum safety span of the unsupported area in 476 the Barton stope width empirical formula is 23.21m, and the limit span is 26.95m in the UBC limit 477 span method, which is similar to the Barton stope width empirical formula. Therefore, the 478 maximum safety span of the unsupported area is 23.21m, and the proposed stope structure 479 parameters are within a reasonable range. Finally, the comprehensive evaluation system from the 480 empirical formula, the national standard recommended method, Q classification support chart 481 theory three methods are given different support measures support parameters, which need to be 482 combined with the actual selection of support methods for reference. 483 From Table 6, it can be seen that the surrounding rock quality of four layers is general. Under 484 the proposed mining parameters, Mathews chart method and UBC limit span method are used to 485 evaluate it in the stable area, and it is concluded that the stope is in a stable state. At the same time, 486 under the proposed mining parameters, the national standard recommended method points out that 487 when the span of the cave is 5m, the stability time of the surrounding rock is very short (about 488 several hours to several days), which is different from the 2454.09 hours (about 3 months) judged 489 by the self-stabilization time method. On the one hand, because the national standard method 490 gives the stability of the 5 m span of the cave, and the evaluation of the stope span is 3.5 m, on the 491 other hand, because the national standard method is located in the standard " Technical 492 Specification for Geotechnical Bolt and Shotcrete Support Engineering " proposed by the Ministry 493 of Housing and Urban-Rural Construction of the People 's Republic of China. The application in 494 mines still has certain limitations, but no matter which method. Both reflect the poor stability of 495 the surrounding rock of the stope, and the design of reducing the stope span or strengthening the 496 support can be considered. In addition, the maximum safety span of the unsupported project in the 27 497 Barton stope width empirical formula is 14.20m, and the limit span is 16.33m in the UBC limit 498 span method, which is similar to the Barton stope width empirical formula. Therefore, the 499 maximum safety span of the unsupported project is 14.20m, and the proposed mining parameters 500 are within a reasonable range. Finally, the comprehensive evaluation system proposes the support 501 parameters of different support measures from the three methods of empirical formula, national 502 standard recommendation method and Q classification support chart theory, which needs to be 503 further judged in combination with the actual support method selected on site. 504 3.6 Actual Parameters and Effect of Stope 505 In order to verify the accuracy of the system in judging the stability of the stope, the stability 506 of both layer was investigated, as shown in Fig 14. The main production section of Jiaojia Gold 507 Mine has been mined by upward horizontal approach cemented filling mining method for many 508 years. The existing support methods mainly include bolt through belt support, shotcrete support, 509 U-shaped steel arch support, anchor net support and combined support of various situations. 510 511 Fig 14. Stope investigation (a)Stope investigation; (b)Work face of three layer; (c)Work face of 512 four layer 513 According to the previous rock mechanics investigation, surround rock in three layer belongs 514 to grade III good rock mass. The final acceptance parameters of the stope are 59.84m long, 5.16m 515 wide and 4.01m high. The support is carried out in the form of 1.8m bolt support, the anchorage 516 spacing is 1m and the row spacing is 3m. The investigation of the ground pressure behavior of the 517 stope for 40 days shows that the stope is relatively stable within 40 days, and there is no obvious 28 518 ground pressure behavior. According to the field survey results, the stope is in a stable state, the 519 acceptance span is much smaller than the maximum safety span of the unsupported area of 14.20 520 m, and the self-stability time is longer, which is consistent with the evaluation results of 3.5 521 sections, and the stope structure parameters are reasonable. At the same time, the stope using bolt 522 support, the parameter selection is better than the recommended parameters in Table 3.5, no 523 optimization is required. 524 Rock mass in four layer belongs to II level general rock. The final acceptance parameters of 525 the stope are 31.87m long, 3.5m wide and 3.49m high. The form of bolt-shotcrete combined 526 support is adopted, in which the thickness of shotcrete is 50mm, the length of bolt is 1.8m, the 527 spacing of bolt is 1m, and the row spacing of bolt is 3m. In the investigation of the ground 528 pressure behavior of the stope for 14 days, it can be seen that there was a spalling on the 6th day 529 after excavation and a falling block on the 13th day. From the survey results, it can be seen that 530 although the comprehensive evaluation method gives that the stope is in a stable state under the 531 proposed mining parameters (Table 3.6), and the acceptance span is much smaller than the 532 maximum safety span of the unsupported area 14.20m, but the actual excavation situation is not 533 optimistic, that is, on the 6 th day after excavation, the situation of spalling and falling occurs, and 534 in fact, this instability situation is also roughly consistent with the judgment result of the 535 self-stability time in the comprehensive evaluation method. It can also be seen that the stability 536 evaluation of the surrounding rock of the stope is multifaceted. The judgment is relatively simple 537 from the span and rock quality classification, while the comprehensive evaluation method adds 538 more evaluation factors. Using multiple evaluation methods to evaluate from multiple dimensions 539 can not only self-test the rationality of each result, but also avoid the limitations of a single 29 540 evaluation method to a certain extent. In addition, in terms of support, the stope adopts 541 bolt-shotcrete combined support, and its support parameters are consistent with the recommended 542 values in Fig 15. However, according to the results of self-stabilization time judgment and field 543 investigation, it needs to be further strengthened. 544 545 Fig 15. Stope failure in four layer (a) Bolt support failure; (b) Roof Caving; (c) Cracking of side 546 concrete; (d) Roof concrete caving 547 4 Conclusion 548 In this study, a comprehensive evaluation method of stope stability is proposed. This method 549 combines Mathews stability chart, limit span method, Chinese national standard recommendation 550 method, self-stabilization time judgment method, Barton stope width empirical formula and Q 551 grading support chart theory. The stability of surrounding rock of stope or roadway is evaluated 552 from four aspects : surrounding rock stability, self-stabilization time, safety span and support 553 parameters, and reasonable suggestions are put forward for the selection of support parameters and 554 measures. The test was carried out in the Sizhuang mining area of Jiaojia Gold Mine. The results 555 show that the comprehensive evaluation method can accurately evaluate the stability of the stope 556 or surrounding rock, and compared with the traditional evaluation method, the evaluation results 557 are more abundant. The sub-evaluation methods can confirm and compare each other, and then 558 provide a more comprehensive and accurate reference for mine design. 559 However, it still has limitations and imperfections at present: (1) In order to ensure the 560 multi-dimensional evaluation results, the comprehensive evaluation method uses two non-mine 30 561 field surrounding rock evaluation methods, namely the Chinese national standard recommendation 562 method mentioned in 2.4 and 2.6 sections, which may interfere with the verification and 563 inspection of the evaluation results. (2) The comprehensive evaluation method pays attention to 564 the multidimensional nature of the evaluation, only simply integrates a variety of surrounding rock 565 stability evaluation methods, the output results are more dispersed, and no specific suggestions are 566 put forward for the optimization of structural parameters or support parameters. In view of these 567 shortcomings, in the future, this study is committed to the continuous enrichment and 568 improvement of the comprehensive evaluation method, try to organic integration of various 569 evaluation methods, and combined with the economic benefit analysis of the mine, output more 570 specific and intuitive structural parameters and support parameters optimization value in the 571 results report. In addition, it is necessary to optimize the implementation means of field 572 application, such as the development of evaluation system suitable for mobile communication 573 equipment based on comprehensive evaluation method, which is convenient for mine workers and 574 designers to evaluate stope stability dynamically and quickly. 575 Acknowledgment 576 This work was funded by National Key R&D Program of China (2021YFC3001304) and the 577 Fundamental Research Funds for the Central Universities(N2101044). 578 Conflicts of Interest 579 580 The authors declare that the research was conducted in the absence of any commercial or financial relationships that could be construed as a potential conflict of interest. 31 581 582 583 584 585 586 587 588 589 590 591 592 593 594 595 596 597 598 599 600 601 602 603 604 605 606 607 608 609 610 611 612 613 614 615 616 617 618 619 References 1. Chen S, Wu A, Wang Y. Optimization research on stope structure parameters in broken rock conditions based on the response surface method. Chinese Journal of Rock Mechanics & Engineering. 2017;36:3499-508. 2. Wang X, Li J, Zhang X, ZHAO B. Optimizing mining stope structural parameters using a FAHP. Journal of China University of Mining & Technology. 2010;39(2):163-8. 3. Mathews K, Hoek E, Wyllie D, Steward S. Prediction of Stable Excavations for Mining at Depths below 1000 M in Hard Rock. CANMET report DSS Serial No. OSQ80–00081, DSS File No. 17SQ. 23440-0-9020. 1981. 4. Potvin Y. Empirical open stope design in Canada [Text]: University of British Columbia; 1988. 5. Nickson SD. Cable support guidelines for underground hard rock mine operations [Text]1992. 6. Trueman R, Mikula P, Mawdesley C, Harries N. Experience in Australia with the application of the Mathews' method for open stope design. CIM bull. 2000;93(1036):162-7. 7. Mawdesley C, Trueman R, Whiten WJ. Extending the Mathews stability graph for open–stope design. Mining Technology. 2001;110(1):27-39. 8. Abdellah WRE, Hefni MA, Ahmed HM. Factors Influencing Stope Hanging Wall Stability and Ore Dilution in Narrow-Vein Deposits: Part 1. Geotechnical and Geological Engineering. 2020;38(2):1451-70. 9. Heng WU, Zheng HC, Zhang XJ, Hou XL. The analysis of goaf stability based on the Hoek-Brown criterion. Journal of Shandong University of Technology(Natural Science Edition). 2017. 10. Zhao K, Rao YZ, Cai MF. Stress Monitoring and Stability Analysis in Mined Areas. Mining Research and Development. 2002. 11. Beiniawski ZT. Engineering Rock Mass Classification. New York: John Whily; 1989. 12. Beiniawski ZT. TUNNELLING IN ROCK. CHAPTER 6: GEOMECHANICS CLASSIFICATION OF ROCK MASSES AND ITS APPLICATION IN TUNNELLING. Publication of South African Institute of Civil Engineers. 1974. 13. Barton N, Lien R, Lunde J. Engineering classification of rock masses for the design of tunnel support. Rock mechanics. 1974;6(4):189-236. 14. E.T.Brown BHGB. Rock Mechanics for underground mining Third edition. 628 p. 15. Babak O, Deutsch CV. Statistical approach to inverse distance interpolation. Stochastic Environmental Research and Risk Assessment. 2009;23(5):543-53. 16. Lu GY, Wong DW. An adaptive inverse-distance weighting spatial interpolation technique. Computers & Geosciences. 2008;34(9):1044-55. 17. Mathews K, Hoek E, Wyllie D, Stewart S. Prediction of stable excavations for mining at depths below 1000 metres in hard rock. Canmet Report. 1980:802-1571. 18. Wang J, Pakalnis R, Milne D, Lang B, editors. Empirical underground entry type excavation span design modification. Proceedings, 53rd Annual Conference, Canadian Geotechnical Society; 2000. 19. Ouchi AM, Pakalnis R, Brady TM, editors. Update of span design curve for weak rock masses. Proceedings of the 99th annual AGM-CIM conference, Edmonton, AB; 2004. 32 620 621 622 623 624 625 626 20. Bieniawski ZT. 22 - Classification of Rock Masses for Engineering: The RMR System and Future Trends. In: Hudson JA, editor. Rock Testing and Site Characterization. Oxford: Pergamon; 1993. p. 553-73. 21. Technical code for engineering of ground anchorages and shotcrete support. 2015. 22. Barton N, Lien R, Lunde J, editors. Estimation of support requirements for underground excavations. The 16th US Symposium on Rock Mechanics (USRMS); 1975: OnePetro. 23. NORWEGIAN TUNNELLING. Oslo: NORWEGIAN 627 33 TUNNELLING SOCIETY; 2004. Figure Click here to access/download;Figure;S1_raw_images.pdf fig1 fig2 fig3 fig4 fig5 fig6 fig7 Fig8 Fig9 Fig10 (a) (b) Fig11 Fig12 Fig13 (a) (b) Fig14 (c) (a) (b) (c) (d) fig15