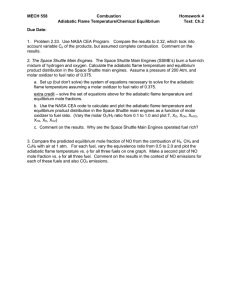

4.7 Adiabatic Flame Temperature If a given reaction goes to completion (that is, equilibrium is achieved) and takes place adiabatically and with very low kinetic energy changes, temperature of the products is the highest possible temperature for the given reactants, and this temperature is known as the adiabatic flame temperature. There are many situations where it is important to know the adiabatic flame temperature. In a furnace for example, the maximum temperature permissible is determined by metallurgical considerations in the furnace, so it is important to know the adiabatic flame temperature for the given fuel and the given fuel- air ratio. (Since there is usually some heat transfer during the combustion process, and since the reaction is usually less than complete to some degree, the actual flame temperature is always somewhat less than the adiabatic flame temperature. The maximum or adiabatic flame temperature may be calculated by assuming that the enthalpy of the products (HP) of combustion is equal to the enthalpy of the reactants (HR). Thus: 𝐻𝑃 = 𝐻𝑅 As an approximation, the lower heating value (L.H.V) may be divided by the summation of the product of the specific heats of the flue gases and their weights. Thus: 𝐿. 𝐻. 𝑉 𝐿. 𝐻. 𝑉 𝑇𝐹 = 𝑥=𝑛 = ∑𝑥=1 𝑚𝑥 × 𝐶𝑃𝑥 𝑚𝑓.𝑔 × 𝐶𝑃 Where: TF = Adiabatic flame temperature L.H.V = Lower heating value of the fuel 𝐿. 𝐻. 𝑉 = 𝐻. 𝐻. 𝑉 − 9 × 𝑚𝐻2 × 588.76 (𝐾. 𝑐𝑎𝑙⁄𝐾𝑔) mH2 = Mass of hydrogen in kg per kg of fuel H.H.V = Higher heating value of the fuel (k.cal/kg) mf.g = Mass of flue gases (wet) in kg per kg of fuel burned Cp = Mean specific heat of flue gases 𝑚𝐶𝑂2 × 𝐶𝑃𝐶𝑂2 𝐶𝑃 = + 𝑚𝐶𝑂 × 𝐶𝑃𝐶𝑂 + 𝑚𝑂2 × 𝐶𝑃𝑂2 + 𝑚𝑁2 × 𝐶𝑃𝑁2 + 𝑚𝑆𝑂2 × 𝐶𝑃𝑆𝑂2 + 𝑚𝐻 2𝑂 𝑚𝐶𝑂2 + 𝑚𝐶𝑂 + 𝑚𝑂2 + 𝑚𝑁2 + 𝑚𝑆𝑂2 + 𝑚𝐻 = ∑𝑥=𝑛 𝑥=1 𝑚𝑥 𝑚𝑓. × 𝐶𝑃𝑥 2𝑂 × 𝐶𝑃𝐻 2𝑂 Where, mx and Cpx are the mass of constituent in flue gases per 1 kg of fuel burned and specific heat constituent respectively. Figure 4.12 Figure 4.12: Specific Heats of Gases Diagram Values of mean specific heat for common products of combustion are given in the above figure for various temperatures. A trial and error solution is necessary to equate the two sides of the equation L. H. V = 𝑇𝐹 × 𝑚𝑓.𝑔 × 𝐶𝑃 The approach to this problem is to assume an adiabatic flame temperature and determine the mean specific heat for this assumed temperature and necessary heat transfer to achieve this assumed temperature. The heat transfer for this assumed temperature can be calculated from the following equation: 𝑄 = 𝐻𝑃 − 𝐻𝑅 Or 𝑄 = 𝑇𝐹 × 𝑚𝑓.𝑔 × 𝐶𝑃 − 𝐿. 𝐻. 𝑉(Q=0 for this reaction) If the heat transferred (Q1) for this assumed temperature is positive (+), the adiabatic flame temperature is less than the assumed temperature. As our second assumption we take TF2 less than TF1 for the first trial. Following the same procedure we find the heat transferred (Q2) for this temperature (TF2). Thus, by linear interpolation the adiabatic flame temperature (TF) can be found for which the heat transfer is zero, and this is the adiabatic flame temperature. Figure 4.13: Graphical solution 4.8 Temperature of flue gases at the furnace exit One of the most complex problems of the heat transmission is the evolution of the performance of combustion chamber of a furnace in which heat is being transmitted simultaneously by radiation, convection and conduction. Two methods of treatment of this problem are possible, either: (1). The theoretical one in which the attempt is made to consider the various individual factors and to combine them (2). The empirical one in which furnace test data are analyzed in the attempt to detect the effect of factors suspected of being of importance. Figure (4.14) shows the variation of temperature measured by high-velocity thermocouple probes in the upper section of a large furnace. Figure 4.14: Temperatures isotherms in a large furnace Figure (4.14) shows how it difficult to find the furnace exits temperature. Never the less, one can predict an approximate furnace exit temperature. The approximate temperature of furnace gases can be calculated by performing a heat balance at the furnace exit. A solution is obtained by equation (1) the furnace heat input minus radiation loss, moisture loss. And unburned fuel loss (2) is heat transported by the gases out of the furnace exit. Thus: 𝑀̇𝐹𝑢𝑒𝑙 × (𝐿. 𝐻. 𝑉) − 𝑄̇1 − 𝑄̇𝑅 − 𝑄̇𝑚𝑜𝑖𝑠𝑡𝑢𝑟𝑒 = 𝑄̇𝑓.𝑔 Where: 𝑀̇𝐹𝑢𝑒𝑙 = fuel consumption (Kg/hr.) (𝐿. 𝐻. 𝑉)= lower heating value of the fuel (k.cal/Kg) 𝑄̇1 = unburned fuel loss( k.cal/hr). 𝑄̇𝑅 = radiation loss (heat transfer to the absorbing surface in the furnace). (K.cal/hr) 𝑄̇𝑚𝑜𝑖𝑠𝑡𝑢𝑟𝑒 = moisture loss (K.cal/hr). 𝑄̇𝑓.𝑔 = heat transported by the flue gases out of the furnace exit (Qavailable) 𝑄̇𝑓.𝑔 = 𝑀̇𝑓.𝑔 . 𝐶𝑝𝑔 (𝑇𝑔1 − 𝑇0 ) The radiation heat transfer to the absorbing surface (water walls) is given by: 𝑄̇𝑅 = 𝜎 𝐴𝑟 ∈ [ 𝑇𝑔41 − 𝑇𝑤4 ] Where σ = Stefan-Boltzmann constant (4.874 x 10-8 K.cal/m2.hr.K4). ∈= emissivity, use: 0.64 for gaseous fuel 0.75 for oil fuel 0.81 For coal fuel. 𝐴𝑟 = Effective area for absorbing heat (m2) calculation is down below. 𝑇𝑔1 = Flue gases temperature leaving the furnace (K). TW = Absorbing surface temperature (K). The effective area 𝐴𝑟 can be calculated as follows: 𝐴𝑟 = 𝐴𝑝 × 𝐹𝑐𝑜𝑚𝑝 𝐴𝑝 : The projected area (tube diameter x exposed length) 𝐴𝑝 = 𝐷 × 𝐿 × 𝑁 D: tube diameter L: length for each tube N: number of tubes 𝐹𝑐𝑜𝑚𝑝 : Factor of comparison can be obtained from figure (4.15) according to the arrangement of water walls. Figure 4.15: Effectiveness chart For example, for touching tubes arrangement, the projected area (𝐴𝑝 ) is used for the effective area (𝐴𝑟 ) for absorbing heat. Where tubes are spaced on centers greater than their diameters Fig (4.15) must be applied to obtain a factor of comparison (𝐹𝑐𝑜𝑚𝑝 ). This factor multiplied by the projected area (𝐴𝑝 ) will give the effective absorbing area (𝐴𝑟 ). The heat balance at the furnace exit can be simplified as follows: 𝑀̇𝐹𝑢𝑒𝑙 × (𝐿. 𝐻. 𝑉) × ŋ𝑐 = 𝜎 𝐴𝑟 ∈ [ 𝑇𝑔41 − 𝑇𝑤4 ] + 𝑀̇𝑓.𝑔 . 𝐶𝑝𝑔 (𝑇𝑔1 − 𝑇0 ) Where 𝑇0 : Room temperature (K) 𝑀̇𝑓.𝑔 = 𝑀̇𝑓𝑢𝑒𝑙 . 𝑚𝑓.𝑔 ŋ𝑐 : Combustion efficiency. It expresses the extent to which the combustion is completed ŋ𝑐 = 𝑅𝑎𝑡𝑒 𝑜𝑓 𝑡𝑜𝑡𝑎𝑙 ℎ𝑒𝑎𝑡 𝑙𝑖𝑏𝑒𝑟𝑎𝑡𝑒𝑑 𝑄̇𝑙𝑖𝑏𝑟𝑎𝑡𝑒𝑑 = 𝐸𝑛𝑒𝑟𝑔𝑦 𝑠𝑡𝑜𝑟𝑒𝑑 𝑖𝑛 𝑓𝑢𝑒𝑙 𝑀̇𝐹𝑢𝑒𝑙 . 𝐿. 𝐻. 𝑉 The equality of the two sides of the heat balance equation of the furnace exit is again a trial and error solution which can be easily solved graphically. Solved Example A boiler uses oil with a calorific value (H.H.V) of 9000 k.cal/Kg. The analysis of the oil is 85% carbon and 15% hydrogen. The air supplied is double the theoretical air required for complete combustion of oil. Calculate the adiabatic flame temperature. Solution: The relevant combustion equation for 100 kg of fuel is: 85 15 79 79 𝐶 + 𝐻2 + 𝑥𝑂2 + 𝑥 𝑁2 → 𝐴𝐶𝑂2 + 𝐵𝐻2 𝑂 + 𝑥 𝑁2 12 2 21 21 Carbon balance: 𝐴 = 85 12 Hydrogen balance: 𝐵 = . 15 2 Oxygen balance: 𝑥 = 𝐴 + 𝐵 2 = 85 12 + 15 2×2 = 10.8333 𝑘.𝑚𝑜𝑙 100𝑘𝑔 𝑜𝑓 𝑓𝑢𝑒𝑙 Thus the theoretical air to fuel ratio is: 𝐴 𝑥 × 32 10.8333 × 32 𝑘𝑔 ( ) = = = 3.4666 𝐹 𝑡ℎ 100 100 𝑘𝑔 𝑜𝑓 𝑓𝑢𝑒𝑙 Thus the Actual air to fuel ratio is: 𝐴 𝐴 𝑘𝑔 ( ) = 2 × ( ) = 3.4666 × 2 = 6.9332 𝐹 𝐴 𝐹 𝑡ℎ 𝑘𝑔 𝑜𝑓 𝑓𝑢𝑒𝑙 The combustion equation with actual air is 85 15 79 85 15 𝐶 + 𝐻2 + 21.666𝑂2 + 21.666 × 𝑁2 → 𝐶𝑂2 + 𝐻2 𝑂 + 10.833𝑂2 + 81.5𝑁2 12 2 21 12 2 The composition of flue gases is given by volume. It can be converted into composition by weight as follows: Gas Volume per 100kg of fuel M Weight per 100 kg of (v) fuel (W=V.M) Weight per Kg of flue 𝒘 𝒘 gases 𝒎𝒊 = ∑ 𝐶𝑂2 85 12 44 311.666 0.1013 𝐻2 𝑂 15 2 18 135 0.044 𝑂2 10.833 32 346.656 0.1127 𝑁2 81.5 28 2282 0.742 ∑ 𝑤 = 3075.322 1 The mass of flue gases per 1 Kg of fuel burned is given by 𝑚𝑓.𝑔 = ∑ 𝑤 3075.322 𝑘𝑔𝑔𝑎𝑠 = = 30.75 100 100 𝑘𝑔𝑓𝑢𝑒𝑙 The lower heating value of the fuel is given by: 𝐿. 𝐻. 𝑉 = 𝐻. 𝐻. 𝑉 − 9𝑚𝐻2 × 588.76 = 9000 − 9 × 0.15 × 588.76 = 8205.174 𝑘. 𝑐𝑎𝑙 𝑘𝑔 To determine the adiabatic flame temperature let us take our first assumption a temperature of 1000˚C. From 𝐶𝑝 chart we find the specific heats of the individual gases at this assumed temperature and presented in the table below: 1000˚C 900˚C Gas 𝒎𝒊 𝑪𝒑 𝒎𝒊 × 𝑪𝒑 𝑪𝒑 𝒎𝒊 × 𝑪𝒑 𝐶𝑂2 0.1013 0.272 0.0272 0.265 0.0266 𝐻2 𝑂 0.044 0.507 0.02195 0.498 0.021562 𝑂2 0.1127 0.249 0.02774 0.247 0.0275 𝑁2 0.742 0.264 0.1953 0.262 0.19526 ̅̅̅ 𝐶𝑝 =∑ 𝑚𝑖 . 𝐶𝑝 =0.27216 ̅̅̅ 𝐶𝑝 =∑ 𝑚𝑖 . 𝐶𝑝 =0.27216 From the table we find that at 1000˚C, 900˚C the ̅̅̅ 𝐶𝑝 =0.27216 and 0.27216 respectively Therefore, the heat transfer for this assumed temperatures can be now calculated by 𝑄 = 𝐿. 𝐻. 𝑉 − 𝑇𝑓 𝑚𝑓.𝑔 ̅̅̅ 𝐶𝑝 For T=1000˚C = 8205.174 − 1000 × 30.75 × 0.27216 = −164 𝑘. 𝑐𝑎𝑙 𝑘𝑔 For T=900˚C = 8205.174 − 900 × 30.75 × 0.27216 = 709.677 𝑘. 𝑐𝑎𝑙 𝑘𝑔 Since the heat transfer for a temperature of 1000˚C is negative, and for 900˚C is positive the adiabatic flame temperature is in between. Thus by linear interpolation we conclude that Q=0 for this reaction at a temperature of 980 ˚C which is therefore the adiabatic flame temperature (figure 4.16) 800 700 Q (kCal/kg) 600 500 400 300 flame temperature 200 100 Temperature oC 0 -100 850 900 950 -200 -300 Graphical solution 1000 1050