FANUC Robot iRVision Inspection Application Operator's Manual

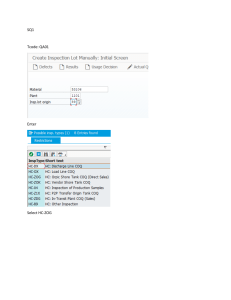

advertisement