Valine Sensing for MSUD using Saffron-Silver Nanoparticles

advertisement

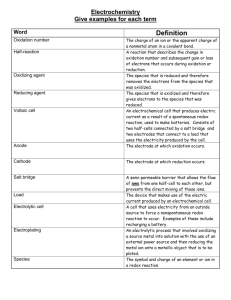

12 (2022) 100275 Contents lists available at ScienceDirect Biosensors and Bioelectronics: X journal homepage: www.journals.elsevier.com/biosensors-and-bioelectronics-x Electrochemical sensing of the maple syrup urine disease biomarker valine, using saffron-silver nanoparticles Sophia Karastogianni *, Ioanna Paraschi, Stella Girousi ** Aristotle University of Thessaloniki, Analytical Chemistry Laboratory, Chemistry Department, 54124, Thessaloniki, Greece A R T I C L E I N F O A B S T R A C T Keywords: Electrochemical sensing Saffron Silver nanoparticles Urine samples Maple syrup disease Valine Metabolic disorders are inherited disorders in which genetic defects prevent a metabolic pathway and cause enzymes to malfunction. Maple syrup urine disease (MSUD) is a rare metabolic disease marked by high levels of branched-chain amino acids (b-AAs), leucine, isoleucine, and valine. Elevated concentrations of b-AAs pose is­ sues including liver failure, neurocognitive impairment, and mortality. Given the unavoidable repercussions for newborns, it is critical to establish quick and adaptable diagnoses in the early stages of life. Thus, this study highlights the development of a novel electrochemical sensor for valine detection (MSDU biomarker) based on a modified carbon paste electrode (CPE) with electropolymerized silver nanoparticles capped with saffron (AgNPs@Sa) synthesized using a green method. Thus, a modified carbon paste electrode (CPE) with a conductive polymer posing silver nanoparticles was employed to sensitively determine Val in this paper. Saffron capped with silver nanoparticles (AgNPs@Sa) were synthesized, using a green method and studied using cyclic and square wave voltammetry. Cyclic voltammetry (CV) was used in the electropolymerization of AgNPs@Sa on CPE (polyAgNPs@Sa-CPE) and utilized in the detection of Val. The modified electrode under the selected conditions produced square wave signals with valine mass concentrations ranging from 0.258 to 11.94 ng L− 1 in the case of buffer solutions and it was successfully applied in urine samples. The assay proved to be simple, rapid, and costeffective, sensitive with a low detection limit of 0.085 and 0.097 ng L− 1 for buffer and urine samples, respectively. 1. Introduction Metabolic disorders differ widely in terms of symptoms, prognosis, and specific breakdown in catabolic pathways. These disorders are not strictly classified, and the most popular classification takes into account the principal compound that is affected (carbohydrates, fatty acids, amino acids, and organic acids) [Jumbo-Lucioni et al., 2012; Burrage et al., 2014]. Maple syrup urine disease (MSUD) is a rare chronic and progressive disease caused by a defect in the branched-chain keto acid dehydroge­ nase complex (bkAD), which is involved in the catabolic pathway of branched-chain amino acids (b-AAs), leucine (Leu) isoleucine (ileu), and valine (Val) [Blackburn et al., 2017]. MSUD has five distinct phenotypes with no obvious genotype-phenotype relationship. MSUD is classified based on the age of onset, the severity of symptoms, the responsiveness to thiamine supplementation, and biochemical findings [Blackburn et al., 2017]. MSUD caused by E3 deficiency is most common in infants, but intermediate, intermittent, and thiamine-responsive MSUD can occur at any age [Blackburn et al., 2017]. To avoid these concerns, it is critical to obtain a prompt and accurate diagnosis during the prime periods of life [Blackburn et al., 2017, Burrage et al., 2014, García-­ Carmona et al. 2019, Scott 2006]. MSUD is characterized by neurological and developmental de­ ficiencies, encephalopathy, eating difficulties, and a maple syrup smell in the urine. Elevated plasma b-AAs biochemically describe MSUD and all b-AAs and allo-isoleucine are routinely examined, and inmates generally have satisfactory clinical outcomes in addition to timely therapy [Burrage et al., 2014; García-Carmona et al., 2019a]. Tandem mass spectrometry (MS/MS), nuclear magnetic resonance (NMR), enzyme activity assays, high-pressure liquid chromatography (HPLC), capillary electrophoresis (CE), and genetic testing are the most prevalent methods for determining Val [Azuma et al., 2016, Castellanos et al., 2016, Delgado-Povedano et al., 2016, Fernández-Del-Campo-­ García et al., 2019, Le et al., 2019, Song et al., 2013, Synaridou et al., * Corresponding author. ** Corresponding author. E-mail addresses: skarastogianni@hotmail.com, karastos@thea.auth.gr (S. Karastogianni), girousi@chem.auth.g (S. Girousi). https://doi.org/10.1016/j.biosx.2022.100275 Received 4 August 2022; Received in revised form 24 October 2022; Accepted 25 October 2022 Available online 4 November 2022 2590-1370/© 2022 The Authors. Published by Elsevier B.V. This is an open access article under the CC BY license (http://creativecommons.org/licenses/by/4.0/). S. Karastogianni et al. Biosensors and Bioelectronics: X 12 (2022) 100275 2021, Tuma and Gojda, 2015, Ulusoy et al., 2016, Wei et al., 2017, Wolak-Dinsmore et al., 2018], using various separation and detection methods. Regardless, all these methods are time-consuming and, in certain situations, require a large sample volume. Another factor that complicates the diagnosis of MSUD is the fact that newborn surveillance criteria vary by country and even within the same country, making the diagnosis of MSUD more difficult. Further­ more, there is no cure, although dietary limitations are recommended, and frequent monitoring of the target molecule should be done throughout the patient’s life to minimize negative effects. In concluding, Song et al. [Song et al., 2018] extensively reviewed current advance­ ments in standard amino acid analysis methods in biological samples, providing thorough information on their analytical features. Problems in MSUD diagnosis and monitoring, as well as the deter­ mination of b-AAs, highlight the need for new diagnostic procedures that are simple to use and require small sample volumes, which is especially relevant in neonates [Lv et al., 2019; Sandlers 2017]. Because of their ease of use, simplicity, selectivity, sensitivity, and low cost, electrochemical sensors represent a reliable means of determining metabolic biomarkers to facilitate their use in the diagnosis and moni­ toring of rare diseases [Dincer et al., 2017; Zhang et al., 2016]. Interestingly, electrochemical sensors have hardly been put to practical use for the determination of MSUD biomarker Val. This is evidenced by the fact that Val is relatively electrochemically inactive on bare electrodes [Xinying 2014]. This constraint can be overcome by utilizing electrode modifiers like metal nanoparticles, polymer nano­ particles, and metals. Consequently, Val had been detected using iron oxides [Hasanzadeh et al., 2013], multiwalled carbon nanotubes (MWCNT) [Saghatforoush et al., 2011], cobalt nanoparticles (CoNPs) [Hasanzadeh et al., 2009], vertically aligned nickel nanowires [García-Carmona et al., 2018], nickel oxide nanoparticles (NiONPs) [Tooley et al., 2018], modified screen-printed electrodes (SPE) with iron [Naqvi et al., 2020], polymer nanocrystals [Bi et al., 2016], enzyme-based microfluidic chip coupled with graphene electrodes [García-Carmona et al., 2019b] with sufficient analytical features. In summary, Karastogianni et al. 2020 extensively reviewed current advancements in electrochemical sensing of MSUD biomarkers like Val, providing thorough information on their analytical features. Conducting polymers (CP) are increasingly being used as sensitive electrode surface modifiers on electrochemical sensors and biosensors [Cosnier and Lepellec 2003]. They are differentiated by their strong electrical conductivity and electrochemical reversibility, permitting them to be used in sensor transducer signaling. Moreover, CPs can generate functional groups that could act as "tags" to recognize biolog­ ical or chemical entities [Garnier 1989]. Yet, detecting small (bioactive) analytes such as Val remains a challenge because their interaction with detectable groups on the CP substrate is inadequate to create the required electrochemical changes for detection. The objective in this respect was to construct particularly specific CP recognition sites, enhancing the selectivity and sensitivity of the iden­ tification method. Silver nanoparticles can be employed in the fabrica­ tion of polymers generated by electrochemical techniques, and their advantages comprise biocompatibility, excellent conductivity, and a large surface-to-volume ratio [Rezaei et al., 2008]. As an outcome, they are especially inspiring tools in electrochemical sensing and biosensing [Barnes et al., 2003; Karastogianni and Girousi 2017; Lai et al., 2013; Li et al., 2013; Papaioannou et al., 2022; Yang et al., 2010], since they can be extensively used in modifying the surface of electrodes, establishing approaches for detecting species biologically relevant, or fabricating diagnostic elements for a variety of pathological states. The novelty of this study lies in the fact that it is the first attempt to determine valine using square wave voltammetry (SWV). Additionally, the proposed electrochemical sensor was found to have high sensitivity, as it presents a lower detection limit than existing methodologies re­ ported in the literature. Furthermore, the proposed procedure was successfully applied in urine samples, indicating the potential applica­ bility of the sensor to real sample analysis. Moreover, the novelty of this paper is the use of silver nanoparticles, fabricated with a simple, costeffective as well as green technology and successfully used in the con­ struction of an electrochemical sensor that selectively and sensitively detects valine both in buffer solution and urine samples. Therefore, silver nanoparticles capped with saffron seem to be a promising tool in sensing since it was successfully applied by our team both in the detection of Valine (present study) and mephedrone [Papaioannou et al., 2022]. Finally, this work led to the improvement of the properties of carbon paste electrodes as well as the accurate application of elec­ trochemical techniques in real sample analysis. 2. Material and methods Unless otherwise noted, all reagents were analytical grade and were used exactly as they were received. Merck provided the tris hydrox­ ymethyl amino-methane (Tris 99.8%, ACS), ethyl-diamino-tetra-acetic acid (EDTA, ACS reagent, 99.4–100.06%), potassium dihydrogen phosphate, and dipotassium hydrogen phosphate (Darmstadt, Ger­ many). Sigma-Aldrich (Saint Louis, MO, USA) provided mineral oil (IR spectroscopy), sodium hydroxide, hydrochloric acid, nitric acid. Graphite powder was purchased from Fluka (USA) (50870, p.a. purity 99.9% and particle size <0.1 mm, synthetic). Saffron was purchased from a local store. As previously reported (Karastogianni and Girousi 2017; Papaioannou et al., 2022], silver nanoparticles were synthesized. Briefly, saffron and silver nitrate (1:1 mass ratio) was dispersed in 25 mL of NaOH aqueous solution (pH 10.0) in a 100 mL beaker with stirring, for 3 min, and then exposed to the sun for 30 min in static condition. The color of the mixture turned from wine red to brownish-yellow, showing that silver nanoparticles were formatted. Afterward, the AgNPs@Sa was preserved at ambient temperature, washed with water and ethanol, and dried in a vacuum desiccator before being utilized. Deionized water was used to make all of the aqueous solutions. A Palm Sens potentiostat/galvanostat model 1 was used for vol­ tammetric experiments (Echo Chemie, The Netherlands). The electrodes in a traditional three-electrode cell were a platinum wire counter elec­ trode, a 3 mol L− 1 KCl saturated Ag/AgCl reference electrode, a carbon paste electrode (CPE) with a 3 mm inner and 9 mm outer diameter of the PTFE sleeve, as well as the proposed modified electrode working elec­ trodes. All of the tests were carried out at room temperature. A Consort C830 pH meter was used to determine the pH of all solutions (Consort bvba, Turnhout, Belgium). The electrochemical cells were washed and rinsed with deionized water after being cleaned with diluted nitric acid. Prior to each experiment, ultrapure nitrogen was utilized to de-aerate the liquids by purging the dissolved oxygen for 15 min. Hand blending the right amount of graphite and paraffin oil in a mass ratio of 75/25 resulted in the carbon paste electrode (CPE) [Svancara et al., 2012]. The PTFE sleeve was filled with a portion of the resulting mixture. Before use, the surface was polished smooth by hand on a piece of weight paper. Stainless steel screws were used to make electrical contact. Using cyclic voltammetry (CV), modified CPE with AgNPs@Sa was created by depositing the electropolymerized silver nanoparticles on the surface of the CPE (poly-AgNPs@Sa-CPE). In the AgNPs@Sa solution (0.100 mol L− 1 acetate buffer pH 5.6 containing 0.010 mol L− 1 NaNO3), cyclic voltammetric electrodeposition from − 0.300 to + 1.300 V for one cycle with a scan rate of 0.200 V s− 1 and a step potential of 0.005 V was performed to immobilize the polymeric form of silver nanoparticles capped with saffron on the surface of the CPE (poly-AgNPs@Sa-CPE). The electrode was then dried for 5 min at room temperature. Following the electrodeposition of poly-AgNPs@Sa on CPE, an in­ cubation step was performed and the dissolving solution of Val (0.100 mol L− 1 Tris-HCl buffer pH 8.0) was stirred for 180 s without applying a potential to allow Val to be transferred to the proposed modified elec­ trode (Val-poly-AgNPs@Sa-CPE). 2 S. Karastogianni et al. Biosensors and Bioelectronics: X 12 (2022) 100275 The prepared Val-poly-AgNPs@Sa-CPE was then transferred to the measurement solution (0.100 mol L− 1 buffer solution pH 4.0), where signal transduction was accomplished using square wave voltammetry and anodic scanning of the working electrode potential between − 0.300 and +1.300 V with a step potential of 0.005 V, a pulse potential of 0.035 V, and a frequency of 5 Hz. The voltammograms that accompanied each measurement correspond to the oxidation peak of saffron-capped silver nanoparticles and the oxidation occurred at about +0.330 V. The raw data were processed using the PalmSens software’s Savitzky and Golay filter (level 2), followed by a moving average baseline correction with a peak width of 0.03. After the CPE surface was regen­ erated by cutting and polishing the electrode, replicated measurements were taken. A member of our laboratory team volunteered to provide urine samples. The urine sample was first filtered. The mixture was then diluted at 1:100 with 0.100 mol L− 1 acetate buffer pH 5.6 containing 0.010 mol L− 1 NaNO3, and sonicated for 10 min. Following that, accompanied with a 45 mm Millipore membrane was conducted, fol­ lowed by a 1:25 dilution and then another 10 min in the ultrasonic bath. The background concentration in the blank matrices was reduced by diluting the urine samples before spiking with standards [Thakare et al., 2016]. A known volume of a standard Val solution of 1.000 μg L− 1 was added to each of seven volumetric flasks (50 mL) holding urine samples. To the first one, no standard solution was added. The oxidation signal of the above-mentioned solutions was used to construct the calibration curve. of the two irreversible oxidation peaks at about +0.369 and + 0.800 V decrease progressively up to the fifteenth scan cycle. The current response of the reduction peak approximately at +0.100 V also de­ creases progressively with increasing the number of scan cycles. Furthermore, above the fifth scan cycle, the current reduction peak disappears. These oxidation and reduction peaks could be attributed to the oxidation and reduction of crocin, respectively [Armellini et al., 2017; Dar et al., 2017]. This behavior of poly-AgNPs@Sa cannot necessarily be related to the destruction of their formed polymeric film in CPE (peroxidation) at the relatively high potentials of the experiment, nor to the fact that the formed polymeric film on the CPE can remain electro-inactive and either prevent the oxidation of an additional monomer from the solution or is exposed to a small number of reactive monomers (depleted reservoir), which is adjacent to the working electrode diffusion layer [Kannan et L. 2011, Velusamy et al., 2011; Wang et al., 2014]. This behavior may be due to the process of structural reorganization carried out in the growing polymer layer adjacent to the working electrode diffusion layer [Velusamy et al., 2011]. . Meanwhile, the potential shifts to more negative prices. This means that different species are formed at the electrode, which is possibly due to the process of structural reorgani­ zation which is carried out in the growing polymer film [Martins et al., 2005]. According to R. Armellini et al., 2017, crocin oxidation occurs via two distinct one-electron oxidation pathways in ethanol:acetonitrile (1:1) solvent system with LiClO4 as supporting electrolyte solution. Furthermore, the creation of the free radical species, crocin., might be attributed to the first irreversible oxidation peak at around +0.360 V (Fig. 1). The peak current was then abruptly increased to approximately +0.800 V, which corresponds to the crocin radical that was further oxidized to crocin2+. Only a minor cathodic wave occurred at +0.100 V, approximately +260 mV less negative than the previous anodic peak, consistent with a pseudo-reversible mechanism [Jorgensen et al., 1997]. In order to clarify this issue, it is necessary to study the polymer film in a solution that does not contain the monomer, so that any response of current arises solely due to the connection of Sa@AgNPs to the surface of CPEThe electrochemical response of the poly-Sa@AgNPs, formed on the CPE surface was studied in the absence of monomer in 0.1 mol L− 1 ac­ etate buffer pH 4.0 using cyclic voltammetry. The polymer film gave two oxidation peaks at about +0.290 and + 0.890 V and two reduction peaks at about +0.100 and + 0.200 V, see Fig. S1. These peaks were similar to those given by the polymerization solution with the difference that an additional reduction peak also appeared around +0.896 V, see Fig. S1. The oxidation and reduction peaks are attributed to the oxidation and reduction of crocin, respectively, located in the polymer film [Armellini et al., 2017; Dar et al., 2017]. In addition, it can be seen from the cyclic voltammograms in Fig. S1 that the current response of the oxidation and the reduction peaks remain almost constant with increasing the number of scan cycles, and the potential of the oxidation and reduction peaks slightly shifts to more positive values with increasing the number of scan cycles. It is noted that the response of the second oxidation peak in­ creases until the ninth scan cycle of the potential (turquoise curve, Fig. S1) and then decreases and finally disappears. This reduction is probably due to the total consumption of crocin free radicals and availability for further oxidation to [crocin]2+ [Armellini et al., 2017] and the partial breakdown of the polymeric film [Mansouri Majd et al., 2013]. Saffron capped with silver nanoparticles was cycled through twenty scans consecutively to evaluate the existence of passivation events in its oxidation process. The change in peak current between the first and last oxidation peaks was found to be less than 3%, indicating a minor passivation impact. Furthermore, when cycling the potential with a scan rate ranging from 15 to 100 mV s− 1, the resulting peak current changed linearly with the square root of the scan rate, consistent with a diffusioncontrolled oxidation process [Bard and Faulkner, 2001, Wopschall and Shain 1967]. 3. Results and discussion 3.1. Electropolymerization of silver nanoparticles Poly-AgNPs@Sa was potentiodynamially polymerized on CPE with a scan rate of 20 mV s− 1 and a potential range of − 0.300 V to +1.300 V vs. Ag/AgCl. It’s worth noting that it wasn’t applied a pretreatment step was not used on CPE [Kang et al., 2002; Sheberla et al., 2015]. Fig. 1 shows the CVs of poly-AgNPs@Sa on CPE, which demonstrate progres­ sive decreases in the peak current over the polymerization process. Furthermore, it can be seen in the figure that the peak current responses Fig. 1. Electrochemical deposition of AgNPs@Sa in acetate buffer pH 5.6 containing 0.010 mol L− 1 NaNO3 at 0.200 V s− 1 on CPE. (a): number of scan 1, (b) number of scan 3, (c): number of scan 5, (d): number of scan 7, (e): number of scan 10, and (g): number of scan 15. Other experimental conditions as mentioned in the materials and methods section. 3 S. Karastogianni et al. Biosensors and Bioelectronics: X 12 (2022) 100275 The peak current intensity of Val on the modified electrode was substantially pH-dependent, peaking at pH = 5.6. Peaks were absent at pH levels greater than 7.6. Furthermore, the peak potential as a function of pH revealed values similar to those predicted for a proton and twoelectron (ΔE/ΔpH) = (24,32 ± 0,668) mV/pH at 25 ◦ C). The stability of poly-AgNPs@Sa was studied, Fig. S1. It was found that the formatted film was stable since it did not lose its reactivity even after two weeks in the air or after multiple cycles (up to 15 scans) with scan rates ranging from 5 to 50 mV s− 1. Furthermore, organic solvents such as ethanol, acetone, chloroform, acetonitrile, and dimethyl sulf­ oxide had no effect on it (data are not shown). These findings support a stiff structure and, most likely, a large molar mass. Instead, when kept in the refrigerator, the film deteriorated. The electrochemical characteristics of the modified electrode were also investigated using cyclic voltammetry in the presence of 1.000 × 10− 3 M K3[Fe(CN)6] containing 0.200 mol L− 1 KCl, Fig. S2. The CPE exhibit two distinct peaks, with an anodic peak potential of +0.309 V and a cathodic peak potential of +0.174 V (black curve, Fig. 2), while the AgNPs@Sa-CPE gave an oxidation peak at +0.339 V and a reduction peak at +0.154 V (pink curve, Fig. S2). Peak current rose for the polyAgNPs@Sa-CPE electrode (pink curve, Fig. S2), whereas the peak po­ tential difference between the anodic and cathodic peaks increased from 135 mV to 185 mV. The result illustrates that poly-AgNPs@Sa covered the surface of CPE and favoured the oxidation and reduction of the electroactive indicator. The enhanced peak current was caused by a pinhole effect, which occurs when larger pores are present and permits [Fe(CN)6]4–/3– to diffuse through the poly-AgNPs@Sa film and to the electrode surface [Bonné et al., 2009]. The increased peak current intensity, also, suggested that the produced electrode had higher electrochemical activity due to its bigger electroactive surface [Poriel et al., 2004]. The electroactive sur­ face area (A) of the poly-AgNPs@Sa-CPE electrode (Randles-Sevcik equation) was calculated to be 0.0220 cm2 and 0.0480 cm2 for CPE [Papaioannou et al., 2022] and poly-AgNPs@Sa-CPE, respectively. Once those two parameters were contrasted, it is clear that adding poly-AgNPs@Sa to CPE increased its electroactive surface area. 3.2. Morphology of Sa@AgNPs and poly-AgNPs@Sa-CPE The morphological characteristics of CPE (Fig. 2a), AgNPs@Sa-CPE (Fig. 2b, c, 2d, 2e) were studied by scanning electron microscopy (SEM). As shown in Fig. 2b, c, 2d, and 2e, spherical-shaped Ag nano­ particles were synthesized. Fig. 2b and c shows the layer particles found in the form of organized aggregates. In addition, Fig. 2a and b, 2c show morphological differences between CPE and poly-AgNPs@Sa-CPE, confirming the deposition of AgNPs@Sa on the surface of CPE. The Fig. 2. SEM images of (a) CPE, (b), (c), (d), (e) AgSa@NPs-CPE at different magnifications and (f) EDX diagram of AgSa@NPs-CPE 4 S. Karastogianni et al. Biosensors and Bioelectronics: X 12 (2022) 100275 CPE electrode (Fig. 2a) is characterized by irregularly shaped graphite particles with significant cohesion and small pore size. The polymer film is homogeneously distributed in the mineral oil on the poly-AgNPs@SaCPE electrode with a fairly compact structure (Fig. 2b and c), as is also the case with CPE (Fig. 2a), but with larger pores. The size of the par­ ticles varied as shown in Fig. 2d and e. Smaller-sized particles were seen, but their dimension could not be precisely calculated with the existing organology. The compositional analysis of AgNPs@Sa-CPE was performed by energy dispersive X-ray (EDX) analysis (Fig. 2f). EDX data (Fig. 2f) showed the presence of silver in the synthesized material, confirming the inclusion of the metal in the saffron structure. The silver content re­ ported in the EDX analysis was determined on a small portion of the sample, assuming its uniform composition. AgNPs@Sa starts with the electrooxidation where the first oxidation peak of polyAgNPs@Sa may be attributed to the formation of the free radical species, probably [AgNPs-crocin -Sa]. Afterward, coupling oc­ curs between [AgNPs-crocin.-Sa] and the [AgNPs-crocin2+-Sa], formed from the subsequent oxidation of [AgNPs-crocin.], [Papaioannou et al., 2022; Armellini et al., 2017; Jorgensen et al., 1997]. Then, termination of the polymerization happens and polyAgNPs-[crocin]n-Sa is formed. On the other hand, the oxidation of valine on CPE gives two low intense oxidation peaks at about +0.120 and + 0.260 V. The first oxidation peak could be ascribed to the oxidation of Val, accordingly to equation 1 [Xinying, 2014] which is also in agreement with the results from cyclic voltammetry. In addition, the second peak could be ascribed to the oxidation of [AgNPs-(crocin)n-Sa] [Papaioannou et al., 2022]. 3.3. Electrochemical behavior of valine 3.4. Analytical performance of the proposed sensor Square wave voltammetry (SWV) was used to evaluate the electro­ chemical characteristics of Val on CPE and poly-AgNPs@Sa-CPE in pH 4.0 acetate buffer. Anodic square wave voltammograms of CPE (Fig. 3a), of Val on CPE (Fig. 3, b), of AgNPs@Sa-CPE, and Val on poly-AgNPs@SaCPE (Fig. 3, green curve) are given in Fig. 3. Val on CPE produced an oxidation peak with a low peak current at about an oxidation peak with a low peak current at approximately +0.294 V. (Fig. 3, black curve). It should be noted that when Val was tested on poly-AgNPs@Sa-CPE, an anodic peak was observed at +0.345 V, which had a bigger peak current than Val on CPE (Fig. 3, green curve). These findings suggest that Val interacted with AgNPs@Sa-CPE. To summarize, the presence of silver nanoparticles improved the sensitivity of the detection of Val. The electrochemical behavior of crocin expresses its capacity to donate electrons accordingly to Armellini et al., 2017. Therefore, the anodic process of crocin occurs through two one-electron oxidation and one proton process processes [Papaioannou et al., 2022; Armellini et al., 2017; Jorgensen et al., 1997]. Based on that, electropolymerization of SWV was used in the developed electrochemical sensor to determine Val in solution under the selected conditions. The sensor’s oxidation currents rose as the concentration increased (Fig. 4). With a correlation coefficient of 0.9997, the calibration graph revealed a linear relation­ ship between the SWV peak current and the Val mass concentration ranging from 2.575 10− 10 g L− 1 to 1.194 10− 8 g L− 1. Equation y (A) = 17.041(±0.078)x (g L− 1) + 1.000 10− 7(±4.388 10− 10) was the linear regression relationship derived from the SWV calibration curve. The detection limit was calculated as 3sb/slope, where sb represents the standard deviation of the blank and slope represents the slope of the calibration curve. The detection limit was determined to be 8.498 10− 11 g L− 1. The relative standard deviations of Val at 9.199 10− 9 g L− 1 and 1.194 − 8 10 ng L− 1 were 4.3% and 4.0%, respectively, showing sufficient reproducibility of the assay (intraday precision). As demonstrated in Table 1, the linear range for the Val of the proposed sensor is greater than that obtained in various earlier reports. Furthermore, the detection limit is much lower than the electroanalytical methods published in the literature, as shown in Table 1. The selectivity of the modified electrode was also investigated. The results showed that the 100 times of K+, Na+, Ca2+, Fe3+, Cu2+, Cl− , NO−3 , sucrose, glucose, fructose, citric acid, ascorbic acid, leucine, isoleucine, had no obvious influence on the results of the determination of vanillin within the ±5% error (Table S1). Other amino acids such as phenylalanine, and tryptophane due to their different oxidation poten­ tials, did not affect its determination. 3.5. Application in real samples By using the standard addition method, the suggested assay was used to determine Val in urine samples, demonstrating the sensor’s applica­ bility in real sample analysis. Equation I(A) = (32.60 ± 0.478)x (ng L− 1) + (8.450 10− 8±9.550 10− 10) with a linear correlation coefficient of 0.9997 was found to be the regression equation for the urine samples (Fig. 5). The LOD was calculated to be 0.097 ng L− 1. The standard deviation between replicates of the same Val content in urine samples did demonstrate some heterogeneity within the data. There was a lot of variation in measurements, making it difficult to accurately determine Val concentrations. This procedure, though, could be used to confirm the presence of Val in mass concentrations greater than 0.258 ng L− 1 in aqueous samples and 0.293 ng mL− 1 in urine samples. The different slopes of the calibration curve in buffer solutions and urinary spiked samples indicate the influence of the matrix effect. Therefore, this difference was calculated and estimated to be 15.56 ng L− 1 A− 1. This value is low and indicative that the matrix impact is minimal [Paul et al., 2014]. Fig. 3. Anodic square wave voltammograms of CPE (a) 0.4 ng L-1 Val on CPE (b) 0.4 ng L-1 Val on poly-AgNPs@Sa-CPE (c) in acetate buffer pH 4.0. Experimental conditions as described in the material and methods section. 5 S. Karastogianni et al. Biosensors and Bioelectronics: X 12 (2022) 100275 Fig. 4. (A) Anodic square wave voltammograms of poly-AgNPs@Sa-CPE using the selected conditions for a mass concentration between 2.575 10-10 g L-1 to 1.194 10-8 g L-1, of Val: 2.575 10-10 g L-1 (a), 9.199 10-10 g L-1 (b), 3.475 10-9 g L-1 (c), 5.939 10-9 g L-1 (d), 7.187 10-9 g L-1 (e), 9.687 10-9 g L-1 (f) and 1.194 10-8 g L1 (g) mass concentration of Val. (B): Calibration curve. Experimental conditions as described in the material and methods section. Table 1 Analytical features of selected Val detections. Detection method Electrode Limit of detection (LOD) Linear range Sample Reference HPLC-fluorescence LC-MS/MS - 0,002 μg/mL 11.5 10− 3 mg/L (0.01–80) μg/mL (38.3–200) μg/L Chocolate Water Amperometry Differential pulse voltammetry Differential pulse voltammetry Cyclic voltammetry MCM-41-Fe2O3/GCEa GCE/MWCNTsc 84 nM 1.67 μM (200–510) nM 25–1000 μM Human blood - Synaridou et al. (2021) Fernández-Del-Campo-García et al. (2019) Hasanzadeh et al. (2013) Saghatforoush et al. (2011) Cobalt hydroxide on glassy carbon electrode Modified glassy carbon electrode and platinum with nickel and iron oxide nanoparticles and Iron-modified screen-printed electrode on glass slab TOCNC/l-Cys/Aub 9.86 μM (25–10000) μM - Hasanzadeh et al. (2009) - - Phosphate buffer saline Tooley et al. (2018) 0.001 M Buffer solution pH 8.0 Blood Naqvi et al. (2020) - (0.1–0.5) M and (10–100) M - Bi et al. (2016) Copper microwires electrodes Silver nanoparticles capped with saffron modified carbon paste electrode 0.006 mM 0.085 ng L− 1 (i. e. 0.073 pM) (0.02–3.3) mM (0.258–11.94) ng L− 1 [(i. e. 0.073–1019) pM] Plasma Urine García-Carmona et al. 2019 This work Cyclic voltammetry Differential pulse voltammetry Chronoamperometry Square wave voltammetry a b c MCM-41-Fe2O3/GCE: Magnetic (Fe2O3) mobile crystalline material-41 (MCM-41) glassy carbon electrode (GCE). 2,2,6,6-tetramethylpiperidine-1-oxyl (TEMPO)-oxidized cellulose nanocrystals (TOCNCs) and l-cystine (l-Cys) modified Au electrode. GCE/MWCNTs: glassy carbon/multiwall carbon nanotubes. 6 S. Karastogianni et al. Biosensors and Bioelectronics: X 12 (2022) 100275 Fig. 5. Standard addition method curve of Val in urine samples. 0.00 ng L-1 (a), 0.220 ng L-1 (b), 0.400 ng L-1 (c), 1.000 ng L-1 (d), 1.398 ng L-1 (e), 2.984 ng L-1 (f), and 3.984 ng L-1 (g) of Val in urine samples. Selected conditions as mentioned in the material and methods section. Other experimental conditions as mentioned in the material and methods section. 4. Conclusions Acknowledgments In this paper, the development of valine’s (MSUD biomarker) elec­ trochemical sensor was described using silver nanoparticles capped with saffron as carbon’s paste electrode modifier, having improved analytical properties. The proposed sensor was the first to be reported. The modified electrode had a broad linear range ranging from 0.258 to 11.94 ng L− 1 of valine mass concentrations in the case of buffer solu­ tions. The assay proved to be simple, rapid, and sensitive with a low detection limit of 0.085 and 0.097 ng L− 1 for buffer and urine samples, respectively. Due to their different oxidation potentials, the chemicals with which valine could interact did not affect its determination. However, there was variation in measurements making it difficult to accurately determine valine. This procedure, though, could be used to confirm the presence of valine at mass concentrations greater than 0.258 ng L− 1 in aqueous samples and 0.293 ng L− 1 in urine samples. Thus, the proposed electrochemical sensor could be a promising tool for the reliable and sensitive detection of valine in clinical samples and therefore for the monitoring of MSUD. Methods currently used for the detection of valine rely on the use of mass detectors, which are expen­ sive and cannot be adapted for in situ analysis. However, electro­ chemical methods benefit from the portable nature of the electrodes used. In conclusion, the proposed approach can be effectively applied to the analysis of real samples in complex matrices such as urine samples, having been successfully applied to them, and therefore can be used in the clinical diagnosis and monitoring of MSUD. The authors wish to thank L. Papadopoulou for her precious help in acquiring SEM images. “This research is co-financed by Greece and the European Union (European Social Fund- ESF) through the Operational Programme “Human Resources Development, Education and Lifelong Learning” in the context of the project “Reinforcement of Postdoctoral Researchers—2nd Cycle” (MIS-5033021), implemented by the State Scholarships Foundation (ІΚΥ)”. Appendix A. Supplementary data Supplementary data to this article can be found online at https://doi. org/10.1016/j.biosx.2022.100275. References Armellini, R., Compagnone, D., Scampicchio, M., Pittia, P., 2017. Electroanalysis 29, 521–528. Azuma, K., Hirao, Y., Hayakawa, Y., Murahata, Y., Osaki, T., Tsuka, T., Imagawa, T., Okamoto, Y., Ito, N., 2016. Metabolites 6, 3. Bard, A.J., Faulkner, L.R., 2001. Electrochemical Methods: Fundamentals and Applications. Wiley & Sons, New York, NY, USA. Barnes, W.L., Dereux, A., Ebbesen, T.W., 2003. Nat. Cell Biol. 424, 824–830. Bi, Q., Dong, S., Sun, Y., Lu, X., Zhao, L., 2016. Anal. Biochem. 508, 50–57. Blackburn, P.R., Gass, J.M., Vairo, F.P.E., Farnham, K.M., Atwal, H.K., Macklin, S., Klee, E.W., Atwal, P.S., 2017. Appl. Clin. Genet. 10, 57–66. Bonné, M.J., Edler, K.J., Buchanan, J.G., Wolverson, D.E., Psillakis, M., Helton, W., Thielemans, Marken F., 2009. J. Phys. Chem. C 112, 2660–2666. Burrage, L.C., Nagamani, S.C., Campeau, P.M., Lee, B.H., 2014. Hum. Mol. Genet. 23, R1–R8. Castellanos, M., van Eendenburg, C.V., Gubern, C., Sanchez, J.M., 2016. J. Chromatogr. B 1029, 137–144. Cosnier, S., Lepellec, A., 2003. Anal. Bioanal. Chem. 377, 507–520. Dar, R.A., Brahman, P.K., Khurana, N., Wagay, J.A., Lone, Z.A., Ganaie, M.A., Pitre, K.S., 2017. Arab. J. Chem. 10, S1119–S1128. Delgado-Povedano, M.M., Calderon-Santiago, M., Priego-Capote, F., Luque de Castro, M. D., 2016. Talanta 146, 310–317. Dincer, C., Bruch, R., Kling, A., Dittrich, P.S., Urban, G.A., 2017. Trends Biotechnol. 35, 728–742. Fernández-Del-Campo-García, M.T., Casas-Ferreira, A.M., Rodríguez-Gonzalo, E., Moreno-Cordero, B., Pérez-Pavón, J.L., 2019. J. Chromatogr. A 1590, 88–95. Declaration of competing interest The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper. Data availability No data was used for the research described in the article. 7 S. Karastogianni et al. Biosensors and Bioelectronics: X 12 (2022) 100275 Poriel, C., Ferrand, Y., Le Maux, P., Berthelot, J.R., Simonneaux, G., 2004. Inorg. Chem. 43, 5086–5095. Rezaei, B., Zare, Z.M., 2008. Anal. Lett. 41, 2267–2286. Saghatforoush, L., Hasanzadeh, M., Shadjou, N., Khalilzadeh, B., 2011. Electrochim. Acta 56, 1051–1061. Sandlers, Y., 2017. Transl. Res. 189, 65–75. Scott, C.R., 2006. Am. J. Med. Genet. Part C Semin. Med. Genet. 142C, 121–126. Sheberla, D., Patra, S., Wijsboom, Y.H., Sharma, S., Sheynin, Y., Haj-Yahia, A.E., Barak, A.H., Gidron, O., Bendikov, M., 2015. Chem. Sci. 6, 360–371. Song, Y., Takatsuki, K., Isokawa, M., Sekiguchi, T., Mizuno, J., Funatsu, T., Shoji, S., Tsunoda, M., 2013. Anal. Bioanal. Chem. 405, 7993–7999. Song, Y., Xu, C., Kuroki, H., Liao, Y., Tsunoda, M., 2018. J. Pharm. Biomed. Anal. J. Pharm. Biomed. Anal. 147, 35–49. Svancara, I., Kalcher, K., Walcarius, A., Vytras, K., 2012. Electroanalysis with Carbon Paste Electrodes. CRC Press, Boca Raton, FL, USA. Synaridou, M.S., Tsamis, V., Sidiropoulou, G., Zacharis, C.K., Panderi, I., Markopoulou, C.K., 2021. Molecules 26 (14), 4325. Thakare, R., Chhonker, Y.S., Gautam, N., Alamoudi, J.A., Alnouti, Y., 2016. J. Pharm. Biomed. Anal. 128, 426–437. Tooley, C.A., Gasperoni, C.H., Marnoto, S., Halpern, J.M., 2018. Sensors 18, 3144–3154. Tuma, P., Gojda, J., 2015. Electrophoresis 36, 1969–1975. Ulusoy, S., Ulusoy, H.I., Pleissner, D., Eriksen, N.T., 2016. RSC Adv. 6, 13120–13128. Velusamy, V., Arshak, K., Yang, C.F., Yu, L., Korostynska, O., Adley, C., 2011. Am. J. Anal. Chem. 2, 392–400. Wei, X., Liu, Z., Jin, X., Huang, L., Gurav, D.D., Sun, X., Liu, B., Ye, J., Qian, K., 2017. Anal. Chim. Acta 950, 147–155. Wolak-Dinsmore, J., Gruppen, E.G., Shalaurova, I., Matyus, S.P., Grant, R.P., Gegen, R., Bakker, S.J.L., Otvos, J.D., Connelly, M.A., Dullaart, R.P.F., 2018. Clin. Biochem. 54, 92–99. Wang, L., Liao, X., Ding, Y., Gao, F., Wang, Q., 2014. Microchim. Acta 181, 155–162. Wopschall, R.H., Shain, I., 1967. Anal. Chem. 39, 1514–1527. Xinying, M.A., 2014. Int. J. Electrochem. Sci. 9, 3181–3189. Yang, D.X., Zhu, L.D., Jiang, X.Y., 2010. J. Electroanal. Chem. 640, 17–22. Zhang, W., Guo, S., Carvalho, W.S.P., Jiang, Y., Serpe, M.J., 2016. Anal. Methods 8, 7847–7867. García-Carmona, L., González, M.C., Escarpa, A., 2018. Electroanalysis 30, 1505–1510. García-Carmona, L., González, M.C., Escarpa, A., 2019a. TrAC, Trends Anal. Chem. 118, 29–42. García-Carmona, L., González, M.C., Escarpa, A., 2019b. Sensor. Actuator. B Chem. 281, 239–244. Garnier, F., 1989. Angew. Chem. 101, 529–533. Hasanzadeh, M., Karim-Nezhad, G., Shadjou, N., Hajjizadeh, M., Khalilzadeh, B., Saghatforoush, L., Abnosi, M.H., Babaei, A., Ershad, S., 2009. Anal. Biochem. 389, 130–137. Hasanzadeh, M., Shadjou, N., Omidinia, E., 2013. Colloids Surf. B Biointerfaces 108, 52–59. Jorgensen, L., Henrik, J., Andersen, L., Skibsted, H., 1997. Free Radic. Res. 27, 73–87. Jumbo-Lucioni, P.P., Garber, K., Kiel, J., Baric, I., Berry, G.T., Bosch, A., Burlina, A., Chiesa, A., Pico, M.L.C., Estrada, S.C., et al., 2012. J. Inherit. Metab. Dis. 35, 1037–1049. Kang, J.F., Perry, J.D., Tian, P., Kilbey, S.M., 2002. Monolayers Langmuir 18, 10196–10201. Kannan, B., Williams, D.E., Booth, M.A., Travas-Sejdic, J., 2011. Anal. Chem. 83, 3415–3421. Karastogianni, S., Girousi, S., 2017. Int. J. Cur. Res. 9, 61118–61124. Karastogianni, S., Girousi, S., 2020. Appl. Sci. 10, 7023. Lai, G., Zhang, H., Yong, J., Yu, A., 2013. Biosens. Bioelectron. 47, 178–183. Le, T.T., Shafaei, A., Genoni, A., Christophersen, C., Devine, A., Lo, J., Lyons Wall, P., Boyce, M.C., 2019. Anal. Bioanal. Chem. 411, 1019–1028. Li, J., Kuang, D., Feng, Y., Zhang, F., Xu, Z., Liu, M., Wang, D., 2013. Biosens. Bioelectron. 42, 198–206. Lv, J., Li, C., Feng, S., Chen, S.M., Ding, Y., Chen, C., Hao, Q., Yang, T.H., Lei, W., 2019. Ionics 25, 4437–4445. Martins, M., Boas, M.V., Castro, B., Hillman, A.R., Freire, C., 2005. Electrochim. Acta 51, 304–314. Mansouri Majd, S., Teymourian, H., Salimi, A., Hallaj, R., 2013. Electrochim. Acta 108, 707–716. Naqvi, S.T.R., Rasheed, T., Ashiq, M.N., ul Haq, M.N., Majeed, S., Fatima, B., Nawaz, R., Hussain, D., Shafi, S., 2020. Polyhedron 180, 114426. Papaioannou, G.C., Karastogianni, S., Girousi, S., 2022. Sensors 22 (4), 1625. Paul, M., Ippisch, J., Herrmann, C., Guber, S., Schultis, W., 2014. Anal. Bioanal. Chem. 406, 4425–4441. 8