M.G. Contractors Pvt. Ltd.

MGCPL/SITE/HSR-PKG1B/2023/1883

DATE 23/01/2023

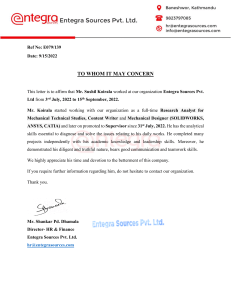

To,

Chief Contracts Manager,

TCEL-CEGL-AARVEE ASSOCIATE- PADECO JV

A-204, 2nd floor, Swatisk Universal,

Opposite Central Mall, Dumas Road,

New Magdalla, Piplod, Surat,

Gujarat – 395007.

Sub: Construction of Bridges for Double Line High Speed Railway for 04 No. PSC Bridges

(GAD 9, 10, 11 & 1441) and 07 No. Steel Truss Bridges (GAD 68, 1134, 12, 61, 14, 15

& 62) [excluding fabrication and transportation of steel truss girders] between Zaroli

Village at Maharashtra-Gujarat Border (MAHSR Km. 156.600) and Vadodara

(MAHSR Km. 393.700), in the State of Gujarat and the Union Territory of Dadra and

Nagar Haveli for the Project for Construction of Mumbai-Ahmedabad High Speed Rail

Package No. MAHSR-P-1(B)

“Submission of Drawing, ITP, Mix Design & Casting Methodology of Noise

Barrier.”

Dear sir,

With reference to the cited subject, we are herewith submitting Drawing, ITP, mix design and

casting methodology of Noise Barrier provided by our approved vendor M/s Fuji Silvetech

Pvt Ltd.

Vendor have already approved these documents for similar nature of work in another package

of MAHSR.

Kindly review the enclosed documents and accord approval as possible early so that

production of noise barriers can be expedite.

Thanking you & assuring you our best services at all the time.

For M.G. Contractors Pvt. Ltd.

(Ritesh Kumar Sinha)

Authorized Signatory

Encl.: - 1. Drawings

2. Casting Methodology

3. ITP

4. Mix Design with supportive documents

Head Office: M.G. House, Plot No- 376 Industrial Area Phase- 2, Panchkula – 134112 (Haryana), Tel: 0172-6731000, 6731025

Regd. Office: # 603, Ring Road Mall, Deepali Chowk, Sector – 3, Rohini, New Delhi – 110085 Tel: 011-47019300, Fax 011-43852385

CIN No.: U70101DL1997PTC091013, E-mail: mgcpl@mgcpl.com website: mgcpl.com

LEGAL NOTES

This drawing is the property of Fuji Silvertech Concrete Pvt. Ltd. and

must not be passed on to any third person or firm not authorized by us,

not be copied/made use of in full or part by such person or firm

without our prior permission in writing.

NOTES

1.

Top view

2.

996

C6

15

16

3.

Wall side detail

C6

S=1/10

200

80

170

996

50

200

250

5

90

A - A

996

2110

C6

C6

C6

2400

2092

B

2110

2400

1998.2

B

C6

200

LIFTING HOLE-B

115

15

16

50

LCX HOLE

250

A

C6

100 280

600

C6

LIFTING HOLE-B

2400

50

φ14

LIFTING HOLE-A

100

A

100 280

100

6

130

130

1.7

LCX HOLE

600

250

15

16

C6

120

φ14

LIFTING HOLE-A

40

250

φ14

Side view

D

5

Front view

15

110

C6

D - D

50 LIFTING HOLE-A

R3

C6

C6

130

250

200

C6

6.

16

250

107.5 55 87.5

5 45 5

Side view

250

420

5.

ALL DIMENSIONS ARE IN MM UNLESS NOTED

OTHERWISE ONLY WRITTEN DIMENSION SHALL BE

FOLLOWED. NO DIMENSION SHALL BE SCALED.

THIS DRAWING IS APPLICABLE FOR ONLY PRECAST

NOISE BARRIER.

ALL CONCRETE WILL BE PRECAST AT PLANT UNDER

SPECIFIED MIXING AND CURING CONDITION. GRADE OF

CONCRETE SHALL BE M50.

REINFORCEMENT BAR SHALL BE TMT BARS

CONFIRMING TO IS 1786-GRADE FE-500/FE-550D.

REINFORCEMENT SHALL BE BENT AND FIXED AT PLANT

UNDER SPECIFIED CONDITIONS

B - B

996

15

C6

200 220

140

248

420

259

130

250

250

LCX HOLE

S=1/10

S=1/10

248

160

103

80

35

30

35

25

60

7

790

C6

103

220 200

C - C

420

996

φ14

75

S=1/10

72

φ14

00

12.01.2023

REV.

DATE

PT

ISSUED FOR APPROVAL

DESCRIPTION

APPROVED

RELEASE FOR

15

FOR PRELIMINARY

FOR CONSTUCTION

FOR INFORMATION

WITH DESIGN SUBMISSION

FOR REVIEW

AS BUILT

CLIENT

M G CONTRACTORS PVT LTD.

PROJECT

9080

656

Mumbai-Ahmedabad High Speed Rail Project

(Package No. MAHSR-P-1(B))

(Package No. MAHSR-P-1(C))

8090

JICA Letter JICA(ID) JFY2021, 4R-0133 dated 14th October 2021

DESIGNER

S=1/10

FUJI SILVERTECH CONCRETE PVT. LTD.

4TH FLOOR, HOUSE NO. 5,

MAGNET CORPORATE PARK,

NEAR SOLA FLYOVER, S.G. HIGHWAY,THALTEJ,

AHMEDABAD-380 054

Website : http://www.fujisilvertech.com

35

30

10

35

60

80

LIFTING HOLE-B

30

155

160

155

LIFTING HOLE-A

20

30

Anchor hole

776

104

420

D

120

11

19 11

DEHA 1.3t-120

340

7

103

420

80

160

12

C6

104

DEHA 1.3t-120

C

220 200

C6

160

160 30

80

C

160 80 30

200

80

16

DRAWING TITLE:

15

DIMENSIONS DETAIL OF

NOISE BARRIER TYPE-A (996 WIDE)

(Size = 996 x 2400 x 420)

DRAWN:

ASP

CHECKED:

SK

DATE:

12.01.2023

APPROVED:

PT

SCALE:

NTS

DRAWING NO.

FSC-MGC-MAH-PNB-SEC-001

Rev. No.

00

LEGAL NOTES

This drawing is the property of Fuji Silvertech Concrete Pvt. Ltd. and

must not be passed on to any third person or firm not authorized by us,

not be copied/made use of in full or part by such person or firm

without our prior permission in writing.

NOTES

1.

2.

Side view

Front view

3.

A - A

250

35

95

A

95

5.

H1 SD10

S1 SD16

6.

S1 SD16

H2 SD10

858

270

H2 SD10

35

100

50

A

W1

55

H2 SD10

926

40

T1 SD10

130

50

40

H2 SD10

250

100

40

55

ALL DIMENSIONS ARE IN MM UNLESS NOTED

OTHERWISE ONLY WRITTEN DIMENSION SHALL BE

FOLLOWED. NO DIMENSION SHALL BE SCALED.

THIS DRAWING IS APPLICABLE FOR ONLY PRECAST

NOISE BARRIER.

ALL CONCRETE WILL BE PRECAST AT PLANT UNDER

SPECIFIED MIXING AND CURING CONDITION. GRADE OF

CONCRETE SHALL BE M50.

REINFORCEMENT BAR SHALL BE TMT BARS

CONFIRMING TO IS 1786-GRADE FE-500/FE-550D.

REINFORCEMENT SHALL BE BENT AND FIXED AT PLANT

UNDER SPECIFIED CONDITIONS

H2 SD10

56

884

56

996

S1 SD16

H2 SD10

45

200

200

884

42

75 56

80

H3 SD10

T1 SD10

length(mm)

250

884

200

42

75

56

996

quantity

S1

SD16

2330

4

1.580

14.726

H1

SD10

2530

2

0.617

3.122

H2

SD10

1160

3

0.617

2.147

H3

SD10

1180

6

0.617

4.368

T1

SD10

350

6

0.617

1.296

T2

SD10

450

4

0.617

1.111

4mm

2290

13

0.099

2.947

4mm

930

31

0.099

2.854

°

100

weight(kg)

kg/m

13

5

1

SIZE(mm)

200

24

No

75

°

56

135

42

996

Rebar Quantity Table

T2 SD10

74

100

250

S1 SD16

137

420

60

420

55

C

T2 SD10

42 200

56 75

340

H1 SD10

265 100

100 265

50

55

160

60

H1 SD10

H3 SD10

C - C

858

H3 SD10

C

150

S1 SD16

T1 SD10

H1 SD10

50

T1 SD10

35

W1

55

S1 SD16

926

100

2200

2400

2110.0

858

35

H3 SD10

50

W1 φ4

926

13

12x@75=900

13

00

12.01.2023

REV.

DATE

PT

ISSUED FOR APPROVAL

DESCRIPTION

APPROVED

RELEASE FOR

FOR PRELIMINARY

FOR CONSTUCTION

FOR INFORMATION

WITH DESIGN SUBMISSION

FOR REVIEW

AS BUILT

Rebar weight

SD16

14.726

SD10

12.044

4mm

5.801

32.571 kg

2290

W1

29x@75=2175

CLIENT

M G CONTRACTORS PVT LTD.

PROJECT

Mumbai-Ahmedabad High Speed Rail Project

(Package No. MAHSR-P-1(B))

(Package No. MAHSR-P-1(C))

JICA Letter JICA(ID) JFY2021, 4R-0133 dated 14th October 2021

60 55

2400

W1

T1 SD10

B - B

B

2330

B

DESIGNER

FUJI SILVERTECH CONCRETE PVT. LTD.

4TH FLOOR, HOUSE NO. 5,

MAGNET CORPORATE PARK,

NEAR SOLA FLYOVER, S.G. HIGHWAY,THALTEJ,

AHMEDABAD-380 054

Website : http://www.fujisilvertech.com

DRAWING TITLE:

REINFORCEMENT DETAIL OF

NOISE BARRIER TYPE-A (996 WIDE)

(Size = 996 x 2400 x 420)

DRAWN:

ASP

CHECKED:

SK

DATE:

12.01.2023

APPROVED:

PT

SCALE:

NTS

DRAWING NO.

FSC-MGC-MAH-PNB-SEC-002

Rev. No.

00

LEGAL NOTES

This drawing is the property of Fuji Silvertech Concrete Pvt. Ltd. and

must not be passed on to any third person or firm not authorized by us,

not be copied/made use of in full or part by such person or firm

without our prior permission in writing.

Top view

NOTES

1.

996

16

C6

200

φ14

LIFTING HOLE-A

250

5

996

C6

C6

C6

2400

2105.8

B

2105.8

2400

1998.2

B

15

16

C6

200

LIFTING HOLE-B

115

2400

90

A - A

50

LCX HOLE

250

LIFTING HOLE-B

A

C6

100 280

600

C6

100

A

100 280

100

130

130

LCX HOLE

600

50

ALL DIMENSIONS ARE IN MM UNLESS NOTED

OTHERWISE ONLY WRITTEN DIMENSION SHALL BE

FOLLOWED. NO DIMENSION SHALL BE SCALED.

THIS DRAWING IS APPLICABLE FOR ONLY PRECAST

NOISE BARRIER.

ALL CONCRETE WILL BE PRECAST AT PLANT UNDER

SPECIFIED MIXING AND CURING CONDITION. GRADE OF

CONCRETE SHALL BE M50.

REINFORCEMENT BAR SHALL BE TMT BARS

CONFIRMING TO IS 1786-GRADE FE-500/FE-550D.

REINFORCEMENT SHALL BE BENT AND FIXED AT PLANT

UNDER SPECIFIED CONDITIONS

16

C6

120

250

15

50

996

40

170

5

80

φ14

LIFTING HOLE-A

6.

110

250

φ14

Side view

D

15

250

107.5 55 87.5

5 45 5

Front view

1.7

R3

D - D

50 LIFTING HOLE-A

3.

5.

130

250

200

S=1/10

16

C6

C6

C6

C6

Side view

2.

Wall side detail

200

250

300

C6

15

B - B

996

15

C6

DEHA 1.3t-120

220

248

250

100

103

30

25

60

155

LIFTING HOLE-B

120

C6

103

996

φ14

75

S=1/10

72

φ14

15

00

12.01.2023

REV.

DATE

PT

ISSUED FOR APPROVAL

DESCRIPTION

APPROVED

RELEASE FOR

200

LIFTING HOLE-A

20

790

7

FOR PRELIMINARY

FOR CONSTUCTION

FOR INFORMATION

WITH DESIGN SUBMISSION

FOR REVIEW

AS BUILT

CLIENT

100

S=1/10

D

S=1/10

776

C - C

200

300

LCX HOLE

7

104

248

300

160

155

130

250

300

300

Anchor hole

140

103

265

164.2

164.2

80

100

35

200

C6

30

104

DEHA 1.3t-120

C

35

C6

C

160 80 30

265 5.1

200

80

16

M G CONTRACTORS PVT LTD.

PROJECT

Mumbai-Ahmedabad High Speed Rail Project

(Package No. MAHSR-P-1(B))

(Package No. MAHSR-P-1(C))

S=1/10

JICA Letter JICA(ID) JFY2021, 4R-0133 dated 14th October 2021

10

160

80

FUJI SILVERTECH CONCRETE PVT. LTD.

4TH FLOOR, HOUSE NO. 5,

MAGNET CORPORATE PARK,

NEAR SOLA FLYOVER, S.G. HIGHWAY,THALTEJ,

AHMEDABAD-380 054

Website : http://www.fujisilvertech.com

35

30

35

60

80

30

DESIGNER

15

DRAWING TITLE:

DIMENSIONS DETAIL OF

NOISE BARRIER TYPE-B (996 WIDE)

(Size = 996 x 2400 x 300)

DRAWN:

ASP

CHECKED:

SK

DATE:

12.01.2023

APPROVED:

PT

SCALE:

NTS

DRAWING NO.

FSC-MGC-MAH-PNB-SEC-003

Rev. No.

00

LEGAL NOTES

This drawing is the property of Fuji Silvertech Concrete Pvt. Ltd. and

must not be passed on to any third person or firm not authorized by us,

not be copied/made use of in full or part by such person or firm

without our prior permission in writing.

NOTES

1.

Side view

Front view

A - A

2.

250

35

95

55

A

S1 SD16

H1 SD10

5.

858

6.

95

H2 SD10

56

884

56

996

S1 SD16

45

200

T1 SD10

884

H3 SD10

42

75 56

42

200

75

56

250

884

200

42

75

74

56

SD16

2330

4

1.580

14.726

H1

SD10

2320

2

0.617

2.863

H2

SD10

1160

3

0.617

2.147

H3

SD10

820

6

0.617

3.036

T1

SD10

350

6

0.617

1.296

T2

SD10

450

4

0.617

1.111

4mm

2290

13

0.099

2.947

4mm

930

31

0.099

2.854

W1

Rebar weight

SD16

14.726

SD10

10.453

4mm

5.801

137

926

Detail

S=1/10

13

12x@75=900

13

00

12.01.2023

REV.

DATE

PT

ISSUED FOR APPROVAL

DESCRIPTION

APPROVED

RELEASE FOR

S1 SD16

H3 SD10

T1 SD10

H1 SD10

13

20

10

2290

S1

100

W1 4mm

weight(kg)

29x@75=2175

kg/m

60 55

quantity

50 60 54.2

length(mm)

5°

1

SIZE(mm)

13

24

Rebar Quantity Table

°

996

No

T2 SD10

T1 SD10

135

996

80

300

200

220

S1 SD16

145100

60

300

250

H1 SD10

55

C

T2 SD10

42 200

56 75

H3 SD10

100

100145

50

55

50

H1 SD10

C - C

858

H3 SD10

C

164.2

60 54.2

T1 SD10

858

S1 SD16

H1 SD10

H3 SD10

35

150

926

W1

55

S1 SD16

H2 SD10

100

2400

2200

35

2105.8

T1 SD10

B - B

B

2330

B

W1

2400

S1 SD16

200

H2 SD10

35

H2 SD10

100

50

130

40

50

A

926

W1

40

T1 SD10

H2 SD10

250

100

H2 SD10

40

55

3.

ALL DIMENSIONS ARE IN MM UNLESS NOTED

OTHERWISE ONLY WRITTEN DIMENSION SHALL BE

FOLLOWED. NO DIMENSION SHALL BE SCALED.

THIS DRAWING IS APPLICABLE FOR ONLY PRECAST

NOISE BARRIER.

ALL CONCRETE WILL BE PRECAST AT PLANT UNDER

SPECIFIED MIXING AND CURING CONDITION. GRADE OF

CONCRETE SHALL BE M50.

REINFORCEMENT BAR SHALL BE TMT BARS

CONFIRMING TO IS 1786-GRADE FE-500/FE-550D.

REINFORCEMENT SHALL BE BENT AND FIXED AT PLANT

UNDER SPECIFIED CONDITIONS

FOR PRELIMINARY

FOR CONSTUCTION

FOR INFORMATION

WITH DESIGN SUBMISSION

FOR REVIEW

AS BUILT

CLIENT

M G CONTRACTORS PVT LTD.

PROJECT

Mumbai-Ahmedabad High Speed Rail Project

(Package No. MAHSR-P-1(B))

(Package No. MAHSR-P-1(C))

JICA Letter JICA(ID) JFY2021, 4R-0133 dated 14th October 2021

DESIGNER

FUJI SILVERTECH CONCRETE PVT. LTD.

4TH FLOOR, HOUSE NO. 5,

MAGNET CORPORATE PARK,

NEAR SOLA FLYOVER, S.G. HIGHWAY,THALTEJ,

AHMEDABAD-380 054

Website : http://www.fujisilvertech.com

30.980 kg

DRAWING TITLE:

REINFORCEMENT DETAIL OF

NOISE BARRIER TYPE-B (996 WIDE)

(Size = 996 x 2400 x 300)

DRAWN:

ASP

CHECKED:

SK

DATE:

12.01.2023

APPROVED:

PT

SCALE:

NTS

DRAWING NO.

FSC-MGC-MAH-PNB-SEC-004

Rev. No.

00

MUMBAI-AHMEDABAD HIGH SPEED RAIL (MAHSR)

DI No.

Version No.

Date

1.0

22.07.2022

METHOD STATEMENT FOR OPERATIONS

FOR NOISE BARRIER

Last updated: 20.01.2023

Fuji Silvertech concrete Private Limited

MUMBAI-AHMEDABAD HIGH SPEED RAIL (MAHSR)

DI No.

Version No.

Date

1.0

22.07.2022

Contents

1.1

Purpose ....................................................................................................................................... 1

1.2

Scope ........................................................................................................................................... 1

1.3

Work Scope ................................................................................................................................. 1

1.4

The Organizational Chart ............................................................................................................ 2

1.5

Raw Material ............................................................................................................................... 3

1.6

Factory Layout ............................................................................................................................ 4

1.7

Machineries and Equipment in Production Plant ..................................................................... 10

2.0

Operations Process Flowchart .................................................................................................. 11

3.0

Mould Line Drawing .................................................................................................................. 27

4.0

Concrete mix design Conformance ........................................................................................... 28

5.0

Truck Loading Drawing.............................................................................................................. 29

6.0

Annexure: .................................................................................................................................. 33

6.1

Annexure: Demoulding and handling stresses ......................................................................... 33

6.2

Checklist (Rev 01) ...................................................................................................................... 40

Fuji Silvertech concrete Private Limited

MUMBAI-AHMEDABAD HIGH SPEED RAIL (MAHSR)

DI No.

Version No.

Date

1.0

22.07.2022

1.1 Purpose

The objective of the Manual is to establish the procedure for timely and consistent

operation for precast concrete noise barrier segments and ensure that all works will

be carried out safely and in accordance with client requirements and specifications.

1.2 Scope

This Method Statement covers the procedure for production planning, production and

post-production activities such as handling and stacking of precast noise barrier

products for producing precast finished noise barrier products manufactured by FUJI

Silvertech Concrete Pvt. Ltd. (FSC).

1.3 Work Scope

The National High Speed Rail Project –consists of 508 km total Mumbai- Ahmedabad

high speed rail (MAHSR) and connects Ahmedabad and Mumbai.

Eight variants of noise barriers are part of the scope. These consist of four Type A and

four Type B variants. The main difference between Type A and Type B is the base width

being 420 mm in Type A and 300 mm in Type B. The four variants vary in panel width

which are 700 mm (696 mm actual), 750 mm (746 mm actual), 900 mm (896 mm

actual) and 1000 mm (969 mm actual).

Activities including raw material procurement, batching, transportation, pouring and

curing of concrete, rebar placement, moulding and demoulding, handling at plant and

stacking in stockyard and quality testing and inspection are within scope of FUJI

Silvertech. All activities except rebar cage manufacture and third party quality testing

will be carried out in the factory premises of FUJI Silvertech Concrete Pvt. Ltd.

Page |1

Fuji Silvertech concrete Private Limited

MUMBAI-AHMEDABAD HIGH SPEED RAIL (MAHSR)

DI No.

Version No.

Date

1.0

22.07.2022

1.4 The Organizational Chart

VP Sales

Sales Team

Design Head

Managing Director

R&D Head

Quality Head

Production Manager

QualityTeam

Production Plant

in-charge

Plant Director

Environment Health and Safety

Office (EHS)

Page |2

Fuji Silvertech concrete Private Limited

Production Team

MUMBAI-AHMEDABAD HIGH SPEED RAIL (MAHSR)

DI No.

Version No.

Date

1.0

22.07.2022

1.5 Raw Material

Sr

No.

Source

Material

Product Name

1

Ultratech Cement Limited

Cement

OPC 53 Gr

2

JSW Steel

Steel

Fe500D (Rev 01)

3

Master Builder Solutions

Admixture

Master Glenium ACE 8761

4

Sayla

Coarse Aggregate

6 / 10 / 18 mm

5

Sand, Vill Metal, Tal Bavla

Sand

Sand

6

RO Water

Water

Water

Page |3

Fuji Silvertech concrete Private Limited

MUMBAI-AHMEDABAD HIGH SPEED RAIL (MAHSR)

DI No.

Version No.

Date

1.0

22.07.2022

1.6 Factory Layout

LEGEND

Ⓖ

Ⓗ

Ⓓ

Ⓓ

Ⓐ

Ⓕ

Ⓒ Ⓑ

Ⓕ

Ⓔ

Ⓒ

Ⓐ

Ⓑ

Ⓐ

Material Storage

Ⓑ

Ⓒ

Silo Plant

Ⓓ

Concrete

Collection

Ⓕ

Concrete

Transfer path

Noise Barrier

Stacking Area

Ⓗ

Fuji Silvertech concrete Private Limited

Mould Location

Ⓔ

Ⓖ

Page | 4

Batching Plant

Dispatch Way

MUMBAI-AHMEDABAD HIGH SPEED RAIL (MAHSR)

DI No.

Version No.

Date

1.0

22.07.2022

Ⓐ

Ⓐ

Plant 2 Material Storage

Plant 1 Material

Storage

Page | 5

Fuji Silvertech concrete Private Limited

MUMBAI-AHMEDABAD HIGH SPEED RAIL (MAHSR)

DI No.

Ⓑ

Ⓒ

Ⓑ

Ⓑ

Version No.

Date

1.0

22.07.2022

Ⓒ

Ⓑ

Ⓑ

Ⓑ

Plant 2 Batching

Plant and Silo Plant

Plant 1 Batching

Plant and Silo Plant

Page | 6

Fuji Silvertech concrete Private Limited

MUMBAI-AHMEDABAD HIGH SPEED RAIL (MAHSR)

DI No.

Ⓓ

Version No.

Date

1.0

22.07.2022

s

Ⓓ

Plant 2 Mould Location

Plant 1 Mould Location

Page | 7

Fuji Silvertech concrete Private Limited

MUMBAI-AHMEDABAD HIGH SPEED RAIL (MAHSR)

DI No.

Version No.

Date

1.0

22.07.2022

Concrete Collection, Concrete transfer path and Pouring

Page | 8

Fuji Silvertech concrete Private Limited

MUMBAI-AHMEDABAD HIGH SPEED RAIL (MAHSR)

DI No.

Version No.

Date

1.0

22.07.2022

Ⓖ

Ⓗ

Noise Barrier Stacking Area

Dispatch way

Page | 9

Fuji Silvertech concrete Private Limited

MUMBAI-AHMEDABAD HIGH SPEED RAIL (MAHSR)

DI No.

Version No.

Date

1.0

22.07.2022

1.7 Machineries and Equipment in

Production Plant

Sr. No.

Category

Capacity

Numbers

1

Cranes

2.5 T, 3 T, 5T, 10 T, 20 T

6

2

Boilers

850 , 600 Btu/hour

7

3

Forklift

3 T – 16 T

13

4

Batching Plant

60 cum, 120 cum

2

5

Concrete Distribution

and Transportation

2 cum

1

Sr. No.

1

2

3

4

5

6

7

8

P a g e | 10

Equipment and Machineries

Clamp handle for mold opening/closing

Spanners

Scrapers mold cleaning

EOT crane

Sling 2.5 tonne

Deha clamp for lifting/rotating

Wooden plank for stacking

Fork lift for transportation

Fuji Silvertech concrete Private Limited

MUMBAI-AHMEDABAD HIGH SPEED RAIL (MAHSR)

DI No.

2.0

Version No.

Date

1.0

22.07.2022

Operations Process Flowchart

(1) Space Allocation

(2) Mold Preparation

Page | 11

1.1 The spaces shall be allocated to mould based on the production plan by the production manager.

1.2 The production team shall ensure that the spaces are clean before production. The space is to be

free from raw material powder, concrete chips, wooden elements, metal elements, plastic

elements and other scrap. The space is to be free from lying water.

1.3 The helmets, tools, tackles and accessories are to be in their designated spaces / shelves / racks /

containers. The space is to be free from safety hazards such as open wiring, oil leakage, low

hanging crane belts or piercing metal pieces or rebars.

1.4 The EHS shall to carry out safety inspection of production area before production work

commences.

2.1 The moulds are to be placed at the location as per space allocation plan prepared and

approved in the plant.

2.2 The moulds surface shall be cleaned every time before use.

2.3 The moulds shall be suitably levelled with spirit level.

2.4 The mould release agent/oil shall be applied on the internal surface of the mould.

2.5 The locks of the mould shall be tightened before pouring concrete.

2.6 The hole arrangement for lifting and LCX Cables is an inbuilt part of the mould and is

incorporated as such in casting process. (Rev 01)

Fuji Silvertech concrete Private Limited

MUMBAI-AHMEDABAD HIGH SPEED RAIL (MAHSR)

DI No.

Version No.

Date

1.0

22.07.2022

Reference Photos of Area set up, Mould preparation and rebar replacement

Mould cleaning activity

Page | 12

Mould Measurement

Fuji Silvertech concrete Private Limited

Mould oiling activity

MUMBAI-AHMEDABAD HIGH SPEED RAIL (MAHSR)

DI No.

(3) Rebar

Placement

(4)

P a g e | 13

Version No.

Date

1.0

22.07.2022

3.1 The rebar mesh shall be brought near the mould as per linked product.

3.2 The rebar mesh shall be inspected for welded wire mesh and rebar.

3.3 The rebar mesh shall be checked with linked product/shop floor drawing for parameters such

as: bar diameters, bar spacing, length of rebar.

3.4 The rebar shall be placed in mould after checking and inspection

Fuji Silvertech concrete Private Limited

MUMBAI-AHMEDABAD HIGH SPEED RAIL (MAHSR)

DI No.

(4) Concrete

Pouring

Version No.

Date

1.0

22.07.2022

4.1 The unloading of concrete bucket is to be started by the production team, without making any delay, after the

bucket is received at the pour point.

4.2 Concrete in the bucket is to be inspected visually before taking up for placing.

4.3 Temperature of incoming concrete is to be inspected and the details shall be retained in the shop floor

production Report by the production engineer.

4.4 The quantity of concrete, which goes into one product or cluster of products, is to be ensured to be available

continuously. Concrete buckets ordering is to be made based on the production planning.

4.5 Concrete in the mould is to be levelled to the brim of strips, fixed along edges of the mould after the concrete is

placed in the mould. M40 High Flow Concrete (HFC) is to be used.

4.6 Final trowel with a float is to be carried out after a time frame after the concrete is levelled. This is to allow free

and full escape of the entrapped air from the concrete.

4.7 The concrete in the mould is to be allowed to cool down to attain the temperature of surrounding (ambient

temperature) for 20 minutes after trowel finishing.

4.8 It is to be covered with tarpaulin after the concrete temperature reaches atmospheric temperature.

4.9 Cleaning of encrusted concrete from the bucket’s inner surfaces and mould oil application is to be carried out

after every two deliveries of concrete; so as to avoid accumulation of stiffened concrete and its undesirable placing

into mould.

Concrete distribution by

monorail

P a g e | 14

Fuji Silvertech concrete Private Limited

MUMBAI-AHMEDABAD HIGH SPEED RAIL (MAHSR)

DI No.

(5) Curing

P a g e | 15

Version No.

Date

1.0

22.07.2022

Steam curing

5.1 Steam curing is to be applied to the products by the production team.

5.2 The duration and temperature regime of steam curing is to be maintained as per the established steam curing

regime, applicable to the given type of product.

5.3 More or less, the duration of steam curing for noise barrier product shall be 5 to 6 hours and temperature

regimes shall be between 45 ±2 Deg. Centigrade to 65 ±2 Deg. Centigrade.

5.4 The hourly temperature readings are to be retained in the shop floor production report.

5.5 Steam valve are to be closed after curing to avoid any steam wastage. The unwanted curing leads to steam

wastage as well as product quality.

Fuji Silvertech concrete Private Limited

MUMBAI-AHMEDABAD HIGH SPEED RAIL (MAHSR)

DI No.

(6) Demolding

P a g e | 16

Version No.

Date

1.0

22.07.2022

Stripping

6.1 Demoulding process shall be carried out by the production team.

6.2 Tarpaulin cover over the mould / cluster of moulds shall be removed slowly either manually or with the help of

EOT Crane.

6.3 Inspection shall be carried out to ensure the concrete of product is hardened / set enough for de- moulding.

6.4 Lock-chains and lock-bolts of the mould/s shall be opened for mould opening. The sequence of opening lockbolts should be from bottom to top of the mould.

6.5 After stripping-off, the product in the mould shall be allowed to cool down within the mould, before it is

removed from the mould.

6.6 A gentle flow of compressed air may be applied all around exposed surfaces of the product, in order to aid this

cooling, if the ambient temperature is above 40°C.

6.7 Min. stripping time of 3.5 to 4 hrs should be allowed. The concrete should have gained 8 N/sq mm compressive

strength required at stripping time. This can be measured using non-destructive testing.

6.8 The product shall be taken out of the mould, safely and securely, with the help of applicable tools with EOT

crane..

6.9 The product is to be placed close to the mould, in the designated region (of freshly de-moulded product) over

the Shop Floor.

6.10

The product shall be allowed to cool down further for about 30 minutes.

6.11

After the above step, if the product’s temperature reaches a range of ± 10 degree centigrade with respect

to the ambient temperature, the product shall be treated as ready to move to the Stock Yard.

6.12

After demoulding the product shall be water cured (moist curing) for 15 days or compound cured.

Fuji Silvertech concrete Private Limited

MUMBAI-AHMEDABAD HIGH SPEED RAIL (MAHSR)

DI No.

Version No.

Date

1.0

22.07.2022

Production Cycle: The cycle time shall be 7 to 8 hours.

1. Placement of mould

Slide Door

P a g e | 17

3. Reinforcement Installation

2. Mould Opening

Door-1

Fuji Silvertech concrete Private Limited

MUMBAI-AHMEDABAD HIGH SPEED RAIL (MAHSR)

DI No.

4. Placement the Reinforcement

Date

1.0

22.07.2022

5. After placement the reinforcement

closing mould door-1 and slide door

Slide Door

P a g e | 18

Version No.

Door-1

Fuji Silvertech concrete Private Limited

6. Concrete pouring from top

MUMBAI-AHMEDABAD HIGH SPEED RAIL (MAHSR)

DI No.

Date

1.0

22.07.2022

9. Vertically raising the Noise

Barrier

8. Demoulding

7. After Concreting

Slide Door

P a g e | 19

Version No.

Door-2

Door-1

Fuji Silvertech concrete Private Limited

MUMBAI-AHMEDABAD HIGH SPEED RAIL (MAHSR)

DI No.

10. Pull the slightly horizontally

P a g e | 20

Version No.

Date

1.0

22.07.2022

11. Take off from the Mould

Fuji Silvertech concrete Private Limited

12. After demoulding, the Noise Barrier

lifts upside from the floor and forward to

a nearby allocated safe stacking place.

MUMBAI-AHMEDABAD HIGH SPEED RAIL (MAHSR)

DI No.

13. Place the Noise Barrier down on a rubber

s to stack on wooden planks.

mat

P a g e | 21

Version No.

Date

1.0

22.07.2022

14. Place the Noise Barrier down on a rubber

mat to stack on wooden planks.

Fuji Silvertech concrete Private Limited

MUMBAI-AHMEDABAD HIGH SPEED RAIL (MAHSR)

DI No.

15. Noise Barrier stacking on wooden planks

P a g e | 22

Version No.

Date

1.0

22.07.2022

16. Forklift lifting capacity based on the weight of

the Noise Barrier and transferring in stockyard

Fuji Silvertech concrete Private Limited

MUMBAI-AHMEDABAD HIGH SPEED RAIL (MAHSR)

DI No.

Version No.

Date

1.0

22.07.2022

17. Way to stock-yard for stacking

18. Noise Barrier Stacking on Wooden Planks in

Stock-Yard

P a g e | 23

Fuji Silvertech concrete Private Limited

MUMBAI-AHMEDABAD HIGH SPEED RAIL (MAHSR)

DI No.

(7) Finished

product

inventory

(8)

P a g e | 24

Version No.

Date

1.0

22.07.2022

Record of Production actual

7.1 The daily production records shall be maintained plant-wise by the production team with planned product

code and description, planned/target numbers and weights and actual numbers of products manufactured.

7.2 The daily production records shall also indicate the total products manufactured in each shift in each plant,

the number of dispatchable products, gross production and % production with respect to target.

7.3 The daily production records shall also indicate any comments or remarks that may be noted in case of daily

production not achieved or major observations in the process.

7.4 The product manager shall maintain monthly record of production plan Vs actual quantities.

Fuji Silvertech concrete Private Limited

MUMBAI-AHMEDABAD HIGH SPEED RAIL (MAHSR)

DI No.

(8) Lifting

Version No.

Date

1.0

22.07.2022

8.1 Products are to be lifted and placed in a dispatch goods stockyard as per stockyard planning.

8.2 The product is to be moved to the Stock Yard by using 5 Tonne capacity Fork Lift, depending upon the size and

mass of the products to be shifted.

8.3 The number of products to be moved collectively to the Stock Yard with the Fork Lift, is not be exceeded the

forklift capacity.

8.4 Care is to be taken to ensure that the distance between two Forks of the Fork Lift should be adjusted, every

time, in such a way that the load on the lifting surface of the product is uniformly distributed in the spans,

formed by the lifting forks.

8.5 Also, lifting forks are to be centrally placed and not touch the corners of the product.

8.6 While moving, the edges of two or more products are not to hit against each other and get damaged.

8.7 The levelled and concreted surface is to be preferred for carrying movement of products to the stock yard

through Fork Lifts.

Lifting with forklift

P a g e | 25

Fuji Silvertech concrete Private Limited

MUMBAI-AHMEDABAD HIGH SPEED RAIL (MAHSR)

DI No.

(9) Storage

Version No.

Date

1.0

22.07.2022

9.1 The location of stacking each product shall be according to the Stock Yard Plan.

9.2 The noise barrier products may be stacked vertically in one layer or horizontally in upto 8 layers.

9.3 Appropriately sized wooden battens are to be placed below each stack / layer of the products.

9.4 The lowermost wooden battens should be of larger section (like 4 X 4 inches).

9.5 Spacing of wooden battens kept beneath and across the product (length) is to be such that one-fourth (1/4th)

of the product’s length is maintained from both the shorter edges of the product, i.e., battens are placed at

about 450 mm from outside edge and about 500 mm from both the cross-sectional faces of product.

9.6 Care is to be taken to avoid tilted stacking of products and stacking over loose and flexible surfaces like soil and

surfaces, susceptible to turn marshy with water / rains.

Stacking of noise barrier products in truck (3 – 4 layers)

P a g e | 26

Fuji Silvertech concrete Private Limited

MUMBAI-AHMEDABAD HIGH SPEED RAIL (MAHSR)

DI No.

Version No.

Date

1.0

22.07.2022

3.0 Mould Line Drawing

P a g e | 27

Fuji Silvertech concrete Private Limited

MUMBAI-AHMEDABAD HIGH SPEED RAIL (MAHSR)

DI No.

Version No.

Date

1.0

22.07.2022

4.0 Concrete mix design Conformance

Note: Further ITP will be followed for concrete testing.

FUJI SILVERTECH CONCRETE PVT.LTD.

Bagodara Plant

Concrete Mix Design Compliance

Project

Mumbai–Ahmedabad High-Speed Rail

(MAHSR)

NB C-4

Mix

M40 HFC

Customer

Specification Details

Mix Description

M40 HFC

Max. Water/Cement ratio

0.40

Cement Type

OPC 53

Min Cement content

350 kg/cum

Max Cement content

500 kg/cum

Flyash content

Nil

GGBS

Nil

Max. Chloride content

0.43 kg/cum

Mix Details

Material

OPC

IS Code Compliance

IS 269-2015

Fine Aggregate

IS 383

Course Aggregate

IS 383

Water

IS 456

Admixtures

IS 9103

P a g e | 28

Fuji Silvertech concrete Private Limited

MUMBAI-AHMEDABAD HIGH SPEED RAIL (MAHSR)

DI No.

Version No.

Date

1.0

22.07.2022

5.0 Truck Loading Drawing

P a g e | 29

Fuji Silvertech concrete Private Limited

MUMBAI-AHMEDABAD HIGH SPEED RAIL (MAHSR)

DI No.

P a g e | 30

Version No.

Date

1.0

22.07.2022

Fuji Silvertech concrete Private Limited

MUMBAI-AHMEDABAD HIGH SPEED RAIL (MAHSR)

DI No.

P a g e | 31

Version No.

Date

1.0

22.07.2022

Fuji Silvertech concrete Private Limited

MUMBAI-AHMEDABAD HIGH SPEED RAIL (MAHSR)

DI No.

P a g e | 32

Version No.

Date

1.0

22.07.2022

Fuji Silvertech concrete Private Limited

MUMBAI-AHMEDABAD HIGH SPEED RAIL (MAHSR)

DI No.

Version No.

Date

1.0

22.07.2022

6.0 Annexure:

6.1 Annexure: Demoulding and handling stresses

Lifting strength calculation (Type A 996mm)

SLS Moment =

0.52 kN.m

SLS Shear force, V = 8.13 kN

Load combination factors- (Table 12-IRS CBC)

Load case

Dead Load

Working

-

ULS

1.30

SLS

-

As per IRS CBC clause 6.4 the concrete have gained more than twice the strength.

Factored Moment (ULS) Mu = 1.35 kN.m (considering twice the strength requirement)

Vu = 21.14 kN (considering twice the strength requirement)

Lifting point

Check for flexure

b=

d=

fck=

Ast =

fy =

0.996 m

0.12 m

8 Mpa

471 mm2

500 Mpa

(6-10# bar)

As per Cl15.4.2.2.1/52/IRS Concrete Bridge code

Req. d eff = Sqrt (1.35*10^6/ 0.15 x 8 x 996)

34 mm

Provided deff= 120 mm > 34m

Mu = 0.87fy Ast Z

Z = (1-(1.1fyAs/(fckbd))x d

=

0.729 d

or

=

Z=

P a g e | 33

Hence Safe

0.95d

whichever is lesser

0.729 d

87.5 mm

Fuji Silvertech concrete Private Limited

MUMBAI-AHMEDABAD HIGH SPEED RAIL (MAHSR)

DI No.

Version No.

Date

1.0

22.07.2022

CI 15.4.2.2.1/52/IRS Concrete Bridge code

Ast = 1.35x10^6/0.87/500/87.49

= 35.53 mm2

Ast min =

=

=

=

0.200 %bd

0.200 x 1000/100 x 120

240 mm²

240 mm²

Hence Ast = 240 mm²

Provided 10 dia 6 Nos (for 0.996m length)

(Ast provided = 473.13 mm²)

(For 0.996m length)

Hence Ast provided is OK

Check for Shear Stress

Shear Force, V =

Factored Shear Force, Vu

=

Shear Stress v =

v

=

8.13 kN

21.138 kN

21140/ (996x120)

0.18 N/mm2

Referring to IRS Concrete Bridge Code, Table - 15

Pt % =

=

Permissible Shear Stress, τc =

100 Ast / b d

0.40

0.31

Hence Safe

s, depth factor =

max of ((500/d)^(1/4) or 0.7)

s, depth factor =

1.43 or0.7

s, depth factor =

1.43

(As per Table 16 IRS CBC)

vc, is the ultimate shear stress in concrete

As per Cl.15.4.3.1-IRS CBC

vc

s*vc

=

=

=

(0.27/Ym) (100AS/bwd)1/3 (fck)1/3

0.32

0.45 N/mm2

As per Cl.15.5.4-IRS CBC-, if v < s vc, No shear reinforcement is required

P a g e | 34

Fuji Silvertech concrete Private Limited

MUMBAI-AHMEDABAD HIGH SPEED RAIL (MAHSR)

DI No.

P a g e | 35

Version No.

Date

1.0

22.07.2022

% STEEL

< 0.15

M8

0.23

0.25

0.27

0.5

0.343

1

0.432

2

0.544

>3

0.623

Fuji Silvertech concrete Private Limited

MUMBAI-AHMEDABAD HIGH SPEED RAIL (MAHSR)

DI No.

Version No.

Date

1.0

22.07.2022

Transportation strength calculation (Type A996mm)

SLS Moment = 0.7

SLS Shear force, V =

P a g e | 36

kN.m

2.25 kN

Fuji Silvertech concrete Private Limited

MUMBAI-AHMEDABAD HIGH SPEED RAIL (MAHSR)

DI No.

Version No.

Date

1.0

22.07.2022

Load combination factors- (Table 12-IRS CBC)

Load case

Working

ULS

SLS

Dead Load

1.30

As per IRS CBC clause 6.4 the concrete have gained more than twice the strength.

Factored Moment,(ULS) Mu = 1.82 kN.m (considering twice the strength requirement)

Vu = 5.85 kN (considering twice the strength requirement)

Check for flexure

b=

D=

d=

fck=

Ast =

fy =

0.996 m

0.08 m

0.041 m

8 Mpa

164 mm2

410 Mpa

(13-4# bar)

As per Cl15.4.2.2.1/52/IRS Concrete Bridge code

Req. d eff = Sqrt (1.82*10^6/ 0.15 x 8 x 996)

39 mm

Provided deff=

41 mm

Mu = 0.87fy Ast Z

Z = (1-(1.1fyAs/(fckbd))x d

=

0.774 d

or

=

=

> 39mm

Hence Safe

0.95d

whichever is lesser

0.774 d

31.7 mm

Cl15.4.2.2.1/52/IRS Concrete Bridge code

Ast = 1.82x10^6 / 0.87/410/31.72

=

160.87 mm2

Ast min =

=

=

=

P a g e | 37

0.200 %bd

0.200 x 1000/100 x

82 mm²

161 mm²

Hence Ast required

41

=

161

mm2

Fuji Silvertech concrete Private Limited

MUMBAI-AHMEDABAD HIGH SPEED RAIL (MAHSR)

DI No.

Provided

4 dia

Version No.

Date

1.0

22.07.2022

13 Nos

(Ast provided = 164.02 mm²)

(For 0.996m length)

(For 0.996m length)

Hence Ast provided is OK

Check for Shear Stress

Shear Force, V =

Factored Shear Force, Vu

=

Shear Stress v =

v

=

2.25 kN

5.85 kN

5850/ (996x41)

0.14 N/mm2

Referring to IRS Concrete Bridge Code, Table - 15

Pt % =

100 Ast / b d

=

0.40

Permissible Shear Stress, τc =

0.31

s,depth factor =

s,depth factor =

s,depth factor =

Hence Safe

max of ((500/d)^(1/4) or 0.7)

1.87 or 0.7

1.87

(As per Table 16 IRS CBC)

vc, is the ultimate shear stress in concrete

As per Cl.15.4.3.1-IRS CBC

Vc

s*vc

=

(0.27/Ym) (100AS/bwd)1/3 (fck)1/3

=

0.32

=

0.60 N/mm2

As per Cl.15.5.4-IRS CBC-, if v < s vc, No shear reinforcement is required

P a g e | 38

Fuji Silvertech concrete Private Limited

MUMBAI-AHMEDABAD HIGH SPEED RAIL (MAHSR)

DI No.

P a g e | 39

Version No.

Date

1.0

22.07.2022

Fuji Silvertech concrete Private Limited

% STEEL

M8

< 0.15

0.25

0.5

1

2

>3

0.23

0.27

0.343

0.432

0.544

0.623

MUMBAI-AHMEDABAD HIGH SPEED RAIL (MAHSR)

DI No.

Version No.

Date

1.0

22.07.2022

6.2 Checklist (Rev 01)

Checklist of activities

Sr. No.

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

Activity

Space allocation of mould

Cleanliness of mould area

Safety inspection of area

Placement of moulds

Cleanliness of moulds

Levelling of mould

Release agent/oil application on mould

Tightening of mould

Rebar mesh placement near mould

Rebar mesh inspection for overall condition

Rebar mesh inspection for diameter and numbers of bars

Visual inspection of concrete

Unloading of concrete at pour point

Temperature recording of concrete

Levelling of concrete

Final troweling of concrete

Concrete cooling

Covering concrete with tarpaulin at atmospheric temperature

Cleaning of bucket for stiffened concrete

Application of steam curing

Recording temperature readings of steam curing

Closing steam valves

Removal of tarpaulin for demoulding process

Inspection of product for hardening

Opening lock chains/bolts

Cooling down of product in mould

If ambient temperature is more than 40 deg C, compressed air flow to be

applied

Inspection to check that product has sufficient demoulding strength (check

nondestructive test 8 N/sq mm or 3.5 to 4 hours stripping time.)

Removal of product from mould

Placement of product near mould

Cooling of product for 30 min on shop floor

Compound curing or water curing to be applied

Moving product to stockyard (If product temperature is ± 10 degree centigrade

with respect to the ambient temperature)

Lifting of product in 5 Ton forklift with care such that outer edge of noise

barrier is about 450 mm from fork

Placement of product in stockyard and stamping of casting date, product

identification no, product size and product type on side wall

P a g e | 40

Fuji Silvertech concrete Private Limited

Check

MUMBAI-AHMEDABAD HIGH SPEED RAIL (MAHSR)

DI No.

36

37

Version No.

Date

1.0

22.07.2022

Stacking of product in stockyard in max 4 layers with wooden battens between

them

Lifting of product with forklift and placement in dispatch vehicle

Quality Checklist of activities

Sr. No.

1

2

3

4

5

6

7

8

9

10

Activity

Testing of cement as per ITP

Testing of coarse aggregates as per ITP

Testing of fine aggregates as per ITP

Testing of reinforcement as per ITP

Testing of water as per ITP

Testing of concrete as per ITP

Inspection of mould and shutter as per ITP

Inspection of rebar as per ITP

Inspection of full product as per ITP

Calibration of equipment

P a g e | 41

Fuji Silvertech concrete Private Limited

Check

Quality plan

DI No.

Version No.

Date

1.0

08.07.2022

FSC-IMS/QC/FM-01C

Updated as on : 20.01.23

Product: Noise Barrier

Project : Mumbai – Ahmedabad High Speed Rail

Sizes: 1000 mm, 900 mm, 750 mm, 700 mm

Types: Type A and Type B for all sizes

Purchaser / Client : MGCPL

Document No :

Raw material: Cement (OPC 53 Grade)

SI.

NO

Activity / Process

Reference Document /

Code

Acceptance criteria

Quantum of Check

/ Frequency

Vendor /

Sub-Contr.

Responsibility

EMPLOYER /

MGCPL

EMPLOYER's

QC

ENGINEER

Verification / Inspection Records

Physical Requirements

1

Normal consistency

2

Initial Setting time

3

Final Setting time

IS 269 - 201 5

IS 4031 - 1988 (Part 4)

IS 269 - 201 5

IS 4031 - 1988 (Part 5)

IS 269 - 2015

IS 4031 - 1988 (Part 5)

30 min (min)

-

MTC – each batch

per week

10 hrs (max)

H

R

R

H

R

R

H

R

R

4

Soundness By

Le-Chatelier Method

IS 269 -2015 /

IS 403 - 1988 (Part-2)

10 mm (max)

One In-house test

per week /batch*

H

R

R

5

Compressive Strength

IS 269 - 2015

IS 4031 - 1988 (Part 5)

3d Strength - 27 MPa (min),

7d Strength - 37 MPa (min),

28 d Strength - 53 MPa (min).

Third-party once in

3 month

H

R

R

6

Fineness

IS 269 - 2015

IS 4031 - 1988 (Part 2)

225 m2/I<g (min)

H

R

R

0.80 to 1.02

H

R

R

0.66 (min)

H

R

R

H

R

R

H

R

R

H

H

R

R

R

R

H

R

R

MTC per week

Each week as per contract/

Independent report per Quarter (3

months)

Chemical Analysis

7

8

9

Ratio of % of lime to % silica, alumina

and iron oxide (Lime Saturation

Factor)

Ratio of alumina to that of Iron

oxide % AL203/Fe203, Min.

Magnesia % by Mass

10

Sulphur content as Sulphuric

Anhydride (So3) % by mass, Max.

11

12

Insoluble Residue (by mass)

Loss on Ignition % by Mass

13

Total Chloride Contents % by Mass.

IS 260 - 2015

IS 4032: 2014

Legend: C - Check; W - Witness; R - Review, H - Hold

Page 1 of 10/ Fuji Silvertech concrete Private Limited

6.0096 (max)

3.5% max

5.00% (max)

4.00% max

Max Limit is 0.1%for RCC Works and

0.05% for prestressed concrete

One test at every six

months & MTC for

every week no.

MTC for Every Week No. &

/ Independent Lab Test Report

once in six months.

Quality plan

DI No.

FSC-IMS/QC/FM-01C

Version No.

Date

1.0

08.07.2022

Updated as on : 20.01.23

Product: Noise Barrier

Project : Mumbai – Ahmedabad High Speed Rail

Sizes: 1000 mm, 900 mm, 750 mm, 700 mm

Types: Type A and Type B for all sizes

Purchaser / Client : MGCPL

Document No :

Raw material: Coarse Aggregate

SI.

NO

Activity / Process

Reference Document / Code

Acceptance criteria

Quantum of Check /

Frequency

Vendor

/ SubContr.

Responsibility

EMPLOYER /

MGCPL QC

EMPLOYER's

ENGINEER

Verification / Inspection

Records

Test Requirements

1

Gradation

2

Surface Moisture Content

3

Aggregate Impact Value

4

Flakiness & Elongation Index

5

Los angeles Abrasion Value

6

Aggregate Crushing Value

7

Specific Gravity

8

Water Absorption

9

10

11

IS: 2386 (part 1) : 1963/4

IS 383:2016

IS: 2386 (part III): 1963 /

IS 383:2016

IS: 2386 (part IV): 1963 /

IS 383:2016

IS: 2386 (part I): 1963 /

IS 383:2016

IS: 2386 (part IV): 1963 /

IS 383:2016

IS: 2386 (part IV): 1963 /

IS 383:2016

IS: 2386 (part III): 1963 /

IS 383:2016

IS: 2386 (part III): 1963 /

Clause 4.2, Technical specification

VI - 3

Soundness With Sodium

Sulphate (Na2SO4)

Soundness With Magnesium

Sulphate(MgSO4)

IS: 2386 (part V): 1963 /

IS 383:2016

Petrography

IS: 2386 (part VIII): 1963 /

IS 383:2017

Alkali Aggregate Reactivity

(By chemical method or by

12

IS 383:2016

mortar bar expansion

method)

Legend: C - Check; W - Witness; R - Review, H - Hold

Page 2 of 10/ Fuji Silvertech concrete Private Limited

Table - 2 of IS: 383 for graded

aggregates of nominal size 10 mm & 20 mm

For water adjustment in batching plant

01 Test (Random) for

each day of supply.

01 Test daily per

Concrete day

H

R

R

H

R

R

45% (Max)

One test weekly

H

R

R

40% (Max)

One test weekly

H

R

R

For wearing surface concrete 30% (max.) and

other than wearing surface: 50% max.

Once in 3 months

H

R

R

30% (Max)

Once in 3 months

H

R

R

-

Once in 3 months

H

R

R

3% (Max)

Once in 3 months

H

R

R

12% (Max)

R

R

R

18% (Max)

R

R

R

R

R

R

R

R

R

Suitable for concrete

Innocuous

Once during source

approval

In-House Test Report

/Independent Lab Test Report

Independent Lab Test Report

Quality plan

DI No.

Version No.

Date

1.0

08.07.2022

FSC-IMS/QC/FM-01C

Updated as on : 20.01.23

Product: Noise Barrier

Project : Mumbai – Ahmedabad High Speed Rail

Sizes: 1000 mm, 900 mm, 750 mm, 700 mm

Types: Type A and Type B for all sizes

Purchaser / Client : MGCPL

Document No :

Raw material: Fine Aggregate

Responsibility

SI.

NO

Activity / Process

Reference Document /

Code

Acceptance criteria

Quantum of Check /

Frequency

Vend

or /

SubContr.

MGCPL

QC

EMPLOYER /

EMPLOYER's

ENGINEER

H

R

R

H

R

R

R

R

Verification / Inspection Records

Test Requirements

1

Gradation

2

Silt Content / materials

finer than 7 5

3

Moisture Content

4

Specific Gravity

5

Water Absorption

6

7

8

9

IS: 2386 (part I): 1963 /

IS 383:2016

IS: 2386 (part I): 1963 /

IS 383:2016

IS: 2386 (part III): 1963

/

IS 383:2016

IS: 2386 (part III): 1963

/ IS 383:2016

IS: 2386 (part III): 1963

/

Clause 4.2, Technical

specification VI - 3

Soundness With Sodium

Sulphate (Na2S04)

Soundness With Magnesium

Sulphate(MgSO4)

IS: 2386 (part V): 1963 /

IS 383:2016

Petrography

IS: 2386 (part VIII):

1963 /

IS 383:2017

Alkali Aggregate Reactivity (By

chemical method or by mortar

bar expansion method)

IS 383:2016

Legend: C - Check; W - Witness; R - Review, H – Hold

Page 3 of 10/ Fuji Silvertech concrete Private Limited

As per IS :383:2016

3.00 %(Max) by weight.

01 Test (Random) for each

day of supply

01 Test (Random) for each

day of supply

For water adjustment in

batching plant

01 Test daily per Concrete

day

H

-

Once in a month

H

R

R

3.00 %(Max)

Once in a month

H

R

R

10% (Max)

Once during source

approval

H

R

R

H

R

R

H

R

R

15% (Max)

Suitable for concrete

Innocuous

Note: In case of Crushed

sand from the same source

of coarse aggregates, no

separate tests for fine

aggregate is required.

In case of Natural sand, the

test shall be carried out

separately apart from the

tests carried out on

coarse aggregates.

In-House Test Report / Independent Lab Test Report

Independent Lab Test Report

H

R

R

Quality plan

DI No.

FSC-IMS/QC/FM-01C

Version No.

Date

1.0

08.07.2022

Updated as on : 20.01.23

Product: Noise Barrier

Project : Mumbai – Ahmedabad High Speed Rail

Sizes: 1000 mm, 900 mm, 750 mm, 700 mm

Types: Type A and Type B for all sizes

Purchaser / Client : MGCPL

Document No :

Raw material: Construction water

SI.

NO

Activity / Process

Reference Document /

Code

Acceptance criteria

Quantum of Check /

Frequency

Vendor /

SubContr.

Responsibility

EMPLOYER /

MGCPL

EMPLOYER's

QC

ENGINEER

Test Requirements

1

pH value

2

Total Organic Solids

IS 3025 (Part-11) 2006

IS 3025 (Part-18) 1984

6.00 min.

200 mg/ltr (max), (IRC CBC-CI 4.3.2 )

H

H

R

R

R

R

3

IS 3025 (Part-18) 1984

3000 mg/ltr (Max) ,(IRC CBC-Cl 4.3.2 )

H

R

R

IS 3025 (Part-32)

2003/IRS CBC-CI 4.3

2000 mg/ltr for Plain concrete

1000 mg/ltr for reinforced concrete

500 mg/I for prestressed concrete

works.

H

R

R

H

R

R

H

R

R

4

Inorganic Solids

Chlorides as CL

Initially one Test

during source approval

and one Test for

every month for the

first quarter thereafter

one test

for every 3 months

5

Sulphate Content as SO3

IS 3025 (Part-24) 2003

500.00 mg.ltr (max)

6

Total Suspended Matter

IS 3025 (Part-l7) 2012

2000.00 mq/ltr (max)

7

To neutralize 200 ml of sample

of water using methyl orange

as an indicator, It should not

require more than 10 ml of 0.1

normal HCI

IS 3025 (Part-23)

2003/IRS CBC-CI 4.3

10 ml (max)

H

R

R

8

To neutralize 200 ml of sample

of water using phenolphalein

as an indicator, it should

require not required more

than 2 ml of 0.1 normal NaOH

IS 3025 (Part-23) 2003/

IRS CBC-CI 4.3

2 ml (max)

H

R

R

Legend: C - Check; W - Witness; R - Review, H - Hold

Page 4 of 10/ Fuji Silvertech concrete Private Limited

Verification / Inspection Records

Independent Lab Test Report

Quality plan

DI No.

FSC-IMS/QC/FM-01C

Version No.

Date

1.0

08.07.2022

Updated as on : 20.01.23

Product: Noise Barrier

Project : Mumbai – Ahmedabad High Speed Rail

Sizes: 1000 mm, 900 mm, 750 mm, 700 mm

Types: Type A and Type B for all sizes

Purchaser / Client : MGCPL

Document No :

Raw material: Reinforcement Steel Grade Fe 500D and Fe 550D

SI.

NO

Activity / Process

Reference Document / Code

Acceptance criteria

Quantum of Check /

Frequency

Vendor /

SubContr.

Responsibility

EMPLOYER /

MGCPL

EMPLOYER's

QC

ENGINEER

Verification / Inspection Records

Test Requirements

1

2

3

4

5

Nominal Mass in kg/m

0.2% Proof Stress/Yield

Stress

Tensile Strength

Elongation Percentage

Bend and Rebend Test

IS 1786 - 2008 (R 2018)

As per Table 1 & 2, Clause

6.2 and 7.2.2 of IS: 1786-2008

H

R

R

IS 1786 - 2008 (R 2018)

500 N/mm2(Min.)

H

R

R

IS 1786 - 2008 (R 2018)

IS 1786 - 2008 (R 2018)

565 N/mm2(Min.)

16 % (Min)

H

H

R

R

R

R

IS 1786 - 2008 (R 2018)

No rupture or cracks visible to a person

of normal or corrected vision on the

bend/rebend portion.

H

R

R

R

R

R

R

R

R

R

R

R

R

R

R

R

R

R

01 Test per dia per 50

MT & MTC for each lot

MTC/Third party test report

Chemical Analysis

6

Carbon Content

IS 1786 - 2008 (R 2018)

0.25% (Max.)

7

8

9

Sulphur Content

Phosphorus Content

Sulphur & Phosphorus

IS 1786 - 2008 (R 2018)

IS 1786 - 2008 (R 2018)

IS 1786 - 2008 (R 2018)

0.04% (Max.)

0.04% (Max.)

0.075 % (Max.)

10

Carbon Equivalent

IS 1786 - 2008 (R 2018)

0.5 % (Max,)

Legend: C - Check; W - Witness; R - Review, H - Hold

Page 5 of 10/ Fuji Silvertech concrete Private Limited

01 Test per 50MT

& MTC for each lot.

MTC /In-house Test Report/Independent

Lab Report

Quality plan

DI No.

FSC-IMS/QC/FM-01C

Version No.

Date

1.0

08.07.2022

Updated as on : 20.01.23

Product: Noise Barrier

Project : Mumbai – Ahmedabad High Speed Rail

Sizes: 1000 mm, 900 mm, 750 mm, 700 mm

Types: Type A and Type B for all sizes

Purchaser / Client : MGCPL

Document No :

Raw material: Chemical Admixture

SI.

NO

Activity / Process

Reference Document / Code

Acceptance criteria

Quantum of Check /

Frequency

Vendor /

SubContr.

Responsibility

EMPLOYER /

MGCPL

EMPLOYER's

QC

ENGINEER

Verification / Inspection Records

Chemical Requirements

1

pH value

IS 9103

2

Chloride content

IS:6925-1 973(RA-2013)

3

Ash content

IS:9103: 1999 RA-(2013)

4

Dry material content

IS:9103: 1999 RA-(2013)

5

Realtive Density

IS:9103: 1999 RA-(2018)

6

Infra red spectrograph

Clause 4.6(c.vi), Technical

specification VI- 3

Legend: C - Check; W - Witness; R - Review, H - Hold

Page 6 of 10/ Fuji Silvertech concrete Private Limited

6.00 (min.)

Within 10 % of the value or within 0.2%

whichever is greater as stated by the

manufacturer

within 5.00% 0 f the value stated

by the Manufacturer

within 5.00% of the value stated

by the Manufacturer

within +/-0.02 of the value stated by the

Manufacturer

Consistency for each product to

be monitored

One 3rd Party test

once in 3 months &

Review of MTC for

each Lot.

TPT once during

source approval &

Review of report for

each Lot

H

R

R

H

R

R

H

R

R

H

R

R

H

R

R

H

R

R

MTC /Independent Lab Test Report

Infrared test report

Quality plan

DI No.

FSC-IMS/QC/FM-01C

Version No.

Date

1.0

08.07.2022

Sizes: 1000 mm, 900 mm, 750 mm, 700 mm

Updated as on : 20.01.23

Product: Noise Barrier

Project : Mumbai – Ahmedabad High Speed Rail

Types: Type A and Type B for all sizes

Purchaser / Client : MGCPL

Document No :

Raw material: Concrete

SI.

NO

Activity / Process

Acceptance criteria

Quantum of Check / Frequency

Responsibility

Vendor

EMPLOYER /

MGCPL

/ SubEMPLOYER's

QC

Contr.

ENGINEER

Verification / Inspection Records

Pre-Requisite

1

Concrete Mix Design

2

Calibration of

Batching Plant

Technical specification VI-3 clause 4.8

Each Grade of Concrete.

Whenever there is change ln souce, redesign shall be

Revalidation at every 12 months.

done.

Cement: +/- 2%

Agg, Water & Admix. : +/- 3% of the Qty of

Once in 3 months

constituents being measured.

H

R

R

Approved Concrete Mix Design with Trial and

Test records

H

R

R

Calibration Certificate / Batching Plane

Calibration For/flat.

H

R

R

Slump test report

Batch sheet

Pour Card

H

R

R

Batch sheet

Pour Card

Fresh Concrete

a) Every Truck

b) If the placing is in the same place of the Plant. then

it shall be one test per day.

a) Every Truck

b) If the placing is in the same place of the Plant. then

it shall be one test per shift.

One test per week by Quantab Papers.

Theoretical Chloride Content - Once during the mix

design & once every year during validation of mix

design.

3

Slump / Workability

As per mix design.

4

Concrete

Temperature

Shall be less than 40 Deg C.

5

Total Chloride

Content

0.43 Kg/cum (max) for RCC & PSC. Tested using

Quantab Papers.

Test method, as per Mfr. recommendation

Concrete Bleeding

(For

High Slump Concrete)

No bleeding as per IS 9103

Once during mix design approval & then once per

week.

H

R

R

Concrete Bleeding Test Format.

Air content

As per IS 1199

Shall not be more than 1%hiqher than of the

corresponding control mix

Once during mix design approval & then once per

month for each grade of concrete.

H

R

R

Air content of concrete Test Format

During Trial Mix & As per IS 456.

CI 1.5.2.2

H

R

R

Cube Compressive strength test results

Once a months

H

R

R

Permeability Test Format

Once during mix design approval.

H

R

R

Drying Shrinkage test report

Once during mix design approval.

H

R

R

Flexural Strength test report.

6

7

Hardened Concrete

Compressive Strength Average strength of samples:

8

of Concrete

fck + 3 (min)

Water Permeability

9

25mm (max)

(For RCC)

Drying Shrinkage of

10

0.03% (max)

Concrete

11 Flexural Strength

0.7 √fck (min)

Legend: C - Check; W - Witness; R - Review, H - Hold

Page 7 of 10/ Fuji Silvertech concrete Private Limited

Chloride Content Test Report.

H

R

R

Chloride Content Calculation sheet,

Quality plan

DI No.

Version No.

Date

1.0

08.07.2022

FSC-IMS/QC/FM-01C

Updated as on : 20.01.23

Product: Noise Barrier

Project : Mumbai – Ahmedabad High Speed Rail

Sizes: 1000 mm, 900 mm, 750 mm, 700 mm

Types: Type A and Type B for all sizes

Purchaser / Client : MGCPL

Document No :

Post pour Inspection/Product Inspection

Responsibility

SI.

NO

Activity / Process

Acceptance criteria

Quantum of Check /

Frequency

Vendor / SubContr.

MGCPL QC

EMPLOYER / EMPLOYER's

ENGINEER

Verification / Inspection Records

1

Dimensions – Length

+ / - 3 mm

4 in 100

H

R

R

In-house inspection report

2

Dimensions – Width

+ / - 3 mm

4 in 100

H

R

R

In-house inspection report

3

Dimensions – Height

+ / - 3 mm

4 in 100

H

R

R

In-house inspection report

4

Dimensions- Thickness

+ / - 3 mm

4 in 100

H

R

R

In-house inspection report

Note: Combined tolerance of 1 lot (25 noise barriers) should be within +/-20 mm.

Page 8 of 10/ Fuji Silvertech concrete Private Limited

Quality plan

DI No.

FSC-IMS/QC/FM-01C

Version No.

Date

1.0

08.07.2022

Updated as on : 20.01.23

Product: Noise Barrier

Project : Mumbai – Ahmedabad High Speed Rail

Sizes: 1000 mm, 900 mm, 750 mm, 700 mm

Types: Type A and Type B for all sizes

Purchaser / Client : MGCPL

Document No :

Pre-pour Inspection (Reinforcement Inspection)

Responsibility

SI NO

1

Activity / Process

Reinforcement

cage inspection

of Type A

Reference Document / Code

Acceptance criteria

As per BBS

As per BBS

As per BBS

As per BBS

As per BBS

As per BBS

As per BBS

As per BBS

1000 mm

2

900 mm

3

750 mm

4

700 mm

5

1000 mm

Reinforcement

6

900 mm

cage inspection

7

750 mm

of Type B

8

700 mm

Legend: C - Check; W - Witness; R - Review, H – Hold

Page 9 of 10/ Fuji Silvertech concrete Private Limited

Quantum of

Check /

Frequency

Vendor /

Sub-Contr.

MGCPL QC

EMPLOYER /

EMPLOYER's ENGINEER

As per Approval Drawing

H

R

R

As per Approval Drawing

As per Approval Drawing

As per Approval Drawing

As per Approval Drawing

As per Approval Drawing

As per Approval Drawing

As per Approval Drawing

H

H

H

H

H

H

H

R

R

R

R

R

R

R

R

R

R

R

R

R

R

4 in 100

Verification / Inspection

Records

In-house inspection

report

Quality plan

DI No.

FSC-IMS/QC/FM-01C

Version No.

Date

1.0

08.07.2022

Updated as on : 20.01.23

Product: Noise Barrier

Project : Mumbai – Ahmedabad High Speed Rail

Sizes: 1000 mm, 900 mm, 750 mm, 700 mm

Types: Type A and Type B for all sizes

Purchaser / Client : MGCPL

Document No :

Pre-pour Inspection (Shutter and Mould Inspection)

Responsibility

SI.

NO

Activity / Process

Acceptance criteria

Quantum of Check /

Frequency

+-2 mm

Vendor / SubContr.

MGCPL QC

EMPLOYER /

EMPLOYER's

ENGINEER

4 in 100

R

R

R

1

Level of shutter

2

Oiling

As per FSC checklist

Every casting

R

R

R

3

Cleaning of shutter

As per FSC checklist

Every casting

R

R

R

Legend: C - Check; W - Witness; R - Review, H – Hold

Page 10 of 10/ Fuji Silvertech concrete Private Limited

Verification / Inspection Records

In-house inspection report

MIX DESIGN REPORT FOR NOISE BARRIER

MUMBAI-AHMEDABAD HIGH SPEED RAIL (MAHSR-C4)

DI No.

Version No.

Date

FS-IMS/QC/CR/001

1.0

20.09.2022

FS-IMS/QC/CR/001-REV00

PREPARED BY

REVIEWED BY

APPROVED BY

Name :

M/s, FUJI SILVERTECH

CONCRETE PVT. LTD

L&T

TCAP/NHSRCL

Designation :

VENDOR

Reviewed

Signature :

Date :

24-09-2022

MUMBAI-AHMEDABAD HIGH SPEED RAIL (MAHSR-C4)

DI No.

FS-IMS/QC/CR/001

Version No.

1.0

Date

20.09.2022

CONTENT

1.1

Mix design sheet ....................................................................... Page 1

1.2

Concrete trial mix observation & record ................................... Page 4

1.3

Sieve Analysis for Fine aggregates ............................................. Page 7

1.4

Sp. Gravity & water absorption for fine aggregates ................... Page 7

1.5

Chemical test for Fine aggregates ............................................. Page 8

1.6

Sieve Analysis for Coarse aggregates ........................................ Page 13

1.7

Sp. Gravity & water absorption for fine aggregates .................. Page 13

1.8

Chemical test for Coarse aggregates ........................................ Page 14

1.9

ACT Test ................................................................................... Page 18

1.10 Compressive Strength .............................................................. Page 19

1.11 Water Test ................................................................................ Page 21

1.12 Admixture Test ......................................................................... Page 23

1.13 Cement Test ............................................................................. Page 24

1.14 Air content of Concrete ........................................................... Page 27

1.15 Bleeding of Concrete ............................................................... Page 29

1.16 Chloride content by Quantab paper ......................................... Page 31

1.17 Cement MTC ............................................................................ Page 33

1.18 Admixture MTC ........................................................................ Page 42

Fuji Silvertech concrete Private Limited

MIX DESIGN

Page1

Page2

Page3

CONCRETE TRIAL MIX

OBSERVATION

Page4

Page5

FINE AGGREGATES

TEST REPORT

Page6

CIMEC TECHNOLOGIES PRIVATE LIMITED

CIN: U29100GJ2011PTC064482

ISO 9001 : 2015 Certified Company

Regd. Office & Lab 23 / H Meldi Estate, Nr. Gota Railway Crossing, Gota,

Ahmedabad - 382481, Gujarat P +91 2717 241209 E info@cimec.in

Technical Queries +91 99250 28369 Customer Care +91 75679 55968

TC-5549

9

CIMEC

www.cimec.in

TEST REPORT

FINAL REPORT

Customer's Details; FUJI SILVERTECH CONCRETE PVT. LTD.

4TH FLOOR, HOUSE NO 5, MAGNET

CORPORATE PARK, NEAR SOLA FLYOVER, S.G.

ROAD, THALTEJ, AHMEDABAD GUJARAT

Your Ref. No.

Format No. : QF/7.8/01

ULR : TC554922000014620F

: CT/ME/2208100058

Report No.