G1.Mechanical Properties and Temper Resistance of Deformation induced ferrite in a low carbon steel

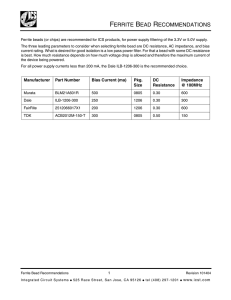

advertisement

J. Mater. Sci. Technol., 2010, 26(12), 1107-1113. Mechanical Properties and Temper Resistance of Deformation Induced Ferrite in a Low Carbon Steel Luhan Hao, Namin Xiao, Chengwu Zheng and Dianzhong Li† Shenyang National Laboratory for Materials Science, Institute of Metal Research, Chinese Academy of Sciences, Shenyang 110016, China [Manuscript received August 11, 2009, in revised form March 2, 2010] The microstructures and mechanical properties of deformation induced ferrite (DIF) in the low carbon steel Q235 under different deformation temperatures have been investigated systematically. Through deformation induced ferrite transformation (DIFT), ferrite grain can be refined to 3 μm and accounts for above 85% of the overall fraction. Yield strength of DIF (>500 MPa) is increased by up to 100% compared with the conventional low carbon steel. Comparison of microstructure and mechanical properties in the Q235 steel with DIF and tempered DIF microstructure illustrates that the strengthening mechanism of DIF microstructure is the combination of grain boundary strengthening and carbon supersaturated strengthening. Electron back-scattered diffraction (EBSD) analysis and high magnification scanning electron microscopy (SEM) observation denote that high-angle grain boundary among ultrafine ferrite grain and the transformation product of retain austenite membrane along ferrite boundaries are responsible for the stability of ferrite grain size during tempering process. Transmission electron microscopy (TEM) analysis demonstrates that the transformation product of retained austenite membrane between ferrite grain boundaries is cementite. KEY WORDS: Low carbon steel; Deformation induced ferrite transformation; Grain size; Mechanical properties; Temper resistance 1. Introduction Low carbon steels are one of the most widely used structural materials in industry. However, their relatively low strength because of the low carbon content and ferrite structure limits them to be used in a wider range. It is well-known that refining grain size is an effective way to strengthen metallic material, as clearly clarified by Hall-Petch relationship. Without adding too much alloy elements, grain refinement strengthening is not only economical but also makes steels easily recycled. Besides, in comparison to other strengthening mechanisms, grain refinement strengthening is the only way to attain high strength without sacrificing toughness. During last decades, considerable research works have been implemented in producing † Corresponding author. Prof., Ph.D.; Tel.: +86 24 23971281; Fax: +86 24 23891320; E-mail address: dzli@imr.ac.cn (D.Z. Li). steels with ferrite grain size much smaller than that can be achieved by conventional controlled rolling[1–6] . There are mainly two categories to fabricate ultrafine ferrite grains. One is called severe plastic deformation (SPD)[1] process such as equal channel angular pressing (ECAP)[2] , accumulative roll bonding (ARB)[3] and high pressure torsion (HPT). The common ground of SPD is that significant deformation is needed to make ferrite grain size refined and the process is not suitable for mass production. The other category is advanced thermo-mechanical control process (advanced TMCP) which is based on conventional thermo-mechanical control process and relatively convenient to put into effect in industries. Deformation induced ferrite transformation (DIFT, some researchers call it as strain induced transformation[4–6] ) is a sort of advanced TMCP. It has been proved to be an effective way to refine ferrite grains. In this approach, the refinement of ferrite 1108 L.H. Hao et al.: J. Mater. Sci. Technol., 2010, 26(12), 1107–1113 Fig. 1 Schematic diagrams of experiment schemes: (a) deformation at 830 and 850◦ C, (b) deformation at 780 and 800◦ C, (c) tempering at different temperatures for 1 h is achieved by the un-saturated nucleation and limited growth[5] . Heavy deformation above critical temperature Ar3 introduces highly deformed regions such as deformation bands at austenite grain interiors, which become active sites for ferrite nucleation; the ferrite grain which nucleates and begins to grow will quickly impinge on adjacent ferrite grains which have also nucleated in its vicinity. The accelerating cooling after deformation is important to inhibit the possibility of ferrite coarsening and reverse transformation to austenite. Previous work has been done on microstructures of DIFT, effect of deformation parameters (temperature, strain rate, strain, cooling rate etc.) on DIFT and carbon distribution of deformation induced ferrite (DIF) in low carbon steels[7–9] . However, the mechanical property of the low carbon steels containing DIF microstructure was usually denoted by micro-hardness due to the lack of bulk steels[10,11] . Hence, the detailed mechanical data and strengthening mechanism of DIF microstructure can not be clearly identified. Besides, as a non-equilibrium transformation product, the stability of DIF microstructure under different reheating temperature is also a crucial issue needed to be discussed. In the present work, the detailed mechanical properties (using miniature dog-bone specimens) and microstructures of DIF in the low carbon steel Q235 via different temperature deformations are investigated to study the more appropriate schedules and the strengthening mechanism of DIFT. The temper resistance of DIF microstructure and mechanical properties of tempered DIF in the Q235 steel are also discussed in this paper. 2. Experimental The low carbon steel used in this experiment was a Q235 rough slab from Anshan Iron and Steel Group Cooperation, China. The chemical composition is shown in Table 1. The austenite to ferrite equilibrium transformation temperature was 845◦ C (Ae3 ) as calculated by Thermo-Calc software. After normalizing at 920◦ C for 1 h to get uniform original microstructure, the rough slab was machined into a number of cylindrical specimens with the diameter of 8 mm and Table 1 Chemical composition of the Q235 steel used in the study (%, mass fraction) C 0.14 Si 0.24 Mn 0.64 P 0.011 S 0.005 Al 0.05 Fe Bal. Fig. 2 Specimens before deformation (a), after deformation (b) and for tensile test (c) the height of 15 mm for thermal-mechanical simulation experiments on Gleeble 3500 machine (USA). The route to get DIF microstructure and the tempering route afterwards are shown schematically in Fig. 1. After austenitizing at 950◦ C for 5 min, the specimens were cooled at the cooling rate of 15◦ C/s to 780 and 800◦ C, and 1◦ C/s to 830 and 850◦ C, respectively. Then uniaxial compression was applied to the specimens at the true strain rate of 20/s with the height reduction of 80% (true strain 1.6). The shapes of specimens before and after deformation are shown in Fig. 2. Finally, the deformed specimens were quenched by water immediately after compression to conserve high-temperature microstructure. It is well known that the higher the cooling rate, the lower the ferrite transformation start temperature will be. The above-mentioned different cooling rates between specimens cooled to 780, 800, 830 and 850◦ C were meant to change the critical temperature Ar3 , and thus avoided the proeutectoid ferrite transformation. After thermal-mechanical compression, the specimens were machined as the specification for tensile tests (Fig. 2(c)). The tensile specimen s dimension was designed with a gauge width of 2 mm and a gauge length of 5 mm. Mechanical properties were measured in Instron 5848 micro-tester (USA) with the strain rate of 6×10−3 s−1 . Temper stability of DIF microstructure was also investigated for specimens experienced deformation induced ferrite transformation above Ae3 . L.H. Hao et al.: J. Mater. Sci. Technol., 2010, 26(12), 1107–1113 1109 Fig. 3 Microstructure of DIF in the Q235 steel after compressive deformation at temperature 780◦ C (a) and 850◦ C (b) with strain rate of 20 s−1 and strain of 80% As Fig. 1(c) shows, the specimens were tempered at 200, 400 and 600◦ C for 2 h followed by furnace cooling, respectively. DIF specimens were sectioned through the center parallel to the compression axis for microstructure observations. After the center sections were ground, polished, and etched with a 4% nital solution, the microstructures were observed by optical microscopy (OM, ZEISS AXIOVERT 200MAT, Germany), scanning electron microscopy (SEM, Shimadzu Superscan SS-550, Japan) and transmission electron microscopy (TEM, FEI Tecnai T20, Japan). The electron back-scattered diffraction (EBSD, Hitachi S-3400N, Japan) scanning was carried out at the center of the center section, and in a 50 μm×100 μm area at a step size of 0.4 μm on a hexagonal grid. Quantitative analysis of phase fraction and average grain size was evaluated on SISC-IAS analysis software. 3. Results 3.1 Microstructure Figure 3 shows the optical microstructures of asquenched DIF specimens after compressive deformation at temperature 780 and 850◦ C, respectively. It can be seen that the two microstructures are mainly composed of equiaxed ferrite grains. Ferrite is the major phase with the average grain size of around 3 μm and accounts for above 85% of the overall fraction, as shown in the white areas. The microstructures in Fig. 3(a) and (b) are nearly the same except a slight difference in grain size, which is undistinguishable. Figure 4 represents the SEM microstructures of DIF specimens tempered at different temperatures for 1 h. It is hard to make out the difference in grain size from these photos. Quantitative analysis indicates that tempering temperature has little effect on ferrite grain size. Large quantity of cementite particles present at ferrite grain boundaries and threepoint junctions when the tempering temperature is 600◦ C. 3.2 Mechanical properties Table 2 shows the mechanical properties of DIF specimens under different deformation temperatures. It can be seen that the yield strength of the steel is around 500 MPa, which is increased by up to 100% as compared to that of conventional Q235 steel. The tensile strength is also increased to 550 MPa and the elongation is still in the appropriate range around 35%. The mechanical data demonstrate that DIFT is an effective way to enhance the strength. The tempered DIF specimen s mechanical properties are shown in Table 3. Compared with the untempered one, the ductility is increased while the strength is decreased. With the increase of tempering temperature, the disparity in strength and ductility between untempered specimen and tempered specimen becomes larger. DIFT has the potential to refine ferrite grain size to a larger extent than conventional TMCP. For low carbon steel, the ferrite grain size in conventional TMCP is around 10–20 μm and the yield strength is in the range of 200–300 MPa[12] . In this work, about 3 μm ferrite grain size can be obtained through appropriate DIFT process. The mechanism of DIFT is to increase ferrite nucleation positions and ferrite transformation temperature through heavy deformation above Ar3 . It is usually considered that DIFT occurs during the deformation process[4] and the high nucleation rate is the key factor for the refinement of ferrite grains. 4. Discussion 4.1 Strengthening effect of DIFT The data of strength in Table 2 show a difference of 40 MPa in yield strength between deformation at 780 and 850◦ C. It is because that the lower deformation temperature provides larger driving force for ferrite transformation. And the low temperature makes deformation energy easy to be stored. Those will lead to the higher nucleation rate for the low temperature DIF under the same other deformation parameters, which means that the low temperature induced ferrite is a little finer than that of high temperature (Fig. 3). According to Hall-Petch relationship, the finer the av- 1110 L.H. Hao et al.: J. Mater. Sci. Technol., 2010, 26(12), 1107–1113 Fig. 4 Microstructure changes of DIF in the Q235 steel after tempering at different temperatures for 1 h: (a) untempered, (b) 200◦ C, (c) 400◦ C, (d) 600◦ C Table 2 Mechanical properties of the Q235 steel with the microstructure of proeutectoid ferrite and DIF treated under different deformation temperatures with the strain rate of 20 s−1 and strain of 80% Deformation temperature Without deformtion 780◦ C 800◦ C 830◦ C 850◦ C Yield strength, σy /MPa 245.6 528.5 503.1 515.0 482.0 Tensile strength, σb /MPa 438.2 571.9 551.2 556.8 542.7 erage grain size, the higher the yield strength will be. Hence, from the thermodynamic point of view, it is reasonable that 780◦ C deformation induced ferrite strength is higher than that of 850◦ C. The strengthening of steels is usually accompanied with ductility loss. For the specimens deformed at 780◦ C, uniform elongation is reduced to 11.5% compared with 15%–18% in the relatively high temperature of 850◦ C (Table 2). It is mainly attributed to the more densely distributed grain boundaries that make dislocation and slip bands hard to move and thus inhibit the plastic deformation. It can be concluded that 800–830◦ C is the more appropriate temperature range to induce fine ferrite grains, at which an excellent combination of strength and ductility can be obtained. In addition, the presented mechanical properties data of DIF specimens indicate the decrease of significant work hardening. This is reflected by the increase of yield ratio, which alters from 0.56 of the proeutecoid ferrite to 0.9 of DIF. Except the influence of fine ferrite grain size, residual dislocations and internal stresses brought by heavy deformation and accelerating cooling rate are partially responsible for the decrease in strain hardening. This result corresponds Uniform elongation, δu /% 22.5 11.5 17.2 17.8 14.9 Total elongation, δu /% 37.0 29.2 36.2 40.3 36.2 Yield ratio, σy /σb 0.56 0.92 0.91 0.92 0.89 reasonably well with the previous work by Miller[13] in which refinement of ferrite leads to an enhancement in yield strength with little work hardening. According to Hart and Considere s criterion—the onset of plastic instability in tension occurs when σ≥dσ/dε, where σ is the flow stress and dσ/dε is the work hardening rate, and a higher work hardening rate is essential to enhance uniform elongation in steels. It seems that the ways to reduce yield ratio and increase work hardening behavior of ultrafine ferrite, such as introducing some hard second phase to the microstructure[11,14] and fabricating a layered composite microstructure[15] will exert favorable influence on ductility. 4.2 Temper resistance and strengthening mechanism of DIFT The possibility of remedying the ductility loss of DIF specimens due to residual stress caused by deformation and quenching process and the stability of high temperature DIF specimens was investigated by the tempering experiment. Table 3 demonstrates that the ductilities of tempered specimens are indeed elevated but at the expense of strength. Low temper- L.H. Hao et al.: J. Mater. Sci. Technol., 2010, 26(12), 1107–1113 1111 ◦ Table 3 Mechanical properties of the Q235 steel after DIFT at 850 C and tempered at different temperatures for 1 h Tempering temperature Untempered 200◦ C 400◦ C 600◦ C Yield strength, σy /MPa 482.0 446.0 408.0 380.0 Tensile strength, σb /MPa 542.7 515.0 506.0 474.0 ing temperature 200◦ C is effective to eliminate intrastress in DIF specimen which can make uniform elongation enhance 5% and total elongation increases to the value of proeutectoid ferrite (around 43%). With the enhancement of tempering temperature, the strength gets further decreased while the total elongation remains around 42%. The average grain sizes of the tempered specimens maintain at about 3 μm. Detailed quantitative analysis data of average grain size after tempered at 200, 400 and 600◦ C are 2.81, 2.83 and 2.85 μm, respectively. In comparison to 2.84 μm of untempered ferrite, average ferrite grain size can be considered as invariable during tempering process for 1 h. Nearly equivalent ferrite grain size and an apparent difference in strength denote that grain refinement is not the only strengthening mechanism for the DIF specimens. Previous work[16] has proved that DIF is a kind of carbon supersaturated ferrite by using electron probe microanalyzer (EPMA) line analysis of carbon distribution in proeutecoid ferrite and DIF. The supersaturated carbon in ferrite tends to diffuse to grain boundaries or precipitate within grain interior during long soaking time at the moderate tempering temperature. It demonstrates that carbon supersaturation in untempered DIF microstructure is responsible for the extra strength increment compared with the tempered ones. It can be concluded that Hall-Petch relationship fails to reflect the exact relationship between the average ferrite grain size and strength of DIF because of the effect of complicated carbon distribution in DIF microstructure. During 200–400◦ C tempering process, no significant change in grain boundaries occurs but the amount of dispersed carbide at grain interior increases, as shown in Fig. 5(a) and (b). Figure 5(c) and (d) shows abundant globular carbides precipitate along grain boundaries or at some threepoint junctions at tempering temperature of 600◦ C. Yield ratio drops from 0.9 to 0.8, denoting the working hardening effect of dispersed cementite. Some researchers[17] deduced that precipitation strengthening through pinning effect of dispersive carbide to dislocations can further strengthen the steel with fine ferrite microstructure. The fact does not go in this way as shown in Table 3. The result demonstrates that, as far as DIF microstructure is concerned, the effect of precipitation strengthening is not as good as carbon supersaturated strengthening. DIFT is usually viewed as non-equilibrium phase transformation in respect that at the deformation Uniform elongation, δu /% 14.9 20.0 18.8 22.0 Total elongation, δt /% 36.2 43.0 42.0 43.0 Yield ratio, σy /σb 0.89 0.87 0.81 0.80 temperature, austenite which has lower free-Gibbs energy is the stable phase in deformation-free sample. Non-equilibrium microstructure tends to transform into equilibrium status during reheating process by rearrangement of atoms and grain growth. It has been proved that grain growth does not occur during the tempering process. EBSD measurement of untempered specimen was performed in order to further understand DIFT and explain the stability of ferrite grain size. EBSD boundary misorientation map of DIF microstructure at the deformation temperature 850◦ C is shown in Fig. 6. The bold black lines denote high angle grain boundaries (HAGBs) of which misorientation angles are higher than 15 deg., while the narrow gray lines denote low angle grain boundaries (LAGBs) of which misorientation angles are 2–15 deg. The boundary misorientation maps reveal that ultrafine ferrite grains are mostly surrounded by HAGBs and little substructure exists in the grain interior. Humphreys et al.[18] suggested that the microstructure should be stable against recrystallization and coarsen uniformly, provided that it contained HAGBs greater than about 65%. Hurley et al.[19] also suggested that the degree of misorientation between the ferrite grains limits grain coalescence and growth of ultra-fine ferrite. It seems that the stability of ferrite grain size during tempering process can be roughly explained by the HAGBs after DIFT. However, considering that recrystallized grains which have HAGBs in the same way can still grow at elevated temperature, the explanation using HAGBs seems untenable. Compared DIF with ferrite-pearlite microstructure, as shown in Fig. 7, a huge discrepancy in grain boundary can be found. Ferrite-pearlite microstructure exhibits simple narrow boundaries, whereas most DIF grain boundaries have another phase occupied, making boundary shown as bright white (as ellipse shown in Fig. 7(b)). This phase is deemed as the cooling product of residual austenite membrane (RAM) which is left between fast nucleated ferrite grains because of the high ferrite formation rate. TEM analysis denotes that the RAM is cementite, as shown in Fig. 8. Due to the mass of carbon remaining in the austenite solution, a significant amount of cementites were generated along ferrite grain boundary during the accelerating cooling process. They acted as the obstacle of grain boundary movement by applying pinning effect to boundaries. It is suggested that the stability of ferrite grain size during tempering process is the cooperation of HAGBs and pinning effect of cemen- 1112 L.H. Hao et al.: J. Mater. Sci. Technol., 2010, 26(12), 1107–1113 Fig. 5 Evolution of dispersed carbides during tempering process: (a) 200◦ C, (b) 400◦ C, (c) and (d) 600◦ C Fig. 6 Boundary misorientation maps (a) and distribution of misorientaion angle of adjacent ferrite grains (b) after DIFT at 850◦ C, with strain rate of 20 s−1 and strain of 80% Fig. 7 Comparison of grain boundary among proeutectoid ferrite (a) and DIF (b) of the steel Q235 L.H. Hao et al.: J. Mater. Sci. Technol., 2010, 26(12), 1107–1113 1113 Acknowledgement This work was financially supported by the National Natural Science Foundation of China (NSFC) under Grant No. 50871109. REFERENCES Fig. 8 Cementite on the DIF grain boundary tite along grain boundaries. 5. Conclusions (1) Above 500 MPa of yield strength and 550 MPa of tensile strength can be obtained through appropriate deformation induced ferrite transformation parameters for low carbon steels. The ductility of DIF is a little decreased compared with proeutectoid ferrite but still in the reasonable range. 800–830◦ C is the favorite temperature range to form high performance DIF for the low carbon steel Q235. (2) With the increase of the tempering temperature, the strength of the steel gets decreased step by step, while the grain size of DIF remains in the same grade. The strengthening mechanism of DIFT is the coupling of grain boundary strengthening and carbon supersaturated strengthening. And for DIF microstructure, carbon supersaturated strengthening is better than precipitation strengthening of carbide. (3) DIF grains are mostly surrounded by HAGBs and little substructure exists in the grain interior. The cementite between adjacent grains and HAGBs are the keys to keep non-equilibrium DIF stable in grain size. [1 ] B.Q. Han and S. Yue: J. Mater. Process. Technol., 2003, 136(1-3), 100. [2 ] V.M. Segal: Mater. Sci. Eng. A, 1995, 197(2), 157. [3 ] N. Tsuji, Y. Ito, Y. Saito and Y. Minamino: Scripta Mater., 2002, 47(12), 893. [4 ] M.R. Hickson, R.K. Russell and P.D. Hodgson: ISIJ Int., 1999, 39(11), 1176. [5 ] C.W. Zheng, D.Z. Li, S.P. Lu and Y.Y. Li: Scripta Mater., 2008, 58(10), 838. [6 ] P.D. Hodgson, M.R. Hickson and R.K. Gibbs: Scripta Mater., 1999, 40(10), 1179. [7 ] Z.X. Liu, D.Z. Li and G.W. Qia: Acta Metall. Sin., 2005, 41(11), 1127. (in Chinese) [8 ] R. Priestner, Y.M. Al-Horr and A.K. Ibraheem: Mater. Sci. Technol., 2002, 18(9), 973. [9 ] Z.M. Yang and R.Z. Wang: ISIJ Int., 2003, 43(5), 761. [10] H.S. Zhao, D.Z. Li, Z.X. Liu and Y.Y. Li: Acta Metall. Sin., 2007, 43(3), 286. (in Chinese) [11] A. Ohmori, S. Torizuka and K. Nagai: ISIJ Int., 2004, 44(6), 1063. [12] H. Ding, L. Li, C.Z. Yang, D. Song and L.X. Du: J. Mater. Sci. Technol., 2006, 22(2), 145. [13] R.L. Miller: Metall. Trans., 1972, 3(4), 905. [14] S. Torizuka, E. Muramatsu, S.V.S.N. Murty and K. Nagai: Scripta Mater., 2006, 55(8), 751. [15] M.R. Hickson and P.D. Hodgson: Mater. Sci. Technol., 1999, 15(1), 85. [16] Z.X. Liu, D.Z. Li, G.W. Qiao and Y.Y. Li: Scripta Mater., 2007, 56(9), 777. [17] Z.X. Liu, D.Z. Li, S.P. Lu and G.W. Qiao: ISIJ Int., 2007, 47(2), 289. [18] F.J. Humphreys, P.B. Prangnell, J.R. Bowen, A. Gholinia and C. Harris: Phil. Trans. R. Soc. Lond. A, 1999, 357(1756), 1663. [19] P.J. Hurley, P.D. Hodgson and B.C. Muddle: Scripta Mater., 1999, 40(4), 433.