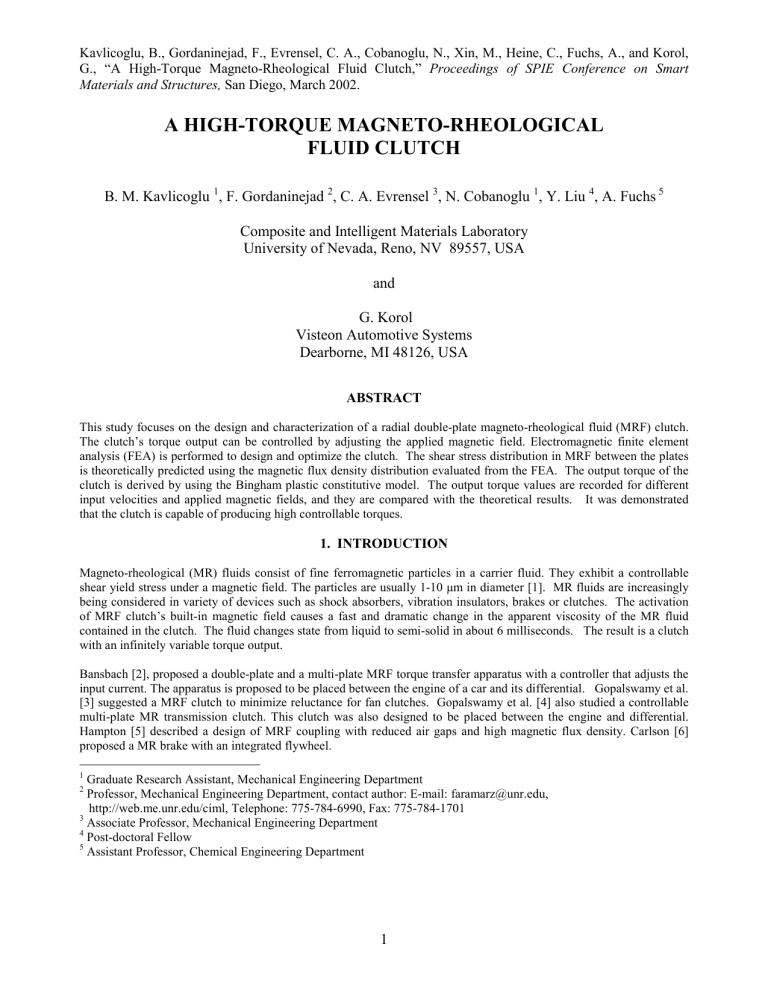

Kavlicoglu, B., Gordaninejad, F., Evrensel, C. A., Cobanoglu, N., Xin, M., Heine, C., Fuchs, A., and Korol, G., “A High-Torque Magneto-Rheological Fluid Clutch,” Proceedings of SPIE Conference on Smart Materials and Structures, San Diego, March 2002. A HIGH-TORQUE MAGNETO-RHEOLOGICAL FLUID CLUTCH B. M. Kavlicoglu 1, F. Gordaninejad 2, C. A. Evrensel 3, N. Cobanoglu 1, Y. Liu 4, A. Fuchs 5 Composite and Intelligent Materials Laboratory University of Nevada, Reno, NV 89557, USA and G. Korol Visteon Automotive Systems Dearborne, MI 48126, USA ABSTRACT This study focuses on the design and characterization of a radial double-plate magneto-rheological fluid (MRF) clutch. The clutch’s torque output can be controlled by adjusting the applied magnetic field. Electromagnetic finite element analysis (FEA) is performed to design and optimize the clutch. The shear stress distribution in MRF between the plates is theoretically predicted using the magnetic flux density distribution evaluated from the FEA. The output torque of the clutch is derived by using the Bingham plastic constitutive model. The output torque values are recorded for different input velocities and applied magnetic fields, and they are compared with the theoretical results. It was demonstrated that the clutch is capable of producing high controllable torques. 1. INTRODUCTION Magneto-rheological (MR) fluids consist of fine ferromagnetic particles in a carrier fluid. They exhibit a controllable shear yield stress under a magnetic field. The particles are usually 1-10 µm in diameter [1]. MR fluids are increasingly being considered in variety of devices such as shock absorbers, vibration insulators, brakes or clutches. The activation of MRF clutch’s built-in magnetic field causes a fast and dramatic change in the apparent viscosity of the MR fluid contained in the clutch. The fluid changes state from liquid to semi-solid in about 6 milliseconds. The result is a clutch with an infinitely variable torque output. Bansbach [2], proposed a double-plate and a multi-plate MRF torque transfer apparatus with a controller that adjusts the input current. The apparatus is proposed to be placed between the engine of a car and its differential. Gopalswamy et al. [3] suggested a MRF clutch to minimize reluctance for fan clutches. Gopalswamy et al. [4] also studied a controllable multi-plate MR transmission clutch. This clutch was also designed to be placed between the engine and differential. Hampton [5] described a design of MRF coupling with reduced air gaps and high magnetic flux density. Carlson [6] proposed a MR brake with an integrated flywheel. 1 Graduate Research Assistant, Mechanical Engineering Department Professor, Mechanical Engineering Department, contact author: E-mail: faramarz@unr.edu, http://web.me.unr.edu/ciml, Telephone: 775-784-6990, Fax: 775-784-1701 3 Associate Professor, Mechanical Engineering Department 4 Post-doctoral Fellow 5 Assistant Professor, Chemical Engineering Department 2 1 Kavlicoglu, B., Gordaninejad, F., Evrensel, C. A., Cobanoglu, N., Xin, M., Heine, C., Fuchs, A., and Korol, G., “A High-Torque Magneto-Rheological Fluid Clutch,” Proceedings of SPIE Conference on Smart Materials and Structures, San Diego, March 2002. 2. DOUBLE-PLATE MRF CLUTCH DESIGN The main goal of this study is to design, develop and understand the performance of a double-plate prototype MRF clutch. By varying the input current to the clutch, one can achieve a variable torque range. Other factors such as geometric constraints and magnetic properties of materials play major roles on the performance of the MRF clutches. Casing Electromagnetic Coil Electromagnet Core Input Side Cap O-Rings MR Fluid Output Shaft and Plate Input Shaft and Plate Output Bearing Output Side Cap Input Bearing Figure 1. A three-dimensional view of the double-plate prototype MR fluid clutch. Figure 1 shows a three-dimensional view of the double-plate prototype MRF clutch. The MR fluid is located in the gap between the input and output plates, with the diameter of 51.94 mm. These plates are connected to 30 mm diameter input and output shafts. The shafts are supported by deep groove ball bearings, which are press-fitted into the side caps. The electromagnet circuit of this clutch consists of an electromagnetic coil, which is wound around an electromagnetic core. This assembly is located inside a 152.4 mm outer diameter casing with 6.35 mm wall thickness, which is also acting as a return path for the magnetic field. Two O-rings are located in the grooves machined on the circumferences of plates to prevent leakage of MR fluid. The MRF clutch is activated by a power supply connected to two ends of the electromagnet. The total width of the clutch is 31.75 mm. 2 Kavlicoglu, B., Gordaninejad, F., Evrensel, C. A., Cobanoglu, N., Xin, M., Heine, C., Fuchs, A., and Korol, G., “A High-Torque Magneto-Rheological Fluid Clutch,” Proceedings of SPIE Conference on Smart Materials and Structures, San Diego, March 2002. 3. ELECTROMAGNETIC FINITE ELEMENT ANALYSIS Electromagnetic finite element analysis is performed, using Maxwell ANSOFT software [7], to optimize the design of the double-plate prototype MRF clutch. This is done to determine the material and the dimensions of each individual element of the clutch. One of the design goals is to increase the magnetic field of the MR fluid as much as possible. Flux line density, Wb/ m2 Figure 2. Contour plot of flux line density from Maxwell ANSOFT for double plate MRF clutch. Figure 2 shows the contour plot of flux line density of the double-plate MRF clutch for an input current of 3 Amps. For this case magnetic flux density as a function of radius of the clutch in MRF section can be seen in Figure 3. As explained in the following section results shown in Figure 3 are used in theoretical torque output calculations for a given input electric current. It can be observed from Figures 2 and 3 that, the magnetic field increases with increasing radial distance from the rotational axis. This is a desirable outcome since the contribution of the resulting shear yield stress on the torque transmitted increases with increasing radial distance. 0.650 B (Tesla) 0.600 0.550 0.500 0.450 0.400 0 10 20 30 40 50 3. THEORETICAL TORQUE MODELING Radius (mm) Figure 3. Magnetic field strength as a function of radius in the MRF section. 3 60 Kavlicoglu, B., Gordaninejad, F., Evrensel, C. A., Cobanoglu, N., Xin, M., Heine, C., Fuchs, A., and Korol, G., “A High-Torque Magneto-Rheological Fluid Clutch,” Proceedings of SPIE Conference on Smart Materials and Structures, San Diego, March 2002. In order to derive the output torque equation for this clutch, the Bingham Plastic model is used as the constitutive equation for behavior of the MR fluid. Bingham Plastic model gives the total shear stress, as follows: τ = τ y ⋅ sgn( ∂u ∂u ) + µp ∂y ∂y (1) ∂u is the shear strain rate, µ p and τ y are the plastic viscosity and shear yield stress of the MR fluid, ∂y respectively. τ y is a function of the magnetic field while µ p is assumed to be constant. The first part of the right hand where, side of Equation (1) produces a torque, which is dependent on the magnetic field, and the second term generates a viscous torque. Therefore, the total output torque can be expressed as: Tout = TMR + Tvis Derivation of MR torque, (2) TMR , requires the relationship between MRF shear yield stress, τ y , and the applied magnetic flux density, B. This relationship is obtained experimentally for the fluid designed by our group and from the manufacturer’s data sheet for the commercial MR fluid. Since the magnetic field is a function of the radial location, shear yield stress can be determined as function of the plate radius. For a given yield stress distribution, the output torque can be obtained by: ro TMR = 2π ∫ τ y ( r , B) sgn( 0 du 2 ) r dr dy (3) where r0 is the radial location of seals. For small gap between the plates one can derive the tangential fluid velocity by assuming no slip condition and linear velocity distribution as follows: u (r , y ) = r ⋅ ∆ω y + ω2 ⋅ r g (4) where ∆ω = ω1 − ω 2 , is the angular velocity difference between the input and output plates, g is the gap between the plates, y, is the coordinate axis normal to plate surfaces. Differentiation of Eq. (4) with respect to y gives the shear rate: ∂u r∆ω = ∂y g (5) The sign of shear rate can be written as: sign ( ∂u r ∆ω ) = sign ( ) = sign (ω1 − ω 2 ) ∂y g Substituting Equation (6) into Equation (3) gives: 4 (6) Kavlicoglu, B., Gordaninejad, F., Evrensel, C. A., Cobanoglu, N., Xin, M., Heine, C., Fuchs, A., and Korol, G., “A High-Torque Magneto-Rheological Fluid Clutch,” Proceedings of SPIE Conference on Smart Materials and Structures, San Diego, March 2002. ro TMR = 2π sgn(ω1 − ω 2 ) ∫τ y (r , B )r 2 dr (7) 0 By numerically integrating Eq. (7), MR torque equation for the yield stress function for a given input current, output torque versus input current relationship is derived. Similarly, the viscous torque can be derived as: πµ p ∆ωr04 Tvis = 2g For the dimensions and material properties used, the viscous torque, (8) Tvis , is determined to be very small compared to MR torque, TMR , therefore, viscous effects can be neglected in the total torque output equation. Then, the total torque for the MRF clutch can be written as a function of input current as: Tout ≅ TMR = c1 I C2 sgn(ω1 − ω2 ) (9) where, C1 and C2 are the constants obtained numerically using electromagnetic FEA. 4. EXPERIMENTAL STUDY To examine the performance of the MRF clutch, a detailed experimental setup is designed, as shown in Figure 4. In the design process, the expected performance of the MRF clutch and the given design requirements are considered. The MRF clutch is driven by a 5-HP Dayton EPACT efficient AC-motor, which is controlled by a General Electric’s AC adjustable frequency drive AF-300 G11. Adjustable frequency drive can only reduce the motor speed to 1:10, efficiently. In order to reach the velocity range required for experimental analysis a WinSmith C-Face right angle gearbox with a 1:15 gear ratio is used. Lovejoy flexible coupling is used to connect the gearbox to the MRF clutch. Two M12x1-180DSAw digital speed sensors are used for the velocity feedback. For static torque measurement the beltpulley system is replaced by a lever arm connected to the output shaft of the MRF clutch. Force exerted by the lever arm is measured by a Lebow Load Cell Model 3132. The experimental study is performed to explore the torque output and velocity response of the prototype MRF clutch. In this study, a UNR-MRPG (MR polymeric gel based fluid), which is developed at University of Nevada Reno (UNR), and a commercially available MR fluid, LORD MRF-132LD, are used. Output torque is measured using lever arm system as described previously. The output torque is determined by multiplying exerted force on the load cell with the distance from exertion point of the load to the center of the output shaft. The torque output determined by this method is the maximum torque produced by the clutch, since the static output plate maximizes the shear rate by maximizing the angular velocity difference. The torque output is measured for input velocities of 30, 60, 90 and 120 rpm and the input current is varied from 0 Amp to 4 Amps. Figures 5 and 6 present the torque output relations for the UNR-MRPG and LORD-MRF132LD fluids. It can be observed from Figures 5 and 6 that the velocity effects are minimal on the torque output. For the UNR-MRPG fluid the maximum torque obtained is 7.9 Nm at 4 Amps, and for the LORD-MRF132LD fluid the maximum torque is 6.9 Nm at 4 Amps. 5 Kavlicoglu, B., Gordaninejad, F., Evrensel, C. A., Cobanoglu, N., Xin, M., Heine, C., Fuchs, A., and Korol, G., “A High-Torque Magneto-Rheological Fluid Clutch,” Proceedings of SPIE Conference on Smart Materials and Structures, San Diego, March 2002. AC Motor AC Inverter Gearbox Coupling Speed Sensors MRF Clutch Signal Converters Belt-Pulley System Load Cell Figure 4. Experimental setup for the prototype MRF clutch characterization. 9 8 7 Torque(N.m) 6 5 30rpm 60rpm 90rpm 120rpm Theoretical 4 3 2 1 0 0 0.5 1 1.5 2 2.5 3 3.5 Input Current (A) Figure 5. Torque output as a function of electric input current for UNR – MRPG fluid for different input velocities. 6 4 4.5 Kavlicoglu, B., Gordaninejad, F., Evrensel, C. A., Cobanoglu, N., Xin, M., Heine, C., Fuchs, A., and Korol, G., “A High-Torque Magneto-Rheological Fluid Clutch,” Proceedings of SPIE Conference on Smart Materials and Structures, San Diego, March 2002. 9 8 7 Torque(N.m) 6 5 4 30rpm 60rpm 90rpm 120rpm Theoretical 3 2 1 0 0 0.5 1 1.5 2 2.5 3 3.5 4 4.5 Input Current (A) Figure 6. Torque output as a function of electric input current for LORD – MRF – 132LD fluid for different input velocities. Transient velocity of the input and output plates are measured to determine the response time of the system. These experiments are performed by initially restraining the rotation of the output shaft by exerting a large enough resistance torque via the belt-pulley system. At time t0, the power supply for the electromagnet coil is turned on and velocities of both shafts are recorded. For this case the clutch output plate reaches the input plate velocity in about 20 milliseconds when the power to the electromagnet is turned on, as demonstrated in Figure 7. 5. CONCLUSIONS AND FUTURE WORK The performance of a double-plate magneto-rheological fluid limited slip differential clutch, which is designed and developed at UNR, is studied using two types of MR fluids. Theoretical and experimental analyses have illustrated that this MR fluid clutch can transfer high controllable torques with a very fast time response. This study provides basic knowledge of MR fluid torque transfer mechanism for the development of a multi-plate MRF fluid limited slip differential clutch, which is underway. 6. ACKNOWLEDGEMENTS The authors would like to thank Visteon Corporation for supporting this research. 7 Kavlicoglu, B., Gordaninejad, F., Evrensel, C. A., Cobanoglu, N., Xin, M., Heine, C., Fuchs, A., and Korol, G., “A High-Torque Magneto-Rheological Fluid Clutch,” Proceedings of SPIE Conference on Smart Materials and Structures, San Diego, March 2002. Figure 7. Velocity response of the MRF clutch. REFERENCES 1. 2. 3. 4. 5. 6. 7. Ashour O., Rogers C.A, and Kordonsky W., “ Magnetorheological Fluids; Materials, Characterization and Devices,” Journal of Intelligent Material systems and Structures, Volume 7- pp 123-130, March 1996. Bansbach, E. E., “Torque Transfer Apparatus Using Magnetorheological Fluids,” United States Patent Number 5,779,013, 1998. Gopalswamy ,S., Linzell, S., M., Jones, G.L, “ Magnetorheological Fluid Clutch with Minimized Reluctance,” United States Patent Number 5,845,752, 1998. Gopalswamy, S., and Jones G., L., “Magnetorheological Transmission Clutch,” United States Patent Number 5,823,309, 1998. Hampton, K., “Magnetorheological Fluid Coupling,” United States Patent Number 5,967,273, 1999. Carlson, J.D., “Magnetorheological Brake with Integrated Flywheel,” United States Patent Number 6, 186,290 B1, 2001. Ansoft Corporation, Pittsburgh, PA, www.ansoft.com 8