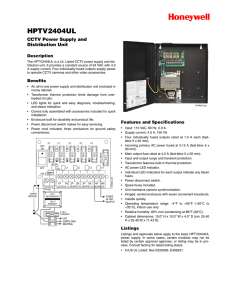

2012 Honeywell Users’ Group EMEA Sustain.Ability. Richard Siereveld Terminal Automation Solutions Is Automation Strategic? Here’s what Owner Operators Believe… Piping, Vessels & Structure Rotating Equip Automation 5-10% 15-30% Bulks Percent of Project Spend 2 Impact on Operations Over Time Does the perfect Terminal Automation Solution Exist? 3 Agenda Industry Challenges Integrated Portfolio Case Studies Why buy from Honeywell 4 What is it that our customers do? • Terminal is a facility where products are moved from one media (ship, truck, train, pipeline, drums, bags, ..) to an other usually with “temporary” storage Transfer of Ownership 5 Core Challenges Accurate Measurements and Recording of all Transactions 6 Other Challenges Safety Security Buncefield report recommends: OSCE recommends: Common safety assessment Holistic risk assessment, mitigate against series of hazards, weather natural, technological (cyber attack) or manmade, tailored to particular infrastructure and scalable High integrity, automated, independent safety system Regulatory Compliance Alternative fuels represent both a challenge and a potentially profitable opportunity. Disparate blending, injection, loading and inventory management systems must be integrated in the new era of alternative fuels. Operational Excellence Price volatility is driving the need for continuous improvements in both precision and operational efficiencies. Automation Must Solve a “Bigger Problem” 7 Agenda Industry Challenges Integrated Portfolio Case Studies Why buy from Honeywell 8 In an Ideal World …. Honeywell’s holistic approach: Integrated solution, single view Non-Integrated Approach: Each supplier has a different view Planning & Scheduling Accounting Terminal Mgt Customs Security Solution attributes: Single solution view Common design philosophy Integrated “out of the box” Less expensive to implement & manage (by as much as half) Safety Loading Control Gauging Multiple solution providers Only focus on subsystem Plant staff become the integrators More expensive to implement & manage … Point Solutions Are Pointless … 9 Potential Savings Integrated Solution … It's All About Integration … 10 Tank Inventory Management Field displays Sampling PDA’s DCS, SCADA Asset Management Terminal Automation Solution Additives, Blending Manual Tank Gauging Oil Movement Stock Reconciliation Access Control Reporting and Historian Fire detection system CCTV Planning & Scheduling, KPI, … ERP Safety system Overfill protection Metering skid Gas detection Flow computer Flow Prover Grounding Density 11 Communicatio n interface unit Automatic Tank Gauging Control Valves Loading skid Flow Prover Temperature Pumps Shutdown valves Flow meters Blend Skids Pressure Additive Injection Flame Arrester Analytical 3rd party scope Honeywell scope Load Computer Grounding Some Impressions FIELD 12 Some Impressions MANAGE CONTROL 13 Technology Honeywell Businesses • Process Solutions (including Enraf, RMG & Field Solutions) • UOP • Building Solutions • Sensing and Control • Environmental Combustion and Controls (Callidus, Maxon) • Security and Data Collection • Life Safety (BW Technologies) PKS Advantage Partners Strategic Partners Integrated Main Automation Contractor 14 Global Expertise and Local Support • Experts in each segment of our offering – Over 700 employees working daily in O&G S&D industry – Over 450 TUV certified safety engineers – Member of ASM consortium – Active member in various ISO, API and Namur committees 17 Benefits of Domain Expertise Domain Knowledge means Ability to Apply Best Practices 18 Benefits of Domain Expertise Domain Knowledge means Ability to Apply Best Practices 19 Benefits of Domain Expertise 4 3 2 1 Achieve total integration Build on the value of previous projects and reuse assets Pick an on-ramp project and start rationalizing Start with disparate systems with complex integration Time Smooth Transitions to Operational Excellence 20 Global Expertise and Local Support • Experts in each segment of our offering – Over 700 employees working daily in O&G S&D industry – Over 450 TUV certified safety engineers – Member of ASM consortium – Active member in various ISO, API and Namur committees • Best-in-class project management capability • Your Honeywell support team can tap into over 6,000 engineering, maintenance and software support personnel worldwide • Leading Edge Technology – Virtualization – Wireless – Cyber security 21 Value of Honeywell Here’s what IPA believes… Streamlined procurement Joint engineering/standardized design Value 5 - 10% project cost 10 - 20% project cost Improved project management 5 - 10% project cost Accelerated realization of benefits (moderniz) 15 - 30% faster completion Reduced capital contingency 2 - 14% reduction Incident avoidance 3 - 8% annual production Post implementation cost savings 10 - 15% of lifecycle cost Basis • IPA Benchmarking study comparing 38 Automation projects against the industry • Honeywell internal data added to broaden base of experience and update results … It's All About Integration and Standardization … 25 Reduce Lifecycle Cost Benefit Category Where do the Benefits Come From? People and Experience • • • • Global Organization Processes & Infrastructure • Global Capability – Regional Resources • Knowledge Mgmt. • Improved Project Management 5-10% Project Cost Breadth of Integrated Technology 30yr. Continuous Evolution Culture 26 Greatest Number of Engineers in Industry Industry Knowledge & Experience Best in Class Safety Incident Avoidance 3-8% annual production • Streamlined Procurement • Reduced Capital Contingency • Accelerated realization of Benefits • Post Implementation Cost Savings 20 – 50% lifecycle cost reduction People make the difference Agenda Industry Challenges Integrated Portfolio Case Studies Why buy from Honeywell 27 Diamond Shamrock Ceylon Petroleum Indian Oil tanking More than 100 terminal references… More than 1500 tank farms --28 Case Study #1 – Baltic Chemical Terminal What was the Customer Challenge? • Comply with European standards, rules and legislation Terminal up and running in less than 6 months due to contractual obligations • • • 1,000,000 tons/yr Ammonia Transfer + 500,000 tons/yr UAN transfer No incidents related to healthy, safety and environment What did We Offer? • • • • • • • • • • Honeywell Enraf Tank Gauging Honeywell Pressure, Temperature and Flow Honeywell Fire and Gas Detectors Honeywell CCTV Cameras Honeywell Experion PKS with C200’s Honeywell Terminal Manager HIMA Himatrix Safety System OMNI Flow Computers Project Engineering & Implementation including FEED On-site services Business Results Why was Honeywell Selected? • Early involvement (custody transfer applications) • Domain expertise • Only supplier that could provide complete scope (reduced risk of being technically out of compliance; only one supplier liable) • Project delivered on time in budget • Terminal that complies with European and International standards, rules and legislation • No safety incidents • Investors are satisfied and expansions are planned 29 Honeywell well equipped for greenfield terminals Case Study #2 – Botlek Tank Terminal What was the Customer Challenge? • • • • Basic Engineering package not “complete” Maintainability and openness Minimize total cost of ownership Phased approach due to delays in permits Why was Honeywell Selected? • Fit for purpose (terminal focus) • Cost effectiveness, time to market (standard repeatable solutions) 30 • Honeywell Enraf Tank Gauging • Honeywell Experion PKS with C200E • HIMA Himatrix Safety System • Project Engineering & Implementation • On-site services Business Results • Operation and Business Readiness from Day One • Ongoing expansions/new constructions without disrupting the daily terminal operations • Responsive support (right competences e.g. field and system) What did We Offer? • Fixed OPEX and fixed CAPEX; predictable due to fixed service cost and repeatable solution Honeywell well equipped for greenfield terminals Case Study #3 – Vopak Tianjin What was the Customer Challenge? • • • Implement global blueprint Align global solution with local requirements and demands Local support Why was Honeywell Selected? • Domain knowledge with the ability to translate local requirements into global solution • Global organization with very good local support • Responsive support (right competences e.g. field and system) 31 What did We Offer? • Honeywell Enraf Tank Gauging • Honeywell Experion PKS with C300 • Honeywell Safety System • Honeywell Terminal Manager • Project Engineering & Implementation • Program Management • On-site services Business Results • Best practices of Vopak implemented from day one while still compliant with local requirements e.g. semiautomated options • 24 hours/365 days/year availability with only one single point of contact and one single point of responsibility Honeywell well equipped for greenfield terminals Case Study #4 – Standic What was the Customer Challenge? • • • • • Improve operator effectiveness Comply with security requirements (ISPS) Maintainability and openess Minimize total cost of ownership Fast track delivery due to delays in permits and contractual obligations What did We Offer? • • • • • • • Honeywell Enraf Tank Gauging Honeywell Experion PKS with C200E HIMA Himatrix Safety System Honeywell Analytics Honeywell OneWireless Honeywell CCTV Project Engineering & Implementation incl. FEED and on-site services Why was Honeywell Selected? • Fit for purpose (terminal focus) • Cost effectiveness, time to market (standard repeatable solutions) • Responsive support (right competences e.g. field and system) 32 Business Results • Ability to react quick to market requirements improving customer focus through the use of standard components and solutions • Regulatory compliance • Improved operator effectiveness Honeywell well equipped for brownfield terminals Case Study #5 – ConocoPhillips What was the Customer Challenge? • Safety issues with on-site Emerson rail loading system • Unreliable system with a lot of risk of human error. Automation not working thus operation was/is handled mainly manually • A customer specific solution that is difficult to What did We Offer? • Experion PKS • Honeywell Terminal Manager • Spektra-Tek S600 flow computers • Project Engineering & Implementation including FEED maintain and supported by “a single resource” Why was Honeywell Selected? • Price was important criteria • Domain know-how • Strong local presence (refinery is running Experion system and BMA) • Standard offering Business Results • “100 times better than the old system” • Safety of operation greatly improved • Manual intervention and data entry is significantly reduced; Operator experience much more intuitive with better user interface • Batching is significantly more accurate hitting the set-point within +/- 10-20 l on average (the old system was +/- 200-400 l) 33 Honeywell well equipped for refinery offsites Case Study #6 – SAMIR What was the Customer Challenge? • • • Revamp of truck loading operations that was run mainly manually Link operations with business (e.g. ERP integration) Qualify loading skids for custody transfer purpose e.g. accepted by local metrological authorities • Realize state-of-the-art truck loading operations according to European standards What did We Offer? • • • • • • • • Experion PKS Honeywell Terminal Manager Honeywell Loading Skids Honeywell Loading Equipment Honeywell CCTV Project Engineering & Implementation On-site services Metrological services Why was Honeywell Selected? • Domain know-how ranging from cameras, skids to terminal management and ERP integration • • • Integrated solution 34 Expertise with metrological institutes Business Results • Direct link between operations (TAS) and business (ERP) allows direct invoicing without error e.g. no delays/errors caused by processing/manual entry of paper BOL’s. • Higher operating accuracy e.g. accurate metering is used instead of manual dips • • Increased safety and security Interface experience with ERP systems explicitly SAP Ability to adopt to future requirements e.g. loading skids are designed to cater for both top and bottom loading. Honeywell well equipped for refinery offsites Case Study #7 – MAIN What was the Customer Challenge? • • • Compliancy with national and international standards No experience with greenfield depots Various domains require expertise • Safety • Security • Loading • Gauging Why was Honeywell Selected? • Terminal domain know-how • Complete offering field-to-boardroom in a safe and secure environment What did We Offer? • • • • • • • • • • Honeywell Enraf Tank Gauging Honeywell Enraf Loading Automation Honeywell Pressure, Temperature and Flow Honeywell CCTV Camera’s Honeywell Experion PKS with C200 Honeywell Terminal Manager HIMA Himatrix Safety System Project Engineering & Implementation including FEED Installation activities On-site services Business Results • Able to manage project without EPC due to the fact that Honeywell was able to provide all products, solutions and domain know-how necessary for a state-of-the-art terminal • Minimized workforce due to high degree of automation e.g. unmanned truck loading operation, video analytics that replace security officers, etc 35 Honeywell well equipped for greenfield depots Case Study #8 – CLC What was the Customer Challenge? • Revamp of old AEG Cegelec TAS / SCADA Systems • 600 to 1000 trucks per day • Automation of product receipt (pipeline from Sines refinery), product storage (interfacing with Enraf tank gauging system; 50 tanks), product dispatch (15 bays, 52 arms) and LPG bottling plant Why was Honeywell Selected? • Price was important criteria • Strong local presence • MAC capabilities What did We Offer? • Experion PKS • Honeywell Terminal Automation Software • Loading Equipment • Project Engineering & Implementation Business Results • Terminal automated with minimum impact on daily operation. Aveiras terminal is the Lisbon Metropolitan Depot • Terminal optimization possible because all operations are automated. Functionality such as stock accounting and reconciliation in place 36 Honeywell well equipped for brownfield depots Case Study #9 – Saudi Aramco What was the Customer Challenge? • 2 Grades of Gasoline Program • Obsolete systems with: • No local support • Major components in these legacy systems were not COTS • SAP interfacing • Efficient deployment of Electronic Sales and Payment system Why was Honeywell Selected? • Technology leader • Proven track record for on-time delivery • Global presence locally • Use of standard COTS technology • Certified SAP interface • Total solution provider for L1 to L4 integration 37 What did We Offer? • Experion PKS • ICS Triplex Safety System • GE Fanuc controllers • Honeywell Terminal Automation Software • Honeywell Enraf Loading Equipment and Tank Gauging • Project Engineering & Implementation Business Results • Projects implemented in time, in budget • Supply chain automated and optimized • Real-time data available in business domain • Minimum down-time due to 24/7 support for ENTIRE solution • No obsolescence issues due to lifecycle support program Honeywell well equipped for brownfield depots Agenda Industry Challenges Integrated Portfolio Case Studies Why buy from Honeywell 38 Why Choose Honeywell EFS? Industry experience and proven results We have the technology and service expertise to deliver the results you want and need Complete, integrated solutions Our complete, integrated solutions bring superior safety and performance across the enterprise We protect your investment Longest product life plus easy migration and updates for lowest total cost of ownership Why Choose Honeywell? We are there from project start to finish and throughout the asset lifecycle Bringing better ideas and technology to the industry The Honeywell Partnership Our better ideas and technology deliver better business performance and bottom-line results today and for decades to come Questions? 42