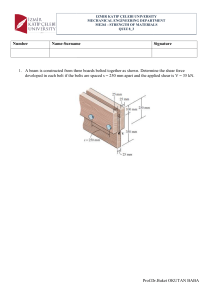

ARCH 342 STEEL STRUCTURES Chapter 2 BOLTED CONNECTIONS Main Reference: William T. Segui 2007 and 2013. «Steel Design», CENGAGE Learning, 4th and 5th Edition. Prof. Dr. Nesrin YARDIMCI TİRYAKİOĞLU 2.1 INTRODUCTION A steel structure may be considered to be an assemblage of various members that must be fastened together to make the finished product (Connections and splices). If the necessary connections are inadequate, the result could be collapse. At the beginning riveting was the accepted method used for connecting the members of steel structures. For the last few decades bolting and welding used for making structural steel connections. Selection of type of fasteners involves many factors, including requirements of local building codes. Bolting of steel structures is very rapid field erection process and requires less skilled labour than riveting and welding. For bolted connections it is possible to alter or disassemble the structures and changes in connections are quite simple. Bolting is satisfactory for fieldwork. 2.2 TYPES OF BOLTS Ordinary or common bolts (Machine bolts and unfinished bolts.): Easy to turn and need less turning space. Used in structures subjected to static loads and for secondary members (purlins, girts, bracing, etc.). Installed in the snug-tight condition. High strength bolts (Pre-tension and high strength bolts.) : Tensile strength is two or more times greater than ordinary bolts. Used for all types of structures. Installed in the snug-tight, pretensioned, or slip-critical condition. Bolt Nut Washer Shank Thread Bolts: M12, M16, M20, M24, M30, M36 Holes : Standard Oversized Short-slotted Long-slotted holes • Common bolts : 4.6; 5.6; 6.8 • High strength bolts: 8.8; 10.9 • Mechanical Bolt type Fyb (N/mm2) Fub (N/mm2) properties of bolts 4.6 5.6 6.8 240 300 480 400 500 600 8.8 640 800 10.9 900 1000 Fub: Tensile strength Fyb : Yield stress ; 5= Fub /100 ; 6=10(Fyb / Fub) d: Bolt diameter M12~M14 : d=(12~14)mm M16~M24 : d=(16~24)mm M27 and › : d=27mm h: Standard hole diameters h=d+1mm h=d+2mm h=d+3mm Snug-Tight A snug-tight condition is defined as the tightness required to bring the pieces into firm contact. Pre-tension (Slip-critical) Tensioning the high-strength bolts up to 70% of the minimum tensile strength of the bolts. The installation of tensioned bolts may consist of; turn-of-the-nut method, calibrated wrench tightening, twist-off-type bolts, direct-tension indicators. 2.3 SIMPLE BOLTED CONNECTIONS Connections of structural steel members are of critical importance. An inadequate connection, which can be the «weak link» in a structure, has been the cause of numerous failures. Most structural failures are the result of poorly designed or detailed connections. In considering the behavior of different types of connections, it is convenient to categorize them according to the type of loading. Bolted connections in shear Bolted connections in tension Bolted connections in combined shear and tension Bolts in tension Bolts in shear Bolts in combined tension and shear Load transfer of bolts (Shear and bearing) Bolt is required to prevent the movement of connected material in a direction perpendicular to the axis of the bolt. Bolts may be transmit the load in shear but if the material is not capable of transmitting the loads into bolts the connection fails. Bolt in single shear The bolt has a tendency to shear off along the single contact plane. Plates slip in the direction of applied force until they bear against the bolt. The lap joint : The simplest form but not commonly used because of the tendency to deform •Centre of gravity of the members are not in line. This causes bending in the connection. •Used only for minor connections. •Should be design with at least two fasteners in each line parallel to the length of the member. Bolt in double shear There are two contact planes. The butt joint: More common type, may be used for tension member splices. •Total shearing force is split into two parts; bolts are in double shear; the load-carrying ability twice as great as single shear connections. •A more symmetrical loading condition is provided. More than three members are being connected •The bolts are in multiple shear. (Loads are tending to shear on four separate planes.) •Shear failure can occur on four planes. 2.4 FAILURE OF BOLTED CONNECTIONS Failure Modes Failure of fasteners Failure of parts being connected Failure of fasteners (Shear connections) Single shear Double shear : fv=P/Ab=P/(πd2/4) and : fv=P/2Ab=P/(2(πd2/4)) and fv : Average shearing stress Ab: Cross-sectional area of the fastener d : Diameter of the fastener P : Applied force on bolt P=fvAb P=2fvAb Failure of the parts being connected 1. 2. Failure resulting from excessive tension, shear or bending in the parts being connected. Tension on gross area and on effective net area must be investigated and block shear must be considered. Failure of connected part because of bearing exerted by the fasteners. For simplicity an average stress is used in computing the bearing stress. Bearing stress : fp =P/(dt) Bearing load : P =fp dt t: Minimum thickness of the part subjected to bearing Failure Modes 2.5 DESIGN OF BOLTED CONNECTIONS Bn Ba Bd Ba : Required strength of a bolt Bd : Allowable strength of a bolt (allowable tensile strength, allowable shear strength or allowable bearing strength of the parts being connected) Bn : Nominal strength of a bolt (nominal tensile strength, nominal shear strength or nominal bearing strength of the parts being connected) : Safety factor ( = 2.00) With the bolt numbers (n), nominal and allowable strength of a bolted connection (Rn and Rd) may then be calculated as follows R n nB n Rd nB d Rn Ra Rd Ra : Required strength of the connection Rn : Nominal strength of the connection Rd : Allowable strength of the connection Connection is adequate if one of the following condition is satisfied : For the connection For one bolt Ra Rd or Ba Bd 2.6 BOLTS IN TENSION Area of threaded part is: An= 0.75Ab Bnt=FubAn=Fub(0.75Ab)= Ab(0.75 Fub ) Fub: Tensile strength of bolt material Ab : Gross area of one bolt Fnt =0.75 Fub Bdt=Bnt/Ω :Safety factor(= 2.00) Bat Bdt=Bnt/Ω Bnt : Nominal tensile strength of a bolt Bdt : Allowable tensile strength of a bolt Bat : Required tensile strength of a bolt Allowable Tensile Stress for Structural Bolts ( = 2.00) Bolt Grades 4.6 Nominal Tensile Stress [N/mm2] (Fnt = 0.75Fub) 300 Allowable Tensile Stress [N/mm2] (Fdt = Fnt / ) 150 5.6 375 190 8.8 600 300 10.9 750 375 With the bolt numbers (n), nominal and allowable strength of a bolted connection (Rnt and Rdt) may then be calculated as follows: Rnt nBnt Rdt nBdt Rat Rdt 2.7 BOLTS IN SHEAR - 2.7.1 Bearing-Type Connections - 2.7.2 Slip-Critical Connections Clamping Force Bearing Bearing Shear Bearing Shear Bearing-Type Connection Friction Friction Slip-Critical Connection 2.7.1 BEARING TYPE CONNECTIONS Slip is acceptable; shear and bearing occur. (Common or high strength bolts installed by snug-tight method) SHEAR STRENGTH Nominal shear strength of one bolt is: Bnv=mFnv Ab Fnv: Nominal shear stress of bolt material Ab : Cross-sectional area of unthreaded part of the bolt m : Number of shear planes Fub: Tensile strength of bolt material Based on the experimental studies, the nominal shear stress of bolt material is given as, Fnv 0.625Fub Threads are in the shear plane Threads are not in the shear plane The test results revealed that there is no uniform force distribution among the bolts in a connection. In bearing-type connections, therefore, the initial reduction factor of 0.90 is imposed on connections with lengths up to and including 965mm. Thus: If the threads are not in the shear plane the nominal shear stress of a bolt given in AISC 360-10 is, Fnv 0.90(0.625Fub ) 0.563Fub If the threads are in the shear plane the bolt area subjected to shear, denoted Av, is assumed to be Av = 0.80Ab. Thus, the nominal shear stress of a bolt given in AISC 360-10 is Fnv 0.800.563Fub 0.450Fub In the connections with common (unfinished) bolts (4.6, 5.6, etc.), the shear strength of the bolt shall be obtained from above equation for all cases regardless of the position of threads. Allowable shear strength of a bolt is: B dv B nv mAb Fnv , 2.00 Bdv B av Bnv Bdv Bav : : : : Nominal shear strength of a bolt Allowable shear strength of a bolt Required shear strength of a bolt Safety factor(= 2.00) BEARING STRENGTH Bearing strength is independent of the type of fasteners. A possible failure mode from excessive bearing is: Shear tear-out at the end of connected element Rn/2=0.6FuLCt 0.6Fu LC t Fu : : : : Shear fracture stress of connected part Clear distance from edge of hole to the connected part Minimum thickness of part subjected to bearing Ultimate tensile strength of the connected part ll Nominal bearing strength of a bolt is: Bnb=1.2FuLCt ≤ 2.4dtFu 1.2 Fu Lc t Bnb min 2 . 4 dtF u Bnb Bdb Bdb Bad Bnb Bdb Bab Shear failure of plate 1.2FuLCt : : : : Bearing failure of plate Nominal bearing strength of a bolt Allowable bearing strength of a bolt Required bearing strength of a bolt Safety factor(= 2.00) s : Center to center spacing of holes h : Hole diameter Le: Edge distance to center of the hole For the edge bolts Lc=Le-h/2 For inner bolts Lc=s-h 2.4dtFu Spacing and edge distance requirements Minimum spacing and edge distances: s ≥ 3d Le ≥ 1.5d Maximum spacing and edge distances For corrosion protected elements s ≤ 24t or 305mm For non-protected elements s ≤ 14t or 180mm Le ≤ 12t or 150mm t=tmin d=bolt diameter Nominal strength (load capacity) of a bearing-type connection is lower of the followings; (a) sum of the shear strengths of the bolts in the connection, Rnv nBnv (b) sum of the each bearing strength of individual bolts both end and inner bolts in the connection Rnb ne Bnbe ni Bnbi Rnv : Nominal shear strength of the connection Bnv : Nominal shear strength of one bolt n : Total number of bolts Rnb : Nominal bearing strength of the connection ne : Number of end bolts Bnbe : Nominal bearing strength of one end hole ni : Number of inner bolts Bnbi : Nominal bearing strength of one inner hole Thus, nominal strength of a bearing-type connection is: Rn min ( Rnv ; Rnb ) The connection is adequate if the following condition is satisfied: Rn Rd Ra Ra : Required shear strength of the connection : Safety factor