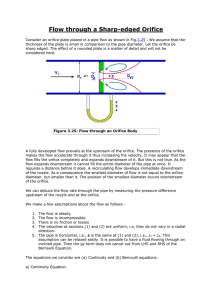

NF EN ISO 5167-2: Fluid Flow Measurement with Orifice Plates

advertisement