CIV 3218 STRUCTURAL DESIGN II WEEK 1 Timber as an engineering material: orthotropic behaviour, engineering properties, MOE, MOR, tension, compression, shear and bearing strength parallel, perpendicular and at an angle to the grain. Design codes and standards. Stress grading, strength grouping, derivation of design stresses. INTRODUCTION 01 02 Timber from well-managed forests is one of the most sustainable resources available and it is one of the oldest known materials used in construction. It has a very high strength to weight ratio, is capable of transferring both tension and compression forces, and is naturally suitable as a flexural member. CHARACTERISTICS There are a number of inherent characteristics that make timber an ideal construction material. • These include its high strength to weight ratio, its impressive record for durability and performance and good insulating properties against heat and sound. • Timber also benefits from its natural growth characteristics such as grain patterns, colours and its availability in many species, sizes and shapes that make it a remarkably versatile and an aesthetically pleasing material. • Timber can easily be shaped and connected using nails, screws, bolts and dowels or adhesively bonded together Wamara Wooden Floor Scientific Name:Swartzia Leiocalycina Benth Wamara is a very dense wood like a typical rosewood, with dark purple heartwood and pale yellow sapwood. Its density makes it hard on your tools, but the beautiful colours and sheen it takes on finishing make it very worthwhile. No finishing difficulties that I have come across, as it is not an oily wood. Orthotropic Nature of Wood Wood may be described as an orthotropic material; that is, it has unique and independent mechanical properties in the directions of three mutually perpendicular axes: I. longitudinal, II. radial, and III. tangential. The longitudinal axis L is parallel to the fiber (grain); the radial axis R is normal to the growth rings (perpendicular to the grain in the radial direction); and the tangential axis T is perpendicular to the grain but tangent to the growth rings. Orthotropic Nature of Wood Three principal axes of wood with respect to the grain direction and growth rings STRENGTH GRADING OF TIMBER The strength of timber is a function of several parameters including the species type, density, size and form of members, moisture content, duration of the applied load and presence of various strength reducing characteristics such as slope of grain, knots, fissures and wane. To overcome this difficulty, the strength grading method of strength classification has been devised. Several design properties are associated with a strength grade; these include modulus of elasticity and bending strength parallel to the grain, strength properties in tension and compression parallel and perpendicular to the grain, shear strength parallel to the grain and density. Strength grading provides a possibility to assess the strength of a piece of sawn timber. This process can be carried out by visual or machine based method. Visual grading rules and standards define growth characteristics, such as knots, wane, slope of grain, fissures, distortions, reaction wood, fungal and insect damage, etc. Standards provide restrictions on the size, type and number of defects allowed in each grade. A certified grader visually assesses each piece of timber. Grading rules specify acceptable limits for these features. Visual strength grading produces two strength grades - GS (General Structural) and SS (Special Structural). Machine strength grading is based on the relationship between the stiffness and strength properties of a timber. SS (Special Structural) - Used as a basis for strength and modulus of elasticity determination - Done by subjecting large number of structural sized specimens to short term load test - Fifth percentile stresses obtained. - Fifth percentile is defined as the value at which no more than 5% of the test results fell. - The grade stresses were obtained by dividing the fifth percentile stresses by a reduction factor, which included adjustments for the standard depth of specimen 300mm, duration of load and factor of safety. Grade stresses for softwoods graded in accordance with BS 4978: for service classes 1 and 2 (Table 10, BS 5268) What is the difference between SS and GS? How do you identify strength graded timber? Each piece of strength graded timber is clearly marked and provides vital information. The key elements of these marks are: • The moisture content condition at the time of grading, i.e. DRY, KD or WET. • The strength grade or strength class of the piece. • The timber species or species combination. • Identification of the grader and company responsible for grading. • The relevant British/European Standard number. • The mark of the independent certification body. • The use of the term 'DRY' or 'KD' confirms that at the time of grading the piece of timber satisfied the moisture content requirements of the Standard. 'KD' indicates that the timber has been kiln dried as opposed to air dried. 'DRY' indicates that either air drying or kiln drying has been undertaken. Strength classes The concept of grouping timber into strength classes was introduced into the United Kingdom with BS 5268-2 in 1984. Strength classes offer a number of advantages both to the designer and the supplier of timber. The designer can undertake the design without the need to check on the availability and price of a large number of species and grades that might be used. Suppliers can supply any of the species/grade combinations that meet the strength class called for in a specification. The concept also allows new species to be introduced to the market without affecting existing specifications for timber. Strength classes • In all there are sixteen strength classes, C14, C16, C18, C22, C24, TR26, C27, C30, C35, C40, D30, D35, D40, D50, D60 and D70, with C14 having the lowest strength characteristics. • The strength class designations indicate the bending strength of the timber. • Strength classes C14 to C40 and TR26 are for softwoods and D30 to D70 are for hardwoods. • Strength class TR26 is intended for use in the design of trussed rafters. Grade stresses and moduli of elasticity BS5268 • When the specification specifically prohibits wane at bearing areas, the higher value may be used. The term "wane" is often used to describe missing areas on lumber. The term typically refers to defects on the ends or sides of the lumber, but wane can occur just about anywhere on milled wood. Wane is often associated with bark that remains on the lumber after it's milled. • For calculation of dead load, the average density should be used. https://www.hunker.com/12582774/the-definition-of-wane-inlumber Permissible stresses The grade stresses given in Tables 6.1 and 6.3 were derived assuming particular conditions of service and loading. In order to take account of the actual conditions that individual members will be subject to during their design life, the grade stresses are multiplied by modification factors known as K-factors. The modified stresses are termed permissible stresses. Modification Factors Modification factors relevant to the design of simple flexural and compression members are: K2: Moisture content factor K3: Duration of loading factor K5: Notched ends factor K7: Depth factor K8: Load-sharing systems factor K12: Compression member stress factor. MOISTURE CONTENT, K2 The strength and stiffness of timber decreases with increasing moisture content. This effect is taken into account by assigning timber used for structural work to a service class. BS 5628 recognizes three service classes MOISTURE CONTENT, K2 The grade stresses and moduli of elasticity shown in Tables 6.1 and 6.3 apply to timber exposed to service classes 1 and 2. According to clause 2.6.2 of BS 5268 where service class 3 exists, the values in Tables 6.1 and 6.3 should be multiplied by a modification factor K2 given in the Table. MOISTURE CONTENT, K2 Because it is difficult to dry thick timber, service class 3 stresses and moduli should be used for solid timber members more than 100 mm thick, unless they have been specially dried. DURATION OF LOADING, K3 The stresses given in Tables 6.1 and 6.3 apply to long-term loading. Where the applied loads will act for shorter durations e.g. snow and wind, the grade stresses can be increased. This is because timber and wood based materials can sustain much greater loads for shorter periods. NOTCHED ENDS, K5 • Notches at the ends of flexural members will result in high shear concentrations which may cause structural failure and must, therefore, be taken into account during design. • In notched members the grade shear stresses parallel to the grain are multiplied by a modification factor K5 calculated as follows: NOTCHED ENDS, K5 For a notch at the top edge ℎ ℎ𝑒 − 𝑎 + 𝑎ℎ𝑒 𝐾5 = ℎ𝑒2 For a notch on the underside ℎ𝑒 𝐾5 = ℎ the effective depth, he, should not be less than 0.5h, i.e. K5 ≥ 0.5. DEPTH FACTOR, K7 The grade bending stresses given in Table 6.3 only apply to timber sections having a depth h of 300 mm. For other depths of beams, the grade bending stresses are multiplied by the depth factor K7, defined in clause 2.10.6 of BS 5268 as follows: K7 = 1.17 for solid beams having a depth ≤ 72mm 300 0.11 ℎ 𝐾7 = 300mm 𝐾7 = mm for solid beams with 72mm < h < 0.81 (ℎ2 +923000) (ℎ2 +56800) for solid beams with h > 300 LOAD-SHARING SYSTEMS, K8 The grade stresses given in Tables 6.1 and 6.3 apply to individual members, e.g. isolated beams and columns, rather than assemblies. When four or more members such as rafters, joists or wall studs, spaced a maximum of 610 mm centre to centre act together to resist a common load, the grade stress should be multiplied by a load-sharing factor K8 which has a value of 1.1 (clause 2.9, BS 5268). COMPRESSION MEMBERS, K12 The grade compression stresses parallel to the grain given in Tables 6.1 and 6.3 are used to design struts and columns. These values apply to compression members with slenderness ratios less than 5 which would fail by crushing. Where the slenderness ratio of the member is equal to or greater than 5 the grade stresses should be multiplied by the modification factor K12 The factor K12 takes into account the tendency of the member to fail by buckling and allows for imperfections such as out of straightness and accidental load eccentricities. The factor K12 is based on the minimum modulus of elasticity, Emin, irrespective of whether the compression member acts alone or forms part of a load-sharing system. Questions Discuss Discuss the factors which influence the strength of timber and explain how the strength of timber is assessed in practice. Give Give typical applications of timber in the construction industry and for each case discuss possible desirable properties Distinguish Distinguish between softwood and hardwood and grade stress and permissible stress. Discuss Discuss the factors accounted for by the modification factor K12 in the design of timber compression members. Beams, rafters and joists are examples of flexural members. Flexural members All calculations relating to their design are based on the effective span and principally involves consideration of the following: 1. bending 2. deflection 3. lateral buckling 4. shear 5. bearing. Generally, for medium-span beams the design process follows the sequence indicated above. Deflection is usually critical for long-span beams and shear for heavily loaded short-span beams. Effective span of simply supported beams According to clause 2.10.3 of BS 5268, for simply supported beams, the effective span is normally taken as the distance between the centres of bearings. BENDING If flexural members are not to fail in bending, the design moment, M, must not exceed the moment of resistance, MR M ≤ MR The design moment is a function of the applied loads. The moment of resistance for a beam can be derived from the theory of bending and is given by: MR = σm,adm,||Zxx where σm,adm,|| is the permissible bending stress parallel to grain and Zxx is the section modulus For rectangular sections Zxx= 𝑏𝑑 2 6 The permissible bending stress is calculated by multiplying the grade bending stress, σm,g,||, by any relevant K-factors: σm,adm,|| = σm,g,||K2K3K7K8 (as appropriate). For a given design moment the minimum required section modulus, Zxx req, can be calculated as follows: Zxx req ≥ 𝑀 σm,adm,|| A suitable timber section can then be selected from Tables NA.2, NA.3 and NA.4 of BS EN 336: Structural timber. Table NA.2 is reproduced as Table 6.7. Table 6.8 is an expanded version. DEFLECTION • Excessive deflection of flexural members may result in damage to surfacing materials, ceilings, partitions and finishes, and to the functional needs as well as aesthetic requirements. • Clause 2.10.7 of BS 5268 recommends that generally such damage can be avoided if the total deflection, δt ≤ δp • The permissible deflection is generally given by δp = 0.003 × span • for longer-span domestic floor joists, i.e. spans over 4.67 m, should not exceed 14 mm: δp ≤ 14 mm • The total deflection is the deflection due to bending and the deflection due to shear. δt = δm + δ v LATERAL BUCKLING • If flexural members are not effectively laterally restrained, it is possible for the member to twist sideways before developing its full flexural strength thereby causing it to fail in bending, shear or deflection. • This phenomenon is called lateral buckling and can be avoided by ensuring that the depth to breadth ratios are checked LATERAL BUCKLING Table 6.10 Maximum depth to breadth ratios Table 19, BS 5268 SHEAR If flexural members are not to fail in shear, the applied shear stress parallel to the grain, τa, should not exceed the permissible shear stress, τadm τa ≤ τadm For a beam with a rectangular cross-section, the maximum applied shear stress occurs at the neutral axis and is given by: 3Fv τa = 2A where Fv = applied maximum vertical shear force A = cross-sectional area The permissible shear stress is given by τadm = τgK2K3K5K8 where τg is the grade shear stress parallel to the grain BEARING PERPENDICULAR TO GRAIN • Bearing failure may arise in flexural members which are supported at their ends on narrow beams or wall plates. • Such failures can be avoided by ensuring that the applied bearing stress, σc,a,⊥, never exceeds the permissible compression stress perpendicular to the grain, σc,adm,⊥: σc,a,⊥ ≤ σc,adm,⊥ The applied bearing stress is given by: 𝐹 σc,a,⊥ = 𝑏𝑙𝑏 where F bearing force (usually maximum reaction) b breadth of section lb bearing length σc,adm,⊥ = σc,g,⊥K2K3K8 Moreover, two values for the grade compression stress perpendicular to the grain are given for each strength class (Table 6.3). The lower value takes into account the amount of wane which is permitted within each stress grade. Solid timber beams: Design for flexure, shear, bearing, deflection. modification factors, permissible stresses. Design of a timber beam (BS 5268) A timber beam with a clear span of 2.85 m supports a uniformly distributed load of 10 kN including self-weight of beam. Determine a suitable section for the beam using timber of strength class C16 under service class 1. Assume that the bearing length is 150 mm and that the ends of the beam are held in position and compression edge held in line. EFFECTIVE SPAN Distance between centres of bearing (l) = 3000 mm GRADE STRESS AND MODULUS OF ELASTICITY FOR C16 Values in N/mm2 are as follows MODIFICATION FACTORS • K2, moisture content factor does not apply since the beam is subject to service class 1 • K3, duration of loading factor = 1.0 • K8, load sharing factor, does not apply since there is only a single beam • K7, depth factor = 300 0.11 h • Assume h = 250, K7 = 1.020 DEFLECTION M= 𝑊𝐿 8 = 10 𝑋 3 8 = 3.75 KNm σm,adm,||(assuming h = 250) = σm,g,||K3K7 = 5.3 × 1.0 × 1.020 = 5.406 N/mm2 Zxx req≥ 𝑀 σm,adm,|| = 3.75 x 106 𝑁𝑚 5.046 𝑁/𝑚𝑚2 = 694 x 103 mm3 DEFLECTION Permissible deflection (δp) = 0.003 × span The deflection due to shear (δs) is likely to be insignificant in comparison to the bending deflection (δb) and may be ignored in order to make a first estimate of the total deflection (δt): DEFLECTION δt(ignoring shear deflection) = 5Wl3 384Emin Ixx Since δp ≥ δt 0.003 x 3000 ≥ 5 x 104 x 30003 384 x 5800 x Ixx Ixxreq ≥ 67.3 × 106 mm4 From Table 6.8, section 75 × 250 provides Zxx = 781 × 103 mm3 Ixx = 97.7 × 106 mm4 A = 18.8 × 103 mm2 DEFLECTION Hence total deflection including shear deflection can now be calculated and is given by δ t including shear deflection = 5 x104 x 30003 = 384 x 5800 x 97.7 x 106 + 5Wl3 384Emin Ixx + 12 x104 x 3000 5 x 5800 x 18.8 x 103 12𝑊𝑙 5 𝐸𝑚𝑖𝑛 𝐴 = 6.2mm + 0.7mm = 6.9mm < δp δp = 0.003 x 3 = 0.009 = 9 mm Therefore a beam with a 75 × 250 section is adequate for bending and deflection Lateral Buckling Permissible d/b = 5 Actual = 250/75 = 3.3 (ok) Hence the section is adequate for lateral buckling. Shear Permissible shear stress is τadm = τgK2 K3= 0.67 × 1.0 = 0.67 N/mm2 Maximum shear force is =Fv= 𝑊 2 = 10 𝑋 103 2 = 5 X 103 N Maximum shear stress at neutral axis is τa = = 3 𝑋 5 𝑋 103 2 𝑋 18.8 𝑋 103 = 0.4 N/mm2 < permissible. The section is adequate in shear. 3Fv 2A BEARING Permissible bearing stress is σc,adm,⊥ = σc,g,⊥K2 K3 = 1.7 × 1.0 = 1.7 N/mm2 End reaction, F, is = 𝑊 2 = 10 𝑋 103 2 = 5 X 103 N The applied bearing stress is given by: σc,a,⊥ = F blb = 5 x 103 75 x 150 = 0.44 N/mm2 < permissible Therefore the section is adequate in bearing. Since all the checks are satisfactory, use 75 mm × 250 mm sawn C16 beam. Design of floor joist A timber floor spanning 3.8 m centre is to be designed using timber joist at 400 mm centres. The floor is subjected to domestic imposed load of 1.5kN/m2 and carries dead loading, including self weight of 0.35 kN/m2. Carry out design checks to show that a 44 mm x 200 mm deep sawn section Bruce spruce grade SS under service class 1 suitable. Joist Hanger Joist hangers are designed to provide support underneath the joist, rafter or beam to provide a strong a connection. Geometrical Properties Effective span Le = 3.8 m Joist Spacing Js = 0.4 m Joist dimensions Breath of section, b = 44mm Depth of section, h = 200mm Area of section = b x h = 8.8 x 103 mm2 1 bh3 12 Second Moment of area Ixx= Loading Dead load, DL = 0.35kNm-2 Imposed load, IL = 1.5kNm-2 Total load , W = (DL + IL) .Js . Le (0.35 + 1.5) x 0.4 x 3.8 = 2.81 kN = 2.93 x 107 mm4 K-factors Service Class 1 (K2 table 13) K2 = 1 Load duration (K3, Table 14) K3 =1 for long term Bearing: assume 50mm, but located < 75mm from the end of the member (K4, Table 15) (K4 = 1) Notched end effect (K5 clause 2.10.4) (K5 =1) for no notch Form factor K6 clause 2.10.5 (K6 =1) (2.10.5 Form factor Grade bending stresses apply to solid timber members of rectangular cross-section. For other shapes of cross-section the grade bending stresses should be multiplied by the modification factor, K6, where K6 = 1.18 for solid circular sections; and K6 = 1.41 for solid square sections loaded on a diagonal) Depth factor K7 clause 2.10.6 Load Sharing applies (K8, clause 2.9) K7 = K8 =1.1 300 0.11 h = 1.05 2.9 Load-sharing systems In a load-sharing system which consists of four or more members such as rafters, joists, trusses or wall studs, spaced a maximum of 610 mm centre to centre, and which has adequate provision for the lateral distribution of loads by means of purlins, binders, boarding, battens, etc., the following permissible stresses and moduli of elasticity appropriate to the strength class or species and grade should apply. a) The appropriate grade stresses should be multiplied by the load sharing modification factor, K8, which has a value of 1.1. b) The mean modulus of elasticity should be used to calculate deflections and displacements under both dead and imposed load unless the imposed load is for an area intended for mechanical plant and equipment, or for storage, or for floors subject to vibrations, e.g. gymnasia and ballrooms, in which case the minimum modulus of elasticity should be used. Special provisions for built-up beams, trimmer joists and lintels, and laminated beams, are given in 2.10.10, 2.10.11 and section 3, respectively. The provisions of this clause do not extend to the calculation of modification factor, K12, (given in Table 22 and Annex B) for load-sharing columns Grade Stresses BS5268: Part 2, Tables 2 and 7 British Spruce SS Strength Class = C18 Bending parallel to the grain σm,g,|| = 5.8N/mm2 Compression perpendicular to the grain σc,g,|| = 2.2N/mm2 (No wane) Shear parallel to the grain τg// =0.67N/mm2 Mean modulus of elasticity, load sharing Emean = 9100 N/mm2 Bending Stress 𝑊𝐿𝑒 8 2.82 x 3.8 M= = = 1.34 kNm 8 44 x 2002 Zprovided = = 2.93 x 105 mm3 (For rectangular 6 M 1.34 x 106 2 σm,a,|| = = =4.55N/mm Z provided 2.93 x 105 sections Zxx= 𝑏𝑑 2 ) 6 Permissible Bending Stress σm,adm,|| = σm,g,|| x K2K3K6K7K8 = 5.8N/mm2 x 1.05 x1.1= 6.67N/mm2 Bending stress is satisfactory Lateral Stability BS5268: Part 2, Clause 2.10.8 and Table 16 Permissible d/b = 5 (Ends held in position and compression edges held in line) Actual = 200/44 = 4.55 (ok) Hence the section is adequate for lateral stability. Shear Stress Permissible shear stress is τadm = τgK2K3K5K8 = 0.67 × 1.1 = 0.74 N/mm2 𝑊 2.81 Applied shear force is =Fv= = = 1.41kN 2 2 Applied shear stress at neutral axis is τa = 3 𝑋 1.41 𝑋 103 2 𝑋 8.8 𝑋 103 3Fv 2A = = 0.24 N/mm2 < permissible. The section is adequate in shear. Applied shear force is =Fv= 𝑊 2 = 2.81 2 = 1.41kN Assume a bearing length of 50mm on either side 𝑙𝑏 =50mm The applied bearing stress is given by: σc,a,⊥ = 𝐹 𝑏𝑙𝑏 = 1.41 x 103 44 x 50 = 0.64 N/mm2 σc,adm,⊥ = σc,g,⊥K2 K3 K4 K8 = 2.2N/mm2 × 1.1 = 2.42 N/mm2 σc,a,⊥ ≤ σc,adm,⊥ (Bearing stress satisfactory) δt = δm + δv 5Wl3 384Em𝑒𝑎𝑛 Ixx 19.2 𝑀𝑚𝑎𝑥 𝐴𝐸 + 19.2 𝑀𝑚𝑎𝑥 𝐴𝐸𝑚𝑒𝑎𝑛 is the maximum shear deflection induced in a single span simply supported beam of either rectangular or square cross section. δm = Δv = 5Wl3 384Em𝑒𝑎𝑛 Ixx 19.2 𝑀𝑚𝑎𝑥 𝐴𝐸𝑚𝑒𝑎𝑛 = = 5 x 2810 x 38003 384 x 9100 x 2.93 x 107 19.2x 1.34 x 106 8.8 x 103 x 9100 = 7.53mm = 0.32mm δt = 7.53 + 0.32 = 7.85mm The permissible deflection is generally given by δp = 0.003 × span =0.003 x 3800 =11.4mm Therefore the 44mm x 200mm sawn sections in C18 timber is satisfactory Design of floor joist – selection of suitable and design for notched ends. The cross-section of a suspended timber flooring is shown in the figure below. It consist of tongued and grooved (t & g) boarding with a self-weight of 0.15kN/m2 and carries a plasterboard ceiling of 0.2kN/m2. The floor has an effective span of 4.0 m and is subjected to domestic imposed load of 1.5 kN/m2. Design the timber floor joists using timber in strength class C18 under service class 1. If the joist are to be notched at bearings with a 72mm deep notch, check that the notched section is adequate. Geometrical properties Effective span Le = 4.0 m Joist Spacing Js = 0.45 m Loading Dead load, t & g boarding = 0.15kNm-2 Plasterboard ceiling Pb = 0.2kNm-2 Self-weight Swt. = 0.1kNm-2 (assumed) Imposed load, IL = 1.5kNm-2 Total load , W = (tg + Pb + Swt + IL) .Js . Le (0.15 + 0.2 + 0.1 + 1.5) x 0.45 x 4= 3.51 kN K-factors Service Class 1 (K2 table 16) K2 = 1 Load duration (K3, Table 17) K3 =1 for long term (K4, Table 18) assume (K4 = 1) Notched end effect (K5 clause 2.10.4) (K5 =1) for no notch Form factor K6 clause 2.10.5 (K6 =1) (2.10.5 Form factor Grade bending stresses apply to solid timber members of rectangular cross-section. For other shapes of cross-section the grade bending stresses should be multiplied by the modification factor, K6, where K6 = 1.18 for solid circular sections; and K6 = 1.41 for solid square sections loaded on a diagonal) Depth factor K7 clause 2.10.6 Load Sharing applies (K8, clause 2.9) K7 = 300 0.11 h K8 =1.1 Grade Stresses BS5268: Part 2, Table 7 Strength Class = C18 Bending parallel to the grain σm,g,|| = 5.8N/mm2 Compression perpendicular to the grain σc,g,|| = 2.2N/mm2 (No wane) Shear parallel to the grain τg// =0.67N/mm2 Mean modulus of elasticity, load sharing Emean = 9100 N/mm2 Bending Stress M= 𝑊𝐿𝑒 8 = 3.51 x 4 8 = 1.755 kNm Permissible bending stress σm,adm,|| = σm,g,|| x K2K3K6K8 = 5.8N/mm2 x 1.1= 6.38N/mm2 Zrequired = M σm,a,|| = 1.755 x 106 6.38 = 2.75 x 105 mm3 Lateral Stability BS5268: Part 2, Clause 2.10.8 and Table 16 In order to achieve lateral stability by direct fixing of decking to joists, the depth to breath ratio should be limited to 5, i.e. h ≤ 5b. Substituting for h = 5b and Zxx =bh2/6 and equating Zxx required gives: Zrequired = b= b x (5b)2 6 1 6 x zreq 3 52 =b= 6 x 2.75 x 105 105 52 1 3 = 40.42 mm h = 5b = 5 x 40.42 = 202.08mm Selecting a beam section from table A2, Appendix A. Try a 47mm x 200mm deep section Beam dimensions Breath of section, b = 47 mm Depth of section, h = 200mm Zprovided = b x h2 6 = 3.13 x 105 300 0.11 h Modification factor K7 for section depth = = 1.05 Permissible Bending Stress σm,adm,|| = σm,g,|| x K2K3K6K7K8 = 5.8N/mm2 x 1.05 x1.1= 6.67N/mm2 Bending stress is satisfactory. Self Weight BS5268: Part 2, Table 7 Average density ρ = 380 kgm-3 Total joist selfweight = Swtactual = ρghbLe (380 kgm-3/1000) (9.81m/s2)(0.047m x 0.2m x 4m) Swtactual = 0.14kN Swtassumed =Swt x Le x Js = 0.1kN/m2 x 4m x 0.45m = 0.18kN ( Self weight is satisfactory) Shear Stress Permissible shear stress is (i) No notch τadm = τgK2K3K5K8 = 0.67 × 1.1 = 0.74 N/mm2 With notch 72mm deep Effective section depth he = h – notch he = 128mm BS5268: Part 2, Clause 2.10.4 K5 = ℎ𝑒 ℎ = 128/200 = 0.64 With notch τadm = τgK2K3K5K8 = 0.67 × 1.1 x 0.64 = 0.47 N/mm2 Applied shear force is =Fv= 𝑊 2 = 3.51 2 = 1.75kN Applied shear stress at neutral axis is τa = 3 X 1.75 X 103 2 X 47 x 200 3Fv 2A = = 0.24 N/mm2 < permissible. The section is adequate in shear. Bearing Stress Applied shear force is =Fv= 𝑊 2 = 3.51 2 = 1.75kN σc,adm,⊥ = σc,g,⊥K2 K3 K4 K8 = 2.2N/mm2 × 1.1 = 2.42 N/mm2 Minimum bearing width bw required= Fv b x σc,adm,⊥ = 15.43mm δt = δm + δv 5Wl3 384Em𝑒𝑎𝑛 Ixx Ixx= 𝑏ℎ3 12 δm = Δv = + 19.2 𝑀𝑚𝑎𝑥 𝐴𝐸𝑚𝑒𝑎𝑛 = 3.13 x 107 mm4 5Wl3 384Em𝑒𝑎𝑛 Ixx 19.2 𝑀𝑚𝑎𝑥 𝐴𝐸𝑚𝑒𝑎𝑛 = = 5 x 3510 x 40003 384 x 9100 x 3.13 x 107 19.2x 1.75 x 106 47 x 200 x 9100 = 10.26mm = 0.39mm δt = 10.26 + 0.39 = 10.65mm The permissible deflection is generally given by δp = 0.003 × span =0.003 x 4000 =12 mm Therefore the 47mm x 200mm sawn sections in C18 timber is satisfactory Design of flooring elements and components in solid timber Design of a flooring system- floor boards and joist Design of a flooring system- floor boards and joist The ground floor of a shop is to comprise a series of timber joist at 600mm centres with tongued and groove boardings (t & g) The joist are simply supported on 100 mm hangers attached to load bearing walls 4.2 m apart. Determine the thickness of the floor boarding using timber in strength class C18 and a suitable size for joists using timber in C22 under service class 2. Assume imposed load of 2.0kN/m2 • • • The floor boards may be designed as simply supported beams Calculations are required for bending strength and deflections Assume tongued and groove boarding 100mm wide and thickness t simply supported on joist Geometrical properties Effective span Le = joist spacing js = 0.6m Assume a t & g boarding of width b = 100 mm Loading t & g boarding = 0.1kNm-2 Imposed load, IL = 2 kNm-2 Total load , W = (tg + IL) . b . Le (0.1 + 2 ) x 0.1 x 0.6 = 0.126 kN K-factors Service Class 1 (K2 table 13) K2 = 1 Load duration (K3, Table 14) K3 =1 for long term Bearing assume (K4, Table 15) (K4 = 1) assumed Notched end effect (K5 clause 2.10.4) (K5 =1) for no notch Form factor K6 clause 2.10.5 (K6 =1) Depth factor K7 clause 2.10.6 for h ≤ 72mm K7 =1.17 Load Shearing applies (K8, clause 2.9) K8 =1.1 K-factors Service Class 1 (K2 table 13) K2 = 1 Load duration (K3, Table 14) K3 =1 for long term Bearing assume (K4, Table 15) (K4 = 1) assumed Notched end effect (K5 clause 2.10.4) (K5 =1) for no notch Form factor K6 clause 2.10.5 (K6 =1) Depth factor K7 clause 2.10.6 for h<72mm K7 = 1.17 Load Shearing applies (K8, clause 2.9) K8 =1.1 Grade Stresses (t&g) BS5268: Part 2, Tables 8 and 9 Strength Class = 18 Bending parallel to the grain σm,g,|| = 5.8N/mm2 Compression perpendicular to the grain σc,g,|| = 2.2N/mm2 (No wane) Shear parallel to the grain τg// =0.67N/mm2 Mean modulus of elasticity, load sharing Emean = 9100 N/mm2 Bending Stress 𝑊𝐿𝑒 0.126 x 0.6 M= = = 9.45 x 10-3 kNm 8 8 Permissible bending stress σm,adm,|| = σm,g,|| x K2K3K6K7K8 = 5.8N/mm2 x 1.1 x 1.17= 7.46N/mm2 M Zrequired = σm,a,|| 9.45 x 10−3 x 106 𝑁𝑚𝑚 Zrequired = = 1.27 x 103 mm3 2 7.46 N/mm Zrequired = b t2 6 = 1.27 x 103 mm3 where b = 100mm t = 8.72 mm Deflection The permissible deflection is generally given by δp = 0.003 × span =0.003 x 600 =1.8 mm δm = 5Wl3 384Em𝑒𝑎𝑛 Ixx = 5 x 0.126 x 1000 x 6003 = 384 x 9100 x Ixx Ixx = 2.16 x 104 mm4 Ixx = b t3 12 t = 13.74 mm Use t = 16 mm t & g boarding of strength class C18 1.8mm Design of floor joist Geometrical properties Effective span Le = 4.1 m joist spacing js = 0.6 m Bearing width bw = 100 mm Loading Average density ( Table 7) = 410 kg m-3 t & g boarding = ρgt = 410kg m-3 x 9.81m/s2 x 0.016m = 64Nm-2 = 0.064 kNm-2 Self weight of each joist = 0.1 kNm-2 assumed Imposed load, IL = 2 kNm-2 Total load , W = (tg + sw+ IL) . js . Le (0.064 + 0.1 + 2 ) x 0.6 x 4.1 = 5.32 kN K-factors Service Class 2 (K2 table 13) Load duration (K3, Table 14) Bearing assume (K4, Table 15) Notched end effect (K5 clause 2.10.4) Form factor K6 clause 2.10.5 Depth factor K7 clause 2.10.6 Load Shearing applies (K8, clause 2.9) K2 = 1 K3 =1 for long term (K4 = 1) assumed (K5 =1) for no notch (K6 =1) Ignore K7 at this stage K8 =1.1 Grade Stresses BS5268: Part 2, Table 8 Strength Class = C22 Bending parallel to the grain σm,g,|| = 6.8N/mm2 Compression perpendicular to the grain σc,g,|| = 2.3 N/mm2 (No wane) Shear parallel to the grain τg// =0.71N/mm2 Mean modulus of elasticity, load sharing Emean = 9700 N/mm2 Bending Stress 𝑊𝐿𝑒 5.32 x 4.1 M= = = 2.73 kNm 8 8 Permissible bending stress σm,adm,|| = σm,g,|| x K2K3K6K8 = 6.8N/mm2 x 1.1 = 7.48N/mm2 M Zrequired = σm,a,|| 2.73 x 106 Zrequired = = 3.65 x 105 mm3 7.48 Lateral Stability BS5268: Part 2, Clause 2.10.8 and Table 16 In order to achieve lateral stability by direct fixing of decking to joists, the depth to breath ratio should be limited to 5, i.e. h ≤ 5b. Substituting for h = 5b and Zxx =bh2/6 and equating Zxx required gives: Zrequired = b= b x (5b)2 6 1 6 x zreq 3 52 =b= 1 6 x 3.65 x 105 3 52 = 44.4 mm h = 5b = 5 x 44.4 = 222.02mm Selecting a beam section from table A2, Appendix A. Try a 47mm x 225 mm deep section Beam dimension Depth h = 225mm Breadth b = 47mm b x (h)2 6 Section Modulus Zprovided = Zprovided = 3.97 x 105 mm3 300 0.11 Depth factor K7 K7 = = 1.03 h Permissible Bending Stress σm,adm,|| = σm,g,|| x K2K3K6K7K8 = 6.8N/mm2 x 1.03 x1.1= 7.7N/mm2 Bending stress is satisfactory. Self Weight BS5268: Part 2, Table 7 Average density ρ = 410 kgm-3 Total joist self weight = Swtactual = ρghbLe = 410 x 9.81 x 0.047 x 0.225 x 4.1 = 174 N Swtactual = 0.17kN Swtassumed =Swt x Le x Js = 0.1 x 0.6 x 4.1 = 0.25kN ( Self weight is satisfactory) Shear Stress Permissible shear stress is (i) No notch τadm = τgK2K3K5K8 = 0.71 × 1.1 = 0.78 N/mm2 Applied shear force is =Fv= 𝑊 2 = 5.32 2 = 2.66 kN Applied shear stress at neutral axis is τa = = 3 X 2.66 X 103 2 X 47 x 225 3Fv 2A = 0.38 N/mm2 < permissible. The section is adequate in shear. Bearing Stress Applied shear force is =Fv= 𝑊 2 = 5.32 2 = 2.66 kN σc,adm,⊥ = σc,g,⊥K2 K3 K4 K8 = 2.3N/mm2 × 1.1 = 2.53 N/mm2 Fv Minimum bearing width bw required= = b x σc,adm,⊥ mm, OK 2.66 x 1000 47 x 2.53 22.39mm < 100 δt = δm + δv 5Wl3 384Em𝑒𝑎𝑛 Ixx Ixx= 𝑏ℎ3 12 + 19.2 𝑀𝑚𝑎𝑥 𝐴𝐸𝑚𝑒𝑎𝑛 = 4.46 x 107 mm4 5Wl3 5 x 5320 x 41003 δm = = = 11.04mm 7 384Em𝑒𝑎𝑛 Ixx 384 x 9700 x 4.46 x 10 19.2 𝑀𝑚𝑎𝑥 19.2x 2.73 x 106 Δv = = = 0.51mm 𝐴𝐸𝑚𝑒𝑎𝑛 47 x 225 x 9700 δt = 11.04+ 0.51 = 11.55mm The permissible deflection is generally given by δp = 0.003 × span =0.003 x 4100 =12.3 mm Therefore the 47mm x 225mm sawn sections in C22 timber is satisfactory Design of axially loaded members Compression members include posts or columns, vertical wall stud, and struts and truss girders. Permissible stresses are governed by the particle conditions of service and loading in clause 2.6.2, 2.8 and 2.9 of BS5268: Part 2: 1968. Clause 2.11 deals with the design of compression members and divides them into two categories: • members subjected to axial compression (without bending), and members subjected to combined axial compression and bending ( due to eccentric compressive force) Design considerations The main design considerations for compression members are: (i) Slenderness ratio – This relates the positional restraint of ends, lateral restraint along the length and cross sectional dimensions of the member. (ii) Axial compression and bending stress. Slenderness Ratio, λ The load-carrying capacity of compression members is a function of the slenderness ratio, λ, which is calculated as the effective length Le divided by the radius of gyration, i: λ= 𝐿𝑒 𝑖 and the radius of gyration is given by 𝑖 = 𝐼 𝐴 Where I is the second moment of area and A is the cross sectional area of the member Slenderness Ratio, λ For rectangular sections, where b is the least lateral dimension, the value of i simplifies to: i= 𝑏 12 Clause 2.11.4 of BS5268: Part 2: 1996 recommends that the slenderness ratio should not exceed the value of : λ = 180 for compression members carrying dead and imposed loads other than loads resulting from wind, λ = 250 for any member subject to reversal of axial stress solely from the effect of wind and any compression member carrying self weight and wind loads only. Slenderness Ratio, λ The effective length Le of a column given in clause 2.11.3 should be derived from either : 1. The deflected form of compression member affected by any restraint and fixing moment(s). Then the effective length is considered as the distance between adjacent points of zero bending moment. 2. Table 21 of the code for particular end conditions at the column ends. The effective length is obtained by multiplying a relevant coefficient by the actual length. Effective lengths and end conditions Slenderness Ratio, λ • For compression members with slenderness ratios equal to or greater than 5, Clause 2.11.5 of the code requires that the permissible compressive stresses be further modified by K12 – the modification factor for compression members. • The modification factor for K12 can be determined by using table 22 of BS5268 or calculated from equation. For either method, the value of the modulus of elasticity Emin should be used in all cases , including when load sharing is present. • The value of σc,|| for use in either method should be the σc,g,|| given in tables 7 – 12a of the code modified only for moisture content, duration of loading and size where appropiate. • Members comprising of two or more pieces connected together in parallel and acting together to support the loads, the minimum modulus of elasticity should be modified by K9 ( Table 20) or K28 (Table 25) of the code Slenderness Ratio, λ • For horizontally laminated members, the mean modulus of elasticity should be used ( see clause 3.2 and 3.6 of the code). K12 may calculated as follows: K12 = 1 2 + 1+ η π2 𝐸 3λ2 σ𝑐 − 1 2 + 1+ η π2 𝐸 2 3λ2 σ𝑐 − π2 𝐸 1/2 1.5λ2 σ𝑐 σ𝑐 = permissible stress for very short column λ < 5, σc,g,|| x K2K3 E = minimum modulus of elasticity Emin λ= 𝑠𝑙𝑒𝑛𝑑𝑒𝑟𝑛𝑒𝑠𝑠 η = 0.005 λ 𝐿𝑒 𝑟𝑎𝑡𝑖𝑜, 𝑖 Members subjected to axial compression only (Clause 1.11.5) An axially loaded column has its line of action of load passing through the centroid axis of the column. The axial compressive stress σc,g,|| is given as σc,g,|| = 𝑃 𝐴 Where P is the axial compressive load and A is the cross sectional area. If λ < 5 σc,adm,|| = σc,g,|| x k2k3K8 If λ ≥ 5 σc,adm,|| = σc,g,|| x k2k3K8K12 The Compression member is designed so that σc,a,|| ≤ σc,adm,|| Axial, concentric and eccentric loads Members subjected to axial compression and bending ( Clause 2.11.6) This includes compression members subject to eccentric loading, where the load acts through a point at a certain distance from the centroidal axis, which can be equated to the axial compression and bending moment (b, c or d). Members which are restrained at both ends in position but not direction should be so proportioned so that: Interaction formula Interaction Formula The interaction formula is used to ensure lateral instability does not arise in compression members subject to axial force and bending. If the column is subjected to compressive loading only σm,a,|| = 0, and the equation simplifies to σc,a,|| /σc,adm,|| ≤ 1. If the column is subjected to bending only σc,a,|| = 0, and the equation simplifies to σm,a,|| /σm,adm,|| ≤ 1. Design of Load Bearing Stud Walls Stud walls are often constructed as load bearing walls in timber framed housing. Details of a typical stud wall Stud walls • Stud walls consist of vertical timber members, commonly referred to as studs, which are held in position by nailing them to timber rails or plates, located along the top and bottom of the studs. • The walls can be designed to resist vertical and lateral loadings, wind load being a typical example of a lateral load. • Each stud may be considered to be laterally restrained about the y-y axis, fully or partially restrained, (e.g. at mid-height), either by cladding/sheathing materials, such as plasterboard and internal noggins or diagonal bracing. • In situations where the cladding/ sheathing material is properly attached to the stud along its whole length, the strength of the stud can be calculated about the x-x axis; otherwise, the greater of the slenderness ratio about the individual stud’s x-x and y-y axis should be considered in the design calculation. Stud walls Design Examples – Load capacity of timber column A timber column of strength class C18 is 4m in height with rectangular cross-section of 97mm x 145mm. The column is restrained at both ends in position but not in direction and is subjected to service class 2 conditions. (i) Determine the maximum axial long-term load that the column could support. (ii)Check the adequacy of the column to resist a long-term axial load at 12kN and a bending moment of 0.8kNm about the x-x axis. Column Details Geometrical Properties K-factors Service Class 2 (K2 table 16) Load duration (K3, Table 17) Form factor K6 clause 2.10.5 Depth factor K7 clause 2.10.6 K7 = 1.08 Load Sharing (K8, clause 2.9) K2 = 1 K3 =1 for long term (K6 =1) K7 = 300 0.11 h K8 =1.0 ( no load sharing) K12 Using Table 22

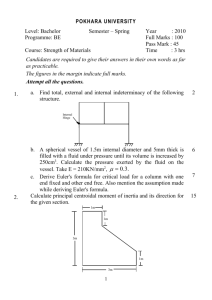

![Applied Strength of Materials [Opens in New Window]](http://s3.studylib.net/store/data/009007576_1-1087675879e3bc9d4b7f82c1627d321d-300x300.png)