CalculiX CrunchiX USER’S MANUAL version

2.20

Guido Dhondt

July 31, 2022

Contents

1 Introduction.

11

2 How to perform CalculiX calculations in parallel

12

3 Units

14

4 Golden rules

16

5 Simple example problems

5.1 Cantilever beam . . . . . . . . . . . . . . . . . . . . . . . . .

5.2 Frequency calculation of a beam loaded by compressive forces

5.3 Frequency calculation of a rotating disk on a slender shaft . .

5.4 Thermal calculation of a furnace . . . . . . . . . . . . . . . .

5.5 Seepage under a dam . . . . . . . . . . . . . . . . . . . . . . .

5.6 Capacitance of a cylindrical capacitor . . . . . . . . . . . . .

5.7 Hydraulic pipe system . . . . . . . . . . . . . . . . . . . . . .

5.8 Lid-driven cavity . . . . . . . . . . . . . . . . . . . . . . . . .

5.9 Transient laminar incompressible Couette problem . . . . . .

5.10 Stationary laminar inviscid compressible airfoil flow . . . . .

5.11 Laminar viscous compressible compression corner flow . . . .

5.12 Laminar viscous compressible airfoil flow . . . . . . . . . . . .

5.13 Channel with hydraulic jump . . . . . . . . . . . . . . . . . .

5.14 Cantilever beam using beam elements . . . . . . . . . . . . .

5.15 Reinforced concrete cantilever beam . . . . . . . . . . . . . .

5.16 Wrinkling of a thin sheet . . . . . . . . . . . . . . . . . . . . .

5.17 Optimization of a simply supported beam . . . . . . . . . . .

5.18 Mesh refinement of a curved cantilever beam . . . . . . . . .

1

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

18

18

25

27

33

38

40

44

49

55

55

60

63

64

66

72

76

78

84

2

CONTENTS

6 Theory

6.1 Node Types . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.2 Element Types . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.2.1 Eight-node brick element (C3D8 and F3D8) . . . . . . .

6.2.2 C3D8R . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.2.3 Incompatible mode eight-node brick element (C3D8I) .

6.2.4 Twenty-node brick element (C3D20) . . . . . . . . . . .

6.2.5 C3D20R . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.2.6 Four-node tetrahedral element (C3D4 and F3D4) . . . .

6.2.7 Ten-node tetrahedral element (C3D10) . . . . . . . . . .

6.2.8 Modified ten-node tetrahedral element (C3D10T) . . . .

6.2.9 Six-node wedge element (C3D6 and F3D6) . . . . . . .

6.2.10 Fifteen-node wedge element (C3D15) . . . . . . . . . . .

6.2.11 Three-node shell element (S3) . . . . . . . . . . . . . . .

6.2.12 Four-node shell element (S4 and S4R) . . . . . . . . . .

6.2.13 Six-node shell element (S6) . . . . . . . . . . . . . . . .

6.2.14 Eight-node shell element (S8 and S8R) . . . . . . . . . .

6.2.15 Three-node membrane element (M3D3) . . . . . . . . .

6.2.16 Four-node membrane element (M3D4 and M3D4R) . . .

6.2.17 Six-node membrane element (M3D6) . . . . . . . . . . .

6.2.18 Eight-node membrane element (M3D8 and M3D8R) . .

6.2.19 Three-node plane stress element (CPS3) . . . . . . . . .

6.2.20 Four-node plane stress element (CPS4 and CPS4R) . .

6.2.21 Six-node plane stress element (CPS6) . . . . . . . . . .

6.2.22 Eight-node plane stress element (CPS8 and CPS8R) . .

6.2.23 Three-node plane strain element (CPE3) . . . . . . . . .

6.2.24 Four-node plane strain element (CPE4 and CPE4R) . .

6.2.25 Six-node plane strain element (CPE6) . . . . . . . . . .

6.2.26 Eight-node plane strain element (CPE8 and CPE8R) . .

6.2.27 Three-node axisymmetric element (CAX3) . . . . . . .

6.2.28 Four-node axisymmetric element (CAX4 and CAX4R) .

6.2.29 Six-node axisymmetric element (CAX6) . . . . . . . . .

6.2.30 Eight-node axisymmetric element (CAX8 and CAX8R)

6.2.31 Two-node 2D beam element (B21) . . . . . . . . . . . .

6.2.32 Two-node 3D beam element (B31 and B31R) . . . . . .

6.2.33 Three-node 3D beam element (B32 and B32R) . . . . .

6.2.34 Two-node 2D truss element (T2D2) . . . . . . . . . . .

6.2.35 Two-node 3D truss element (T3D2) . . . . . . . . . . .

6.2.36 Three-node 3D truss element (T3D3) . . . . . . . . . . .

6.2.37 Three-node network element (D) . . . . . . . . . . . . .

6.2.38 Two-node unidirectional gap element (GAPUNI) . . . .

6.2.39 Two-node 3-dimensional dashpot (DASHPOTA) . . . .

6.2.40 One-node 3-dimensional spring (SPRING1) . . . . . . .

6.2.41 Two-node 3-dimensional spring (SPRING2) . . . . . .

6.2.42 Two-node 3-dimensional spring (SPRINGA) . . . . . .

6.2.43 One-node coupling element (DCOUP3D) . . . . . . . .

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

89

91

91

92

93

94

94

96

97

97

97

100

100

102

102

102

102

111

111

111

111

111

111

112

112

114

114

114

114

114

115

115

115

117

117

117

123

123

125

125

126

126

127

127

128

128

CONTENTS

6.3

6.4

6.5

6.6

6.2.44 One-node mass element (MASS) . . . . . . . . . .

6.2.45 User Element (Uxxxx) . . . . . . . . . . . . . . . .

6.2.46 User Element: 3D Timoshenko beam element (U1)

6.2.47 User Element: 3-node shell element (US3) . . . . .

Beam Section Types . . . . . . . . . . . . . . . . . . . . .

6.3.1 Pipe . . . . . . . . . . . . . . . . . . . . . . . . . .

6.3.2 Box . . . . . . . . . . . . . . . . . . . . . . . . . .

6.3.3 General . . . . . . . . . . . . . . . . . . . . . . . .

Fluid Section Types: Gases . . . . . . . . . . . . . . . . .

6.4.1 Orifice . . . . . . . . . . . . . . . . . . . . . . . . .

6.4.2 Bleed Tapping . . . . . . . . . . . . . . . . . . . .

6.4.3 Preswirl Nozzle . . . . . . . . . . . . . . . . . . . .

6.4.4 Straight and Stepped Labyrinth . . . . . . . . . . .

6.4.5 Characteristic . . . . . . . . . . . . . . . . . . . . .

6.4.6 Carbon Seal . . . . . . . . . . . . . . . . . . . . . .

6.4.7 Gas Pipe (Fanno) . . . . . . . . . . . . . . . . . .

6.4.8 Rotating Gas Pipe (subsonic applications) . . . . .

6.4.9 Restrictor, Long Orifice . . . . . . . . . . . . . . .

6.4.10 Restrictor, Enlargement . . . . . . . . . . . . . . .

6.4.11 Restrictor, Contraction . . . . . . . . . . . . . . .

6.4.12 Restrictor, Bend . . . . . . . . . . . . . . . . . . .

6.4.13 Restrictor, Wall Orifice . . . . . . . . . . . . . . .

6.4.14 Restrictor, Entrance . . . . . . . . . . . . . . . . .

6.4.15 Restrictor, Exit . . . . . . . . . . . . . . . . . . . .

6.4.16 Restrictor, User . . . . . . . . . . . . . . . . . . . .

6.4.17 Branch, Joint . . . . . . . . . . . . . . . . . . . . .

6.4.18 Branch, Split . . . . . . . . . . . . . . . . . . . . .

6.4.19 Cross, Split . . . . . . . . . . . . . . . . . . . . . .

6.4.20 Vortex . . . . . . . . . . . . . . . . . . . . . . . . .

6.4.21 Möhring . . . . . . . . . . . . . . . . . . . . . . . .

6.4.22 Change absolute/relative system . . . . . . . . . .

6.4.23 In/Out . . . . . . . . . . . . . . . . . . . . . . . .

6.4.24 Mass Flow Percent . . . . . . . . . . . . . . . . . .

6.4.25 Network User Element . . . . . . . . . . . . . . . .

Fluid Section Types: Liquids . . . . . . . . . . . . . . . .

6.5.1 Pipe, Manning . . . . . . . . . . . . . . . . . . . .

6.5.2 Pipe, White-Colebrook . . . . . . . . . . . . . . . .

6.5.3 Pipe, Sudden Enlargement . . . . . . . . . . . . .

6.5.4 Pipe, Sudden Contraction . . . . . . . . . . . . . .

6.5.5 Pipe, Entrance . . . . . . . . . . . . . . . . . . . .

6.5.6 Pipe, Diaphragm . . . . . . . . . . . . . . . . . . .

6.5.7 Pipe, Bend . . . . . . . . . . . . . . . . . . . . . .

6.5.8 Pipe, Gate Valve . . . . . . . . . . . . . . . . . . .

6.5.9 Pump . . . . . . . . . . . . . . . . . . . . . . . . .

6.5.10 In/Out . . . . . . . . . . . . . . . . . . . . . . . .

Fluid Section Types: Open Channels . . . . . . . . . . . .

3

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

128

128

129

129

130

131

131

133

134

138

141

143

144

148

149

151

157

160

164

165

166

167

169

169

170

170

174

178

179

183

184

187

187

188

188

189

190

191

192

193

194

195

197

197

199

199

4

CONTENTS

6.7

6.8

6.9

6.6.1 Straight Channel . . . . . . . . . . . . . . . . . . . . . . . 200

6.6.2 Sluice Gate . . . . . . . . . . . . . . . . . . . . . . . . . . 200

6.6.3 Weir . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 202

6.6.4 Reservoir . . . . . . . . . . . . . . . . . . . . . . . . . . . 203

6.6.5 Contraction . . . . . . . . . . . . . . . . . . . . . . . . . . 205

6.6.6 Enlargement . . . . . . . . . . . . . . . . . . . . . . . . . 207

6.6.7 Step . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 209

6.6.8 In/Out . . . . . . . . . . . . . . . . . . . . . . . . . . . . 209

Boundary conditions . . . . . . . . . . . . . . . . . . . . . . . . . 209

6.7.1 Single point constraints (SPC) . . . . . . . . . . . . . . . 209

6.7.2 Multiple point constraints (MPC) . . . . . . . . . . . . . 210

6.7.3 Kinematic and Distributing Coupling . . . . . . . . . . . 210

6.7.4 Mathematical description of a knot . . . . . . . . . . . . . 215

6.7.5 Node-to-Face Penalty Contact . . . . . . . . . . . . . . . 217

6.7.6 Face-to-Face Penalty Contact . . . . . . . . . . . . . . . . 233

6.7.7 Face-to-Face Mortar Contact . . . . . . . . . . . . . . . . 239

6.7.8 Massless Node-to-Face Contact . . . . . . . . . . . . . . . 240

Materials . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 249

6.8.1 Linear elastic materials . . . . . . . . . . . . . . . . . . . 249

6.8.2 Linear elastic materials for large strains (Ciarlet model) . 250

6.8.3 Linear elastic materials for rotation-insensitive small strains251

6.8.4 Ideal gas for quasi-static calculations . . . . . . . . . . . . 252

6.8.5 Hyperelastic and hyperfoam materials . . . . . . . . . . . 253

6.8.6 Deformation plasticity . . . . . . . . . . . . . . . . . . . . 253

6.8.7 Incremental (visco)plasticity: multiplicative decomposition 254

6.8.8 Incremental (visco)plasticity: additive decomposition . . . 255

6.8.9 Tension-only and compression-only materials. . . . . . . . 256

6.8.10 Fiber reinforced materials. . . . . . . . . . . . . . . . . . . 257

6.8.11 The Cailletaud single crystal model. . . . . . . . . . . . . 258

6.8.12 The Cailletaud single crystal creep model. . . . . . . . . . 262

6.8.13 Elastic anisotropy with isotropic viscoplasticity. . . . . . . 263

6.8.14 Elastic anisotropy with isotropic creep defined by a creep user subroutine.267

6.8.15 User materials . . . . . . . . . . . . . . . . . . . . . . . . 268

Types of analysis . . . . . . . . . . . . . . . . . . . . . . . . . . . 268

6.9.1 Static analysis . . . . . . . . . . . . . . . . . . . . . . . . 268

6.9.2 Frequency analysis . . . . . . . . . . . . . . . . . . . . . . 269

6.9.3 Complex frequency analysis . . . . . . . . . . . . . . . . . 275

6.9.4 Buckling analysis . . . . . . . . . . . . . . . . . . . . . . . 276

6.9.5 Modal dynamic analysis . . . . . . . . . . . . . . . . . . . 277

6.9.6 Steady state dynamics . . . . . . . . . . . . . . . . . . . . 279

6.9.7 Direct integration dynamic analysis . . . . . . . . . . . . 282

6.9.8 Heat transfer . . . . . . . . . . . . . . . . . . . . . . . . . 284

6.9.9 Acoustics . . . . . . . . . . . . . . . . . . . . . . . . . . . 286

6.9.10 Shallow water motion . . . . . . . . . . . . . . . . . . . . 287

6.9.11 Hydrodynamic lubrication . . . . . . . . . . . . . . . . . . 288

6.9.12 Irrotational incompressible inviscid flow . . . . . . . . . . 289

CONTENTS

6.10

6.11

6.12

6.13

5

6.9.13 Electrostatics . . . . . . . . . . . . . . . . . . .

6.9.14 Stationary groundwater flow . . . . . . . . . .

6.9.15 Diffusion mass transfer in a stationary medium

6.9.16 Aerodynamic Networks . . . . . . . . . . . . .

6.9.17 Hydraulic Networks . . . . . . . . . . . . . . .

6.9.18 Turbulent Flow in Open Channels . . . . . . .

6.9.19 Three-dimensional Navier-Stokes Calculations

6.9.20 Shallow water calculations . . . . . . . . . . .

6.9.21 Substructure Generation . . . . . . . . . . . .

6.9.22 Electromagnetism . . . . . . . . . . . . . . . .

6.9.23 Sensitivity . . . . . . . . . . . . . . . . . . . .

6.9.24 Green functions . . . . . . . . . . . . . . . . . .

6.9.25 Crack propagation . . . . . . . . . . . . . . . .

Convergence criteria . . . . . . . . . . . . . . . . . . .

6.10.1 Thermomechanical iterations . . . . . . . . . .

6.10.2 Contact . . . . . . . . . . . . . . . . . . . . . .

6.10.3 Line search . . . . . . . . . . . . . . . . . . . .

6.10.4 Network iterations . . . . . . . . . . . . . . . .

6.10.5 Implicit dynamics . . . . . . . . . . . . . . . .

Loading . . . . . . . . . . . . . . . . . . . . . . . . . .

6.11.1 Point loads . . . . . . . . . . . . . . . . . . . .

6.11.2 Facial distributed loading . . . . . . . . . . . .

6.11.3 Centrifugal distributed loading . . . . . . . . .

6.11.4 Gravity distributed loading . . . . . . . . . . .

6.11.5 Forces obtained by selecting RF . . . . . . . .

6.11.6 Temperature loading in a mechanical analysis .

6.11.7 Initial(residual) stresses . . . . . . . . . . . . .

6.11.8 Concentrated heat flux . . . . . . . . . . . . . .

6.11.9 Distributed heat flux . . . . . . . . . . . . . . .

6.11.10 Convective heat flux . . . . . . . . . . . . . . .

6.11.11 Radiative heat flux . . . . . . . . . . . . . . . .

Error estimators . . . . . . . . . . . . . . . . . . . . .

6.12.1 Zienkiewicz-Zhu error estimator . . . . . . . . .

6.12.2 Gradient error estimator . . . . . . . . . . . . .

Output variables . . . . . . . . . . . . . . . . . . . . .

7 Input deck format

7.1 *AMPLITUDE . . . . . . . . . . .

7.2 *BASE MOTION . . . . . . . . . .

7.3 *BEAM SECTION . . . . . . . . .

7.4 *BOUNDARY . . . . . . . . . . .

7.4.1 Homogeneous Conditions .

7.4.2 Inhomogeneous Conditions

7.4.3 Submodel . . . . . . . . . .

7.5 *BUCKLE . . . . . . . . . . . . .

7.6 *CFD . . . . . . . . . . . . . . . .

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

290

292

293

295

297

300

306

321

326

326

339

342

343

349

349

352

354

355

356

358

358

358

361

362

362

365

365

365

365

365

366

366

366

367

368

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

371

372

374

375

377

379

380

381

381

383

6

CONTENTS

7.7

7.8

7.9

7.10

7.11

7.12

7.13

7.14

7.15

7.16

7.17

7.18

7.19

7.20

7.21

7.22

7.23

7.24

7.25

7.26

7.27

7.28

7.29

7.30

7.31

7.32

7.33

7.34

7.35

7.36

7.37

7.38

7.39

7.40

7.41

7.42

7.43

7.44

7.45

7.46

7.47

7.48

7.49

7.50

7.51

7.52

*CFLUX . . . . . . . . . . . . . . . . . . . . . . .

*CHANGE FRICTION . . . . . . . . . . . . . . .

*CHANGE MATERIAL . . . . . . . . . . . . . . .

*CHANGE PLASTIC . . . . . . . . . . . . . . . .

*CHANGE SURFACE BEHAVIOR . . . . . . . .

*CHANGE SOLID SECTION . . . . . . . . . . . .

*CLEARANCE . . . . . . . . . . . . . . . . . . . .

*CLOAD . . . . . . . . . . . . . . . . . . . . . . .

*COMPLEX FREQUENCY . . . . . . . . . . . . .

*CONDUCTIVITY . . . . . . . . . . . . . . . . .

*CONSTRAINT . . . . . . . . . . . . . . . . . . .

*CONTACT DAMPING . . . . . . . . . . . . . . .

*CONTACT FILE . . . . . . . . . . . . . . . . . .

*CONTACT OUTPUT . . . . . . . . . . . . . . .

*CONTACT PAIR . . . . . . . . . . . . . . . . . .

*CONTACT PRINT . . . . . . . . . . . . . . . . .

*CONTROLS . . . . . . . . . . . . . . . . . . . . .

*CORRELATION LENGTH . . . . . . . . . . . .

*COUPLED TEMPERATURE-DISPLACEMENT

*COUPLING . . . . . . . . . . . . . . . . . . . . .

*CRACK PROPAGATION . . . . . . . . . . . . .

*CREEP . . . . . . . . . . . . . . . . . . . . . . .

*CYCLIC HARDENING . . . . . . . . . . . . . .

*CYCLIC SYMMETRY MODEL . . . . . . . . . .

*DAMPING . . . . . . . . . . . . . . . . . . . . . .

*DASHPOT . . . . . . . . . . . . . . . . . . . . . .

*DEFORMATION PLASTICITY . . . . . . . . . .

*DENSITY . . . . . . . . . . . . . . . . . . . . . .

*DEPVAR . . . . . . . . . . . . . . . . . . . . . . .

*DESIGN RESPONSE . . . . . . . . . . . . . . . .

*DESIGN VARIABLES . . . . . . . . . . . . . . .

*DFLUX . . . . . . . . . . . . . . . . . . . . . . .

*DISTRIBUTING . . . . . . . . . . . . . . . . . .

*DISTRIBUTING COUPLING . . . . . . . . . . .

*DISTRIBUTION . . . . . . . . . . . . . . . . . .

*DLOAD . . . . . . . . . . . . . . . . . . . . . . .

*DSLOAD . . . . . . . . . . . . . . . . . . . . . . .

*DYNAMIC . . . . . . . . . . . . . . . . . . . . . .

*ELASTIC . . . . . . . . . . . . . . . . . . . . . .

*ELECTRICAL CONDUCTIVITY . . . . . . . . .

*ELECTROMAGNETICS . . . . . . . . . . . . . .

*ELEMENT . . . . . . . . . . . . . . . . . . . . .

*ELEMENT OUTPUT . . . . . . . . . . . . . . .

*EL FILE . . . . . . . . . . . . . . . . . . . . . . .

*EL PRINT . . . . . . . . . . . . . . . . . . . . . .

*ELSET . . . . . . . . . . . . . . . . . . . . . . . .

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

385

386

387

387

388

389

390

390

393

394

395

397

398

400

401

403

405

409

410

413

414

415

417

418

420

421

422

423

424

424

426

427

431

433

435

436

442

444

446

449

450

452

456

456

461

464

CONTENTS

7.53

7.54

7.55

7.56

7.57

7.58

7.59

7.60

7.61

7.62

7.63

7.64

7.65

7.66

7.67

7.68

7.69

7.70

7.71

7.72

7.73

7.74

7.75

7.76

7.77

7.78

7.79

7.80

7.81

7.82

7.83

7.84

7.85

7.86

7.87

7.88

7.89

7.90

7.91

7.92

7.93

7.94

7.95

7.96

7.97

7.98

*END STEP . . . . . . . . . . .

*EQUATION . . . . . . . . . . .

*EXPANSION . . . . . . . . . .

*FEASIBLE DIRECTION . . . .

*FILM . . . . . . . . . . . . . . .

*FILTER . . . . . . . . . . . . .

*FLUID CONSTANTS . . . . .

*FLUID SECTION . . . . . . . .

*FREQUENCY . . . . . . . . . .

*FRICTION . . . . . . . . . . .

*GAP . . . . . . . . . . . . . . .

*GAP CONDUCTANCE . . . .

*GAP HEAT GENERATION . .

*GEOMETRIC CONSTRAINT .

*GEOMETRIC TOLERANCES

*GREEN . . . . . . . . . . . . .

*HCF . . . . . . . . . . . . . . .

*HEADING . . . . . . . . . . . .

*HEAT TRANSFER . . . . . . .

*HYPERELASTIC . . . . . . . .

*HYPERFOAM . . . . . . . . .

*INCLUDE . . . . . . . . . . . .

*INITIAL CONDITIONS . . . .

*INITIAL STRAIN INCREASE

*KINEMATIC . . . . . . . . . .

*MAGNETIC PERMEABILITY

*MASS . . . . . . . . . . . . . .

*MASS FLOW . . . . . . . . . .

*MATERIAL . . . . . . . . . . .

*MEMBRANE SECTION . . . .

*MODAL DAMPING . . . . . .

*MODAL DYNAMIC . . . . . .

*MODEL CHANGE . . . . . . .

*MPC . . . . . . . . . . . . . . .

*NETWORK MPC . . . . . . . .

*NO ANALYSIS . . . . . . . . .

*NODAL THICKNESS . . . . .

*NODE . . . . . . . . . . . . . .

*NODE FILE . . . . . . . . . . .

*NODE OUTPUT . . . . . . . .

*NODE PRINT . . . . . . . . . .

*NORMAL . . . . . . . . . . . .

*NSET . . . . . . . . . . . . . .

*OBJECTIVE . . . . . . . . . .

*ORIENTATION . . . . . . . . .

*OUTPUT . . . . . . . . . . . .

7

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

465

465

467

469

469

474

475

475

477

479

480

481

482

483

484

485

486

487

488

492

497

499

499

503

505

506

507

508

509

510

510

511

514

515

516

517

517

518

519

523

524

526

527

528

529

531

8

CONTENTS

7.99 *PHYSICAL CONSTANTS . . . . . . . . . . . . . . .

7.100*PLASTIC . . . . . . . . . . . . . . . . . . . . . . . .

7.101*PRE-TENSION SECTION . . . . . . . . . . . . . . .

7.102*RADIATE . . . . . . . . . . . . . . . . . . . . . . . .

7.103*REFINE MESH . . . . . . . . . . . . . . . . . . . . .

7.104*RESTART . . . . . . . . . . . . . . . . . . . . . . . .

7.105*RETAINED NODAL DOFS . . . . . . . . . . . . . .

7.106*RIGID BODY . . . . . . . . . . . . . . . . . . . . . .

7.107*ROBUST DESIGN . . . . . . . . . . . . . . . . . . .

7.108*SECTION PRINT . . . . . . . . . . . . . . . . . . .

7.109*SELECT CYCLIC SYMMETRY MODES . . . . . .

7.110*SENSITIVITY . . . . . . . . . . . . . . . . . . . . . .

7.111*SHELL SECTION . . . . . . . . . . . . . . . . . . . .

7.112*SOLID SECTION . . . . . . . . . . . . . . . . . . . .

7.113*SPECIFIC GAS CONSTANT . . . . . . . . . . . . .

7.114*SPECIFIC HEAT . . . . . . . . . . . . . . . . . . . .

7.115*SPRING . . . . . . . . . . . . . . . . . . . . . . . . .

7.116*STATIC . . . . . . . . . . . . . . . . . . . . . . . . .

7.117*STEADY STATE DYNAMICS . . . . . . . . . . . .

7.118*STEP . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.119*SUBMODEL . . . . . . . . . . . . . . . . . . . . . . .

7.120*SUBSTRUCTURE GENERATE . . . . . . . . . . .

7.121*SUBSTRUCTURE MATRIX OUTPUT . . . . . . .

7.122*SURFACE . . . . . . . . . . . . . . . . . . . . . . . .

7.123*SURFACE BEHAVIOR . . . . . . . . . . . . . . . . .

7.124*SURFACE INTERACTION . . . . . . . . . . . . . .

7.125*TEMPERATURE . . . . . . . . . . . . . . . . . . . .

7.126*TIE . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.127*TIME POINTS . . . . . . . . . . . . . . . . . . . . .

7.128*TRANSFORM . . . . . . . . . . . . . . . . . . . . . .

7.129*UNCOUPLED TEMPERATURE-DISPLACEMENT

7.130*USER ELEMENT . . . . . . . . . . . . . . . . . . . .

7.131*USER MATERIAL . . . . . . . . . . . . . . . . . . .

7.132*USER SECTION . . . . . . . . . . . . . . . . . . . .

7.133*VALUES AT INFINITY . . . . . . . . . . . . . . . .

7.134*VIEWFACTOR . . . . . . . . . . . . . . . . . . . . .

7.135*VISCO . . . . . . . . . . . . . . . . . . . . . . . . . .

8 User subroutines.

8.1 Creep (creep.f) . . . . . . . . . . . . . . .

8.2 Hardening (uhardening.f) . . . . . . . . .

8.3 User-defined initial conditions . . . . . . .

8.3.1 Initial internal variables (sdvini.f)

8.3.2 Initial stress field (sigini.f) . . . . .

8.4 User-defined loading . . . . . . . . . . . .

8.4.1 Concentrated flux (cflux.f) . . . .

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

532

532

534

535

541

542

543

544

546

546

549

549

550

552

552

553

554

556

558

561

563

566

566

567

570

572

572

575

577

579

581

583

584

585

586

586

588

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

588

589

590

591

591

592

592

592

CONTENTS

8.5

8.6

8.7

8.8

8.4.2 Concentrated load (cload.f) . . .

8.4.3 Distributed flux (dflux.f) . . . .

8.4.4 Distribruted load (dload.f) . . .

8.4.5 Heat convection (film.f) . . . . .

8.4.6 Boundary conditions(uboun.f) .

8.4.7 Heat radiation (radiate.f) . . . .

8.4.8 Temperature (utemp.f) . . . . .

8.4.9 Amplitude (uamplitude.f) . . . .

8.4.10 Face loading (ufaceload.f) . . . .

8.4.11 Gap conductance (gapcon.f) . . .

8.4.12 Gap heat generation (fricheat.f)

User-defined mechanical material laws. .

8.5.1 The CalculiX interface . . . . . .

8.5.2 ABAQUS umat routines . . . . .

User-defined thermal material laws. . . .

User-defined nonlinear equations . . . .

8.7.1 Mean rotation MPC. . . . . . . .

8.7.2 Maximum distance MPC. . . . .

8.7.3 Network MPC. . . . . . . . . . .

User-defined elements . . . . . . . . . .

8.8.1 Network element . . . . . . . . .

9

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

593

594

596

598

601

601

602

602

603

603

604

604

605

611

614

616

617

620

620

620

620

9 Programming rules.

622

10 Program structure.

10.1 Allocation of the fields . . . . . . . . . . . . . . . . . . . . . . . .

10.1.1 openfile . . . . . . . . . . . . . . . . . . . . . . . . . . . .

10.1.2 readinput . . . . . . . . . . . . . . . . . . . . . . . . . . .

10.1.3 allocate . . . . . . . . . . . . . . . . . . . . . . . . . . . .

10.1.4 restart . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

10.2 Reading the step input data . . . . . . . . . . . . . . . . . . . . .

10.2.1 SPC’s . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

10.2.2 Homogeneous linear equations . . . . . . . . . . . . . . .

10.2.3 Concentrated loads . . . . . . . . . . . . . . . . . . . . . .

10.2.4 Facial distributed loads . . . . . . . . . . . . . . . . . . .

10.2.5 Mechanical body loads . . . . . . . . . . . . . . . . . . . .

10.2.6 Distributing coupling loads . . . . . . . . . . . . . . . . .

10.2.7 Sets . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

10.2.8 Material description . . . . . . . . . . . . . . . . . . . . .

10.3 Expansion of the one-dimensional and two-dimensional elements

10.3.1 Cataloguing the elements belonging to a given node . . .

10.3.2 Calculating the normals in the nodes . . . . . . . . . . . .

10.3.3 Expanding the 1D and 2D elements . . . . . . . . . . . .

10.3.4 Connecting 1D and 2D elements to 3D elements . . . . .

10.3.5 Applying the SPC’s to the expanded structure . . . . . .

10.3.6 Applying the MPC’s to the expanded structure . . . . . .

623

623

623

624

626

633

633

633

636

638

638

640

641

643

644

646

647

647

649

650

651

652

10

CONTENTS

10.3.7 Applying temperatures and temperature gradients . . . . 652

10.3.8 Applying concentrated forces to the expanded structure . 652

10.3.9 Integrating the stresses in beams to obtain the section forces653

10.4 Contact . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 654

10.4.1 Penalty contact . . . . . . . . . . . . . . . . . . . . . . . . 654

10.4.2 Massless contact . . . . . . . . . . . . . . . . . . . . . . . 669

10.5 Storing distributions for local coordinate systems . . . . . . . . . 671

10.6 Determining the matrix structure . . . . . . . . . . . . . . . . . . 672

10.6.1 Matching the SPC’s . . . . . . . . . . . . . . . . . . . . . 672

10.6.2 De-cascading the MPC’s . . . . . . . . . . . . . . . . . . . 673

10.6.3 Determining the matrix structure. . . . . . . . . . . . . . 674

10.7 Filling and solving the set of equations, storing the results . . . . 675

10.7.1 Linear static analysis . . . . . . . . . . . . . . . . . . . . . 676

10.7.2 Nonlinear calculations . . . . . . . . . . . . . . . . . . . . 676

10.7.3 Frequency calculations . . . . . . . . . . . . . . . . . . . . 680

10.7.4 Buckling calculations . . . . . . . . . . . . . . . . . . . . . 681

10.7.5 Modal dynamic calculations . . . . . . . . . . . . . . . . . 682

10.7.6 Steady state dynamics calculations . . . . . . . . . . . . . 682

10.8 Major routines . . . . . . . . . . . . . . . . . . . . . . . . . . . . 683

10.8.1 mafillsm . . . . . . . . . . . . . . . . . . . . . . . . . . . . 683

10.8.2 results . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 684

10.9 Aerodynamic and hydraulic networks . . . . . . . . . . . . . . . . 685

10.9.1 The variables and the equations . . . . . . . . . . . . . . 686

10.9.2 Determining the basic characteristics of the network . . . 688

10.9.3 Initializing the unknowns . . . . . . . . . . . . . . . . . . 689

10.9.4 Calculating the residual and setting up the equation system690

10.9.5 Convergence criteria . . . . . . . . . . . . . . . . . . . . . 690

10.10Turbulent Flow in Open Channels . . . . . . . . . . . . . . . . . 690

10.10.1 Sluice Gate . . . . . . . . . . . . . . . . . . . . . . . . . . 693

10.10.2 Wear . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 693

10.10.3 Straight Channel . . . . . . . . . . . . . . . . . . . . . . . 694

10.10.4 Reservoir . . . . . . . . . . . . . . . . . . . . . . . . . . . 694

10.10.5 Contraction, Enlargement, Step and Fall . . . . . . . . . . 695

10.11Three-Dimensional Navier-Stokes Calculations . . . . . . . . . . 696

10.11.1 Renumbering . . . . . . . . . . . . . . . . . . . . . . . . . 696

10.11.2 Topological information . . . . . . . . . . . . . . . . . . . 697

10.11.3 Determining the structure of the system matrices . . . . . 697

10.11.4 Initial calculations . . . . . . . . . . . . . . . . . . . . . . 700

10.11.5 The left hand sides of the equation systems . . . . . . . . 700

10.11.6 Determining the time increment . . . . . . . . . . . . . . 701

10.11.7 Determining the loading . . . . . . . . . . . . . . . . . . . 701

10.11.8 Step 1: determining ∆V ∗ . . . . . . . . . . . . . . . . . . 701

10.11.9 Step 2: determining the pressure/density correction . . . 702

10.11.10Step 3: determining the second momentum correction . . 702

10.11.11Step 4: determining the energy correction . . . . . . . . . 702

10.11.12Step 5: determining the turbulence corrections . . . . . . 702

11

10.11.13Updating the conservative variables

10.11.14Smoothing the conservative variables

10.11.15Determining the physical variables .

10.11.16Application of BC’s . . . . . . . . .

10.11.17Calculation of the smoothing field .

10.11.18Convergence check . . . . . . . . . .

10.11.19Result output . . . . . . . . . . . . .

10.12Sensitivity Analysis . . . . . . . . . . . . . .

10.12.1 Preprocessing the sensitivity . . . .

10.12.2 Processing the sensitivity . . . . . .

10.12.3 Postprocessing the sensitivity . . . .

10.13Mesh refinement . . . . . . . . . . . . . . .

10.13.1 Nodal fields . . . . . . . . . . . . . .

10.13.2 Edge fields . . . . . . . . . . . . . .

10.13.3 Face fields . . . . . . . . . . . . . . .

10.13.4 Element fields . . . . . . . . . . . . .

10.13.5 Mesh refining procedure . . . . . . .

10.13.6 Modifying the boundary conditions .

10.14Crack propagation . . . . . . . . . . . . . .

10.15Interpolation procedure . . . . . . . . . . .

10.15.1 Tetrangulation of the master mesh .

10.15.2 Nearest point algorithm . . . . . . .

10.15.3 Tetrahedron containment . . . . . .

10.15.4 Finite element containment . . . . .

10.16List of variables and their meaning . . . . .

11 Verification examples.

1

. .

for

. .

. .

. .

. .

. .

. .

. .

. .

. .

. .

. .

. .

. .

. .

. .

. .

. .

. .

. .

. .

. .

. .

. .

. . . .

gases

. . . .

. . . .

. . . .

. . . .

. . . .

. . . .

. . . .

. . . .

. . . .

. . . .

. . . .

. . . .

. . . .

. . . .

. . . .

. . . .

. . . .

. . . .

. . . .

. . . .

. . . .

. . . .

. . . .

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

703

703

703

703

703

704

704

704

705

711

716

718

719

721

722

723

725

734

740

748

749

750

751

751

754

784

Introduction.

This is a description of CalculiX CrunchiX. If you have any problems using

the program, this document should solve them. If not, send us an E-mail

(dhondt@t-online.de). The next sections contain some useful information on

how to use CalculiX in parallel, hints about units and golden rules you should

always keep in mind before starting an analysis. Section five contains a simple example problems to wet your appetite. Section six is a theoretical section

giving some background on the analysis types, elements, materials etc. Then,

an overview is given of all the available keywords in alphabetical order, followed by detailed instructions on the format of the input deck. If CalculiX

does not run because your input deck has problems, this is the section to look

at. Then, there is a section on the user subroutines and a short overview of

the program structure. The CalculiX distribution contains a large set of test

examples (ccx 2.20.test.tar.bz2). If you try to solve a new kind of problem you

haven’t dealt with in the past, check these examples. You can also use them to

check whether you installed CalculiX correctly (if you do so with the compare

12 2

HOW TO PERFORM CALCULIX CALCULATIONS IN PARALLEL

script and if you experience problems with some of the examples, please check

the comments at the start of the corresponding input deck). Finally, the User’s

Manual ends with some references used while writing the code.

This manual is not a textbook on finite elements. Indeed, a working knowledge of the Finite Element Method is assumed. For people not familiar with

the Finite Element Method, I recommend the book by Zienkiewicz and Taylor

[103] for engineering oriented students and the publications by Hughes [34] and

Dhondt [20] for mathematically minded readers.

2

How to perform CalculiX calculations in parallel

Nowadays most computers have one socket with several cores, allowing for the

calculations to be performed in a parallel way. In CalculiX one can

• create the element stiffness matrices in parallel. No special compilation

flag is needed. At execution time the environment variable OMP NUM THREADS

or the environment variable CCX NPROC STIFFNESS must be set to the

number of cores, default is 1. If both are set, CCX NPROC STIFFNESS

takes precedence. The maximum number of cores is detected automatically by CalculiX by using the sysconf( SC NPROCESSORS CONF) function. It can be overriden by the user by means of environment variable

NUMBER OF CPUS.

Notice that older GNU-compiler versions (e.g. gcc 4.2.1) may have problems with this parallellization due to the size of the fields to be allocated

within each thread (e.g. s(100,100) in routine e 3d.f). This should not be

a problem with the actual compiler version.

• solve the system of equations with the multithreaded version of SPOOLES.

To this end

– the MT-version of SPOOLES must have been compiled. For further

information on this topic please consult the SPOOLES documentation

– CalculiX CrunchiX must have been compiled with the USE MT flag

activated in the Makefile, please consult the README.INSTALL file.

– at execution time the environment variable OMP NUM THREADS

must have been set to the number of cores you want to use. In

Linux this can be done by “export OMP NUM THREADS=n” on

the command line, where n is the number of cores. Default is 1.

Alternatively, you can set the number of cores using the environment

variable CCX NPROC EQUATION SOLVER. If both are set, the

latter takes precedence.

13

• solve the system of equations with the multithreaded version of PARDISO.

PARDISO is proprietary. Look at the PARDISO documentation how to

link the multithreaded version. At execution time the environment variable OMP NUM THREADS must be set to the number of cores, default

is 1.

• create material tangent matrices and calculate the stresses at the integration points in parallel. No special compilation flag is needed. At execution

time the environment variable OMP NUM THREADS or the environment

variable CCX NPROC RESULTS must be set to the number of cores, default is 1. If both are set, CCX NPROC RESULTS takes precedence.

The maximum number of cores is detected automatically by CalculiX by

using the sysconf( SC NPROCESSORS CONF) function. It can be overriden by the user by means of environment variable NUMBER OF CPUS.

Notice that if a material user subroutine (Sections 8.5 and 8.6) is used,

certain rules have to be complied with in order to allow parallelization.

These include (this list is possibly not exhaustive):

– no save statements

– no data statements

– avoid logical variables

– no write statements

• calculate the viewfactors for thermal radiation computations in parallel. No special compilation flag is needed. At execution time the environment variable OMP NUM THREADS or the environment variable

CCX NPROC VIEWFACTOR must be set to the number of cores, default

is 1. If both are set, CCX NPROC VIEWFACTOR takes precedence. The

maximum number of cores is detected automatically by CalculiX by using

the sysconf( SC NPROCESSORS CONF) function. It can be overriden

by the user by means of environment variable NUMBER OF CPUS.

• perform several operations in CFD calculations (computational fluid dynamics) in parallel. No special compilation flag is needed. At execution

time the environment variable OMP NUM THREADS or the environment

variable CCX NPROC CFD must be set to the number of cores, default

is 1. If both are set, CCX NPROC CFD takes precedence. The maximum number of cores is detected automatically by CalculiX by using the

sysconf( SC NPROCESSORS CONF) function. It can be overriden by

the user by means of environment variable NUMBER OF CPUS.

• Calculate the magnetic intensity by use of the Biot-Savart law in parallel. No special compilation flag is needed. At execution time the environment variable OMP NUM THREADS or the environment variable

CCX NPROC BIOTSAVART must be set to the number of cores, default

is 1. If both are set, CCX NPROC BIOTSAVART takes precedence. The

maximum number of cores is detected automatically by CalculiX by using

14

3

UNITS

the sysconf( SC NPROCESSORS CONF) function. It can be overriden

by the user by means of environment variable NUMBER OF CPUS.

• Perform several vector and matrix operations needed by the SLATEC

iterative solvers or by ARPACK in parallel. To this end the user must

have defined the environment variable OMP NUM THREADS, and used

the openmp FORTRAN flag in the Makefile. The parallellization is done

in FORTRAN routines using openmp. The corresponding lines start with

“c$omp”. If the openmp flag is not used, these lines are interpreted by the

compiler as comment lines and no parallellization takes place. Notice that

this parallellization only pays off for rather big systems, let’s say 300,000

degrees of freedom for CFD-calculations or 1,000,000 degrees of freedom

for mechanical frequency calculations.

Examples:

• For some reason the function sysconf does not work on your computer

system and leads to a segmentation fault. You can prevent using the

function by defining the maximum number of cores explicitly using the

NUMBER OF CPUS environment variable

• You want to perform a thermomechanical calculation, but you are using a user defined material subroutine (Sections 8.5 and 8.6) which is

not suitable for parallelization. You can make maximum use of parallelization (e.g. for the calculation of viewfactors) by setting the variable

OMP NUM THREADS to the maximum number of cores on your system,

and prevent parallelization of the material tangent and stress calculation

step by setting CCX NPROC RESULTS to 1.

3

Units

An important issue which frequently raises questions concerns units. Finite

element programs do not know any units. The user has to take care of that. In

fact, there is only one golden rule: the user must make sure that the numbers

he provides have consistent units. The number of units one can freely choose

depends on the application. For thermomechanical problems you can choose

four units, e.g. for length, mass, time and temperature. If these are chosen,

everything else is fixed. If you choose SI units for these quantities, i.e. m for

length, kg for mass, s for time and K for temperature, force will be in kgm/s2 =

N, pressure will be in N/m2 = kg/ms2 , density will be in kg/m3 , thermal

conductivity in W/mK = J/smK = Nm/smK = kgm2 /s3 mK = kgm/s3 K ,

specific heat in J/kgK = Nm/kgK = m2 /s2 K and so on. The density of steel in

the SI system is 7800 kg/m3 .

If you choose mm for length, g for mass, s for time and K for temperature, force will be in gmm/s2 and thermal conductivity in gmm/s3 K. In

the {mm, g, s, K} system the density of steel is 7.8 × 10−3 since 7800kg/m3 =

7800 × 10−6 g/mm3 .

15

Table 1: Frequently used units in different unit systems.

symbol

meaning

m,kg,s,K

mm,N,s,K

cm,g,s,K

E

Young’s Modulus

kg

N

1m

2 = 1 ms2

N

= 10−6 mm

2

g

= 1 mms

2

ρ

Density

F

Force

1N = 1 kgm

s2

cp

Specific Heat

J

1 kgK

= 1 sm

2K

λ

Conductivity

1

h

Film Coefficient

µ

Dynamic Viscosity

1

2

kg

m3

2

Ns

= 10−12 mm

4

g

= 10−6 mm

3

= 1N

= 106 g mm

s2

2

2

= 106 mm

s2 K

= 106 mm

s2 K

N

= 1 sK

= 106 gsmm

3K

kg

1 mW

2 K = 1 s3 K

= 10−3 mmNsK

= 103 s3gK

kg

Ns

1m

2 = 1 ms

Ns

= 10−6 mm

2

g

= 1 mm

s

W

mK

= 1 kgm

s3 K

However, you can also choose other quantities as the independent ones. A

popular system at my company is mm for length, N for force, s for time and K

for temperature. Now, since force = mass × length / time2 , we get that mass

= force × time2 /length. This leads to Ns2 /mm for the mass and Ns2 /mm4 for

density. This means that in the {mm, N, s, K} system the density of steel is

7.8 × 10−9 since 7800kg/m3 = 7800Ns2 /m4 = 7.8 × 10−9 Ns2 /mm4 .

Notice that your are not totally free in choosing the four basic units: you

cannot choose the unit of force, mass, length and time as basic units since they

are linked with each other through force = mass × length / time2 .

Finally, a couple of additional examples. Young’s Modulus for steel is

210000N/mm2 = 210000×106N/m2 = 210000×106kg/ms2 = 210000×106g/mms2 .

So its value in the SI system is 210 × 109 , in the {mm, g, s, K} system it is also

210 × 109 and in the {mm, N, s, K} system it is 210 × 103 . The heat capacity of

steel is 446J/kgK = 446m2 /s2 K = 446 × 106 mm2 /s2 K, so in the SI system it is

446., in the {mm, g, s, K} and {mm, N, s, K} system it is 446 × 106 .

Table 1 gives an overview of frequently used units in three different systems:

the {m, kg, s, K} system, the {mm, N, s, K} system and the {cm, g, s, K} system.

Typical values for air, water and steel at room temperature are:

• air

– cp = 1005 J/kgK = 1005 × 106 mm2 /s2 K

– λ = 0.0257 W/mK = 0.0257 N/sK

16

4 GOLDEN RULES

– µ = 18.21 × 10−6 kg/ms = 18.21 × 10−12 Ns/mm2

– r (specific gas constant) = 287 J/kgK = 287 × 106 mm2 /s2 K

• water

– ρ = 1000 kg/m3 = 10−9 Ns2 /mm4

– cp = 4181.8 J/kgK = 4181.8 × 106 mm2 /s2 K

– λ = 0.5984 W/mK = 0.5984 N/sK

– µ = 10−3 Pa s = 10−9 Ns/mm2

• steel

– E = 2100006 N/m2 = 210000 N/mm2

– ν (Poisson coefficient)= 0.3

– ρ = 7800 kg/m3 = 7.8 × 10−9 Ns2 /mm4

– cp = 446 J/kgK = 446 × 106 mm2 /s2 K

– λ = 50 W/mK = 50 N/sK

4

Golden rules

Applying the finite element method to real-life problems is not always a piece

of cake. Especially achieving convergence for nonlinear applications (large deformation, nonlinear material behavior, contact) can be quite tricky. However,

adhering to a couple of simple rules can make life a lot easier. According to my

experience, the following guidelines are quite helpful:

1. Check the quality of your mesh in CalculiX GraphiX or by using any other

good preprocessor.

2. If you are dealing with a nonlinear problem, RUN A LINEARIZED VERSION FIRST: eliminate large deformations (drop NLGEOM), use a linear

elastic material and drop all other nonlinearities such as contact. If the

linear version doesn’t run, the nonlinear problem won’t run either. The

linear version allows you to check easily whether the boundary conditions

are correct (no unrestrained rigid body modes), the loading is the one

you meant to apply etc. Furthermore, you get a feeling what the solution

should look like.

3. USE QUADRATIC ELEMENTS (C3D10, C3D15, C3D20(R), S8, CPE8,

CPS8, CAX8, B32). The standard shape functions for quadratic elements

are very good. Most finite element programs use these standard functions.

For linear elements this is not the case: linear elements exhibit all kind of

weird behavior such as shear locking and volumetric locking. Therefore,

most finite element programs modify the standard shape functions for linear elements to alleviate these problems. However, there is no standard

17

way of doing this, so each vendor has created his own modifications without necessarily publishing them. This leads to a larger variation in the

results if you use linear elements. Since CalculiX uses the standard shape

functions for linear elements too, the results must be considered with care.

4. If you are using shell elements or beam elements, use the option OUTPUT=3D on the *NODE FILE card in CalculiX (which is default). That

way you get the expanded form of these elements in the .frd file. You can

easily verify whether the thicknesses you specified are correct. Furthermore, you get the 3D stress distribution. It is the basis for the 1D/2D

stress distribution and the internal beam forces. If the former is incorrect,

so will the latter be.

5. If you include contact in your calculations and you are using quadratic elements, use the face-to-face penalty contact method or the mortar method

(which is by default a face-to-face method). In general, for contact between faces the face-to-face penalty method and the mortar method will

converge much better than the node-to-face method. The type of contact

has to be declared on the *CONTACT PAIR card. Notice that the mortar

method in CalculiX can only be used for static calculations.

6. if you do not have enough space to run a problem, check the numbering.

The memory needed to run a problem depends on the largest node and

element numbers (the computational time, though, does not). So if you

notice large gaps in the numbering, get rid of them and you will need less

memory. In some problems you can save memory by choosing an iterative

solution method. The iterative scaling method (cf. *STATIC) needs less

memory than the iterative Cholesky method, the latter needs less memory

than SPOOLES or PARDISO.

If you experience problems you can:

1. look at the screen output. In particular, the convergence information for

nonlinear calculations may indicate the source of your problem.

2. look at the .sta file. This file contains information on the number of

iterations needed in each increment to obtain convergence

3. look at the .cvg file. This file is a synopsis of the screen output: it gives you

a very fast overview of the number of contact elements, the residual force

and the largest change in solution in each iteration (no matter whether

convergent or not).

4. use the “last iterations” option on the *NODE FILE or similar card. This

generates a file with the name ResultsForLastIterations.frd with the deformation (for mechanical calculations) and the temperature (for thermal

calculations) for all non-converged iterations starting after the last convergent increment.

18

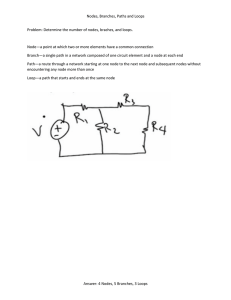

5 SIMPLE EXAMPLE PROBLEMS

F=9MN

y

y

1m

z

8m

x

1m

Figure 1: Geometry and boundary conditions of the beam problem

5. if you have contact definitions in your input deck you may use the “contact

elements” option on the *NODE FILE or similar card. This generates a

file with the name jobname.cel with all contact elements in all iterations

of the increment in which this option is active. By reading this file in

CalculiX GraphiX you can visualize all contact elements in each iteration

and maybe find the source of your problems.

6. if you experience a segmentation fault, you may set the environment variable CCX LOG ALLOC to 1 by typing “export CCX LOG ALLOC=1”

in a terminal window. Running CalculiX you will get information on which

fields are allocated, reallocated or freed at which line in the code (default

is 0).

7. this is for experts: if you experience problems with dependencies between

different equations you can print the SPC’s at the beginning of each step

by removing the comment in front of the call to writeboun in ccx 2.20.c

and recompile, and you can print the MPC’s each time they are set up

by decommenting the loop in which writempc is called at the beginning

of cascade.c and recompile.

5

5.1

Simple example problems

Cantilever beam

In this section, a cantilever beam loaded by point forces at its free end is analyzed.

The geometry, loading and boundary conditions of the cantilever beam are

shown in Figure 1. The size of the beam is 1x1x8 m3 , the loading consists of

a point force of 9 × 106 N and the beam is completely fixed (in all directions)

on the left end. Let us take 1 m and 1 MN as units of length and force,

respectively. Assume that the beam geometry was generated and meshed with

CalculiX GraphiX (cgx) resulting in the mesh in Figure 2. For reasons of clarity,

only element labels are displayed.

5.1 Cantilever beam

19

Figure 2: Mesh for the beam

20

5 SIMPLE EXAMPLE PROBLEMS

A CalculiX input deck basically consists of a model definition section describing the geometry and boundary conditions of the problem and one or more

steps (Figure 3) defining the loads.

The model definition section starts at the beginning of the file and ends at

the occurrence of the first *STEP card. All input is preceded by keyword cards,

which all start with an asterisk (*), indicating the kind of data which follows.

*STEP is such a keyword card. Most keyword cards are either model definition

cards (i.e. they can only occur before the first *STEP card) or step cards (i.e.

they can only occur between *STEP and *END STEP cards). A few can be

both.

In our example (Figure 4), the first keyword card is *HEADING, followed

by a short description of the problem. This has no effect on the output and only

serves for identification. Then, the coordinates are given as triplets preceded

by the *NODE keyword. Notice that data on the same line are separated by

commas and must not exceed a record length of 132 columns. A keyword card

can be repeated as often as needed. For instance, each node could have been

preceded by its own *NODE keyword card.

Next, the topology is defined by use of the keyword card *ELEMENT. Defining the topology means listing for each element its type, which nodes belong to

the element and in what order. The element type is a parameter on the keyword

card. In the beam case 20-node brick elements with reduced integration have

been used, abbreviated as C3D20R. In addition, by adding ELSET=Eall, all

elements following the *ELEMENT card are stored in set Eall. This set will be

later referred to in the material definition. Now, each element is listed followed

by the 20 node numbers defining it. With *NODE and *ELEMENT, the core

of the geometry description is finished. Remaining model definition items are

geometric boundary conditions and the material description.

The only geometric boundary condition in the beam problem is the fixation

at z=0. To this end, the nodes at z=0 are collected and stored in node set FIX

defined by the keyword card *NSET. The nodes belonging to the set follow on

the lines underneath the keyword card. By means of the card *BOUNDARY,

the nodes belonging to set FIX are subsequently fixed in 1, 2 and 3-direction,

corresponding to x,y and z. The three *BOUNDARY statements in Figure 4

can actually be grouped yielding:

*BOUNDARY

FIX,1

FIX,2

FIX,3

or even shorter:

*BOUNDARY

FIX,1,3

meaning that degrees of freedom 1 through 3 are to be fixed (i.e. set to

zero).

5.1 Cantilever beam

Model Definition

material description

*STEP

Step 1

*END STEP

*STEP

Step 2

*END STEP

*STEP

Step n

*END STEP

Figure 3: Structure of a CalculiX input deck

21