Cumene Production Optimization: Process Simulation Assignment

advertisement

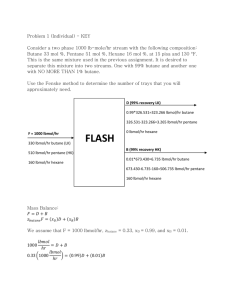

Assignment 5 Somya Verma CH19B028 PFD + Stream Table - T = (a+b+10*c) = 0 + 2 + 10*8 = 82 X = 82 mod 9 = 1 Y = 82 mod 19 = 6 So outlet cold temperature = 90 + 6 = 96 F Required purity of cumene in product stream = 99.1% With the information provided in the problem, we are unable to meet all the requirements. We change the values of variables like the propylene input flow rate and plug flow reactor length to cancel out the degree of freedom of the problem. We specify the purity of cumene to 99.5% by changing the propylene inlet flow rate. We can customise the conversion of cumene to 99% by adjusting the reactor's length. Ultimately, we may reduce the flow rate of waste gas to below 38 kmol/hr by adjusting the vapour flow distillate rate. Using the design specifications in the flowsheeting options, we can find values for these variables. Variable Value of Specification Variable varied Value of Variable Waste Gas Flow (to be limited below 37 lbmol/hr) 33.96 lbmol/hr Vapour flow in distillate of benzene column 0.02 Conversion of Cumene 99% Length of Reactor 782.174611 Purity of Cumene 99.5% Propylene Inlet Flow Rate 111.12 I) Design Specification 1 : Waste Gas Flow Rate As seen in the image below, flow rate of the waste gas stream has been limited to 33.96 lbmol/hr II) Design Specification 2: Purity of Cumene If we look at the composition of the cumene product stream, the total flow rate = 89.37 lbmol/hr, cumene flow rate = 88.93 lbmol/hr. This gives a purity of 99.5% III) Conversion of 99% in plug flow reactor For a conversion of 99% for a slightly less than 90 lbmol/hr flow rate, the target flow rate for the product is 89 or 89.1 lbmol/hr. B) Sensitivity Analysis By varying the preheater temperature and measuring cumene product flow rate, we find an optimal temperature of C. To maximize cumene product flow, we can use this temperature for a marginal increase in energy costs. Stream Table Link: CH19B028