AN AMERICAN NATIONAL STANDARD

zyx

ASME B16.47a-1998

ADDENDA

to

zyx

ASME 816.47-1996

LARGE DIAMETER STEEL FLANGES

NPS 26 Through NPS 60

THE AMERICAN SOCIETY OF MECHANICAL ENGINEERS

Three Park Avenue

COPYRIGHT American Society of Mechanical Engineers

Licensed by Information Handling Services

New York, NY 10016

zyxwvu

Date of Issuance: October 26. 1998

ASME is the registeredtrademark of The American Society of Mechanical Engineers.

This code or standard was developed under procedures

accredited as meeting the criteria for

American National Standards. The Standards committee that approved the code or standard

was balanced to assure that individuals from competent and concerned interests have had an

opportunity to participate. The proposed code or standard

was made available for public review

and comment that providesan opportunity for additional public input fromindustry, academia,

regulatory agencies, and the public-at-large.

ASME does not "approve," "rate," or "endorse" any item, construction, proprietary device,

or activlty.

ASME does not take any position with respect to the validity of any patent rights asserted in

connection with any items mentioned

in thisdocument, and does not undertake to insure anyone

utilizing a standard against

liability for infringement

of any applicable

Letters Patent, nor assumes

any such liability. Users of a code or standard are expressly advised that determination of the

validity of any such patent rights, and the risk of infringement of such rights, is entirely their

own responsibility.

Participation by federal agency representativels) or person(s) affiliated with industry is not to

be interpreted as government or industry endorsement of this code or standard.

ASME acceptsresponsibilityfor only those

interpretations issued in accordance with governing

ASME procedures and policies which preclude the issuance of interpretations by individual

volunteers.

zyxwvu

zyxwvutsrqp

No part of this document may be reproduced in any form,

in an electronic retrieval system or otherwise,

without the prior written permission of the publisher.

The American Society of Mechanical Engineers

Three Park Avenue, New York, NY 10016-5990

zyxwvut

Copyright O 1998 by

THE AMERICAN SOCIETY OF MECHANICAL ENGINEERS

All Rights Reserved

Printed in U.S.A.

COPYRIGHT American Society of Mechanical Engineers

Licensed by Information Handling Services

ASME B16.47a-1998

zyxw

Following approval by the ASME B16 Committee and ASME, and after public review, ASME B16.47a1998 was approved by the American National Standards Institute on February 20, 1998.

zyxwvuts

zyxwvutsrqp

zyxwv

wvutsrqponm

Addenda to the 1996 Edition of ASME B16.47

are issued in the form of replacement pages. Revisions,

additions, and deletions are incorporated directly into the affected pages. It is advisable, however, that this

page, the Addenda title and copyright pages, and all replaced pages be retained for reference.

SUMMARY OF CHANGES

This is the first Addenda to be published to ASME B16.47-1996.

Replace or insert the pages listed. Changes given below are identified on the pages by a margin note, (a),

placed next to the affected area. The pages not listed are the reverse sides of the listed pages and contain

no changes.

ommittee

Change

Page

Location

...

111

Foreword

paragraph,

last In the

2

2.4

sentence

8, 9

Table 1A

(1) A 350 Gr. LF6 Cl. 1 added to material

group l . 1

(2) A 350 Gr. LF6 Cl. 2 added to material

group 1.2

(3) New material group l . 15 added

(4) A 351 Gr. CESMN, A 351 Gr. CD4MCu,

A 351 Gr. CD~MWCUN,

A 182 Gr. F55,

and A 240 Gr. S32760 added to material

group 2.8

11

Table 2- l. I

(1) A 350 Gr. LF6 Cl. 1 added

(2) Note (4) added

(3) Entries for last four class temperatures

corrected by Errata

12

Table 2- 1.2

( I ) A 350 Gr. LF6 Cl. 2 added

(2) Note (3) added

(3) Working pressure for Class 75 at 500°F

corrected by Errata to read 85

ASME

updated

address

vii

COPYRIGHT American Society of Mechanical Engineers

Licensed by Information Handling Services

First

corrected by Errata

zyxwvutsrqpo

Location

Change

Table 2- 1.15

Added

27

Table 2-2.7

Working pressure for Class 400 at 850°F

corrected by Errata to read 570

28

Table 2-2.8

A 35 I Gr. CE8MN, A 35 1 Gr. CD4MCu, A

351 Gr. CD3MWCuN. A 182 Gr. F55, and

A 240 Gr. S32760 added

42

Table 13

Depth of C in sketch corrected by Errata

43

Table 14

Depth of C in sketch corrected by Errata

44

Table 15

Depth of C in sketch corrected by Errata

59

Annex D

Addresses of ASME and ASTM updated

61

Interpretations

ASME address updated

Page

20. I

zyxw

zyxw

zyxwvuts

zyxwvuts

SPECIAL NOTE:

TheInterpretations to ASMEB16.47 are includedinthisAddenda

as a separatesection for theuser’s

convenience. This section, however, is not part of the Addenda or the edition.

COPYRIGHT American Society of Mechanical Engineers

Licensed by Information Handling Services

zyxwvuts

zyxwvut

zyxwv

(This Foreword is not part of ASME B16.47-1996.)

zy

zyx

zyxwvut

In November, 1980,a task force was appointed within Subcommittee C of the American

in size

National Standards(ANSI) B16 Committee to developa standardforpipeflanges

N P S 26 through NPS 48. Everyattempt was made to standardize those dimensions that

existed withintheindustry for thematerials covered by ANSI B16.5.

Prompted by suggestions received from committee members, the task force was authorized

to increase the size range to NPS 60. The first draft was developed in December 1982 to

includeClass 75 through Class 1500 forthe size range N P S 26 through N P S 60. Flange

dimensions werebasedon

the Manufacturers Standardization SocietyStandard Practice

(MSS SP) 44 flanges except for Class 75 flanges which are ANSUAPI 605 flanges.

At the request of the American Petroleum Institute (API), flange dimensions in accordance

with the API Standard 605 were included in the subsequent drafts. Class 1500 flanges were

deleted due to lack of interest in using large size flanges in that pressure-temperature rating.

TheAPL605 flanges for Classes 150 and 300 and for sizes N P S 36 and smaller for

classes higherthan Class 300 are not compatible with the MSSSP-44flanges. Thus, the

MSS SP-44 flanges are designated as Series A flanges and the APL605 flanges are designated

as Series B flangesinthis

Standard. Materials coveredinthisStandard

are as in ANSI

B16.5 except nickel base alloys are excluded. Pressure-temperature ratings are in accordance

withANSI B165

In 1982, AmericanNational Standards Committee B16 was reorganized as the American

Society of Mechanical Engineers (ASME) B16 Committee operatingunder

procedures

accredited byANSI. Following approval by the Standards Committee and ASME, approval

as an AmericanNational Standard wasgiven by ANSI on June 12, 1990.

This 1996 Edition allows flanges marked with more than onematerial grade or specification,

revises flange facing finish requirements, has revised pressure-temperature ratings for several

material groups, adds permissible flange facing imperfections, adds blindflanges for Series

B flanges, and includes several other revisions. Following approval by the Standards

by ANSI

Committee andASME, approval as an American National Standardwasgiven

on October 3, 1996 withthenew

designation ASME B16.47-1996.

All requests for interpretations or suggestions for revisions should be sent to the Administrative Secretary B16, TheAmerican Society of MechanicalEngineers,Three Park Avenue,

New York, NY 10016-5990.

iii

COPYRIGHT American Society of Mechanical Engineers

Licensed by Information Handling Services

zyxwv

zyxwv

ASME B16 COMMllTEE

Standardization of Valves, Flanges, Fittings, Gaskets, andValve

Actuators

(a)

zyxwvu

zyxwv

(The following is a roster of the Committee at the time of approval of this Standard.)

OFFICERS

W. N. McLean, Chair

R. A. Schmidt, Vice Chair

P. A. Reddington, Secretary

COMMIITEE PERSONNEL

zyxwvutsrqp

W. L. Ballis, Consultant, London, Ohio

R. W. Barnes, Anric Enterprises, Elobicoke, Ontario, Canada

R. R. Brodin, Fisher Controls International, Inc., Marshalltown, Iowa

M. A. Clark, Nibco Inc., Elkhart, Indiana

C. E. Floren, Mueller Co., Decatur, Illinois

D. R. Frikken, Monsanto Co., St. Louis, Missouri

R. Henrich, Minnegasco Inc., Golden Valley, Minnesota

J. C. Inch, Mueller Refrigeration Products Co., Hartsville, Tennessee

G. A. Jolly, Vogt Valve Co., Louisville, Kentucky

W. G. Knecht, Consultant, Williamsport, Pennsylvania

R. A. Koester, The William Powell Co., Cincinnati, Ohio

W. N. McLean, Newco Valve Co., Palos Park, Illinois

M. L. Nayyar, Bechtel Corp., Gaithersburg, Maryland

R. A. Schmidt, Ladish Co., Russellville, Arkansas

H. R. Sonderegger, Grinnel Corp., Cranston, Rhode Island

W. M. Stephan, Flexitallic Inc., Pennsauken, New Jersey

T. F. Stroud, Ductile Iron Research Association, Birmingham, Alabama

M. D. Wasicek, ABS Americas, Houston, Texas

R. E. White, Richard E. White & Associates, South Bend, Indiana

D.A. Wtlliams, Southern Company Services, Birmingham, Alabama

L. A. willis, Dow Chemical Co., Freeport, Texas

W. R. Worley. Union Carbide Corp., South Charleston. West Virginia

PERSONNEL OF SUBCOMMllTEE C

FLANGED FIlTINGS

- STEEL FLANGES AND

D. R. Frikken, Chair, Monsanto Co., St. Louis, Missouri

P. A. Reddington, Secretary, ASME International, New York, New York

V. C. Bhasin, Sigmatech, Pittsburgh, Pennsylvania

G. D. Conlee, Consultant, St. Louis, Missouri

W. C. Farrell, Jr., Consultant, Birmingham, Alabama

M. L. Henderson, Coffer Corp., Houston, Texas

R. E. Johnson, Flowline Div., New Castle, Pennsylvania

R. Koester, The William Powell Co., Cincinnati, Ohio

R. Madewell, FIO-Bendlnc., Sand Springs, Oklahoma

W. N. McLean, Newco Valve Co., Palos Park, Illinois

V

COPYRIGHT American Society of Mechanical Engineers

Licensed by Information Handling Services

zyxwvuts

zyxwvutsrqpo

zyxwvutsrqp

M. L. Nayyar, Bechtel Corp., Gaithersburg, Maryland

R. A. Schmidt, Ladish Co., Russellville, Arkansas

D. L. Shira, Taylor Forge, Cordova, Tennessee

J. C. Thompson, Milwaukee Valve, Rising Sun, Maryland

L. A. Willis, Dow Chemical Co., Freeport, Texas

vi

COPYRIGHT American Society of Mechanical Engineers

Licensed by Information Handling Services

zyx

ASME B1 6.47a-1998

LARGE DIAMETER STEEL FLANGES

1 SCOPE

zyxwvutsrqp

zyxwvutsr

zyxwvuts

zyx

zyxwvutsrq

foroperation at a pressure exceeding the pressuretemperatureratingsinthisStandard.

1.1 General

1.4 Applicable Ratings

ThisStandardcovers

pressure-temperatureratings,

materials, dimensions, tolerances, marking,andtesting

for pipe flanges in sizes N P S 26 through N P S 60 and

in ratings Classes 75, 150, 300, 400, 600, and 900.

Flanges may be cast, forged, or plate (for blind flanges

only) materials, as listed in Table 1A.

Requirements and recommendations

regarding bolting

and gaskets are also included.

The pressure-temperature ratings in this Standard are

applicable upon its publication

to all flanges within its

scope which otherwise meet its requirements. For unused

flangesmaintained in inventory,the manufacturer of

theflangemaycertify

conformance to this Edition,

providedhecan

demonstrate that all requirements of

thisEditionhavebeenmet.

Where such components

were installed in accordance with the pressure-temperature ratings of an earlier edition of this Standard, those

ratingsare applicable, except as maybe governed by

the applicable code or regulation (see para. 1.3.2).

1.2 Flange Series

This Standard provides two series offlangedimensions. Series A specifies flange dimensions for general

use flanges. Series B specifies fiange dimensions for

compact flanges which, ingeneral,have

smaller bolt

circle diameters than Series A flanges. These two series

of flanges are not interchangeable. The usershould

recognize that some flangedvalves,equipmentbolted

between flanges, andflangedequipment

may onlybe

compatible with bolt circle diameter of oneseries of

flanges.

1.5 User Accountability

This Standard cites dutiesand responsibilities that

are to be assumed by the user in the areas of application,

installation, hydrostatic testing, operation, and material

selection.

1.6 Quality Systems

Nonmandatoryrequirements relating to the product

manufacturer’sQualitySystemProgram

are described

in Annex D.

1.3 References

1.3.1 Referenced Standards. Standards and specifications adopted by reference in thisStandardare

shown in Annex E, whichis part of thisStandard. It

is not considered practical to identify the specific edition

of eachstandard andspecification in theindividual

references. Instead, the specificeditionreferenceis

identified in Annex E. A flange manufactured in accordance with earlier editions of thereferenced standards,

andinall other respects conforming tothis Standard,

will beconsidered to be in conformancewiththis

Standard.

2 PRESSURE-TEMPERATURE RATINGS

2.1 Rating Basis

Ratings are maximum allowable working gage pressures, atthe temperaturesshown in Table 2 for the

applicable material and rating. For intermediate temperatures, linear interpolation is permitted. See Annex A for

methods of establishing pressure-temperatureratings.

2.2 Ratings of Flanged Joints

1.3.2 Codes and Regulations. A flangeused

under the jurisdiction of the ASME Boiler and Pressure

Vessel Code (ASME BPV Code), the ASME Code for

Pressure Piping, or a governmental regulation is subject

to any limitation of that code or regulation. This includes

anymaximum temperature limitation, rulegoverning

the use of a material at low temperature, or provisions

A flanged joint iscomposed of three separate and

independent,althoughinterrelated,components:

the

flanges, the gasket, and the bolting, whichare assembled

by yet another influence, the assembler. Proper controls

mustbe exercised in theselectionand application for

all these elements in order to attain a joint which has

1

COPYRIGHT American Society of Mechanical Engineers

Licensed by Information Handling Services

zyxwvutsrqpon

zyxwvutsrqpo

ASME B16.47a-1998

LARGE DIAMETER STEEL FLANGES

zyxwvutsr

2.4.2 Low Temperature Service.Some

ofthe

materialslisted in theratingtablesundergosufficient

decrease intoughness at low temperaturesthat they

cannot safelysustain shock loadings,suddenchanges

of stressortemperature,orhighstressconcentrations.

acceptableleaktightness.Specialtechniquessuchas

controlled bolt tightening may be necessary to achieve

atightjointinservice.

Ratings in this Standard apply to flanged joints which

conform tothelimitationsonboltinginpara.

5.3 and

5.4, andwhicharemadeup

in

ongasketsinpara.

accordance with good practice for alignment and assembly. See alsopara.2.4.Useoftheratingsforflanged

joints not conforming totheselimitations

isthesole

responsibility of theuser.Requirementsforalignment

andassembly of joints are notgiveninthisStandard.

Ifthetwoflangesinaflanged

joint do nothave

the same pressure-temperatureratings,theratingof

the joint at anytemperature is the lower ofthetwo

flangeratings at thattemperature.

2.5 System Hydrostatic Test

Flanged joints may be subjected to system hydrostatic

tests at apressurenot

to exceed 1.5 timesthe 100°F

ratingroundedofftothe

next higher 25 psi.

Testing at anyhigherpressureis

the responsibility

of the user, subject to the requirements of the applicable

code orregulation.

2.6 Welding NeckFlanges

Ratings for carbon steel cylindricallyboredwelding

neckflangescovered by this Standard are basedupon

theirhubs at thewelding end havingathickness

at

least equal to thatcalculatedfor pipe having40.0ksi

specified

minimum

yield

strength.The

ratings

also

apply to such flanges used with components of unequal

strength and unequal wall thickness when the attachment

welds ismadein accordance withtheapplicable code

orregulation. See Figs. 5, 6, and 7.

2.3 Rating Temperature

The temperature shown for a corresponding pressure

ratingisthetemperature

ofthepressurecontaining

shell oftheflange.Ingeneral,thistemperatureisthe

same as thatofthecontainedfluid.

Use of a pressure

rating correspondingtoatemperatureotherthanthat

of the contained fluid is the responsibility of the user,

of theapplicable code or

subject totherequirements

regulation. For any temperature below -20°F the rating

shallbenagreaterthantherating

shown for-20°F.

(a)

zyxwv

2.7 MultipleMaterial

Materials for flanges may meet the requirements for

more than one specification or grade of a specification

listed in Table 1A. In that event, the pressure-temperatureratingsforany

of thesespecificationsorgrades

may be used provided that the marking is in accordance

withpara.4.1.2(d).

2.4 Temperature Considerations

Application of the ratings in this Standard to flanged

joints at bothhighandlowtemperaturesshalltake

into considerationtherisk

of leakage due toforces

andmomentsdeveloped

in theconnectedpipingor

equipment. The followingprovisions are intendedto

minimizethese risks.

3 SIZE

3.1 Nominal Size

The size of aflange covered bythisStandardisits

nominal pipe size (NPS). The diameter of a bolt is its

nominal size. Use ofnominalindicatesthatthestated

size or dimension is only for designation, not measurement. Theactualdimension

may ormaynotbethe

nominalsizeandis

subject toestablishedtolerances.

2.4.1 High Temperature Service. At temperatures in the creep range, gradual relaxation of flanges,

bolts, and gaskets may progressively reduce bolt loads.

It maybenecessary to arrangeforperiodictightening

of bolts to prevent leakage. Joints subject to substantial

thermalgradientsmayrequirethe

same attention.

When used above 400"F, Classes 75 and 150 flanged

joints may develop leakageunlesscareistakento

avoidimposingsevereexternalloadsand/orsevere

thermalgradients.Forotherclasses,similarconsiderationshould be givenabove 750°F.

4 MARKING

4.1 General

Except as modified herein, flangesshall be marked

as required in MSS SP-25.

2

COPYRIGHT American Society of Mechanical Engineers

Licensed by Information Handling Services

Grades

zyxwvutsrqponm

zyx

zyxwvutsr

METER

LARGE

STEEL FLANGES

ASME B16.47a-1998

7.6.2 Center-to-center of adjacent bolt holes, 0.03 in.

7.6.3Eccentricitybetweenbolt

circle diameter and

machinedfacing diameters, 0.06 in.

8 TEST

8.1 Flange Testing

Flanges are not required to be hydrostatically tested.

7

COPYRIGHT American Society of Mechanical Engineers

Licensed by Information Handling Services

wvutsrqponmlkji

LARGEASME B16.47a-1998

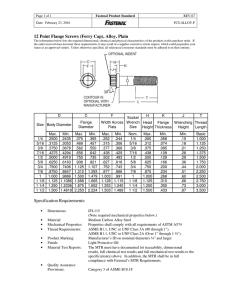

TABLE I A LIST OF MATERIAL

SPECIFICATIONS

(a)

~~

~

~~

Material

Group

Nominal

Designation

c-si

1.I

C-Mn-Si

1

1.2

I

PressureTemperature

Rating Table

2-1‘1

I

C-Mn-Si-V

C-Mn-Si

Plates

Castings

A 515 Gr.70

A 516 Gr. 70

A 537 CI. 1

A 216 Gr. WCB

LF2 Gr.

I

I

2-1.2 A 216 Gr. WCC

A 352 Gr. LCC

A 350 Gr. LF6 CL2

A 203 Gr. B

A 203 Gr. E

A 352 Gr. LC2

A 352 Gr. LC3

A 350 Gr. LF3

c-si Gr. LCB

352

C-Mn-Si

2’/2Ni

3’/2Ni

A

I

Forgings

CI.1

LF6

Gr.

350A

C-Mn-Si-V

2’/2Ni

3%Ni

1.3

Applicable ASTM Specifications’

2-1.3

I

A 515 Gr. 65

A 516 Gr. 65

A 203 Gr. A

A 203 Gr. D

~~

2-1.4c-si

C-Mn-Si A 350 Gr.

1.4

I

1.5

1.7

2-1.5

A 182 Gr. F I

2-1.7

1

1.13

A 204 Gr. C

A 217 Gr. WC4

A 217 Gr. WC5

182 Gr. F12 Cl. 2

A 217 Gr. WC6

A 387 Gr. 11 CI. 2

182 Gr. F11 CI. 2

21/4Cr-1 MO

Gr. F22 CI. 3

5Cr-1í*Mo

A 204 Gr. A

A 204 Gr. B

A 182 Gr. F2

1Cr-’/ZMo 2-1.9 A

1’/4Cr-’/~Mo

11/4Cr-1/zMo-SiA

1.10

A 217 Gr. WC1

A 352 Gr. LC1

C-’/~MO

C-Y~MO

1í2Cr-1/2Mo

Ni-’/~Cr-~/2Mo

3/4Ni-3/‘Cr-l M o

1.9

A 515 Gr. 60

A 516 Gr. 60

LFI Cl. 1

2-1.13 A

2-1.10

A 217 Gr. WC9 A 182

A 387 Gr. 22 C1.2

182 Gr. F5

A 182 Gr. F5a

A 217 Gr. C5

~

~~

~

1. I 4

~~

2-1.14

9Cr-1 Mo

9Cr-1Mo-V

A 182 Gr. F9

182

1.15

2-2.1

Gr.

A 217 Gr. C12

F91

2-1.15

A 217 Gr. C12A A

182 Gr. F304

182 Gr. F304H

A 351 Gr. CF3 A

A 351 Gr. CF8 A

A 35116Cr-12Ni-2Mo

Gr. CF3M

A 182 Gr. F316 2-2.2

2.2

A 182 Gr. F316H A 351

Gr. CFBM

18Cr-13Ni-3Mo

19Cr-1 ON¡-3Mo A

2.3

18Cr-8Ni

2.4 A

COPYRIGHT American Society of Mechanical Engineers

Licensed by Information Handling Services

A 387 Gr. 91 CL2

A 240 Gr. 304

A 240 Gr. 304H

A 240 Gr. 316

A 240 Gr. 316H

A 240 Gr. 317

351 Gr. CG8M

A

A

182

182

Gr.

Gr.

F304L

F316L

182 Gr. F321

A 182 Gr. F321H

2-2.3

16Cr-12Ni-2Mo

2-2.4

18Cr-ION¡-Ti

A 240 Gr. 304L

A 240 Gr. 316L

A 240 Gr. 321

A 240 Gr. 321 H

METER

LARGE

ASME B16.47a-1998

TABLE

LIST

1A

(a)

Material

Group

Nominal

Designation

zy

OF MATERIAL

SPECIFICATIONS

(CONT'D)

Applicable ASTM Specifications'

PressureTemperature

Rating Table

2.5

18Cr-1ONi-Cb

2-2.5

2.6

25Cr-12Ni

2-2.6

Forgings

A

A

A

A

182 Gr. F347

182 Gr. F347H

182 Gr. F348

182 Gr. F348H

Plates

Castings

A 351 Gr. CF8C

A

A

A

A

240 Gr. 347

240 Gr. 347H

240 Gr. 348

240 Gr. 348H

A 351 Gr. CH8

A 351 Gr. CH20

A 240 Gr. 309s

A 240 Gr. 309H

23Cr-12Ni

2.7

25Cr-20Ni

2-2.7

2.8

20Cr-18Ni-6Mo

22CrSNi-3Mo-N

25Cr-7Ni-4Mo-N

24Cr-1ONi4Mo-V

25Cr-5Ni-2Mo-3Cu

25Cr-7Ni-3.5Mo-W-Cb

25Cr-7Ni-3.5Mo-N-Cu-W

2-2.8

NOTE:

A 182 Gr. F310

A 351 Gr. CK20

A 240 Gr. 310s

A 240 Gr. 310H

A 351 Gr. CK3MCuN A 182 A

Gr.240

F44Gr. S31254

A 240 Gr. S31803

A 240 Gr. S32750

A 182 Gr. F51

A 182 Gr. F53

A 351 Gr. CE8MN

A 351 Gr. CD4MCu

A 351 Gr. CD3MWCuN

zyxwvutsrqp

A 182 Gr. F55

A 240 Gr. S32760

(1) ASME Boiler and Pressure

Vessel Code, Section II materials, whichalso meet the requirementsof the listed ASTM specifications, may also be used.

9

COPYRIGHT American Society of Mechanical Engineers

Licensed by Information Handling Services

wvutsrqponmlkji

zyxwvutsr

zyxwvut

zyxwvutsrqpo

R

LARGEASME B16.47a-1998

TABLE1B

LIST OF BOLTINGSPECIFICATIONS

Applicable ASTM Specifications”

Bolting Materials’

High Strength (2)

Spec.-Gr.

Notes

A 193-B7

A 193-BI6

.,.

A 320-L7

A 320-L7A

A 320-L7B

320-L7C

A

320-L43

A

A 354-BC

A 354-BD

A 540-B21

A 540-B22

A 540-B23

A 540-B24

...

(6)

(6)

(6)

(6)

(6)

Low Strength (4)

Intermediate Strength (3)

Spec.-Gr.

193-85

193-86

193-B6X

193-B7M

...

A 193-88 Cl. 2

193-B8C

A Cl.

2

A 193-B8M CI. 2

A 193-B8T

Cl.

2

(7)

A

A

A

A

Spec.-Gr.

Notes

...

...

...

A

A

A

A

193-B8 Cl. 1

193-B8C Cl. 1

193-B8M CI. 1

193-B8T Cl. 1

(7)

(7)

A 193-B8A

A 193-B8CA

A 193-B8MA

A 193-B8TA

(7)

A 307-B

(71

(7)

A 320-88 Cl.

(7)

Notes

...

...

...

...

...

A

A

A

A

A

320-B8 Cl.

320-B8C

Cl.

320-B8F

Cl.

320-B8M

Cl.

320-B8T

Cl.

2

2

2

2

2

(7)

(7)

...

A 449

(9)

A 453-651

A 453-660

(10)

(1O)

1

A 320-B8C Cl. 1

A 320-B8M Cl. 1

A 320-B8T CI. 1

GENERAL NOTE:

Bolting material shall not be used beyond temperature limits specified in the governing code.

NOTES:

(1) Repair welding of bolting material is prohibited.

(2) These bolting materials may be used with all listed materials and gaskets.

(3) These bolting materials may be used with all listed materialsand gaskets, provided it has

been verified that a sealed joint can be maintained under rated working pressure and

temperature.

(4) These bolting materials may be used with all listed materials but are limited to Class 150

and Class 300 joints. See para. 5.4.1 for recommended gasket practices.

but strainhardened.

(5) This austenitic stainless material has been carbide solution treated not

Use A 194 nuts of corresponding material.

(6) This ferritic materialis intended for low temperature service.Use A 194 Gr.4 or Gr. 7 nuts.

(7) This austenitic stainless material has been carbide solution treated and strain hardened.

Use A 194 nuts of corresponding material.

(8) This carbon steel fastener shall not be used above 400°F or below -20°F. See also Note

(4). Bolts with drilled or undersized heads shall not be used.

(9) Acceptable nuts for use with quenched and tempered bolts are A 194 Gr. 2 and Gr. 2H.

Mechanical property requirements for studs shall be the same as those for bolts.

(IO)

This special alloy is intended for high temperature service with austenitic stainless steel.

(11) ASME Boiler and Pressure Vessel Code, Section II materials, which also meet the requirements of the listed ASTM specifications, may also be used.

zyxwvu

10

COPYRIGHT American Society of Mechanical Engineers

Licensed by Information Handling Services

zyxwvut

zyxwv

zyxw

m

S T D = A S M E B L b = q 7 A - E N G L L798

METER

0757b70 OLlr8Y3L 7 T 4

LARGE

ASME B16.47a-1998

TABLES 2 PRESSURE-TEMPERATURE RATINGS FOR GROUPS 1.1

THROUGH 2.8 MATERIALS

TABLE 2-1.1 RATINGS FOR GROUP 1.1 MATERIALS

Nominal

Designation

Castings

c-si

A 105 (1)

C-Mn-Si

A 350 Gr. LF2 (1)

C-Mn-Si-V

A 350 Gr. LF6 Cl. 1 (4)

Plates

Forgings

A 216 Gr. WCB (1)

A 515 Gr. 70 (1)

A 516 Gr. 70 (1)(2)

A 537 Cl. 1 i3)

zyxwvutsrqpo

zyxwv

zyxwvuts

zyxwv

NOTES:

(1) Upon prolonged exposure to temperatures above 800°F. the carbide phase of steel may be

converted to graphite. Permissible, but not recommended for prolonged use above 800°F.

(2) Not to be used over 850°F.

(3) Not to be used over 700°F.

(4) Not to be used over 500'F.

WORKING PRESSURES BY CLASSES, psi!

. .J

600

900

1480

1350

2220

2025

1970

1900

1795

Class Temp., 'F

75

150

300

-20 to 100

200

300

400

500

140

130

115

1O0

85

285

260

740

675

200

170

600

900

875 655

845 635

800

70

60

140

125

110

95

80

550

535

535

505

41O

730

715

710

670

550

1095

1075

1065

1010

825

65

50

35

270

170

105

20

50

355

230

140

70

535

345

205

105

600

650

700

750

800

850

900

950

1O00

...

...

...

...

...

...

...

230

11

COPYRIGHT American Society of Mechanical Engineers

Licensed by Information Handling Services

400

990

1270

1200

1640

1610

1600

1510

1235

805

515

310

155

1315

vutsrqponmlkji

zyxwvut

LARGE ASME B16.47a-1998

TABLE 2-1.2 RATINGS FOR GROUP 1.2 MATERIALS

(a)

Nominal

Designation

Castings

Plates

Forgings

A 216 Gr. WCC (1)

A 352 Gr. LCC (2)

A 350 Gr. LF6 C-Mn-Si-V

CI. 2 (3)

C-Mn-Si

2’4Ni

A 350 Gr. LF3

3%Ni

A 352 Gr. LC2

A 203 Gr. B (1)

A 352 Gr. LC3

A 203 Gr. E (1)

NOTES:

(1) Upon prolonged exposure to temperatures above 800°F, the carbide phase of steelmay be

converted to graphite. Permissible, but not recommended for prolonged use above 800’F.

(2) Not to be used over 650°F.

(3) Not to be used over 500OF.

zyxwvuts

zyxwvu

zyx

WORKING PRESSURES BY CLASSES. mia

75

150

300

400

600

-20 to 100

200

300

400

500

145

130

115

1O0

85

290

260

230

200

750

750

730

705

665

1O00

1000

1500

170

600

650

700

750

800

70

60

140

605

590

125

...

110

Class Temp.,

850

900

950

1O00

OF

1455

940

...

...

...

80

41O

65

50

35

20

270

170

105

50

12

COPYRIGHT American Society of Mechanical Engineers

Licensed by Information Handling Services

2250

2250

970 2185

21 15

1995

1500

1410

1330

1815 1210

1765 1175

1705 1135

1010 670 1510

505 95

825 550 1235

...

...

...

900

355

230

140

70

345

205

805 535

51 5

31O

155 105

885

805

785

755

570

zyxwvutsrqponm

zy

STEEL U R G E DIAMETER

ASME B16.47a-1998

TABLE 2-1.15

Nominal

Designation

MeV

Class Temp., 'F

-20 to 100

200

300

400

500

600

650

700

750

800

850

900

950

1O00

1050

1100

1150

1200

RATINGS FOR GROUP 1.15 MATERIALS

(a)

zyxwvuts

zyxwvuts

zyxwvutsrqp

zyxwvu

Plates

Castings

Forgings

A 387 Gr. 91 Cl. 2

A 182 Gr. F91 9Cr-1 A 217 Gr. C12A

400

600

900

750

290

750

260

230 115 730

705

200

665

170

1O00

1O 0 0

970

940

885

1500

1500

2250

2250

21 85

21 15

1995

605

590

570

530

51O

805

785

755

710

675

75

150

145

130

1O0

85

70

60

...

...

...

...

...

...

...

...

...

...

...

300

140

125

110

95

80

65

50

35

20

...

...

...

...

485

650

515

485

480

300

225

145

400

295

190

20.1

COPYRIGHT American Society of Mechanical Engineers

Licensed by Information Handling Services

600

450

385

365

360

1410

1330

1815

1210

1765

1175

1135 1705

1065 1595

1015

1525

1460

1350

1160

1O90

1080

975

900

775

725

720

605

445

290

905

670

430

1455

zyxwv

zyxw

~

STD.ASME BLh.47A-ENGL

STEEL LARGE DIAMETER

1778

m

zyxwvutsrqponmlkjihgfedcba

0757b70 DhLO434 b03

m

ASME B16.47a-1998

FLANGES

TABLE 2-2.7 RATINGS FOR GROUP 2.7 MATERIALS

Nominal

Designation

25Cr-20Ni

zyxwvuts

zyxw

Plates

Forgings

Castings

A 182 Gr. F310 (1)(3)

A 351 Gr. C U 0 (1)

A 240 Gr. 310s (1)(2)(3)

A 240 Gr. 310H

NOTES:

(1) At temperatures over lOOO'F, use only when the carbon content is 0.04% or higher.

(2) For temperatures above 1000°F. use only if the material is heat treated by heating it to a

temperature of at least 1900°F and quenching in water or rapidly cooling by other means.

(3) Service temperaturesof 1050°Fand above should beused only when assurance is provided

that grain size is not finer thanASTM 6.

WORKING PRESSURES BY CLASSES, psig

.~

Class Temp., OF

75

150

300

400

600

900

-20 to 100

200

300

400

500

130

115

110

1O0

85

260

235

220

200

170

670

570

535

505

895

81O

760

715

675

1345

1215

1140

1070

1015

2015

1820

1705

1605

1520

70

60

140

125

110

95

80

480

470

455

450

435

640

625

61O

600

580

960

935

91o

900

875

1440

1405

1370

1345

1310

65

50

35

20

425

420

385

345

335

570

555

515

460

450

855

835

775

685

670

1280

1255

1160

1030

1010

260

190

135

105

75

345

250

185

135

1O0

520

375

275

205

150

780

565

41O

31O

225

60

45

35

80

60

45

35

115

90

65

50

175

135

1O0

75

600

650

700

750

800

850

900

950

1O00

1050

1100

1150

1200

1250

1300

1350

1400

1450

1500

...

...

...

...

...

...

...

...

...

...

...

...

...

...

...

...

...

605

...

.

f

.

...

...

...

...

...

...

...

...

zyxwv

25

21

COPYRIGHT American Society of Mechanical Engineers

Licensed by Information Handling Services

zyxwvuts

zyxwvuts

zyxw

LI70

*STD.ASflE BLb.47A-ENGL

ASME B16.47a-1998

m

0757b7fl ObLB'i35 5 4 T

FLANGES

llpl

STEEL LARGE DIAMETER

TABLE 2-2.8 RATINGS FOR GROUP 2.8 MATERIALS

(a)

Nominal

Designation

Forgings

Castings

Plates

20Cr-18Ni-6Mo

A 182 Gr. F44

22Cr-5Ni-3Mo-N

A 182 Gr. F51

A 240 Gr. S31803 (1)

25Cr-7Ni-4Mo-N

A 182 Gr. F53

A 240 Gr. S32750 (1)

A 240 Gr. S31254

A 351 Gr. CK3MCuN

24Cr-lONi-4Mo-V

A 351 Gr. CE8MN (1)

25Cr-5Ni-2Mo-3Cu

A 351 Gr. CD4MCu (1)

25Cr-7Ni-3.5Mo-W-Cb

A 351 Gr. CD3MWCuN (1)

25Cr-7Ni-3.5Mo-N-Cu-W

A 240 Gr. S32760 (1)

4 182 Gr. F55

NOTE:

(1) This steel may become brittle after service at moderately elevated temperatures. Not

to be

used over 600°F.

zyxwvu

zyxwvutsrq

WORKING PRESSURES BY CLASSES, psig

Class Temp., "F

-20 to 100

200

300

400

500

600

650

700

750

75

150

1O0

85

750 290 1

145

O00

260 130 720

960

230 115 665

200

615

820

170

575

770

70

60

.. .

...

300

140

125

110

95

555

550

540

28

COPYRIGHT American Society of Mechanical Engineers

Licensed by Information Handling Services

600

400

1500

1440

1330

1230

1150

740

735

1115

710

530

1100

1065

900

2250

2160

885 1995

1845

1730

1670

1650

1625 1085

1595

725

zyxwvutsrqponm

zyx

AMETER

STEEL FLANGES

LARGE

ASME B16.47a-1998

zyxwv

TABLE 12 DIMENSIONS OF CLASS 300 SERIES B FLANGES’+

1

2

O. D.

of

Nominal

Pipe

Size

60

r

3

Thickness of

Flange, Min.’

Flange

M F

O

C

73.94

4

0.69

5.94

Blind

C

5

6

7

8

Length

Through

Hub

Diam.

of

Hub8

Diams

fop

Raised

Face

Diam.

A

R

Y

X

119

Hub

r

Diam.

of Bolt

Circle

12

10

Drilling

No. of

Bolt

Holes

of Bok

Hole

2.38

6.56

Diam.

of

Bolt

13

Fillet

Radius

Diam.

Min.

r1

zyxw

40

2%

69.44

(Notes follow Table 15)

41

COPYRIGHT American Society of Mechanical Engineers

Licensed by Information Handling Services

65.00

60.3

zyxwvut

zyxwvuts

zyx

S T D * A S M E BLb-LI7A-ENGL 1778 E 0 7 5 7 b 7 l l Ob18437 312 I

A S M E B16.47a-1998

DIAMETER

LARGE

zyxwvutsrqp

zyxwvut

TABLE 13 DIMENSIONS OF CLASS 400 SERIES

B

(a)

1

2

I

3

36

Thickness of

Flange,

Min.’

45.50

I

38

...

40

...

I

WNF

...

...

...

...

I

...

...

...

...

I

Hub

Diams

lop

37.50

I

8

7

I

Diam.

of

7.88

4.69

I

I

Length

Through

Hub8

Hub

Blind

4.69

I

6

S

4

l

O. D.

of

Flange

Pipe

STEEL FLANGES

9

...

...

10

I

Raised

Face

Diam.

No. Of

Bolt

Diam.

of Bolt

42.00

I

I

f

.

.

...

11

Drilling

38.62

36.00

I

FIANGES’4*’o

...

...

28

I

...

...

*..

...

...

...

...

...

...

...

...

13

Diarn.

Fillet

Radius

Min.

1 - 4I

Diam.

r?

0.44

zyx

zyxw

zyx

...

60

12

I

I

...

1

...

l

(Notes follow Table 15)

42

COPYRIGHT American Society of Mechanical Engineers

Licensed by Information Handling Services

zyxwvutsrqponm

zyxwvutsrq

zyx

METER

STEEL FLANGES

LARGE

ASME 816.47a-1998

TABLE 14 DIMENSIONS OF CLASS 600 SERIES B FIANGES'-6,'o

1

2

4

5

7

8

Diam.s

TOP

Raised

Face

Diam.

X

A

R

27.50

26.00

7.12

28.62

4.38

6

12

13

Drilling

Fillet

Diam.

NO. Of

Diam.

Diam.

of Bolt

Bott

Holes

of Bolt

of

Radius

Min.

Hole

Bolt

r1

28

31.75

1.75

178

0.50

1.88

28

13/4

0.50

2.00

17/8

0.50

9

10

11

zyxwvutsrqpo

zyxwv

O. D.

of

Nominal

Pipe

Size

26

3

Thickness of

Flange, Min.'

mange

WNF

O

C

4.38

C

Diam.

Length

of

Through

Hub8

Hub Blind

r

35.00

Hub

Circle

28

37.50

7.50

4.56

28.00

4.56

29.62

30.88

34.00

30

40.25

8.06

31.75

5.00

4.94

33.12

36.50

30.00

32

33.88

5.12

34

45.75

36

47.75

5.68

5.75

...

38

42.75

8.50

5.56

9.19

9.56

5.94

28

5.31

2.12

28

2

0.50

38.75

37.50

41.50

34.00

24

36.00

2.38

2'/4

0.56

39.75

43.50

36.00

38.12

28

2.38

2'/4

0.56

...

...

...

...

...

...

...

...

...

...

...

...

......

...

...

...

...

...

...

...

...

...

...

...

...

...

...

...

...

...

...

...

...

...

40

...

42

...

...

...

...

...

...

60

...

...

...

...

...

35.25

(Notes follow Table 75)

43

COPYRIGHT American Society of Mechanical Engineers

Licensed by Information Handling Services

32.00

zyxwvutsrqp

zyxwvutsrqp

ASME B16.47a-1998

LARGE DIAMETER STEEL FLANGES

zyxwvutsrq

zyxwvuts

TABLE 15 DIMENSIONS OF CLASS 900 SERIES B FLANGES1b, lo

(a)

1

Nominal

Pipe

Size

2

3

4

Thickness of

Flange, Min.'

5

6

Diam.

of

Hube

X

O. D.

of

Flange

WNF

Blind

Length

Through

Hub

O

C

C

Y

26

6.06

43.50

528

.81

6.12

46.50

6.93

32

6.31

748.75

.31

6.75

7.68

34

51.75

36

53.00

38

...

...

...

40

...

...

60

...

...

8

9

Diam.

of

Bolt

13

Fillet

Radius

Min.

rl

2.62

35.50

38.25

28.00

20

2.88

274

0.50

40.75

34.50

20

3.12

30.00

333.50

11.38

0.50

43.00

36.50

20

3.12

3

0.50

39.00

45.50

34.00

37.88

20

3.38

3'/4

0.56

12.81

7.94

47.25

6.81

40.50

24

3.12

36.00

3

0.56

...

..

...

...

...

...

*

...

.*.

...

...

...

...

...

...

...

32.25

32.00

11.94

12.56

40.00

12

11

20

6.56

31.38

35.75

10

Hub

Raised

Drilling

'

Diam.s Face

Diam. No.

Diam.

of

Diam.

of Bolt

Bolt

of Bolt

A

R

Hole

Holes Circle

10.19 40.25

5.31

10.88

30

7

...

...

...

...

...

...

...

...

...

...

...

30.00

2'12

0.44

26.00

...

zyxw

zyxw

...

(Notes follow on next page)

44

COPYRIGHT American Society of Mechanical Engineers

Licensed by Information Handling Services

29.25

...

zyx

zyxwvutsrqpo

LARGE DIAMETER STEEL FLANGES

(a)

ASME

ASME B16.47-1996

zyxwvutsrqp

zyxw

The -American Society of Mechanical Engineers

Three Park Avenue, New York, New York 10016-5990

ASME Order Department

22 Law Dnve, Box 2300, Fairfield, New Jersey 07007-2300

(a)

ASTM

MSS

American Society for Testing and Materials

100 Barr Harbor Drive, West Conshohocken, Pennsylvania 19428-2959

Manufacturers Standardization Society of the Valve & Fittings Industry

127 Park Street, N.E., Vienna, Virginia 22180

IS0 documents are available from ANSI. Publications appearing above which have been approved

National Standards may also be obtained from ANSI.

ANSI

American National Standards Institute, Inc.

11 West 42nd St., New York, New York 10036

59

COPYRIGHT American Society of Mechanical Engineers

Licensed by Information Handling Services

as American

zyxwvu

~~

S T D - A S t l E BLb*Y7A-ENGL 1778

zyxwvutsrqponmlkjihgfedcbaZYXWVUTSRQPONMLKJIHGFE

0757b70 Ob18441 843

m

INTERPRETATIONS TO ASME B16.47

(These interpretations are not part of ASME 816.47-1996 and areincludedfor information only. These interpretations

apply to the 1988 and earlier editions and the requirements cited may be different in this Edition. Therefore, some

replies may not be valid in regard to this Edition.)

INTRODUCTION

zyxwvutsrq

As a service to persons whousethe

B16 standards, the B16 Committee rendersinterpretations

in

the requirements upon request. The procedure for requesting an interpretationisdescribed

following paragraphs.

been approved by the B16 MainCommittee

The interpretations include all replieswhichhave

response to inquiries concerning interpretation of this Standard.

An interpretation applies either to the Edition and Addenda in effect on the date of issuance of

in theinterpretation.Subsequentrevisionstothis

interpretation or the Edition andAddendastated

Standard may supersede the interpretation.

of

the

in

the

PROCEDUREFOR REQUESTING INTERPRETATIONS

On request, the B16 Committee will render an interpretation of anyrequirement of this Standard.

Interpretations canonly be renderedinresponse

to a writtenrequest,whichshouldbeaddressedto:

zyxwvutsrq

zyxwvuts

zy

zyxwvutsrqpo

Secretary, B16 Main Committee

The American Society of MechanicalEngineers

T h r e e Park Avenue

New York, NY 10016-5990

The request for interpretation should be clear and unambiguous. It is further recommended that the

inquirer submit his request usingthefollowingformat:

(a) Subject. Cite the applicable paragraph number(s) and/or give a concise description of the subject.

(b) Question. Phrase the question as a request for an interpretation of a specific requirement suitable

for general understanding and use, not as a request for an approval of a proprietary design or situation.

The inquirer may also include anyplans ordrawings whicharenecessary

to explainthe question;

however, they should notcontainproprietarynames

or information.

Requests which are notinthisformatmayberewritten

in thisformatpriortobeing

answered,

whichmay inadvertently change theoriginalintent of the request.

ASME procedures provide for reconsideration of an interpretation when or if additional information

is available which the inquire believesmight affect theinterpretation.Further,personsaggrieved

by

an interpretation may appeal to thecognizantASME

committee or subcommittee. ASME does not

“approve,” “certify,” “rate,” or “endorse”anyitem, construction, proprietary device, or activity.

61

COPYRIGHT American Society of Mechanical Engineers

Licensed by Information Handling Services

zyxwvutsrqp

816.47 interpretations No. 2

2-1

INTERPRETATIONS NO. 2

zy

zyx

zyxw

Replies to Technical Inquiries Issued from January 1, 1996 Through December 31, 1997

Interpretation: 2-1

Subject:

Series A Flanges

Date Issued:

April 30, 1997

File:

B 16-96-013

Question: According to ASME B16.47-1990, may Series A flanges be manufactured and used for all

materials listed in Table IA?

Reply: Yes, within the restriction of General Note (b) of Table 1A.

65

COPYRIGHT American Society of Mechanical Engineers

Licensed by Information Handling Services

S T D - A S M E BLb.47A-ENGL

COPYRIGHT American Society of Mechanical Engineers

Licensed by Information Handling Services

zyxwv

zy

1778 9 0 7 5 9 6 7 0 Ob18443 b l b

COPYRIGHT American Society of Mechanical Engineers

Licensed by Information Handling Services

The American Society of

Mechanical Engineers

A N

A M E R I

C A N A T I O N A S

L T A N D A R D

z

LARGE DIAMETER

STEEL FLANGESz

-

"-v

NPS 26 Through NPS 60

ASME B16.47-1MUM

(Revision of ASME B16.47-1990)

COPYRIGHT American Society of Mechanical Engineers

Licensed by Information Handling Services

zyxwvuts

z

S T D - A S M E BLb-47-ENGL L77b

m

0757b70 0 5 7 7 L b U q 7 T H

Date of Issuance: January 31, 1997

zyxw

The 1996 edition of this Standard is being issued with an automatic addenda

subscription service. The useof an addendaallows revisions made in response

to public reviewcomments or committee actions to be published as necessary;

revisions published in addenda will become effective 6 months after the Date

of Issuance of the addenda. The next edition of this Standard is scheduled for

publication in 2001.

ASME issues written replies to inquiries concerning interpretations of technical

aspects of this Standard. The interpretations will be included with the above

addenda service. Interpretations are not part of the addenda to the Standard.

ASME is the registeredtrademark of The American Society of Mechanical Engineers.

This code or standard was developed under procedures accreditedas meeting the criteria for

American NationalStandards. The ConsensusCommittee that approved the code

or standard was

balanced t o assure that individuals from competent and concerned interests have had

an

opportunity to participate. The proposed code or standard was made available for public review

and comment which providesan opportunity for additional public inputfrom industry, academia,

regulatory agencies, and the public-at-large.

ASME does not "approve," "rate," or "endorse" any item,

construction, proprietary device, or

activity.

ASME does not take any position with respect to the validity of any patent rights asserted in

connection with any items mentionedin this document, and does not undertaketo insure anyone

utilizing a standardagainst liability for infringement of any applicable LettersPatent, nor assume

any such liability. Users of a code or standard are expressly advised that determination of the

validity of any such patentrights, and the riskof infringement of such rights, is entirely their own

responsibility.

Participation by federal agency representative(s) orperson(s) affiliated with industry

is not to be

interpreted as government or industry endorsementof this code or standard.

ASME acceptsresponsibility for only those interpretations issued

in accordance with governing

ASME procedures and policies which preclude theissuance of interpretations by individual

volunteers.

zyxwvutsrqp

No part of this documentmay be reproduced in any form,

in an electronic retrieval system or otherwise,

without the prior written permissionof the publisher.

The American Society of Mechanical Engineers

345 East 47th Street, New York, NY 10017

Copyright Q 1997 by

THE AMERICAN SOCIETY OF MECHANICAL ENGINEERS

All Rights Reserved

Printed in U.S.A.

COPYRIGHT American Society of Mechanical Engineers

Licensed by Information Handling Services

FOREWORD

(This Foreword is not part of ASME 616.47-1996.)

zyxwv

In November, 1980, a task force was appointed within Subcommittee C of the American

National Standards (ANSI)B16Committee to developastandard for pipeflangesin size

NPS26throughNPS48.Everyattemptwasmade

to standardize those dimensionsthat

existedwithintheindustry

for the materialscoveredbyANSIB16.5.

Prompted by suggestions received from committee members, the task force was authorized

toincrease the sizerange to NPS60. The firstdraftwasdevelopedinDecember

1982 to

include Class 75 throughClass 1500 forthe size rangeNPS26throughNPS

60. Hange

dimensions were basedontheManufacturersStandardizationSociety

Standard Practice

(MSS SP)44 flangesexcept for Class 75 flangeswhich are ANSUAPI 605 flanges.

At the request of the American Petroleum Institute (API), flange dimensions in accordance

with the API Standard 605 were included in the subsequent drafts. Class

1500 flanges were

deleted due to lack of interest in using large size flanges in that pressure-temperature rating.

The APL605flanges for Classes 150 and 300 and for sizes NPS 36 andsmaller for

classes higherthan Class 300 are notcompatiblewiththe

MSS SP-44flanges.Thus, the

MSS SP-44 flanges are designated as Series A flanges and the API-605 flanges are designated

this Standard are as inANSI

as Series B flanges in this Standard. Materialscoveredin

B16.5 except nickel base alloys are excluded. Pressure-temperature ratings are in accordance

withANSI B16.5.

In 1982,AmericanNationalStandardsCommitteeB16wasreorganized

as theAmerican

Society of Mechanical Engineers(ASME)

B16 Committeeoperatingunderprocedures

accredited by ANSI. Following approval by the Standards Committee and ASME, approval

asanAmericanNationalStandardwasgiven

by ANSIon June 12,1990.

This 1996 Edition allows flanges marked with more thanone material grade or specification,

revises flange facing finish requirements, has revised pressure-temperature ratings for several

material groups, adds permissible flange facing imperfections,

adds blind flanges for Series

Bflanges,and

includes several otherrevisions.Followingapprovalby

the Standards

CommitteeandASME,approval

as anAmericanNationalStandardwasgiven

by ANSI

onOctober 3, 1996withthenewdesignation

ASME B16.47-1996.

All requests for interpretations or suggestions for revisions should be sent to the AdministrativeSecretaryB16,

The AmericanSociety of MechanicalEngineers,UnitedEngineering

Center, 345East47th

Street, New York, NY 10017.

zyx

...

zyxwvutsrq

111

COPYRIGHT American Society of Mechanical Engineers

Licensed by Information Handling Services

zyxwv

ASME B16 Committee

Standardization of Valves, Flanges, Fittings, Gaskets, and Valve

Actuators

(The following is a roster of the Committeeat the time of approval of this Standard.)

OFFICERS

W. N. McLean, Chair

zyxwvu

R. A. Schmidt, Vice Chair

K. M . Ciciora, Secretary

COMMITTEE PERSONNEL

W. L. Ballis, Columbia Gas Distribution Co., Columbus, Ohio

R. R. Brodin, Fisher Controls International, Inc., Marshalltown, Iowa

M. A. Clark, Nibco Inc., Elkhart, Indiana

A. Cohen, Copper Development Association, Inc., New York, New York

W. C. Farrell, Jr., Consultant, Birmingham, Alabama

C. E. Floren, Mueller Co., Decatur, Illinois

D. R. Frikken, Monsanto Co., St. Louis, Missouri

M. W. Garland, Frick Co., Waynesboro, Pennsylvania

J. C. Inch, Mueller RefrigerationProducts Co., Hartsville, Tennessee

G. A. Jolly, The Henry Vogt Machine Co., Louisville, Kentucky

W. G. Knecht, Consultant, Williamsport, Pennsylvania

R. A. Koester, The William Powell Co., Cincinnati, Ohio

W. N. McLean, Newco Valve Co., Palos Park, Illinois

M. L. Nayyar, Bechtel Corp., Gaithersburg, Maryland

R. A. Schmidt, Ladish Co., Russellville, Arkansas

W. M. Stephen, Flexitallic Inc., Pennsauken, New Jersey

T. F. Stroud, Ductile Iron Research Association, Birmingham, Alabama

M. D. Wasicek, ABS Americas, Houston, Texas

R. E. White, Richard E. White b Associates, South Bend, Indiana

D. A. Williams, Southern Company Services, Birmingham, Alabama

L. A. Willis, Dow Chemical Co., Freeport, Texas

W. R. Worley, Union Carbide Corp., South Charleston, West Virginia

PERSONNEL OF SUBCOMMITTEE C

FLANGED FllTlNGS

- STEEL FLANGES AND

D. R. Frikken, Chair, Monsanto Co., St. Louis, Missouri

K. M. Ciciora, Secretary, ASME International, New York, New York

V. C. Bhasin, Sigmatech, Pittsburgh, Pennsylvania

G. D. Conlee, Consultant, St. Louis, Missouri

W. C. Farrell, Jr., Consultant, Birmingham, Alabama

M. L. Henderson, Coffer Corp., Houston, Texas

R. E. Johnson, Flowline Div., New Castle, Pennsylvania

R. Koester, The William Powell Co., Cincinnati, Ohio

R. Madewell, Flo-Bend Inc., Sand Springs, Oklahoma

W. N. McLean, Newco Valve Co., Palos Park, Illinois

V

COPYRIGHT American Society of Mechanical Engineers

Licensed by Information Handling Services

zyxwvutsr

zyxwvut

M. L Nayyar, Bechtel Corp., Gaithersburg, Maryland

R. A. Schmidt, Ladish Co., Russellville, Arkansas

D. L. Shira, Taylor Forge, Cordova, Tennessee

J. C.Thompson, Milwaukee Valve, Rising Sun, Maryland

L. A. Willis, Dow Chemical Co., Freeport, Texas

vi

COPYRIGHT American Society of Mechanical Engineers

Licensed by Information Handling Services

zyxw

zyxwvutsrq

CONTENTS

Foreword .......................................................................

Standards CommitteeRoster ......................................................

1 scope ....................................................................

2 Pressure-Temperature Ratings ..............................................

3 Size ......................................................................

4 Marking ..................................................................

Materials

5

.................................................................

6 Dimensions ...............................................................

7 Tolerances ................................................................

8 Test ......................................................................

zyx

zyx

Figures

1WeldingEnds(WeldingNeckFlanges.

No BackingRings):Bevel

for

Wall Thicknesses r from 0.19 in . to 0.88 in.,Inclusive ...................

2 Welding Ends (WeldingNeckFlanges.

No BackingRings):Bevel

for

Wall Thicknesses t Greater Than 0.88 in .................................

3 WeldingEnds(WeldingNeckFlangesWithBackingRings):

Inside

Contour for UseWithRectangularBackingRing

.........................

4 WeldingEnds(WeldingNeckFlangesWithBackingRings):Inside

Contour for UseWith Taper BackingRing ...............................

5 WeldingEnds(WeldingNeckFlanges):Additional

Thickness for

Welding to Higher Strength Pipe.Bevel for OutsideThickness ............

6 Welding Ends (WeldingNeckFlanges):Additional

Thickness for

Welding to Higher Strength Pipe.Bevel for Inside Thickness .............

7 WeldingEnds(WeldingNeck

Flanges): Additional Thickness for

Welding to HigherStrength Pipe. Bevel for Combined Thickness . . . . . . . . . .

iii

V

zyxw

Tables

1A List of Material Specifications .............................................

1B List ofBoltingSpecifications

..............................................

2 Pressure-TemperatureRatingsfor

Groups 1.1 through 2.8 Materials . . . . . . . . . .

3 Dimensions of Ring-JointFacings

..........................................

4 FlangeBolting DimensionalRecommendations

..............................

5Dimensions

of Class 150 Series A Flanges .................................

6 Dimensions of Class 300 Series A Flanges .................................

7 Dimensionsof Class400 Series A Flanges .................................

8 Dimensions of Class 600 Series A Flanges .................................

9 Dimensions of Class900 Series A Flanges .................................

10 Dimensions of Class75 Series BFlanges

..................................

11 Dimensions of Class150 SeriesBFlanges

.................................

vii

COPYRIGHT American Society of Mechanical Engineers

Licensed by Information Handling Services

31

31

32

32

33

33

33

8

10

11

29

30

34

35

36

37

38

39

40

12

13

14

15

16

zyxwvu

zyxwvut

zyxwvutsr

zy

Dimensions of Class 300 Series B Flanges .................................

Dimensions of Class 400 Series B Flanges .................................

Dimensions of Class 600Series B Flanges .................................

Dimensions of Class 900 Series B Flanges .................................

Permissible Imperfections in Flange Facing Finish ..........................

41

42

43

44

46

Annexes

A

Methods for Establishing Pressure-Temperature Ratings .....................

B

Gaskets (Other Than Ring-Joint) ...........................................

C

Method for Calculating Bolt Lengths .......................................

D

Quality System Program ...................................................

E

References ................................................................

47

51

53

55

57

Figures

Gasket Groups and Typical Materials .......................................

Cl Specified Stud-Bolt Length ................................................

52

53

Tables

A l Rating Ceiling Values .....................................................

C l F Values .................................................................

C2 n Values ..................................................................

49

53

53

B1

zyxwvutsrqp

zyxwvuts

Interpretations

...............................................................

viii

COPYRIGHT American Society of Mechanical Engineers

Licensed by Information Handling Services

61

zyxwvut

~~

STD-ASME BLb.47-ENGL L99b

m

zyxwvutsrqponmlkjihgfe

~

0 7 5 9 b 7 0 0 5 7 9 L b b 908 H

ASME 816.47-1996

LARGE DIAMETER STEEL FLANGES

1

SCOPE

1.1 General

zyxwvutsrqp

zyxwvutsrq

zyxwvuts

for operationat a pressureexceedingthepressuretemperatureratingsin this Standard.

1.4ApplicableRatings

ThisStandardcovers

pressure-temperatureratings,

materials, dimensions, tolerances, marking, and testing

for pipe flanges in sizes NPS 26 through N P S 60 and

in ratings Classes 75, 150, 300, 400, 600, and 900.

Flanges may be cast, forged, or plate (for blind flanges

only) materials, as listed in Table 1A.

Requirements and recommendations regarding bolting

and gaskets are also included.

The pressure-temperature ratings in this Standard are

applicable upon its publication to all flanges within its

scope which otherwise meet its requirements. For unused

flangesmaintainedin

inventory, themanufacturerof

theflangemaycertify

conformance to this Edition,

providedhecan

demonstrate thatallrequirements

of

thisEditionhavebeenmet.Wheresuchcomponents

were installed in accordance with the pressure-temperature ratings of an earlier edition of this Standard, those

ratings are applicable, except as may be governedby

theapplicable code or regulation (see para. 1.3.2).

1.2FlangeSeries

This Standardprovidestwo series of flangedimensions. Series A specifies flange dimensions for general

useflanges. Series B specifies flange dimensionsfor

compact flangeswhich,in

general, havesmallerbolt

circle diameters than Series A flanges. These two series

offlangesarenot

interchangeable. The usershould

recognize thatsomeflangedvalves,equipmentbolted

betweenflanges,andflangedequipmentmayonlybe

compatible withbolt circle diameter ofone series of

flanges.

1.5UserAccountability

ThisStandard cites duties andresponsibilities that

are to be assumedby the user in the areasof application,

installation, hydrostatic testing, operation, and material

selection.

1.6 QualitySystems

Nonmandatory requirements relating to the product

manufacturer’sQuality System Programaredescribed

inAnnex D.

1.3 References

1.3.1 Referenced Standards. Standards and specificationsadoptedby

reference inthisStandard

are

showninAnnexE,whichispartofthisStandard.It

is not considered practical to identify the specific edition

ofeachstandardandspecificationinthe

individual

references. Instead, the specificeditionreference

is

identified in Annex E. A flange manufactured in accordance with earlier editions of the referencedstandards,

andinall other respects conforming to this Standard,

will beconsideredto

bein

conformance withthis

Standard.

2 PRESSURE-TEMPERATURE RATINGS

2.1 RatingBasis

Ratings are maximum allowable working gage pressures, at the temperatures shownin Table 2 for the

applicable material and rating. For intermediate temperatures, linear interpolationispermitted.

S e e Annex A,

which is part of this Standard, for methods of establishingpressure-temperatureratings.

1.3.2CodesandRegulations.

A flange

used

under the jurisdiction of the ASME Boiler and Pressure

Vessel Code (ASME BPV Code), the ASME Code for

Pressure Piping, or a governmental regulation is subject

to any limitation of that code or regulation. This includes

anymaximum temperature limitation, rulegoverning

the use of a material at low temperature, or provisions

2.2 RatingsofFlangedJoints

A flanged joint iscomposed of three separate and

independent,althoughinterrelated,components:the

flanges, the gasket, and thebolting, which are assembled

by yet another influence, the assembler. Proper controls

mustbeexercisedinthe

selection andapplication for

1

COPYRIGHT American Society of Mechanical Engineers

Licensed by Information Handling Services

ASME B16.47-1996

zyxwvutsrqpon

LARGE DIAMETER STEEL FLANGES

zyxwvut

zy

2.4.2 Low Temperature Service. Some of the

materials listed inthe rating tables undergosufficient

decrease intoughness at lowtemperaturesthatthey

cannot safelysustain shock loadings,sudden changes

of stress or temperature, or high stress concentrations.

all these elements in order to attain a joint which has

acceptable leaktightness. Special techniques such as

controlled bolt tightening may be necessary to achieve

a tight joint in service.

Ratings in this Standard apply toflanged joints which

conform to the limitations on bolting inpara. 5.3 and

on gaskets in para. 5.4, andwhicharemade

up in

accordance with good practice for alignment and assembly. See also para. 2.4. Use of the ratings

for flanged

joints not conformingto these limitations isthesole

responsibilityoftheuser,Requirements

for alignment

and assembly of joints are not given in this Standard.

If the two flangesinaflanged

jointdo nothave

the same pressure-temperature ratings, the rating of

the joint at any temperature is the lower of the two

flangeratings at thattemperature.

2.5 System Hydrostatic Test

Flanged joints may be subjected to system hydrostatic

tests ata pressure notto exceed 1.5times the 100°F

ratingrounded off to thenexthigher

25 psi.

Testing at any higher pressure is the responsibility

of the user, subject to the requirements of the applicable

code or regulation.

2.6 Welding NeckFlanges

Ratings for carbon steel cylindrically bored welding

neck flanges covered by this Standard are basedupon

their hubsattheweldingendhavinga

thickness at

least equal to that calculated for pipe having 40.0 ksi

specifiedminimumyield

strength. The ratings also

apply to such flanges used with components of unequal

strength and unequal wallthickness when the attachment

welds is madein accordance withthe applicable code

or regulation. See Figs. 5, 6, and 7.

2.3 Rating Temperature

zyxw

The temperature shown for a corresponding pressure

ratingis the temperature of the pressure containing

shell oftheflange. In general,thistemperature is the

same as that of the contained fluid. Use of a pressure

ratingcorresponding to a temperature other thanthat

of the contained fluid is the responsibility of the user,

subject to the requirements ofthe applicable code or

regulation. For any temperature below -20°F the rating

shall beno greater thantheratingshown

for -20°F.

2.7 MultipleMaterial Grades

Materials for flanges may meet the requirements for

more than one specification or grade of a specification

listed in Table 1A. In that event, the pressure-temperatureratingsforanyof

these specifications or grades

may be used provided that the marking is in accordance

withpara.4.1.2(d).

2.4 Temperature Considerations

Application of the ratings in this Standard to flanged

joints both highandlow temperatures shall takeinto

consideration the riskof leakagedueto

forces and

moments developed in the connected piping or equipment. The following provisions are intended to minimize

these risks.

3 SIZE

3.1 Nominal Size

The size of a flange covered by this Standard is its

nominal pipe size (NPS). The diameter of a bolt is its

nominal size. Use of nominal

indicates that the stated

size or dimension is only for designation, not measurement. The actual dimension may or maynotbethe

nominal size andis subject to established tolerances.

2.4.1High Temperature Service.Attempemtures in the creep range, gradual relaxation of flanges,

bolts, and gaskets may progressively reduce bolt loads.

It may be necessary to arrange for -periodic tightening

of bolts to prevent leakage. Joints subject to substantial

thermal gradientsmayrequire

the same attention.

When used above 400°F, Classes 75 and 150 flanged

joints may developleakage unless care istaken to

avoidimposing

severe external loads andor severe

thermal gradients. For other classes, similarconsiderationshould be given above 750 F.

4 MARKING

4.1 General

zyxw

Except as modified herein, flanges shall bemarked

as requiredin MSS SP-25.

zyxwvutsrq

.T

L

COPYRIGHT American Society of Mechanical Engineers

Licensed by Information Handling Services

~

zyxwvuts

zyxwvutsrqp

zyxwvutsrqponmlkjihgfedcbaZYXWVUTSRQPONMLKJIHGFEDCBA

~

L 7 7 b H 0 7 5 7 b 7 0 0 5 7 9 L b 8 780

S T D - A S M E BLb.47-ENGL

zyxwvutsr

zyxwvuts

zyxwvutsrqp

LARGE DIAMETER STEEL FLANGES

ASME B16.47-1996

4.1.1 Name. The manufacturer’sname or trademark

shall be applied.

in Table1B. (See also para.5.3.) The ASME Boiler

and Pressure Vessel Code, Section II materials, which

also meet the requirements of the specifications listed

in Table 1, may also beused.

4.1.2 Materials

( a ) Cast flanges shall bemarkedwiththeASTM

specification’, grade identification symbol, and the melt

numberidentification or meltidentification.

( b ) Plate flanges and forged flanges shall be marked

with the ASTM specification number and grade identification symbol.

( c ) A manufacturer may supplement these mandatory

material indications withhistradedesignation

for the

materialgrade,but

confusion of symbols shall be

avoided.

(d) Flanges manufactured from material which meets

the requirements for morethanone

specification or

grade of a specification listed in Table 1Amaybe

marked with more than one of the applicable specification or grade symbols. The symbols shall beplaced

to avoidconfusioninidentification.

5.1.1 Application. Criteria for the selection of materialsarenotwithin

the scope of this Standard. The

possibility of material deterioration in service should

be considered by the user. Carbidephaseconversion

to graphite and excessive oxidation of femtic materials

or susceptibility to intergranular corrosion of austenitic

materials are among those items requiring attention. A

detailed discussion of precautionary considerations can

be found inAppendix F ofASMEB31.3.

5.1.2 Toughness. Some of the materials listedin

Table 1Aundergo a decrease intoughnesswhenused

at low temperatures, to the extent that codes referencing

this Standard may require impact tests

for applications

evenattemperatures

higher than +20”F. It is the

responsibility of the user to assure that such testing is

performed.

4.1.3 Rating Class. The marking shall be the applicable pressurerating class: 75 (Series B only), 150,

300, 400, 600, or 900.

5.1.3 Responsibility. When service

conditions dictate the implementation of special material requirements,