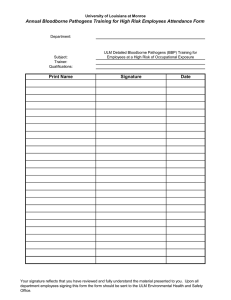

Bloodborne Pathogen Exposure Control Plan We are committed to providing a safe and healthful work environment for our entire staff. In pursuit of this goal, the following exposure control plan is provided to eliminate or minimize occupational exposure to bloodborne pathogens in accordance with OSHA Standard 29 CFR 1910.1030, Occupational Exposure to Bloodborne Pathogens. The ECP is a key documentation to assist our organization in implementing and ensuring compliance with the OSHA Standard, thereby protecting our employees. The ECP includes; 1. Determination of employee exposure 2. Implementation of various methods of exposure control, including: a. Universal Precautions or Standard precautions b. Engineering and work practice controls c. Personal protective equipment d. Housekeeping 3. Hepatitis B vaccination 4. Post-exposure evaluation and follow-up 5. Communication of hazards to employees and trainings 6. Procedures for evaluating circumstances surrounding exposure incidents 7. Recordkeeping-Training Records, Medical Records, Employee Exposure Report, Hepatitis B declination form Implementation methods for these elements of the standard are discussed in the subsequent pages of this ECP. _____ is responsible for implementation of this ECP. _____ will maintain, review, and update the ECP at least annually, and whenever necessary to include new or modified tasks and procedures. Contact location / phone number: ___________ and _____________ Those employees who are determined to have occupational exposure to blood or other potentially infectious materials (OPIM) must comply with the procedures and work practices outlined in this ECP. _____ will be provide and maintain all necessary personal protective equipment (PPE), engineering controls (e.g. sharps containers), labels, and red bags as required by the Standard. _____ will ensure that adequate supplies of the aforementioned equipment are available in the appropriate sizes. Contact location / phone number ____________ and _________ _____ will be responsible for ensuring that all medical actions required by the standard are performed and that appropriate employee health and OSHA records are maintained. Contact location / phone number _____________ and ____________ ______ will be responsible for training, documentation of training, and making the written ECP available to employees, OSHA, and NIOSH representatives. Contact location and phone number. ____________ and _____________ List of Exposure Tasks Date of preparation Following Tasks and Procedures with potential for exposure to bloodborne pathogens are performed in this facility: 1. Examining patients’ teeth and gums 2. Remove soft and hard deposits from teeth 3. Clean and polish teeth, which includes removing tartar, stains, and plaque 4. Administer cavity-preventative agents such as fluoride and pit fissure sealants 5. Place dental dams to isolate teeth for treatment 6. Administer anesthetics 7. Remove sutures 8. Place and carve filling materials, temporary fillings, and periodontal dressings 9. Remove excess cement used in the filling process 10. Sterilize and disinfect instruments and equipment 11. Coronal polishing and restorative dentistry 12. Minor surgeries 13. Assisting in minor surgeries 14. Wound dressing 15. Handling specimens of blood and OPIM 16. Cleaning contaminated instruments and equipment 17. Handling contaminated sharps 18. Cleaning up after examination and procedures on patients 19. Handling contaminated laundry 20. Handling medical waste Other Job Classification Form A The following is a list of all job classifications at our establishment in which all employees have potential occupational exposure. Job Title Department / Location Form B The following is a list of job classifications in which some employees at our establishment have potential occupational exposure. Included is a list of tasks and procedures, or groups of closely related tasks and procedures, in which potential occupational exposure may occur for these individuals. Job Title Department / Location Task / Procedure Methods of Implementation and Control Universal Precautions Under this approach, all human blood and certain bodily fluids are treated as if know to be infectious for HIV, HBV, and other bloodborne pathogens. A key element of infection control is the concept of Universal Precautions., introduced in 1996 by the Centers of Disease Control and Prevention (CDC) as a means to reduce the risk of bloodborne pathogen transmission (e.g., the Human Immunodeficiency Virus [HIV], Hepatitis B Virus [HBV], and others) in the healthcare settings. The primary principle behind the universal precautions centers on the premise that medical history and examination cannot reliably identify all patients infected with bloodborne pathogens. All patients, therefore, must be regarded as potentially infectious. As such, applying universal precautions requires handwashing, use of protective barriers and care in the use and disposal of needles and other sharp instruments) are used for every patient. Basic Elements of Universal Precautions against infectious agents, both bloodborne and airborne involve: 1. Handwashing 2. Use of gloves, masks, eye protection, and gowns 3. Patient care equipment 4. Environmental surfaces 5. Injury protection Exposure Control Plan Employees covered by the Bloodborne Pathogens Standard receive an explanation of this ECP during their initial training session. It will also be reviewed in their annual refresher training. All employees can review this plan at any time during his/her work shift by contacting Dr. Tan. If requested, we will provide employees with a copy of the ECP free of charge within 15 days of the request. ______ is responsible for reviewing and updating the ECP annually or more frequently if necessary to reflect any new or modified tasks and procedures that affect potential occupational exposure and to reflect new or revised employee positions with potential occupational exposure. Engineering Controls and Work Practices Engineering controls and work practice controls will be used to prevent or minimize exposure to bloodborne pathogens. The specific engineering controls and work practice controls used are listed below: Example: Non-glass capillary tubes, Safety Engineered Needles (SESIPs), Needless Systems, SelfBlunting Needles, and etc. Sharps disposal containers are inspected / maintained / replaced by ___________ every __________ (list of frequency) or whenever necessary to prevent overfilling. This facility has the following general safety equipment: 1. Needle recapping devices 2.