8th NDT in Aerospace Symposium Program, Bangalore 2016

advertisement

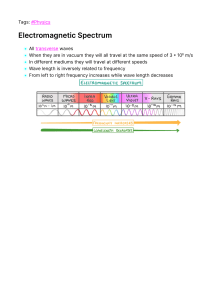

8th International Symposium

on NDT in Aerospace

3rd – 5th November, 2016, Bangalore, India

8th International Symposium on Non-Destructive Testing in Aerospace

3rd – 5th November, 2016, Bangalore, India

Contents

Overview

Programme

About the Symposium

About Indian Institute of Science, Bangalore

Papers

Overview

0800 - 0830

0830 - 1005

rd

3 November, 2016,

Thursday

th

4 November, 2016,

Thursday

th

5 November, 2016,

Thursday

1005 - 1035

1035 - 1235

1235 – 1330

1330 – 1520

1520 – 1550

1550 – 1740

1930 onwards

0830 - 1000

1000 - 1030

1030 - 1230

1230 – 1330

1330 – 1520

1520 – 1550

1550 – 1740

1830 – 1930

2000 onwards

0830 - 1000

1000 - 1030

1030 - 1230

1230 – 1330

1330 – 1520

1520 – 1545

1600 – 1800

REGISTRATION STARTS

SYMPOSIYM INAUGURATION and PLENARY

SESSION 1

COFFEE BREAK

PLENARY SESSION 2

LUNCH

PARALLEL SESSIONS

COFFEE BREAK

PARALLEL SESSIONS

BANQUET DINNER

PLENARY SESSION 3

COFFEE BREAK

PLENARY SESSION 4

LUNCH

PARALLEL SESSIONS

COFFEE BREAK

PARALLEL SESSIONS

CULTURAL EVENING

DINNER

PLENARY SESSION 5

COFFEE BREAK

PLENARY SESSION 6

LUNCH

PARALLEL SESSIONS

COFFEE BREAK

VISIT TO IISc HYPERSONIC TEST FACILITY

Schedule

November 3, 2016

8.30-10.05 am – Symposium Inauguration and Plenary Session 1

Session Chair: Dr. Christian Boller, University of Saarland, Germany

8.30-8.35am: Welcome and about the Conference, Prof. S Gopalakrishnan

8.35-8.40 am: About NDT in Aerospace Symposium, Dr. Christian Boller

8.40-9.20 am: NDT Initiatives in Indian Aerospace programs, Dr. Kota

Harinarayana, Former Program Director, ADA, India

9.20-10.05 am: Plenary Talk: Hand Operated Shock Tube (Reddy Tube) for

Non Destructive Testing, Prof. K P J Reddy, Department of Aerospace

Engineering, Indian Institute of Science, Bangalore, India

10.05 am-10.35 am: Coffee/Tea

10.35 am-12.35 pm: Plenary Session 2

NDE Aspects for Military Aviation and Defense

Session Chair: Dr. Kota Harinarayana, India

10.35-11.05am: New NDE Technologies and Solutions from CNDE@IITM for

Aerospace Industries, Krishnan Balasubramaniam, Indian Institute of

Technology, Madras, Chennai , India (Invited Talk)

11.05-11.35 am: Role of NDT in ensuring Structural Integrity of Aircraft, Dr. P

D Mangalgiri, Visiting professor, Indian Institute of Technology Kanpur,

India (Invited Talk)

11.35 am-12.05 pm: Aviation Safety, Prof. B Dattaguru, Jain University,

Bangalore, India (Invited Talk)

12.05-12.35 pm: Electromechanical Impedance Method for Assessment of

Adhesive Bonds of CFRP at the Production and Repair Stage, Prof. Wiesław M

Ostachowicz, Polish Academy of Sciences, Poland (Invited Talk)

12.35 pm-1.30 pm: Lunch

1.30 pm-3.20pm: Parallel Sessions

Composites-I

Metallic Materials-I

Applications-I

3.20 pm-3.50 pm: Tea/Coffee

4.00 pm-6.00 pm: Parallel Sessions

Composites-II

Metallic Materials -II

Applications-II

7.30 pm: Banquet Dinner

November 4, 2016

8.30 am-10.00 am: Plenary Session 3

Chair: Prof. Krishnan Balasubramaniam, IITM, India

8.30-9.15 am : Use of NDE Methodologies in Marine Composites, Dr. Yapa

Rajapakse, Programme Manager, Solid Mechanics, Office of Naval Research,

USA

9.15-10.00am: A Permanent Inspection System for Damage Detection at

Composite Laminates, Based on Distributed Fibre Optics, Prof. Alfredo

Gümes, Universidad Politécnica de Madrid, Spain

10.00 am-10.30 am: Tea/Coffee

10.30 am-12.30 pm: Plenary Session 4

SHM Simulation Platform

Chair: Prof. B Dattaguru, IIAEM, India

10.30-11.00 am: Simulation as a Prerequisite in Structural Health

Monitoring, Prof. Christian Boller, University of Saarland, Germany (Invited

Talk)

11.00-11.30 am: SHM System Simulation Based Design Considering

Composite Patch Repaired Stiffened Panel of Aircrafts, Rakesh Shivamurthy,

Keerthy M Simon, Nitin Balajee Ravi, Nibir Chakraborty, Debiprosad Roy

Mahapatra, IISc, Bangalore, India (Invited Talk)

11.30 am-12.00 noon: Feasibility Study of SHM Simulation Based Design of

Accelerated Fatigue Tests, Nitin Balajee Ravi, Nibir Chakraborty, Rakesh

Shivamurthy, Keerthy M Simon, Ramanan Sridaran Venkat, Mirko Steckel,

Debiprosad Roy Mahapatra, Christian Boller, IISc, Bangalore, India (Invited

Talk)

12.00-12.30 pm : Simulation as Key Enabler to Support ISHM Certification,

Matthias Buderath, Partha Adhikari, Harsha Gururaja Rao, Airbus,

Bangalore, India (Invited Talk)

12.30 pm-1.30 pm: Lunch

1.30 pm-3.20 pm: Parallel Sessions

Composites -III

Guided Waves-I Emerging Technologies

3.20 pm-3.50 pm: Tea/Coffee

3.50 pm-5.40 pm: Parallel Sessions

Composites-IV

Guided Waves-II Applications-III

6.30 pm-7.30pm: Cultural Evening - Demonstration of Indian Art

forms: Mrs. Shyla Prasad

8.00 pm: Dinner

November 5, 2016

8.30 am-10.00 am: Plenary Session 5

Chair: S V Suresh, HAL Helicopters, India

8.30-9.15 am: Real-Time Tracking of Damage Growth in CFRP Composites

during Testing for Durability and Fracture, Dr. R Sunder, BISS Research,

Bangalore, India

9.15-10.00 am: Integrated System Health Monitoring and Management

Initiatives and Challenges in Military Aviation, Matthias Buderath, Airbus

Defence & Space, Manching, Germany

10.00 am-10.30 am: Tea/Coffee

10.30-12.30 pm: Plenary Session 6

SHM Simulation Platform

Chair: Dr. P D Mangalgiri, IITK, India

10.30-11.0 am: Accelerated Fatigue Data Evaluation for SHM Validation

Activities, Peter Starke and Christian Boller, University of Saarland, Germany

(Invited Talk)

11.00-11.30 am: Simulation of Ultrasonic Inspection of Defects in Thick

Structural Components, Nitin Balajee Ravi, Nibir Chakraborty, Rakesh

Shivamurthy, Ramanan Sridaran Venkat, Debiprosad Roy Mahapatra,

Christian Boller, IISc, India

11.30-12.0 noon: Simulation of Guided Waves Inspection, from NDE to SHM,

Pierre Calmon, Bastien Chapuis CEA LIST, France (Invited Talk)

12.0 noon-12.30 pm: Structural Health Monitoring of Repaired Metallic

Aircraft Panel-Modeling Based Approach, Ramanan Sridaran Venkat, Adrià

Taltvull, Christian Boller, Christian Durager, University of Saarland,

Germany (Invited Talk)

12.30 pm-1.30pm: Lunch

1.30 pm-3.20pm: Parallel Sessions

Composites-V

Applications-IV

3.20 pm 3.45 pm: Tea/Coffee

4.0 pm-6.0pm: Visit to IISc Hypersonic Test Facility

Session Composites-I

Date: November 3, 2016 Time: 1.30-3.20pm

Session Chair:

1.30-2.00 pm: How to Make NDE of Composites More Deterministic, Dr. B V S R

Murthy, Advanced Systems Lab, DRDO, India, (Invited paper)

2.00-2.20 pm: A Novel Nonlinear Acoustics Technique for the Detection of

Defects in Composites, A K Singh, National University of Singapore, Singapore

2.20-2.40 pm: Comparison of Fibre Angles Between Hand Draped Carbon

Fibres and Draping Simulation, C Frommel, DLR, Augsburg, Germany

2.40-3.00 pm: Acoustic Emission Monitoring of the Cracking Load in Composite

Materials, G Nardoni, P Nardoni, M Turconi, I&T Nardoni Institute, Leonardo

Finmeccanica Group, Italy

3.00-3.20 pm: Guided Lamb Wave Based Multi-Level Disbond Detection in a

Honeycomb Composite Sandwich Structure, Shirsendu Sikdar, Sauvik Banerjee,

IIT Mumbai, India

Session Metallic Materials-I

Date: November 3, 2016 Time: 1.30-3.10pm

Session Chair: Dr. R Ganguli, IISc, India

1.30-1.50 pm: NDE Assessment of Aerospace Components – IGCAR Experiences,

Dr B. Venkatraman , IGCAR, Bangalore, India (Invited Talk)

1.50-2.10 pm: Subwavelength Resolution of Delaminations, Amireddy Kiran

Kumar, Prabhu Rajagopal and Krishnan Balasubramaniam, IIT Madras, India

2.10-2.30 pm: Anisotropic Magnetic Properties of Grain-oriented and Nonoriented Si-Fe Electrical Steel, Gholamhossein Shirkoohi, London Southbank

Univ., England

2.30-2.50 pm: Sonic Analysis System as an Effective Means of NDT Analysis for

Cast Iron Nodularity Measurement, Kalyan Ram B, S Arun Kumar, Prajval M S,

Electrono Solutions Pvt. Ltd, India

2.50-3.10 pm: Spectral Finite Element Method for Inspection of Adhesively

Bonded Metallic Joints Using Guided Waves, Shweta Paunikar, S

Gopalakrishnan, IISc, Bangalore, India

Session Applications-I

Date: November 3, 2016 Time: 1.30-3.20pm

Session Chair: Ramesh Sundaam, CSIR-National Aerospace Laboratories,

India

1.30-2.00 pm: NDE for Aircraft Engines: Challenges, Opportunities and

Approaches, Shyam Sundar, GE, Bangalore, India (Invited paper)

2.00-2.20 pm: Non Destructive Evaluation Methodologies to Predict the Strain

Hardening Effect in Landing Gear Components: A Review, Arun Dinesh,

Chanakesava Reddy, Bharath Marappan, Seshadri Venkatadri, UTC Aerospace

Systems, Bangalore, India

2.20-2.40 pm: Main Gear Box Testing for Light Utility Helicopter, Bhawani

Singh Rathore, Muralidhar B S, RWR&DC, HAL, India

2.40-3.00 pm: Experimental Validation of Random Packs for Composite Solid

Propellants Using X- Ray Computed Tomography, Chaitanya V, Raghuvarun K,

Sai Bhargav K V, Krishnan Balasubramaniam, P A Ramakrishna, IIT Chennai,

India

3.00-3.20 pm: Fault Detection in Electrical Wires and Cables, Gholamhossein

Shirkoohi, London South Bank Univ., England

Session: Composites-II

Date: November 3, 2016 Time: 3.50-5.30pm

Session Chair: Dr. Mira Mitra, IITB, India

3.50-4.20 pm: Structural Health Monitoring of Aircraft Composite Structures:

Offline & Online Approach, Ramesh Sundaram, Nitesh Gupta, Augustin M J,

Amitabha Datta, CSIR – National Aerospace Laboratories, Bangalore, India

(Invited Talk)

4.20-4.40 pm: Characterization of Ceramic Composites by High Frequency

Eddy Current Techniques, H Heuer, M Schulze, S Hillmann, Fraunhofer IKTS,

Germany

4.40-5.10 pm: Thermal Properties of Basalt Fibre Epoxy Composites by

Focused Gaussian Illumination Using Infrared Thermography, Kalyanavalli V,

T K Abilasha Ramadhas, and D SastiKumar, Nat. Inst. of Technology,

Tiruchirapalli, India

5.10-5.30 pm: In-situ Nondestructive Evaluation of Composite Panels in an

Aircraft using InfraRed Thermography, S Kshama and S Kalyana Sundaram,

NAL Bangalore, India

Session: Metallic Materials-II

Date: November 3, 2016 Time: 3.50-5.40pm

Session Chair: Dr. Makarand Joshi, DRDO - R&DE(Engrs), India

3.50-4.20 pm: NDE of Aerospace Structural Materials and Components Using

Acoustic Wave Based Tool, M R Bhat, Department of Aerospace Engineering,

IISc, Bangalore, India (Invited paper)

4.20-4.40 pm: A Non-Destructive Methodology of Estimating Single Crystal

Elastic Constants, Phani Mylavarapu, Karthik Karuparthi, Jai Prakash

Gautam, Defence Metallurgical Research Laboratory, Univ. Hyderabad, India

4.40-5.00 pm: Detection of Material Inhomogeneity Using Inverse Time

Domain Spectral Finite Element Method, Raghavendra B Kulkarni, S

Gopalakrishnan and Manish Trikha, ISRO, Bangalore, India

5.00-5.20 pm: Evaluation of Elastic Modulus of Metals Using Acoustic Emission

Technique, R Gopikrishna, M Padma Amani, M Varadanam, Defence Research

Development Laboratory, India

5.20-5.40 pm: Non-Destructive Evaluation of Friction Stir Weld Defects in

Aluminum Alloy, V D Ragupathy, M R Bhat and M V N Prasad, LPSC, ISRO, India

Session: Applications-II

Date: November 3, 2016 Time: 3.50-5.30 pm

Session Chair: Dr. Suresh Bhalla, IITD, India

3.50-4.10 pm: Detection of Blocked Cooling Holes in a Gas Turbine Nozzle using

Infrared Imaging, Joel Jon Bosco, Dheepa Srinivasan, Debabrata

Mukhppadhyay and Paul Dimascio, GE Power, India

4.10-4.30 pm: Studies on Multi Site Damages in Riveted Joints under Fatigue

Cycles with Acoustic Emission Approximate Entropy Approach, S Kalyana

Sundaram, V R Ranganath, M R Bhat, NAL, Bangalore, India

4.30-4.50 pm: Hula Seal Stellite6 Coating Thickness on Service Returned

Combustion Liner Using Ultrasonic Gauge, Santhosh Bangera, Dheepa

Srinivasan, Mohammed Anwar, James Baummer, Francis Reed, GE Power,

India

4.50-5.10 pm: Effects And Corrective Techniques of Helium as Signal Noise in

the MSLD Based Leak Detection Methods, Soumikh Sarkhel, V D Ragupathy and

G Naryanan, Liquid Propulsion System Centre, India

5.10-5.30 pm: Application of Image based technique in Qualification Testing of

Spacecraft Structures & Components, Sriranga T S, Harsh Kumar, Ananthan A,

Raghunatha Behara, C S Varghese, ISRO, Satellite Centre, India

Session: Composites-III

Date: November 4, 2016 Time: 1.30-3.20pm

Session Chair: Prof. D Roy Mahapatra, IISc, India

1.30-2.00 pm: Uncertainty Handling Using Fuzzy Logic in Structural Health

Monitoring, Prof. R Ganguli, Department of Aerospace Engineering, IISc,

Bangalore, India (Invited paper)

2.00-2.20 pm: Damage Assessment of Single Blade Stiffened CFRP Specimen

Subjected to Axial Compression Using AE And DIC Techniques, N R Kolanu, L B

Andraju, M Ramji, G Raju,IIT Hyderabad, India

2.20-2.40 pm: Real Time Monitoring of Interfacial Delamination of Sandwich

Composite Panels Using Optical Sensors, Nilanjan Mitra, IIT Kharagpur, India

2.40-3.00 pm: Locating Delamination in a Composite Laminate Using

Nonlinear Response of Lamb Waves, Nitesh P Yelve, Mira Mitra, and Prasanna

M Mujumdar, IIT Mumbai, India

3.00-3.20 pm: Investigation of Anisotropic Propagation of Shear Horizontal

Modes in Composite Laminates Using Fiber Bragg Grating Sensors, P Ray, P

Rajagopal, B Srinivasan and K Balasubramaniam, IIT Chennai, India

Session: Guided Waves-I

Date: November 4, 2016 Time: 1.30-3.20pm

Session Chair: Dr. Peter Starke, University of Saarland, Germany

1.30-2.00 pm: Damage Detection Using Nonlinear Interaction with Breathing

Crack in 1-D Beam, Mira Mitra, IIT Mumbai, India (Invited paper)

2.00-2.20pm: Corrosion Detection on Aerospace Structural Materials by Lamb

Wave Visualization Method - Advantages & Challenges, Aparna Aradhye, S

Kalyana Sundaram, NAL, Bangalore, India

2.20-2.40 pm: Laser Based Non-Contact Method for Nonlinear Mixing of

Rayleigh waves, Chaitanya Bakre, Prabhu Rajagopal and Krishnan

Balasubramaniam, IIT Chennai, India

2.40-3.00pm: Localization of a Breathing Crack in a Stepped Beam Using a

Method of Harmonic Separation, D M Joglekar, IIT Roorkee, India

3.00-3.20 pm: The Interfacial Stiffness Evaluation of Single Lap Joint

Assemblies Using the Transmission of Lamb Waves, E Siryabe, M Renier, A

Meziane, M Castaings, Univ. Bordeaux, France

Session: Emerging Technologies

Date: November 4, 2016 Time: 1.30-3.20pm

Session Chair: Dr. Prabhu Rajagopal, IITM, India

1.30-2.00 pm: Issues in Piezoelectric Energy Harvesting from Civil Structures,

Dr. Suresh Bhalla, Indian Institute of Technology, Delhi, India (Invited paper)

2.00-2.20 pm: Modeling of Elastic Wave Scattering in Polycrystalline Materials,

Abhishek Pandala, S Shivaprasad, C V Krishnamurthy, Krishnan

Balasubramaniam, IIT Chennai, India

2.20-2.40 pm: Potential for Synchrotron Radiation Based NDE in Aerospace

Industry, C V Krishnamurthy, IIT Chennai, India

2.40-3.00 pm: Effect of Surface Asperity on Thin Film Adhesion using Laser

Induced Stress Waves, S S Singh, R Kitey, IIT Kanpur, India

3.00-3.20 pm: Effect of Shock Induced Acoustic Emission and Shock Wave

Impact on Polyurethane Foam, V Jayaram and G Arvind Raj, IISc, India

Session: Composites-IV

Date: November 4, 2016 Time: 3.50-5.30pm

Session Chair: Wieslaw Ostochowicz, Polish Academy of Sciences, Poland

3.50-4.10 pm: Manufacturing Aspects on Fabrication of Composite Reference

Standard for NDT Ultrasonic Inspection, Pranab Biswal, B N Srinivasa Reddy,

Pratim. M Baruah, HAL, Bangalore, India

4.10-4.30 pm: Wave Propagation in a Delaminated Thin Anisotropic Strip,

Punith P, M Mitra and P J Guruprasad, IIT Mumbai, India

4.30-4.50 pm: Rapid Ultrasonic Inspection of Stiffened Composite Ailerons,

Rabi Sankar Panda, Prabhu Rajagopal and Krishnan Balasubramaniam, IIT

Chennai, India

4.50-5.10 pm: Evaluation of Composite Structures-Using Computed

Tomography (CT) Emerging NDE Methodology, Ramesh Babu G, Pranab

Biswal, B N Srinivasa Reddy, P Mukhopadhyay, Hindustan Aerospace Ltd.

Bangalore, India

5.10-5.30 pm: Non Destructive Evaluation of In-situ Skirt Joint of Filament

Wound Composite Pressure Vessel, Sanjeev Kumar and P J Thakar, ASL, DRDO,

Hyderabad, India

Session: Guided Waves-II

Date: November 4, 2016 Time: 3.50-5.40pm

Session Chair: Prof. Alfredo Güemes, Universidad Politécnica de Madrid,

Spain

3.50-4.20 pm: Feature-Guided Waves: New Paradigm For Inspection and

Health Monitoring of Aerospace Composite Structures and Components, Dr.

Prabhu Rajagopal, IIT Madras, India (Invited paper)

4.20-4.40 pm: Multiphysics Simulation of Guided Wave Propagation under

Load Condition, Lei Qiu, University of Saarland, Germany

4.40-5.00 pm: Lamb Wave Based Damage Detection using Orthogonal

Matching Pursuit and Artificial Neural Network, Navjeet Kumar, Mira Mitra,

IIT Mumbai, India

5.00-5.20 pm: Attenuation of Fundamental Anti-Symmetric Lamb Mode (A0) in

Isotropic Plates, C Ramadas, Irfan Khan and Makarand Joshi , R & DE(Engrs),

Pune, India

5.20-5.40 pm: Interaction of Fundamental S0 Lamb Mode with Delaminations

in Composite Plate Structures, Saurabh Gupta and Prabhu Rajagopal, IIT

Madras, India

Session: Applications-III

Date: November 4, 2016 Time: 3.50-5.30pm

Session Chair: M R Bhat, IISc, India

3.50-4.10 pm: Detecting Onset of Combustion Instability in Gas Turbines

through Flame Visualisation using Fiber Optic Bundle, Suma H, Joel Vasanth,

Balaji Srinivasan and S R Chakravarthy, IIT Chennai, India

4.10-430 pm: Practical Experiences in POD Determination for Airframe ET

Inspection- Virkkunen I, Ylitalo M, Pirtola J and Patronen J, Patria Aviation,

Finland

4.30-4.50 pm: Post Impact Damage Evaluation of High Velocity Impacted EGlass Composites Using Immersion Ultrasonic C-Scan Technique, M Srinivasa

Rao, T Sreekantha Reddy, P Rama Subba Reddy, V Madhu, B V S R Murthy, ASL,

DRDO, Hyderbad, India

4.50-5.10 pm: Model Assisted Probability of Detection for Lognormally

Distributed Defects, Vamsi Krishna Rentala, Phani Mylavarapu ,K.Gopinath ,

J.P.Gautam , Vikas Kumar, University of Hyderabad, India

5.10-5.30 pm: A Scanning Spatial-Wavenumber Filter based On-Line Damage

Imaging Method of Composite Structure, Lei Qiu, Shenfang Yuan, Yuanqiang

Ren, Qiao Bao, NUAA Nanjing, China

5.30-5.50 pm: Non-destructive Evaluation of Wrinkles, Sivaramanivas R,

Megha Navalgund, Debasish Mishra and Richard Klaassen, GE Global

Research, India and GE Aviation, USA

Session: Composites-V

Date: November 5, 2016 Time: 1.30-3.30pm

Session Chair: Dr. B V S R Murthy, DRDO-ASL, India

1.30-1.50 pm: A Study on Highly Porous Carbon-Carbon Aircraft Brake Disc

using Air Coupled Ultrasonic, Suresh Chand Jangir, Srinivasa V, Ramesh

Kumar M, Ramesh Sundaram, Gururaja Rao J, NAL Bangalore, India

1.50-2.10 pm: Evaluation of Thermography and Ultrasonic NDT Techniques for

Detecting Resin Rich and Resin Starved Defects in Composites, YLVD Prasad,

Dr. SK Majee, A O Siddiqui, B V S R Murthy, ASL, DRDO, Hyderabad, India

2.10-2.30 pm: Aging study of Coated Fabric Materials, H Nanjundegowda, R

Sivaraman, K Vembar, B Marappan & V Seshadiri, UTC Aerospace Systems,

India

2.30-2.50 pm: Online Structural Health Monitoring of Composites, Harsh Shah,

Prabhu Rajagopal, Krishnan Balasubramaniam, IIT Madras, India

2.50-3.10 pm: Integrated Approach to Demonstrate Optimum Sensor Positions

in a Guided Wave Based SHM System Using Numerical Simulation Ramanan

Sridaran Venkat, Christian Boller, Lei Qiu, Nitin Balajee Ravi , Debiprosad Roy

Mahapatra, Nibir Chakraborty, University of Saarland, Germany

3.10-3.30 pm: Wave Scattering Analysis in a Delaminated Cross-ply Laminate

due to Incident S0 Wave, Rajendra Kumar Munian, G Kolappan Geetha, D Roy

Mahapatra, S Gopalakrishnan, Indian Institute of Science, India

Session: Applications-IV

Date: November 5, 2016 Time: 1.30-3.10pm

Session Chair: Dr. Lei Qiu, Nanjing University, China

1.30-150 pm: SHM - Prognostic Analysis of Crack Growth retardation in

Fastener Joints with Bush around the Pin- L Chikmath, B V Sravan, K Bharath

and B Dattaguru, Jain University, Bangalore, India

1.50-2.10 pm: Multiple NDE Methods for Crack Characterization on Spur Gear,

M R Vijaya Lakshmi, A K Mondal, Shubhanjali, M V Subbaraju, V Thangavelu

Sreelal Sreedhar, Gas Turbine Research Establishment, Bangalore, India

2.10-2.30 pm: On Health Monitoring of Insert Joints in Spacecraft Structures, P

Sathish Kumar, A Ananthan, T S Srirangaa, Krushna Chandra Dakua S

Shankar Narayan, ISRO, Satellite Centre, India

2.30-2.50 pm: Thermo Elastic Deformation Measurements on Spacecraft

Components using Non-contact Target-less Image Based Technique,

Raghunatha Behara, T S Srirangaa, CS Varghese, C Koteshwar Rao, Swapnil

Pathak,Pravesh Mathur, Krushna Chandra Dakua, ISRO, Satellite Centre, India

2.50-3.10 pm: Advances in Phased Array Ultrasonic Testing Analysis Software,

Bharath Kodumuru and Jay Amos, Textron Aviation, India and USA

About the Symposium

Non-Destructive Testing and Evaluation (NDT&E) is one of the major requirements in aerospace structural

design. Almost all the components have to pass through various NDT quality assurance procedures. For

damage tolerant design used in aviation, NDT is a prerequisite. Appropriate use of NDT guarantees safety in

aerospace and is thus a subject of highest attention.

Although aerospace industries have to clearly stick to certified NDT procedures, there is a large amount of

technology being currently developed within the engineering science discipline, which is worth discussion

with respect to their application potential. The widespread use of emerging materials such as CFRP

composites as well as new manufacturing processes for aerospace structural components has also given rise to

many new questions regarding the materials’ reliability and manufacturing methods in the light of nondestructive evaluation, both from a research as well as a manufacturing and assembly point of view. To

communicate latest R&D achievements to industrial applicants on the one hand and to discuss advanced and

improved methods both with scientists as well as industrial researchers on the other, the Symposium for NDT

in Aerospace has been established in 2008 and has been organised on an annual basis since 2010. It is run in

places worldwide all around the globe where aerospace has a home including Hamburg, Germany, Montreal,

Canada, Augsburg, Germany, Singapore, Madrid, Spain, and Bremen, Germany so far. The 8th Symposium for

NDT in Aerospace is now being held in November 2016 in Bangalore/ India.

This Symposium of NDT in Aerospace is intended to provide the delegates the latest trends in this area

especially in the context of Aerospace Engineering. This year's symposium will have two theme oriented

plenary sessions addressing NDT aspects in Military aviation and in Structural Health Monitoring Simulation

Platform. Well selected Plenary and invited speakers will address some novel topics of high relevance and this

symposium will in particular showcase the experience of Indian Scientists and Engineers in the NDT field

through a number of invited and contributed papers.

Prof. S Gopalakrishnan

Indian Institute of Science,

Bangalore, India

Prof. K Balasubramaniam

Indian Institute of Technology Madras,

Chennai, India

Scientific Advisory Committee

George Akhras

Christian Boller

S Gopalakrishnan

Alfredo Güemes

Randolf Hanke

Johann Kastner

Patrice Masson

William H. Prosser

Matthias Purschke

Christian U. Große

Shenfang Yuan

Wieslaw Ostachowicz

Robert Smith

Gary Georgeson

Philippe Benoist

Esmeralda Cuevas

Royal Military College of Canada, Kingston, Canada

Saarland University, Saarbrücken, Germany

Indian Institute of Science, Bangalore, India

Universidad Politecnica de Madrid, Spain

Fraunhofer IZFP, Saarbrücken, Fraunhofer EZRT, Fürth &

University of Würzburg, Germany

University of Applied Sciences Upper Austria, Wels, Austria

GAUS – Univ. de Sherbrooke, Canada

NASA, Hampton, USA

DGZfP, Berlin, Germany

TU Munich, Germany

Nanjing University of Aeronautics and Astronautics, Nanjing,

China

Polish Academy of Sciences, Gdansk, Poland

University of Bristol, United Kingdom

Boeing Commercial Aircrafts, Seattle, USA

M2M, Les Ulis, France

Tecnatom, Madrid, Spain

National Advisory Committee

Ramesh Sundaram

Roy Mahapatra

M Ramachandra Bhat

Mira Mitra

National Aerospace Laboratories, Bangalore, India

Indian Institute of Science, Bangalore, India

Indian Institute of Science, Bangalore, India

Defence Research and Development Organisation, Hyderabad,

India

Indian Institute of Technology Bombay, Mumbai, India

B Venkataraman

Indira Gandhi Centre for Atomic Research, Kalpakkam, India

Prabhu Rajagopal

Shyamsundar

K Vijayaraju

S Kalyana Sundaram

Indian Institute of Technology Madras, Chennai, India

GE Global Research Centre, Bangalore, India

Aeronautical Development Agency, Bangalore, India

National Aerospace Laboratories, Bangalore, India

Liquid Propulsion Systems Centre, Indian Space Research

Organisation, India

Structural Engineering Research Centre, Chennai, India

B V S R Murthy

Raghupathy

Santosh Kapuria

About the Indian Institute of Science, India

The Indian Institute of Science (IISc) was founded in 1909 as a result of the joint efforts of Jamsetji

Nusserwanji Tata, the Government of India, and the Maharaja of Mysore in Bangalore, India. The name

Bangalore encompasses so many sobriquets like Garden City, Silicon Valley of India, and Pub City and so on.

One of the prettiest cities in India, known for its salubrious climate all year round, Bangalore is bestowed with

tall tree lines streets and several parks adding to its greenery. With its gorgeous parks, boulevards,

multiplexes, bustling shopping bazaars and historical monuments, Bangalore is indubitably sparkling life with

vigour.

Over the 105 years since its establishment, IISc has become the premier institute for advanced scientific and

technological research and education in India. Beginning with 2 departments and 21 students in 1911, today

IISc has 39 departments, units, or centres, 3500 students, and about 500 academic and scientific staff,

supported by 600 administrative personnel. Out of this population of students, about 2200 are in various PhD

programs, almost 900 are enrolled for various Masters degrees, whereas about 400 are registered in the newly

established, research oriented, four-year Bachelor of Science (Research) programme, of which the first batch

graduated in 2015.

In the recent years, with new centres such as CiSTUP (The Centre of Infrastructure, Sustainable

Transportation, and Urban Planning), the Divecha Centre for Climate Change, the Centre for Earth Sciences,

the Centre for NeuroScience, the Centre for Excellence in Nano Science and Engineering (CeNSE), the

Robert Bosch Centre for Cyber Physical Systems (RBCCPS), a new Centre for Brain Research the Institute

has vigorously promoted inter-disciplinary research. With the recent construction of modern buildings,

acquisition of new research facilities, and induction of a large number of new faculty members, the Institute

can look forward to an era of high productivity, increasing impact, and rising prominence in the world.

Papers

Hand Operated Shock Tube (Reddy Tube) for Non Destructive Testing

K P J Reddy

Department of Aerospace Engineering,

Indian Institute of Science, Bangalore, India

Contact: laser@aero.iisc.ernet.in

The field of shock waves has attracted the attention of many researchers for more than a century and the

physics behind the shock wave phenomenon has been well understood. However, applications of shock waves

are relatively unexplored in spite of realizing the potential applications in all fields of science and engineering

in the laboratory. More surprising is the lack of application of shock waves in Non Destructive Testing

(NDT). Similar to light pulse shaping in lasers the pressure pulses of required shape, strength and frequency

can be generated using shock tubes. These pulses can ideally be used for many NDT applications. It is

surprising that there are no reports of using shock waves in NDT except for the pioneering paper published in

the year 2002 (NDT&E Int., 35, 399-406, 2002). This could be due to the bulkiness of the shock tubes capable

of producing the required overpressures and complexity of their operation. Our recent invention of hand

operated shock tube named Reddy tube, shown in Figure 1, has overcome all these limitations and hence is an

ideal devise for NDT. Reddy tube is capable of producing shock Mach numbers exceeding 2 manually without

any high pressure gas supply and it can be made in any size starting from few centimeters to meters with

diameter varying from one millimeter to tens of millimeters. Reddy tube has already found applications in

many fields including science, engineering and medicine. We will describe the basic principle and design of

Reddy tube along with typical examples of few applications which are already in practice. We will also

present a tentative plan for using the Reddy tube for NDT. We feel that the versatility and easy portability of

Reddy tube will eventually make it a preferred tool for NDT. Finally we will describe the manually operated

Reddy tunnel driven by Reddy tube, shown in Figure 2, capable of producing hypersonic flows with flow

Mach numbers exceeding 6 suitable for testing the aerodynamics of hypersonic flight vehicles.

Figure 1: Hand operated shock tube:

Reddy Tube

Figure 2: Hand operated hypersonic shock tunnel:

Reddy Tunnel

New NDE Technologies and Solutions from CNDE@IITM for Aerospace Industries

Prof. Krishnan Balasubramaniam

Centre for Non-destructive Evaluation & Department of Mechanical Engineering

IIT Madras, Chennai-600036, Tamil Nadu, India

Contact: balas@iitm.ac.in

Several NDT methods are currently employed in the quality assurance and in-service inspection of aerospace

components. Most of these techniques are focused on the detection, sizing, and characterization of flaws such

as cracks, at pre-determined critical locations, that lead to fractures and hence failures in the component.

Advanced NDE methods are being developed by the Centre for NDE at the Indian Institute of Technology

Madras (CNDE@IITM) that may potentially influence the fabrication, inspection, safety, costing, and

maintainability of the aerospace components and its fleets in the strategic sector as well as the commercial

sector. Some of the techniques that will be discussed here includes: (a) Use of ultrasonic guided waves for the

improved inspection of complex structures and components including hidden areas, (b) Structural health

monitoring of components and structures using attached and embedded sensor networks, (c) Use of new and

novel active thermography techniques such as induction and laser based, and (d) Waveguide sensors for

process condition measurements. Using the methods discussed here, the operator now has the opportunity to

take vital decisions such as component integrity and propose necessary repair/replacement or estimate the

remaining life of the component.

Role of NDT in Ensuring Structural Integrity of Aircraft

Prakash D Mangalgiri

Formerly, Visiting Professor, Department of Aerospace Engineering,

IIT Kanpur, India 208016

Structural design philosophy of aircraft has evolved over the years, learning often from mishaps and service

experiences, so as to ensure structural integrity and safety. Increasing complexity of aircraft structure to meet

the ever increasing demands on the performance of the aircraft – be it a small combat aircraft or a large longrange passenger aircraft – has brought in the need for constant vigilance for defects and damages during the

manufacture and during the service. Also, the increasing sizes of fleets with shrinking budgets and

competitiveness in commercial sector have brought in the need to keep the costs for diagnosis and prognosis

of defects and damages at an economical level. This has given rise to a constant evolution and refinement of

the Non-destructive Testing (NDT) techniques, as well as devising suitable methodologies and protocols to

use them efficiently. It has also brought in new paradigms of looking at the entire life cycle of the aircraft with

the participation of the Design, Manufacture, Operations and Maintenance agencies. The modern concepts of

Structural Health Management (SHM) thus involve a spread of conventional and new NDT techniques and

their customisation into a strategy to ensure safety and mission-readiness of the aircraft at an affordable cost.

The development of the Light Combat Aircraft (LCA), Tejas, in India has seen a concurrent development of

NDT techniques and their use for ensuring structural integrity. The design philosophy of damage tolerance,

use of fibre-reinforced polymer composites and the need for reducing the maintenance costs – all these have

been the drivers for evolving a suitable strategy for use of NDT techniques leading to a Structural Health

Management (SHM) scheme. Also, National initiatives of R&D Programmes on Smart Technologies and

MEMS based sensors have contributed significantly to development of NDT technologies useful for SHM.

These developments have spanned from NDT at manufacturing stage, such as use of ultrasonics for

composites, to monitoring systems on-board aircraft and rapid NDE systems for reducing maintenance time

and costs.

The talk will highlight some of these developments and issues involved in use of NDT techniques in ensuring

aircraft safety, based on the experiences in the above programmes.

Aviation Safety

B Dattaguru

International Institute of Aerospace Engineering & Management

Department of Aerospace Engineering,

Jakkasandra, Bangalore, India-562112

Contact: datgurb@gmail.com

Aviation safety in aero-vehicles is to ensure safety till the vehicle completes its mission. For example in civil

airlines the requirement is to ensure safety of all passengers from the time they enter the airport till they land

at the destination and leave the airport. In other types of aero-vehicles the most critical mission of the aircraft

is to be clearly defined. This is a multi-dimensional issue covering structural safety during the flight,

continuous monitoring of engine health monitoring, air traffic control to help landing and take-off of a number

of aircraft in a short time avoiding collisions and any other incidents and/or accidents, smooth logistics

operations to ensure availability of aircraft at any instant of time, airport design for user friendly business

operations and introducing anti-terror mechanisms. At Jain University the research groups are progressing on

the basis of “Aviation Safety” as the main theme. The strong structures group is already advanced in their

efforts. The other groups are initiated and are being oriented towards this theme.

The current paper deals with prognostic aspect of Structural Health Monitoring (SHM). There are well known

programs such as NASGRO to study the growth of defects (or cracks) in standard configurations. On the

other hand it is necessary to develop special equations for fracture parameters while dealing with non-linear

problems and novel materials such as composites and its variants. There is considerable progress has been

achieved in the study of fracture parameters at critical fastener and bonded joints, delamination in layered

composites and cracks merging in aging structures. For accurate estimation of fracture parameters special

post-processing techniques such Modified Virtual Crack Closure Integral (MVCCI) is developed. Some of

the results in these areas are presented in this paper.

Most of the problems addressed are non-linear in any one or more of the types of non-linearity. Fastener joints

are moving boundary value and contact problems during load transfer, bonded joints undergo large

deformation and adhesive material has low yielding strength, delaminated composite undergoes large

deformation of sub-laminate and cracks are deemed to have merged when plastic zones of the cracks meet. In

all these problems the main concentration of the work is on prognostic approach estimating the defect growth

life and estimating the remaining life at any instant. Engine health monitoring is initiated by the propulsion

group. Inter-relations between engine parameters and their effect on the engine thrust are being developed.

Several components of the engine are also susceptible to fatigue damage. Growth of three-dimensional cracks

are analysed with and without interaction with neighbouring cracks.

The recent ventures are in the area of “Big Data Analytics” and collision avoidance. Big Data has been

addressed for 2 – different requirements. One is towards analysis of data from Structural Health Monitoring

where the main aim is to identify damage initiation and growth so that estimation can be carried out in the

remaining strength and remaining life. The second is to identify any unusual activity to signify terror activity

which can be prevented. In the area of engine health monitoring the dependence of thrust on the other engine

measured parameters is being developed. Research plans in these directions is found to be essential for safe

installations. Integration of these various activities would go a long way to ensure Aviation safety.

8th International Symposium on NDT in Aerospace, November 3-5, 2016

Electromechanical impedance method for assessment of adhesive bonds

of CFRP at the production and repair stage

Paweł H. MALINOWSKI1, Tomasz WANDOWSKI1, Wiesław M. OSTACHOWICZ1,2

1

Institute of Fluid–Flow Machinery, Polish Academy of Sciences

14 Fiszera Street, 80–231, Gdansk, Poland

Phone: +48 58 341 12 71, Fax: +48 58 341 61 44; e-mail: pmalinowski@imp.gda.pl, tomaszw@imp.gda.pl

2

Warsaw University of Technology, Faculty of Automotive and Construction Machinery, Warsaw, Poland;

e-mail: wieslaw@imp.gda.pl

Abstract

Numerous techniques of non-destructive testing (NDT) of structural parts of CFRP are investigated. In this paper

electromechanical impedance (EMI) technique is studied as an NDT tool for assessment of adhesive bonds. In

order to perform the assessment a surface mounted piezoelectric sensor is used. Due to the piezoelectric effects

the electrical response of the sensor is related to mechanical response of the inspected object. The electrical

quantities of the sensor are tracked in order to find a relation with the mechanical state of the object. In the reported

research adhesively bonded CFRP samples were investigated. The adhesive bonds were modified simulating the

conditions in manufacturing and repair stages. Sample surface was contaminated before bonding with release agent

in order to simulate a manufacturing stage threat to the quality of the bond. Pre-bond thermal treatment, pre-bond

contamination with de-icing fluid, and faulty curing of the adhesive were considered as repair stage threats to the

quality of the bond. The electromechanical impedance spectra were investigated searching for anomalies and

changes caused by modification of the adhesive bond. These spectra for different cases were compared with

reference measurement results gathered from pristine samples. Numerical indexes for comparison of the EMI

characteristics were proposed. The sensitivity of the EMI method to modified bonds was observed.

Keywords: electromechanical impedance, EMI, adhesive bonding, carbon fiber composite, CFRP

1. Introduction

The paper focuses on the assessment of the CFRP adhesive bonds. It is important to have a

reliable tool that allows to verify the integrity of the bond during manufacturing or after repair.

The joints between structural elements should ensure safe usage of a structure. The performance

of adhesive bonds depends on the properties of the adhered surfaces. Improper preparation of

the surface may lead to weak bond and in consequence to failure. Mechanical tests showed that

the bond weakness can be related to contamination or bad curing of the adhesive.

Authors in [1] studied the effect of pre-bond release agent and moisture absorption on mode-I

fracture toughness of CFRP bonded joints. A mode-I double cantilever beam (DCB) specimen

was used to determine the mode-I energy release rate (GIC) referring to crack initiation. The

lowest considered contamination with release agent do not seem to affect the bond. The increase

of the contamination results in 60 % and higher drop in GIC in comparison to samples with

uncontaminated bond. In [2] researchers showed that lower temperature of adhesive curing

have great impact on the bond performance. The GIC for sample cured at 120⁰C drops nearly

by 95% in relation to GIC for properly cured sample at 180⁰C. In research reported here authors

focus on monitoring of adhesive bonds for both manufacturing and repair-related scenarios.

The paper is structured as follows. Firstly, the EMI method is described. Secondly, the samples

with manufacturing-related modification of the adhesive bonds are described and respective

results are presented. Thirdly, the samples with repair-related modifications are described

together with the assessment results. The paper ends with a concluding section.

2. Electromechanical impedance (EMI)

EMI uses measurements of electrical parameters of piezoelectric transducer bonded to a host

structure. Due to electromechanical coupling of the transducer and the structure, mechanical

resonances have their influence on electrical characteristics of the piezoelectric transducer. EMI

is an active method, because transducer works both as actuator and as sensor. Data analysis for

this method is performed in the frequency domain. One of the first publications about this

method is [3]. In experimental research laboratory impedance analysers like HP4194 or HIOKI

IM3570 are utilized. Researchers also utilise impedance analyser AD5933 in the form of

integrated circuit. In research reported here authors utilize the IM3570 analyser, because the

research was focused on thickness mode of the transducer that appears about 4 MHz. The

promising results of using this approach for composites adhesive bonds were presented in [4].

Measurements were performed with a piezoelectric disc transducer that was bonded at the

middle of investigated samples. The disc had 10 mm diameter and 0.5 mm thickness, and was

manufactured by CeramTec out of SONOX P502 material.

3. Samples and results

The material used for samples manufacturing was Hexcel M21E. The size of samples was 10

cm x 10 cm. The samples comprised of two plates bonded together. Each plate was made with

8 plies and layup sequence: [0, 0, 45, -45, -45, 45, 0, 0]. The plates were bonded with film

adhesive. In the case of samples for manufacturing stage the adhesive was FM 300 K cured at

171˚C, while for repair stage the adhesive was FM 300-2 cured at 121˚C.

3.1 Adhesive bonding assessment for manufacturing stage

The manufacturing stage samples comprised of samples contaminated with silicon-based

release agent, the Frekote 700-NC. It was applied in three defined concentrations on clean

CFRP plates by means of dip-coating. Then these plates were bonded to clean ones. The

concentrations of release agent on the surfaces was expressed by silicon concentracion

measured with XPS (3.2, 5.1, 6.2 at% Si). There were 3 samples prepared for each level of

contamination. For comparison three reference samples were prepared (PRE). In total there

were 12 samples in the manufacturing stage scenario. The results are depicted in figure 1. The

results were averaged, because there were four groups of the samples prepared in the same way.

In the results, one observes a slight increase of the RMS value for the first level of

contamination case (PRA1). For the higher levels (PRA2, PRA3) of contamination there is a

sudden drop indicating a significantly different adhesive bond.

Fig. 1. Results of the assessment of samples with pre-bond contamination with release agent

3.2 Adhesive bonding assessment for repair stage

The repair stage samples comprised of four kinds of samples. The investigations were

conducted on 24 samples: 3 reference samples, 9 samples with pre-bond thermal treatment, 9

samples with pre-bond contamination and 3 samples with faulty adhesive curing. The thermal

treatment was performed by exposure of samples to elevated temperatures (220, 260 and

280˚C) for two hours and grinding afterwards before bonding. The pre-bond contamination

with de-icing fluid was prepared by dip coating of the plates in a solution of SAFEWAY KF

de-icer with three concentrations. The contamination was expressed by potassium presence at

the surface measured by XPS (6.4, 10.9, 12.0 at% K). The case of faulty curing of adhesive was

prepared by local pre-curing of the adhesive by IR-spot. This pre-curing was made at the middle

of the sample.

Fig. 2. Results of the assessment of samples with pre-bond thermal treatment

Fig. 3. Results of the assessment of samples with pre-bond contamination with de-icing fluid

Fig. 4. Results of the assessment of samples with faulty curing of the adhesive

Figure 2 depicts the result for the thermally treated samples. An increasing value of RMS is

observed. The reference (RRE) case has the lowest value and the samples treated at 280˚C

(RTD3) have the largest value. Although, there were 3 levels of de-icing fluid contamination

prepared, the second (RDI2) and third (RDI3) level resulted in approximately the same level of

surface contamination, if the error of concentration estimation was considered. For this reason

the results for this two cases were averaged and treated as one level. The result for the de-icing

fluid were depicted in figure 3. A RMS value increase is observed as the contamination level

increases.The last scenario was related to faulty curing of adhesive. Only one level (RFC1) of

modified bond was available at the time of preparing this manuscript. The RMS value increases

by more than 30% (figure 4).

4. Conclusions

It as shown that the EMI method indicates some sensitivity to the modification of adhesive

bonds of CFRP samples for manufacturing and repair stage scenarios. There is a decrease of

RMS as the contamination with release agent increases. In the repair stage samples, there is an

increase of RMS as the modification severity is higher (RTD and RDI samples), so the bond

quality level assessment is possible. The detection of faulty cured adhesive for RFC samples

was also possible. The main difference between the two stages is that for manufacturing case

RMS drop was observed, while an increase was seen for repair stage samples. It should be

remembered that samples for this two stages were prepared in different way. There was

different film adhesive used and the repair stage samples were grinded down to fibers before

bonding.

The research will be continued taking into account the bond performance assessment obtained

from destructive testing and referential nondestructive methods. Moreover other indices and

other scenarios will be also investigated.

Acknowledgements

This project has received funding from the European Union’s Horizon 2020 research and

innovation programme under grant agreement No 636494.

This work was partially supported by the grant no. PBS1/B6/8/2012 (project KOMPNDT) of

Polish National Centre for Research and Development (NCBIR).

References

1. D N Markatos, et al. ‘The effects of manufacturing-induced and in-service related bonding

quality reduction on the mode-I fracture toughness of composite bonded joints for

aeronautical use’, Composites: Part B, 45, pp 556–564, 2013.

2. D N Markatos, et al. ‘ Degradation of Mode-I fracture toughness of CFRP bonded joints

due to moisture and release agent and moisture pre-bond contamination’, Journal of

Adhesion, 90, pp 156-173, 2014.

3. C Liang, et al. ‘An impedance method for dynamic analysis of active material system’,

Journal of Vibration and Acoustics, 116(1), pp 120-128, 1994.

4. P Malinowski, et al. ‘The use of electromechanical impedance conductance signatures for

detection of weak adhesive bonds of carbon fibre–reinforced polymer’, Structural Health

Monitoring, 14(4), pp 332-344, 2015.

NDT Aspects in Marine Composites under Extreme Environments

Yapa D. S. Rajapakse

Office of Naval Research (ONR 332)

875 North Randolph Street (Suite 1425)

Arlington, VA 22203-1995, U.S.A.

Contact: yapa.rajapakse@navy.mil

The Solid Mechanics Program of the Office of Naval Research (ONR) provides the scientific basis for

the effective design and utilization of affordable and reliable naval structures operating in severe

environments. Current emphasis on energy efficient, reliable, agile structures with enhanced

capabilities and reduced life-cycle costs, has led to the increased use of composite materials in ship

structures. The marine environment is hostile because of the presence of high humidity levels, sea

water, wave loading, hydrostatic pressure, and temperature extremes. Marine structures are subjected

to fluid-structure loading, and Naval structures are designed to resist highly dynamic loading (shock,

blast, implosions).The performance of composite structures in this environment, the challenges

encountered, and the physics/mechanics underlying these processes are the central themes addressed

by the ONR Solid Mechanics Program.

The current research focus is on the mechanics of marine composite materials and composite

sandwich structures. The program seeks to establish physically-based models for the processes

involved in the thermo-mechanical response of glass-fiber and carbon-fiber reinforced marine

composite materials and composite sandwich structures, subjected to static, cyclic, and dynamic

loading conditions, in severe environments. The establishment of these of these validated models,

with predictive capabilities, requires multi-scale, multi-physics analyses. Avenues for enhancing the

performance of marine composite structures through the introduction of nanoparticles and nanotubes,

and through the incorporation of novel design concepts, are also being explored in this program.

Research on multi-functional composites seeks to enhance performance through the incorporation of

additional beneficial attributes, without compromising on the mechanical properties.

Several recent accomplishments will be summarized, including: Failure criteria under multi-axial

loading; Effects of loads on sea water absorption, and degradation in mechanical properties; Effect of

extreme cold temperature on dynamic response; Shock/blast effects on composite and sandwich

structures; Implosions in submerged composite structures; Blast mitigation in composite structures;

and Mapping interior deformations using digital volumetric speckle photography

The presentation will include a discussion of future directions of research in mechanics of marine

composites and sandwich structures for affordable naval structures, with enhanced performance and

reduced life-cycle costs. Areas of increased emphasis include: Behavior of composite materials and

structures in extreme cold (Arctic) environments; Mitigation of shock/blast effects in composite

structures; combined effects of sea water, cold temperatures, and highly dynamic loading; and Nondestructive evaluation techniques for internal damage in composites. This research will contribute to

the design of affordable naval structures with enhanced performance and reduced life-cycle costs.

8th International Symposium on NDT in Aerospace, November 3-5,

2016

A permanent inspection system for damage detection at composite

laminates, based on distributed fiber optics sensing

Alfredo GUEMES, A. FERNÁNDEZ-LÓPEZ, P. FERNÁNDEZ DÍAZ-MAROTO

1

Dpt Aeronautics, Polytechnics University of Madrid, Spain

Phone: +34913366327, Fax: +34913366334; e-mail: alfredo.guemes@upm.es

Abstract

Distributed fibre optic systems allow to get information of the local strain all along the optical fibre.

Advanced systems may get strains readings with a spatial resolution of a few mm, and accuracy of a few

micro strains. This new technology offer a wide range of possibilities for structural testing, but also for

Damage detection, because a crack crossing or growing nearby the optical fiber path will be detected as a

local spot with high strains.

Concerning composite laminates, the most feared and common damage are VBID ( Barely visible Impact

Damage) because they may go undetected to visual inspection, but they cause a drop up to 50 % for the

compressive strength. These internal delaminations are also accompanied by some local residual strains at

the damage area, which are easily detectable if a strain sensor was installed just there.

Usually, the laminate edges, like manholes, or the area surrounding doors, are high risk areas for impact

damage, so the proposed approach is to bond or embed optical fiber along this perimeter, that may be

checked regularly for delaminations. The concept was experimentally demonstrated on laminate edges,

and also on internal delaminations, and on stringer run-away. The reliability of the technique has been

found to be 100%, always that the damage happened close to the fiber path.

Keywords: Structural Health Monitoring, SHM, aerospace, carbon fiber composite, CFRP

1. Introduction

Impact damage is considered to be the highest threat for composite structures during its

service life. Low/medium energy impacts (called BVID = Barely Visible Impact

Damage) do not leave any external visible marks, but cause internal delaminations that

drop the compressive strength by nearly 50 %. They need to be identified and repaired

as soon as possible to avoid the growth of the damaged area under repeated loads.

A permanent inspection, without disassembly the structure, even without the need of

moving a probe on the surface, is what may be achieved by SHM, which allows a

continuous automatic surveillance of the structural parts.

Structural Health Monitoring (SHM) is defined [1] as “the process of acquiring and

analyzing data from on-board sensors to evaluate the health of a structure”. The three

elements of an SHM system are:

1. A network of sensors, permanently attached to the structure; this aspect is a

main differentiation with conventional NDT procedures.

2. On-board data handling and computing facilities. Due to the high number of

sensors, data have to be processed on real time; wireless is a desired capability

(avoid cabling, repairability). SHM was feasible when large capacity portable

computers were available ( mid ‘80)

3. Algorithms that collect data from sensors, clean data from environmental

effects, compare to former data from the pristine structure and inform about

occurrence, localization and damage type.

Several kinds of sensors are used for SHM, but the two most commonly employed are

Piezoelectric wafers (PZT) and Fiber Optic sensors (FOS). Piezoelectrics offers a high

sensitivity, with a direct conversion of dynamic strain into voltage, and the opposite, so

they may act also as actuators.

Fiber Optic sensors offer a very low size, the optical fiber has a diameter of 150

microns, so it can be embedded within a ply into the composite material during

manufacturing. Other benefits for FOS are EMI/RFI immunity, wide temperature range,

very long cabling if needed, because of the low attenuation, and the multiplexing

capability (several sensors on the same optical fiber). As sketched at figure 1, three

topologies are possible:

•

•

•

Point sensor: detect measurand variation only in the vicinity of the sensor.

Example: micromirror at fiber tip. This is mostly used for chemical sensors

Multiplexed sensor: Multiple localized sensors are placed at intervals along the

fiber length. i.e . FBG (sensor length 10 mm typical). About 10 sensors/fiber if

multiplexed by wavelength, to 1000 sensors by using OFDR

Distributed sensor: Sensing is distributed along the length of the fiber, the

optical fiber works simultaneously for transmitting the information and for

sensing the local external variables (temperature, strain).

Figure 1 Topology of Fiber Optic Sensors

Fiber Optic Sensors have built a confidence at their performances as strain/temperature

sensors, equaling conventional sensors, and their reliability is now fully proven and

accepted. As damage sensors, the following considerations must be taken into account:

•

•

•

Strain changes caused by damage are very small a few cms away from the crack

tip, and masked by temperature drifting, load changes or any other

environmental factor.

Getting information about damage occurrence from strain measurements is then

a difficult task. Of course the larger the damage and the proximity to some

sensor, the higher the probability to be detected.

It drives to the need to include a large number of sensors into the structure,

which is feasible when using optical fiber sensors,

•

Data processing has to be done in a fully automated approach, algorithms are

needed to compare and extract information from the multiple strain

measurements.

2. Fiber Optic Distributed Sensing

Several kinds of Fiber Optic Distributed sensing systems are available, in dependence of

the wavelength they are working with [2]. Table 1 summarizes its performances.

Rayleigh system working with OFDR (Optical Frequency Domain Reflectometry) is the

only one to offer spatial resolution in the range of mm, as needed for aeronautic

applications (for civil engineering applications, a long measurement range may be the

preferred quality, which may drive to other choices)

Table 1. Comparison of Distributed Fiber Optic sensor systems

This OFDR technology has proven to be very useful for structural tests of large

structures [3]. At figure 2 left, it is shown the static test of a large wind turbine blade,

instrumented with just 4 continuous optical fibers (and 200 conventional electric strain

sensors, for comparison purposes).

Figure 2. Left, static test of a large wind turbine; right: strain measurements

obtained by distributed sensing (pink line), and strain gages (blue dots)

Results are shown at figure 2 right: pink line are the measurements obtained with the OFDR,

blue dots are measurements obtained from the strain gages. Not only if was much simpler to

prepare the test, but a more detailed information is obtained (as the sudden strain changes due

to the ply drops), and also, and very important, information on the initial phases of local

buckling.

3. Residual strains at impacted laminates.

A sixteen plies crossply CFRP laminate was built from UD prepreg material by OOA (Out of

Autoclave) procedures. A poliimide coated optical fiber was embedded inside the laminate

during layup. (Figure 4 A)

The laminate was impacted by a drop weight test, and a delamination was produced, as was

verified by ultrasonic C-Scan (Figure 4 B, green spot). The white line show the position of the

optical fibre, and the lower image (figure 4 C) show the strains measured by the optical fiber

along this line. It can be seen the appearance of residual strains at the delaminated area. In

fact, the delaminated area can nearly be plotted if the optical fiber follows a crooked path,

with parallel fibers every 5 mm. the strain field map of the area can be obtained with

relatively high accuracy (fig 4 D).

Figure 4. Upper left A. Composite laminate with an optical fiber following parallel paths

Upper right B. Ultrasonic C-Scan of the impacted laminate

Lower right C. Strains measured along the with line of the upper figure by an O.F.

Lower left D Strain mapping at the delaminated área, obtained by a set of parallel O.F.

4. Detection of delaminations at laminate edges

The former approach may be used for SHM of similar of structures, like small cylindrical

pressure vessels, or for structural details, like monitoring stringer debondings, but for

practical reasons the whole surface of the aircraft can not be covered with a continuous optical

fiber, the maximum inspectable length is about 100 meters. The proposed approach is to

reduce the covered area to critical regions with a higher risk of damage.

Laminate edges, like surroundings of cargo doors and man holes, are areas of high risk for

accidental impacts, and consequently require a more frequent inspection; a permanent

automated inspection system is highly desirable. The following experiments were done to

demonstrate the validity and reliability of the approach.

Several identical CFRP 16 plies laminates were built from UD prepreg material, by OOA

procedures, with the lay-up (04, 904)s. This special layup sequence was used for simplicity, to

have only two delaminations interfaces; nevertheless the concept is also working for any other

general laminate. Dimension of the cured laminate was 200 mm X 100 mm. An optical fiber

was bonded at the surface of the cured laminate, as sketched at figure 5.

The laminates were submitted to impacts of controlled energy, by using a drop weight test

machine, in both directions, perpendicular to the laminate and on-edge direction (figure 6).

The energy was gradually increased until a visible damage was produced (figure 7), and the

residual strains were recorded after every impact (figure 8)

Figure 5. Laminate with an optical fiber bonded at the surface, for the edge

delamination tests

Figure 6. Local impacts, using a drop weight test machine

Figure 7. Delamination caused at a (04, 904)s CFRP laminate after a 5 J on-edge impact

Figure 8. Strain recorded by the optical fiber after successive impacts of increasing

energy, from 2 to 5 joules. The two identifiable peaks recorded at 100 and 400 mm are

for the first and second loops of the optical fiber, respectively

From these data an strain map of residual strains may be plotted, as shown at figure 9; It may

be seen how the delaminated area increase in size for higher impacts, and that strains are

higher at the surface closer to the delamination, as expected.

Figure 9. Plot of the residual strains caused by on-edge impacts, obtained by the OFDR

system

Figure 10 Up.

Delamination caused by a normal impact, as obtained by ultrasonic

C-Scan ( at the right of the image, a B-Scan is given)

Figure 10 Down. Map of the residual strains after the impact, as measured by an OF.

Similar findings were obtained when impacts were done at the direction normal to the

laminate, figure 10. For these testss, an embedded O.F. was used, located at the second ply of

the surface opposed to the impact. The energy needed to cause a BVID was slightly higher

than in the former case.

5. Conclusions

The following conclusions can be drawn from the former experiments:

•

•

•

•

•

•

•

•

Fiber optics are excellent, fully proven strain sensors.

They are not ‘damage sensors’. Damage can be inferred only by comparing the

collected data to those coming from pristine structure

A crack may drop significantly the strength of the structure, acting as the failure

initiation point, but it only alters locally the strain field around the crack; damage may

go undetected unless a sensor was located just there.

Distributed sensing will detect the crack as far as it crosses the optical fiber, or when it

produces a strain change on the O.F

Delaminations in laminates produce a liberation of residual strain field, and they will

be detected by an O.F located there.

This damage detection method is robust and reliable (at least equivalent to CVM), for

impact prone areas, like doors surroundings areas and man-holes

This technique (detection of impact-created residual strains) is based on detectable

strain changes at the optical fiber. Structure does not need to be loaded (overnight

inspections)

Damage has to happen on the optical fiber path

This approach is fully independent, and conceptually different, from those based on

submitting the structure to external loads, and comparing the response of the structure to

these loads, before and after damage, that were also developed by our group and presented

elsewhere [4]. Algorithms to get information about damage from the slight changes

produced at other sensors are being developed, but improvements in the resolution (size of

damage, distance to sensors) are still needed.

References

1. SAE “Guidelines for Implementation of Structural Health Monitoring on Fixed Wing

Aircraft”, SAE Standard: ARP6461 (2013)

2. Güemes, A, Fernandez-Lopez, A, Soller B. “Optical Fiber Distributed Sensing.

Physical Principles and Applications” J. Structural Health Monitoring, Vol. 9, No.

3, 233- 245. (2010)

3. J. Sierra, M.-A. Torres-Arredondo, A. Guemes, L. Mujica and C.P. Fritzen “Structural

Health Monitoring of Wind Turbine Blades From Distributed Strain Measurements”.

In Proceedings of the 6th World Conference on Structural Control and Monitoring,

2014, Barcelona, Spain.

4. J. Sierra, A. Güemes and L. Mujica. Damage Detection by Using FBGs and Strain

Field Pattern Recognition Techniques. Smart Materials and Structures. 2501125020. 2013

Simulation as a Prerequisite in Structural Health

C. Boller1, D.R. Mahapatra2, R. Sridaran Venkat1, N.B. Ravi2, N.Chakraborty2

1

Chair of Non-Destructive Testing and Quality Assurance (LZfPQ)

Saarland University, Saarbrücken/Germany

2

Department of Aerospace Engineering, Indian Institute of Science, Bangalore 560012, India

Contact: c.boller@mx.uni-saarland.de

Inspection performed today needs to work at highest reliability. In non-destructive testing (NDT) this

is done by achieving the highest level of probability of detection (POD) with the inspection method of

choice, moving the respective transducer as much around until hopefully 100% coverage of the

volume to be inspected is achieved. With structural health monitoring (SHM) this is not achievable

that way since transducers are generally fixed regarding their position once an SHM system has been

implemented onto or into a structure. Hence the optimum transducer configuration has to be found by

other means and a prospective means in that regard is simulation. Different simulation approaches

have been proposed in the past with some being very much focused on and limited to the application

considered while others are gradually finding their way to become generally recognised and a part of

simulation packages on the verge of commercialization. However, those simulation tools need to work

in close to real time in case they should be accepted by the scientific and engineering community and

should make the appropriate contribution regarding a scheme on how to determine POD for SHM

systems. Within the INDEUS project there has been a first attempt to establish a platform which not

only allows to cluster different tools applied for SHM simulation but also to align those into a

structural simulation process chain starting from simulation of loads, the geometry, strength including

fatigue behaviour and a resulting probability of damage and finally ending up with the ability to be

inspected and a resulting SHM system meeting the optimum in terms of POD. In that regard different

case studies will be addressed that will be presented in more detail in further presentations.

SHM System Simulation based Design Considering Composite Patch Repaired

Stiffened Panel of Aircrafts

Rakesh Shivamurthy, Keerthy M Simon, Nitin Balajee Ravi, Nibir Chakraborty Debiprosad Roy

Mahapatra*

Department of Aerospace Engineering,

Indian Institute of Science, Bengaluru, India

Contact: rakeshs@aero.iisc.ernet.in, keerthy@civil.iisc.ernet.in, nitinb@aero.iisc.ernet.in,

nibir.chakraborty@aero.iisc.ernet.in, droymahapatra@aero.iisc.ernet.in

Sometimes repair of a structural component is a cost-effective option as compared to complete dropout of the component or the entire structural assembly. Combining with this option certain health

monitoring capability to enhance the reliability of the repaired structure is an attractive choice. The

present paper reports on the verification and validation effort and on the effectiveness of a structural

health monitoring (SHM) sensor system designed to monitor fatigue crack growth in a post-repaired

structural component such as aircraft fuselage stiffened panel. The SHM system design is developed

through SHM simulation including probabilistic modeling of fatigue damage. The damage tolerant

stiffened panel is subjected to crack growth followed by a composite patch repair. We simulate

probability of fatigue damages (PODm) and the probable locations of damage growth are analyzed for

SHM sensor placement. This consideration is further analyzed for its effectiveness for monitoring

growth of pre-existing crack and any new cracks after repair of the structure. The behavior of the unrepaired and repaired panel with crack is investigated. Complexity of crack growth behavior increases

in a repaired panel and the associated advantages in deploying SHM sensor system on it are evaluated

with example simulation of sensor signals and lab-scale testing with the SHM system as integrated in

the test panel. Further, attempts are made to obtain insight regarding the influence of repair on

damage resistance and fatigue life of repaired stiffened panel from the SHM sensor data.

Feasibility Study of SHM Simulation based Design of Accelerated Fatigue Tests

Nitin Balajee Ravi1, Nibir Chakraborty1, Rakesh Shivamurthy1, Keerthy M Simon1, Ramanan Sridaran

Venkat2, Mirko Steckel3, Debiprosad Roy Mahapatra1, Christian Boller 2

1

Department of Aerospace Engineering, Indian Institute of Science, Bengaluru, India

2

Chair of Non-Destructive Testing and Quality Assurance (LZfPQ), University of Saarland, Campus

Dudweiler, 66125 Saarbrücken, Germany

3 IMA Materialforschung und Anwendungstechnik GmbH, 01109 Dresden, Germany

Email: nitinb@aero.iisc.ernet.in, nibir.chakraborty@aero.iisc.ernet.in, rakeshs@aero.iisc.ernet.in,

keerthy@civil.iisc.ernet.in, ramanan.sridaran@uni‐saarland.de,

Mirko.Steckel@ima-dresden.de, droymahapatra@aero.iisc.ernet.in,

c.boller@mx-uni‐saarland.de

This paper studies the advantages of simulation in extrapolating the crack growth curve based on

applied load and its influence in accelerating the fatigue testing. The studies were conducted on a

stiffened panel subjected to fatigue loading. The crack growth rate was simulated using physics based

model. The current challenges faced in this simulation were twofold – (i) to estimate the number of

cycles required for the propagating crack to reach a particular size when the structural response and

load path is complicated and (ii) to predict the crack growth rate reliably from the data generated by

the SHM system where the SHM system has been designed with the help of simulation. In this study,

the loading condition was based on design load spectrum used to validate damage tolerance design

criteria of a stiffened aircraft. Crack initiation and propagation have been investigated in detail based

on fatigue simulation results obtained within a probabilistic framework. The crack growth curves

were obtained from simulation based correlation derived from data obtained along an actual test

carried out at the IMA Dresden test facility on a stiffened panel while actual crack growth was

monitored visually and from strain gauge data. The SHM system used involved a network of piezo

transducers, which were placed on the panel surface to generate guided waves and were deployed

during the test to monitor fatigue crack growth.

Comparison of predicted crack growth and crack lengths observed have been used as an attempt to

understand the reliability of such an SHM system. The crack growth rate as monitored has been

incorporated in an analytical form to obtain a relationship with the stress amplitude applied.

Following this type of parametric estimation, we performed fatigue simulation at a different stress

level on the identical component with same load case to validate the accelerated crack growth from an

accelerated fatigue testing point of view.

8th International Symposium on NDT in Aerospace, November 3-5, 2016

Simulation as Key Enabler to Support ISHM Certification

Dipl.-Ing. Matthias BUDERATH1, Partha ADHIKARI2, Harsha GURURAJA RAO2

1

Airbus Defence and Space, Rechliner Straße, 85077 – Manching, Germany

E-mail: matthias.buderath@airbus.com

2

Airbus India Engineering, Bangalore, 560 048, India;

E-mail: partha.p.adhikari@airbus.com, harsha.rao@airbus.com

Abstract

Integrated system health monitoring and management (ISHM) is a field of research and development where lot

of different industries and academia are highly focused on. Since the ISHM technology itself is still evolving,

the standards available for certification and successful qualification of the systems are yet to be fully matured.

And these different qualification methods and processes have to be included in the early stages of the

development of the respective systems. This paper highlights the survey of different certification methodologies,

provides an insight into Airbus Defence & Space’s Certification Roadmap, the role of ISHM Simulation

Framework in certification and also the lessons learnt. The paper will also provide an outlook how Structural

Health Monitoring (SHM) technologies can be addressed in the ISHM simulation environment to define the

monitoring concept to contribute to the requirement of probability of detection.

Keywords: ISHM, SHM, Simulation, Certification, CBM, Prognostics, Enhanced Diagnostics

1. Introduction

With growing financial uncertainty, air vehicle operators (both commercial and military) are

under tremendous pressure to reduce operational and support costs. It is accepted across the

aerospace industry that ISHM is a potentially valuable strategy for the manufacturing and

management of vehicle platforms. At the same time, ISHM has not yet fully matured as a