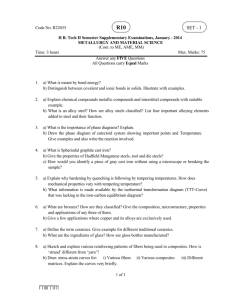

Ferrous Alloys Metallurgy Chapter 3 Ferrous Alloys 3.1. Introduction: Most engineering metallic materials are alloys. Metals are alloyed to enhance their properties, such as strength, hardness or corrosion resistance, and to create new properties, such as shape memory effect. Ferrous alloys could be classified as shown in Figure 2.5. Fig.2.5: Ferrous alloys classification. Ferrous alloys containing Fe as the main element. The most important ferrous alloy system (Fe-C system) Alloys of this system can be further divided into steels and cast irons. Steels contain less Carbon (generally most common <1.4 wt%C) than cast irons (generally 2.14~4.3wt%C), Figure 2.6. All steels solidify into a single γ-Fe structure first and then experience the complex eutectoid reaction. Dr. Rasheed Amirah 58 Ferrous Alloys Metallurgy Fig.2.6 Therefore, heat treatment processes, which alter the eutectoid reaction, are vitally important for controlling microstructure and properties of steels. Cast irons experience complex eutectic reaction during solidification, due to the formation of graphite or cementite. Solidification control is the most important single factor for properties of cast irons. 3.2. Steel Alloys: Dr. Rasheed Amirah 59 Ferrous Alloys Metallurgy Steel is classified into two types. 1. Plain Carbon Steel: Host or base metal is iron and alloying element is carbon. 2. Alloy Steel: Base metal is iron and other alloying elements are other nonferrous metals in small amount other than carbon. Plain Carbon Steels are further classified into: 1. Low Carbon steels, 2. Medium Carbon steels, 3. High Carbon steels. 4. Tool Steel. Alloy steels are further classified into: 1. Low Alloy Steels, 2. medium Alloy Steels, 3. high Alloy Steels A. Plain Carbon Steel: (0.15% carbon steel) ❖ Low carbon steels (mild steels): Composition of 0.05%-0.25% carbon and up to 0.4% manganese. It is a low-cost material that is easy to shape. While not as hard as higher-carbon steels, carburizing can increase its surface hardness. Has High formability, high ductility: elongation: ~30% relatively. Dr. Rasheed Amirah 60 Ferrous Alloys Metallurgy Has Low strength: yield strength: 250~400 MPa. Has excellent weldability. Cannot be strengthened by heat treatment. Usually strengthened by cold working. Typical applications: pipes, panels, sheets, wires, I-beams etc. ❖ Medium-carbon steels (structural steels): Composition of 0.25%-0.54% carbon, with 0.55%-1.65% manganese. (0.4% carbon steel) Medium carbon steel has long-wearing properties. Good combination of strength and ductility. Yield strength: 300~600MPa Tensile strength: 400~800MPa Elongation: ~25% Strengthenable by heat treatment. Weldable; weldability deteriorates with increasing C%. Applications: Used for load-bearing applications, crankshaft, bolts, gears, heavy-duty machinery, mining equipment, cranes. ❖ High strength low alloy steels (HSLA): Medium carbon steels have desired mechanical properties for structural Dr. Rasheed Amirah applications but suffer from welding-induced 61 Ferrous Alloys Metallurgy embrittlement ( )التقصف او الهشاشةdue to the formation of martensite. To overcome this problem: Carbon content in these steels is reduced (<0.3%), And the loss of strength is compensated by increasing Mn content (>1%), And by micro-alloying with Nb, V, Ti, Cr and Cu. This leads to the development of HSLA steels. Applications: These steels are widely used for manufacturing large welded structures, such as Sydney harbor bridge, ocean liners and cargo ships ()عابرات المحيط و سفن الشحن, oil drilling rigs ( منصات )حفر آبار النفطand platforms, large mining and earth moving equipment, and pressure vessels and storage tanks. ❖ High carbon steels (Spring steels): Composition of 0.55%-0.95% carbon, with 0.30%-0.90% manganese. It is very strong and holds shape memory well, making it ideal for springs and wire. Mostly (Predominately )في الغالبeutectoid pearlite at room temperature. Often strengthened and hardened by heat treatment. High strength and moderate toughness. Have poor weldability and poor machinability. ❖ Tool steels: Composition of 0.8~1.2%C. Very high hardness, low toughness, very difficult to machine. Applications: used for chisels, hammers, knives, saw blades, drills, dies, punches, cutlery, chine tools and wear resistant applications. ❖ Stainless Steels: Dr. Rasheed Amirah 62 Ferrous Alloys Metallurgy Stainless steel is a steel alloy with increased corrosion resistance compared to carbon/alloy steel. Common alloying ingredients include chromium (usually at least 11%), nickel, or molybdenum. Adding (Cr → Cr2O3) formation, an oxide which protects the underlying alloy. ❖ Three basic classes, specified by microstructure: Ferritics: Fe-Cr alloys (12~25%Cr), can be cheap. BCC structure Typical. alloy Fe-15Cr-0.6C, used in quench and tempered conditions strengthened by carbide precipitation Uses rust-free ball bearings, scalpels ()المشارط, knives. Austenitics: Fe-Cr-Ni alloys (18Cr-8Ni), FCC structure (stabilized by adding Ni). Dr. Rasheed Amirah 63 Ferrous Alloys Metallurgy Corrosion resistance Precipitation hardened, high strength and hardness. Typical alloy Fe-18Cr-8Ni-1Mn-0.1C. Disadvantage: work hardens rapidly so more difficult to shape and machine. Advantages of all FCC metals and alloys. ➢ ↑ Toughness. ➢ ↑ Ductility. ➢ ↑ creep resistance Martensitics: Fe-Cr alloys, low Cr, hard, cutting tools. BCT structures (body centered tetragonal) and they are classified as a hard Ferro-magnetic group. Due the addition of carbon, they can be hardened and strengthened by heat treatment, in a similar way to carbon steels. The main alloying elements are chromium (10.5 % to 18 %), molybdenum (0.2 % to 1 %), no nickel (except for two grades), and carbon (0.1 % to 1.2 %). Martensitic steels are suitable for applications where the material is subjected to both corrosion and wear. Applications: used for surgical and dental instruments (األدوات )الجراحية وطب األسنان, wire, screws, springs, blades and cutting tools, Dr. Rasheed Amirah 64 Ferrous Alloys Metallurgy fasteners, gears and ball bearings and races, gauge blocks, moulds and dies etc. They are also used in the petrochemical industry for steam and gas turbines blades and buckets. Typical other applications are aerospace, automotive, hydroelectric engines, cutlery ()أدوات تناول الطعام, defense, power hand tools, pump parts, valve seats, chisels, bushings, shafts, and sporting equipment industry etc. Duplex: (18Cr-5Ni) mixed ferrite & austenite. Duplex stainless steels are called “duplex” because they have a twophase microstructure consisting of grains of ferritic and austenitic stainless steel. The picture shows the yellow austenitic phase as “islands” surrounded by the blue ferritic phase. - When duplex stainless steel is melted it solidifies from the liquid phase to a completely ferritic structure. - As the material cools to room temperature, about half of the ferritic grains transform to austenitic grains (“islands”). - The result is a microstructure of roughly 50% austenite and 50% ferrite. Duplex Stainless Steels have roughly twice the yield strength of their counterpart austenitic grades. - This allows equipment designers to use thinner gauge material for vessel construction. Dr. Rasheed Amirah 65 Ferrous Alloys Metallurgy ❖ Classification of steel by alloy content: - Plain carbon steels, Manganese steels, Silicon-manganese steels, Chromium steels, Chromium-nickel (stainless) steels, Tungsten-chromium-vanadium (tool) steels: etc. ❖ Steel Designation based on steel composition: Proposed by organizations such as American Iron and Steel Institute (AISI) and the Society of Automotive Engineers (SAE). A basic four-digit system is used by the SAE/AISI system to designate the chemical composition of alloy steels and carbon steels. Schematic Representation of AISI/SAE Steel Designation System 4-numeral designation system: - 1st digit Type of steel (1 for plain C steels, 2 for nickel steels, etc.). - 2nd digit Approx. % of predominant ( )غالبalloying element. - 3d & 4th digit Mean carbon content divided by 100. Example: 1. SAE 1018: indicates plain carbon steel containing 0.18% of carbon. 2. SAE 5130: indicates a chromium alloy steel containing 1% of chromium and 0.30% of carbon. An additional letter is sometimes added between the second and third digits of the code groups such as 11L41, 12L14 or 50B40. The letter L: indicates the addition of lead (between 0.15% and 0.35%) to improve the machinability of the steel. Dr. Rasheed Amirah 66 Ferrous Alloys Metallurgy The letter B: indicates the addition of boron (between 0.0005% and 0.003%) to low carbon steels to enhance the hardness of the steel. Further, the merchant (commercial) quality steels used as hot-rolled steels bars in production of non- critical parts of machinery and structure are designated with prefix M. The alloy steels with prefix E indicate electric furnace steel and suffix H indicate that the steel has been produced to the required hardenability limits. Given below is a table illustrating the four-digit index classification of alloy steels by the SAE-AISI system. Tab. 2.1: Four-Digit Index Classification of Alloy Steels SAE Designation 1xxx 2xxx 3xxx 4xxx 5xxx 6xxx 7xxx 8xxx 9xxx ❖ Type Carbon steels Nickel steels Nickel-chromium steels Molybdenum steels Chromium steels Chromium-vanadium steels Tungsten steels Nickel-chromium-vanadium steels Silicon-manganese steels Steel Microstructures (As influenced by carbon content) Dr. Rasheed Amirah 67 Ferrous Alloys Metallurgy Tab. 2.2: Commercial plain carbon steels with common uses of these alloys. Type of steel Percentage carbon Dead mild 0.05-0.15 0.90-1.00 1.00-1.10 1.10-1.20 Chain, stampings, rivets, wire, nails, seam-welded pipes, mattresses, hot- and cold-rolled strip for many purposes Structural steels, RSJ, screws, machine parts, tin-plate, case-hardening, drop-forgings, stampings Machine and structural work, gears, free-cutting steels, shafting, levers, forgings Connecting-rods, shafting, wire, axles, fish-plates, crane hooks, hightensile tubes, forgings Crankshafts, axles, gears, shafts, die-blocks, rotors, tyres, heat-treated machine parts Loco tyres, rails, laminated springs, wire ropes Drop-hammer dies, set-screws, screw-drivers, saws, mandrels, caulking tools, hollow drills Band saws, anvil faces, hammers, wrenches, laminated springs, car bumpers, small forgings, cable wire, dies, large dies for cold presses Cold chisels, shear blades, cold setts, punches, rock drills, some hand tools Springs, high-tensile wire, axes, knives, dies, picks Drills, taps, milling cutters, knives, screwing dies Ball bearings, dies, drills, lathe tools, woodworking tools 1 .20-1 .30 Files, reamers, knives, broaches, lathe and wood-working tools 1.30-1.40 Saws, razors, boring and finishing tools, machine parts where resistance to wear is essential 0.10-0,20 Mild 0.20-0.30 0.30-0.40 Medium carbon 0.40-0.50 0.50-0.60 0.60-0.70 High carbon 0.70-0.80 0.80-0.90 Tool steels Uses 3.3. Cast Iron: Cast irons are manufactured by melting pig iron in a cupola or other melting furnaces. Little or no change in composition takes place during melting. On the Fe-C system, these are to the right of steels, With carbon between 2.14 & 5.3 %, but more usual 2.5 to 4%. Really is tertiary alloy system, with the third element silicon. ▪ The microstructures present depend strongly on the chemical composition (%Si) and the cooling rate of the cast. Disadvantage: BRITTLE, due to Presence of high carbon, which limits their formability. Dr. Rasheed Amirah 68 Ferrous Alloys Metallurgy Advantages: can be sand cast to intricate shapes using basic technology. So casting is the only way of making any product using cast irons ❖Some general properties: Low melting point and excellent fluidity. Very good corrosion resistant. Excellent wear resistant. Excellent machinability. ❖Classification of Cast Iron: Type of Graphite cast iron White No Gray Flake Anneal: Malleable flake to nodule Nodular Type of iron Grey Ductile White Malleable Nodular C 2.5-4.0 3.0-4.0 1.8-3.6 2.2-2.9 Ductility No No Fast cooling rates Slow cooling rates Yes white iron + annealing heat treatment Yes additions made so that nodules of graphite form instead of flakes Si 1.0-3.0 1.8-2.8 0.5-1.9 0.9-1.9 Composition, % Mn P 0.2-1.0 0.002-1.0 0.1-1.0 0.01-0.1 0.25-0.8 0.06-0.2 0.15-1.2 0.02-0.2 S 0.02-0.25 0.01-0.03 0.06-0.20 0.02-0.20 ❖Factors influencing which type will form: %C. %Si. Temperature (cooling rate). Dr. Rasheed Amirah 69 Ferrous Alloys A. White Dr. Rasheed Amirah Metallurgy Cast Iron: 70 Ferrous Alloys Metallurgy Produced by rapid cooling of molten gray CI. Carbon presents as extremely hard and brittle iron carbide (Fe3C) compound in pearlite. Because of this carbide phase, the fractured surface takes on a white appearance. Properties: Excellent wear resistance. High compressive stress. Un-machinable. Not workable. Have very little commercial uses. It uses is limited to only where a hard wear-resistant surface is required and for rollers. Fe-2.8wt%C-1.8wt%Si (White cast iron) Dr. Rasheed Amirah 71 Ferrous Alloys Metallurgy B.Grey cast iron: If we put in 2 to 3 % Silicon, and cool the iron reasonably slowly (don’t quench it) the Si will cause the carbon to form as graphite flakes – Gray Cast Iron. If we put in more Silicon and cool slowly we can get virtually all the carbon out of the austenite and into the flakes, so the matrix is ferrite, or we have a ferritic gray CI. Because of carbon presents as free “flaky” graphite, the fractured surface takes on a grey appearance. Properties of grey cast iron: Cheap. Low melting point. Fluid– easy to cast, especially advantageous into large complex shapes. Dr. Rasheed Amirah 72 Ferrous Alloys Metallurgy Excellent machinability. Excellent bearing properties. Good compressive strength, making them suitable for damping applications.. Excellent wear and corrosion resistance. Can be heat treated (surface hardened etc.). Can be alloyed etc. Grey irons are weak and brittle due these graphite flakes, which act as cracks. ❖ the properties of grey cast iron are strongly dependent on the shape of the graphite flakes: Flakes. Spheroids: relatively high toughness and ductility; formed by adding Cu or Mg. Grey Irons – Application: Grey irons are by far the most produced among all cast irons. Grey irons are used primarily for their low cost and excellent castability. Typical applications include: ➢ Engine cylinders, pistons, gear box casing, transmission casing, machine tool bases, balance weight of large cranes, large diameter underground pipework. ➢ They are used always under compressive loading conditions. ➢ They are unsuitable for taking tensile loads or bending loads. C. Malleable Cast Iron: Dr. Rasheed Amirah 73 Ferrous Alloys Metallurgy If we heat white Cast Iron above its critical line, normally between 900 to 1000 °C for 20 hours we’ll make the carbide (cementite) convert to ferrite (almost pure iron) and graphite), And it will produce a rough clusters of graphite, kind of between a flak and a nodule (agglomerate “)”كتل, - malleable CI. the decomposed graphite grouped into clusters ()عناقيد, known as “tempered carbon” Because of this clustered form (not flakey form), cast iron becomes more malleable and ductile than grey iron. Properties of Malleable cast iron: These cast irons are stronger, tougher and much more ductile than grey irons, compatible to nodular irons. They have certain capacity to take shock loading, bending and tension. They are suitable for castings of thin thickness. They are expensive to produce, largely due to the heat treatment. Typical applications include: Gear box casing, transmission casing, and differential casing. Dr. Rasheed Amirah 74 Ferrous Alloys Metallurgy D. Nodular or Ductile Cast Irons: Carbon presents as graphite “nodules” in the ferrite-pearlite matrix. Produced directly by melting low-sulphur grade pig/grey iron and adding a small amount of magnesium or cerium before casting. The graphite formed as nodules or spheroids instead of flake in presence of magnesium or cerium. Properties of nodular cast iron: Ductile/nodular/spheroidal graphite irons are the most ductile and malleable cast irons, having mechanical properties approaching to steels. These irons are much stronger and tougher than grey irons. Dr. Rasheed Amirah 75 Ferrous Alloys Metallurgy They are more expensive than grey irons. Typical applications: They are produced applications. and used for high specification Include: gears, crankshafts, pump bodies, pressure valves, rollers. Typical properties and applications of cast irons Types of Cast Iron Grey Cast Iron White Cast Iron Malleable Cast Iron Ductile Cast Iron Hardness (BHN) Tensile Strength (ksi) 150 – 270 20 – 60 > 320 5 < 135 50 – 65 140 – 270 60 – 90 Dr. Rasheed Amirah Typical Cast Iron Applications Engine block, cylinder heads, piston, heavy machine beds, manhole covers Car wheels, rolls, grinding media balls, production of malleable irons Pipe fittings, valves, connecting rods, transmission gears and differential cases heavy-duty machinery (gears, dies, rolls), pressure castings (pumps, valves, shockresisting parts), railway inserts, pipe fittings 76