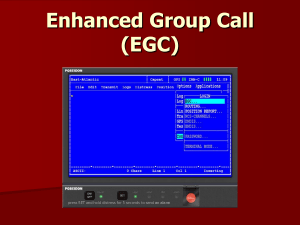

1. Introduction Implementation of proactive maintenance in the Egyptian Glass Company Samir Ismail Mostafa The author Samir Ismail Mostafa is a Visiting Professor at the Education Research Institute, Giza, Egypt. Keywords Maintenance, Reliability management Abstract The implementation of proactive maintenance, as presented here, offers a complete package for maintenance system development. The package contains a methodology, a software package, and a set of tested and verified procedures. The methodology is general enough to be used in various fields of applications, as it was tested in different facilities, and service and production environments. It addresses the total corporate system, augmented by the new concepts of maintenance methods, and utilizes suitable approaches of information systems development. With the present approach process re-engineering becomes essential for computerized maintenance information systems definition. Electronic access The Emerald Research Register for this journal is available at www.emeraldinsight.com/researchregister The current issue and full text archive of this journal is available at www.emeraldinsight.com/1355-2511.htm Journal of Quality in Maintenance Engineering Volume 10 · Number 2 · 2004 · pp. 107-122 q Emerald Group Publishing Limited · ISSN 1355-2511 DOI 10.1108/13552510410539187 Many organizations facing the loss of their market share are adopting one of the new management philosophies such as total quality management, just-in-time manufacturing, or business process re-engineering (BPR). Unfortunately, none of these approaches address the total corporate needs (Juhasz, 1996). For this reason we find that more than one program is adopted in the same organization. For maintenance system improvement, we can find programs as total productive maintenance, reliability centered maintenance, and also total quality maintenance (TQMain) applied as well. In all cases improvement is achieved through rigorous systemic procedures with different levels of intervention. In Egypt, most production facilities efforts are directed towards ISO 9000 certification, where maintenance activities are reviewed and documented as is, with no re-engineering, and for most of these organizations maintenance expenses are considered as overheads. Also, in many cases maintenance systems in Egyptian organizations have been found to be responsible for frequent production and quality loss, and affect the safety of humans and the environment. 2. Maintenance practice in Egypt Although maintenance is one of the oldest jobs in the Egyptian industry, it has not progressed much through the years. In order to examine the state of maintenance practice, we should consider two main factors: the management side of maintenance, and the technology used. Regarding the technology, one may find scattered locations or plants that spend money on buying new devices, tools, or instruments, which are intended to be used in maintenance. Statistical figures about types and models of these devices, locations, and utilization levels in Egypt are not available. But based on the survey conducted by the author through his visits, which covered more than 40 factories during the last seven years, only eight locations were found to have complete sets of instrumentation for predictive maintenance. The The author would like to thank Engineer Mohamed Abdel-Wahab, the Chairman of EGC, for his support for this project. Also, without the support and commitment of Engineer Sherif Georgy (plant manager) and the hard work of Engineer Said Nawar and maintenance personnel, and the cooperation of EGC employees, this effort would have been wasted. I would like also to thank Engineer Mohamed Yehya and Mrs Iman Osman for their programming skills. 107 Implementation of proactive maintenance Journal of Quality in Maintenance Engineering Samir Ismail Mostafa Volume 10 · Number 2 · 2004 · 107-122 others either do not have any, or have some. But it is regrettable to say that none of these sites did develop a maintenance technology package integrated with their maintenance and management procedures. On the management level it is natural that maintenance management suffers all symptoms and difficulties of the management practice in Egypt as expressed by many Egyptian researchers (El-Mikkawy and Handoussa, 2002). Based on the author’s survey and experience the existing state of affairs in most of the industrial organizations regarding maintenance practice in the Egyptian industry and service sector may be summarized as follows (Samir, 1996, 1998, 1999a): . maintenance organizations are developed most of the time randomly and do not reflect the functional needs of the business; . no documented standard maintenance procedures exist; . if these procedures are available it is rarely in a readable, updated form suitable for the technicians’ use; . documentation and recording of maintenance activities are always heavy, uneasy and unpleasant tasks for all levels of maintenance practitioners; . equipment manuals, catalogues and repair instructions are rarely supplied in a complete form; . if equipment documentation was supplied, it is never found in its proper place; . in all cases equipment documentation is normally in a foreign language, has a different format, and with missing or mixed standards and specifications; . for cultural and historical reasons maintenance work is always done based on experience, and sophisticated maintenance engineers are difficult to find; and . individuality on the personal and departmental level governs the pattern of interaction between organization elements in most sectors. administration sub-systems. Dealing with maintenance problems in an organizational context requires considering the holism of the organization and not concentrating on a subset of its components (Coetzee, 1999). Huse (1980) explains this statement as: 3. System approach and development methodologies In search for solutions for maintenance problems, one should look for different methods to handle and investigate previous chronic problems. In the new era of information, an organization is viewed as an information processor (Smith, 1972), and the maintenance system becomes one of the corporate sub-systems along with production, planning, training, technical, research and development, marketing, finance, quality, and The performance of the whole is not the sum of the individual parts, but is a consequence of the relationship of the performance between parts. Thus, problems cannot be solved separately, since they are interdependent. Then, solving maintenance system problems requires a total approach, with many changes on the corporate level as well as on the sub-unit levels. 3.1. Maintenance and information With the wide use of computer systems, maintenance management and technology has changed tremendously. Entire factories can simply run now by computers either locally through a distributed control system (DCS), or remotely integrated with is another control facility. Operations in both options rely heavily on supervisory information, which continuously collected and transmitted to the control system. Also, portable computerized devices are developed to collect data about equipment failure and malfunction symptoms. Data collected has to be analyzed for diagnosis and equipment repair (Sherkhodaie, 2000). With the improvement of the data collection techniques, volumes of data increase together with processing power, which leads to the improvement of the accuracy of failure diagnosis and prediction. In all cases data collected through automated tools or by maintenance personnel are processed through information systems, or specifically maintenance management information systems (MMIS). MMIS can be viewed as “the system which collects, processes, and transmits maintenance information and makes it available to maintenance personnel, managers, and those who need to make decisions which may affect plant operation and performance. It is a human activity system that may employ computers or automated tools for data collection, processing, or diagnosis”. By this definition, data and information collected using the appropriate technology need to be processed for further actions, which lead us to maintenance management. On the management level, since the 1960s, computers manage maintenance operations and activities through a number of computerized applications. Many organizations implemented one or more of these computerized maintenance management systems (CMMS), with different levels of success (Labib, 1998). Success of CMMS implementation depends on the corporate strategic planning and its associated 108 Implementation of proactive maintenance Journal of Quality in Maintenance Engineering Samir Ismail Mostafa Volume 10 · Number 2 · 2004 · 107-122 maintenance practice. The availability of structured maintenance procedures with effective planning mechanisms, integrated with the human activity systems, all contribute to the successful implementation of maintenance system computerization. Consequently, choosing the right technology with a suitable computer application package is not a straightforward task. This fact is supported by the following results of the survey conducted by the Plant Maintenance Resource Center on CMMS implementation: . of the respondents, 90 per cent are currently using CMMS, with the largest portion (23 per cent) from two years, and 10.3 per cent in the process of implementing a package; . between 20 and 40 per cent could not report any benefits from implementing the CMMS; . nearly 20 per cent rated their CMMS implementation as poor; . overall, it appeared that conducting BPR seems to increase the chances of the successful implementation of CMMS (above 50 per cent); . of the respondents, 23 per cent were not aware of the reason for selecting their CMMS; . a total of 20 per cent found that conducting stakeholder analysis during implementation has a positive influence; and . of the respondents, 43 per cent thought the most important factors for their success were obtaining senior management commitment, and selecting the correct CMMS. Organizations need to employ a suitable methodology to help in selecting or developing the right CMMS solution for their maintenance problems, and all methodologies are centered on information. We simply do not manage the asset, or the equipment itself, but we manage the information associated with its functions and failures. 3.2. Maintenance types and methods To find out how the information era shaped maintenance practice, a literature review for maintenance methods was conducted. Each method was closely examined using a number of parameters shown in the appendix at the end of the article. The following represents most of these methods. 3.2.1. Run-to-failure This is the oldest type of maintenance. Now, it is suitable for small, non-critical, low price equipment. 3.2.2. Corrective maintenance Unplanned activities undertaken to return the equipment to its operating condition. 3.2.3. Scheduled maintenance Periodic replacement of parts based on their age (Kececioglu, 1994, p. 335; Nagarrur, 1999). 3.2.4. Planned maintenance When maintenance technicians perform maintenance functions based on a pre-planned basis. 3.2.5. Preventive maintenance This practice encompasses all planned, scheduled and corrective actions before the equipment fails. 3.2.6. Condition-based maintenance (CBM) “Is a maintenance based on objective evidence or predictable failure for system or component”, for US Navy, CBM includes scheduled maintenance as well as corrective maintenance (Jacobs, 2000). CBM is not a technology or a technique, but it depends on other technologies to provide this objective evidence. 3.2.7. Condition monitoring A process characterized by the absence of preventive maintenance tasks. The item is maintained by CM if it is permitted to remain in service without preventive maintenance until function failure occurs (James, 2001, p. 18). 3.2.8. Predictive condition monitoring (PCM) The application of multiple technologies to monitor the condition of machines (Nicholas, 2000). It tracks various conditions and performance measurements to identify pending machine failure (Talbott, 2001). Technology is always combined with various analysis techniques through computerized applications. 3.2.9 Equipment asset management An optimum combination of best practice, technology, organization, and administration directed to gaining lifetime value from process, production, and manufacturing equipment (Michell, 1998). 3.2.10. Reliability-centered maintenance (RCM) A process used to determine the maintenance requirements of any physical asset in its operating context (Moubray, 1993), and to determine what must be done to ensure that it continues to fulfill its function. 3.2.11. Preactive maintenance Preactive maintenance is that which defines equipment maintenance requirements before the process, line, or individual machine commences operation or before major expansion (Donovan, 1998). 109 Implementation of proactive maintenance Journal of Quality in Maintenance Engineering Samir Ismail Mostafa Volume 10 · Number 2 · 2004 · 107-122 3.2.12. Total productive maintenance (TPM) It is basically an asset maintenance methodology that combines the effort of plant operators, safety, energy, materials, and quality with the planning and maintenance efforts. TPM is a plant improving methodology (Robinson and Ginder, 1995), promoted by the Japan Institute of Plant Maintenance in 1983. 3.3. System approach It is clear that all previous maintenance methods are linked to management of maintenance information and the selection and utilization of suitable maintenance technology, and both are highly affected by the supporting infrastructure or organization. For this reason, to investigate maintenance problems, one should examine organizational problems as well as maintenance management and its technology. When dealing with organizational problems one should concentrate on the cause of the problems rather than the symptoms. Most organizational problems originate from its environment, augmented by the policy and procedures of the management, and propagated by the organization. Tackling those problems requires a global view of all procedures; policy, techniques, and also the way people perform their work. This means that we have to consider all problem elements in an organizational context through a total system approach. With system approach a number of methodologies were developed to handle engineering and information systems problems. Soft system methodology (Checkland, 1990) is one of these methodologies which was applied successfully in similar situations (Wilson, 1990). With the information explosion era, a number of other approaches have emerged to handle system development problems, each utilizes a number of methodologies. These approaches range from a managerial-oriented approach as strategic or participative approaches, to technically-oriented as in structured, data, or object-oriented approaches, or a mixture of both as in a prototyping approach (Avison and Nandhakumar, 1995). With this variety of development methodologies, maintenance systems should be viewed with three interacting and overlapping components of: maintenance technology, information systems, and information technology. 3.2.13. TQMain TQMain is a strategy for monitoring and controlling deviations in a process condition and product quality for detecting failure causes and potential failures in order to interfere (Al-Najjar, 1996). 3.2.14. Productive reliability (PR) Based on TPM methodology with the purpose of reducing cost and improving capacity through continuous maintenance improvement, and by utilizing failure mode and effect analysis techniques (Toy and Wogninrich, 2000). 3.2.15. Operating maintenance training and administration This is a holistic approach, which considers all aspects of the supporting infrastructure (operation, maintenance, training, administration) as integral parts of the whole system (Meador, 1997). 3.2.16. Proactive maintenance (PaM) This is a proven, advanced maintenance approach that focuses on reducing the total maintenance required and maximizing the life of machinery (Hedderich, 2002). The results of PaM activities are re-engineered individual system/equipment maintenance practices with enhanced preventive/ predictive maintenance. 3.2.17. Profit center maintenance This is a maintenance management program in which maintenance of machinery, equipment of fixed asset is considered a profit activity and is optimized for maximum value rather than the least cost (Bond, 1994). 3.2.18. Maintenance management metric Here, maintenance management is the allocation of value added resources for the purpose of systematically improving overall equipment effectiveness, while optimizing the cost of per unit production. Other maintenance methods examined included machinery reliability management, total plant performance maintenance, optimized asset utilization, asset utilization, and economic value added. 3.4. System development methodologies Regarding information systems, previous approaches are applied with different levels of success. Each approach utilizes a number of methodologies with associated tools and techniques, to handle business-related problems. Each methodology space covers the activities to be carried out within the development phases (known as system development life cycle), starting from strategic planning to the post-implementation phase. Through the years many methods have been developed, and now more than 1,000 exist (Bubenko, 1986). A review of these methods can be found in Samir (2002, p. 77), and more management of change methodologies can be found in Holmn and Devane (1999). 110 Implementation of proactive maintenance Journal of Quality in Maintenance Engineering Samir Ismail Mostafa Volume 10 · Number 2 · 2004 · 107-122 4. Maintenance system development To identify the basis on which maintenance systems should be established, one should define the needs for its existence. As a matter of fact the needs for maintenance systems stemmed from the way equipment is designed and manufactured, and not necessarily solely by its operation. All equipment is designed and manufactured to satisfy two main operational criteria: reliability and maintainability (Ebling, 1997). In the design process the manufacturer identifies quantifiable figures for maintainability, followed by the determination of the condition under which maintenance should be performed. This information should be provided for the purchaser of the equipment for proper planning of its operations and maintenance. A production line comprises a number of pieces of equipment, and reliability and maintainability of the line will depend on the properties of its sub-assembly, but its repair conditions may not be the same as for its individual components. For this reason it is essential to know: . which unit needs to be repaired rather than replaced; . the preventive maintenance schedule; . maintenance tasks to be performed with the required skills, tools and spares; . level of repair for each unit and component; . the optimum level of spare parts necessary to guarantee proper and timely repair; and . testing procedures and verification of repair to guarantee as good as new equipment. It is clear that previous factors are essential to sustain the pre-designed operation of the production line, and it depends on the combination of economic, technical, and behavioral factors of the organization. At the same time one should also remember that individual pieces of equipment normally are purchased from various manufacturers. They are also subjected to different operating and environmental conditions, and during their useful life cycle, may be subjected to a number of modifications, enhancements, and upgrading. The matter can be complicated further if we are faced with a situation where a piece of equipment is partially failing or its condition is degrading (instead of fail/not-fail). Organizations need to develop skills to deal with all these issues and to keep accurate, up-to-data records about all parameters which will affect production line availability, productivity, and product quality (Wang, 1999). Organizational divisions, which should be designed to perform these functions, constitute maintenance systems. Maintenance systems should perform a number of functions beyond the actual service and repair of the equipment. Now issues such as higher plant availability, greater safety, better product quality, environment hazard-free operation, longer equipment life, greater cost effectiveness (Moubray, 1993, p. 3), and power rationalization, have all become part of maintenance system objectives. 4.1. Mission and objectives Traditionally, technical managers view maintenance missions as an increase in plant equipment availability by the efficient repair or replacement of failed equipment. Technicians see maintenance missions as putting the failed equipment back into operation as quickly as they can (Samir, 1998). This old traditional view of maintenance has changed; maintenance systems should be viewed as a number of business components arranged together according to a structure to achieve predetermined objectives and perform specific functions. Maintenance missions must accommodate a purpose that is larger than simply carrying out repairs or reducing the number of maintenance tasks (Donovan, 1998). Defining the mission sheds more light on how the organization should be structured and its desired future state (Cummings and Worley, 1997). Once systems’ functions are adopted, system developers should think how to structure the new maintenance system in accordance with its mission and objectives, which may depend on types of business, category of industry, and personnel. Maintenance system mission in a continuous process industry is different from a mass production facility, as in aircraft transportation services compared to road fleet operations. Also, maintenance objectives change with the mission and depend on the type of product and its quality level. 4.2. Maintenance and business objectives Based on the defined mission statement a number of objectives should be identified. RCM defines maintenance in terms of asset functions as “maintenance objective is to ensure that the physical assets continue to fulfil its intended functions” (Moubray, 1993). This definition requires that we clearly identify the following two basic points: (1) Functions of the assets. (2) Their desired performance standards. With this concept it becomes essential in maintenance systems to deal with assets failure through the identification of: . ways of function failure; . causes of failure; . consequences of failure; and . effects of failure. 111 Implementation of proactive maintenance Journal of Quality in Maintenance Engineering Samir Ismail Mostafa Volume 10 · Number 2 · 2004 · 107-122 When the business side is considered with the failure management, maintenance activities should cover a wide spectrum to satisfy: . equipment and assets availability; . effectiveness of maintenance labor; . control of maintenance material; and . conservation of energy. In real life many problems arise which prevent maintenance organizations achieving these objectives and performing to satisfy these requirements. One problem, which is found to have a great impact on maintenance practice, is the gap in communication which exists between the people controlling the financial side and those controlling the technical side of maintenance (P/ PM Technology, 1999 p. 21). Egypt is no exception, we find many problems exist concerning the handling of equipment spare parts, plant assets, and maintenance cost accounting, which all are controlled by accountants, although they are highly related to management engineering. 4.3. Scope of maintenance Strategy implementation is one of the major elements of system development methodology (Ward and Griffith, 1998). In our case, maintenance system strategies can be viewed in terms of scope of maintenance systems and their space of influence. Previous maintenance strategies with their associated methods or types may be viewed through their field of influence or their effect (see appendix), through the following four levels. 4.3.4. System Proactive maintenance strategy can be used to its potential benefit when it is applied to system’s concepts. With this view the equipment’s root cause of failure may not be necessarily technical, and the contribution of the human activity subsystem cannot be neglected. Developing the maintenance system based on proactive maintenance strategy requires major changes in structure and culture. 4.4. Organization Based on the mission, objectives, and strategy, management systems are organized and structured. As organization is a collection of people working together in a division of labor to achieve a common purpose (Schermerhorn, 1985); it should be developed through a rational analysis for functions, specialization, and people. Organization development in Egypt is highly governed by cultural values, and “requires change processes that fit local customs and that address business issue” (Cummings and Worley, 1997, p. 528) 5. Situation analysis and problem origin 4.3.1. Equipment Breakdown maintenance strategy, and its associated methods of corrective maintenance or unplanned maintenance, only involves the equipment. Management planning here concentrates on job planning, and the job is considered to be finished when the equipment is put back into operation. 4.3.2. Plant Preventive maintenance strategy is concerned with the production line or plant-wide equipment through maintenance planning and scheduling. Planning here covers maintenance planning and job planning. 4.3.3. Asset With asset management predictive/preventive maintenance strategy is applied to combine the plant scope with cost, safety, and time. It handles plant assets’ potential failures by utilizing equipment risk assessment and trying to reduce the cost of maintenance through the equipment’s useful life time cycle. Methods as RCM, PCM, and PR, if integrated with maintenance management, come into this domain. Through previous lines we set the stage for the basis on which the present approach was used. It is clear that at the present stage of the systems’ age, (Juhasz, 1996) industrial plants and facilities in Egypt should perform their maintenance activities differently. Maintenance management should be considered as one of the corporate management information systems, and the present development of information technology offers the opportunity for improvement on the management and engineering sides. When an industrial organization is managed through an integrated system, data collected through predictive maintenance techniques can efficiently be used to predict the machine condition. This information, when integrated with the production and planning activities of the plant process and operations, will serve marketing, finance, and other elements of a business environment. Different analyses and design methodologies should be explored to achieve this new structure. 5.1. Problem origin With new projects very little, or almost no attention is given to establishing a maintenance management concept until the equipment commences production. With new projects, most 112 Implementation of proactive maintenance Journal of Quality in Maintenance Engineering Samir Ismail Mostafa Volume 10 · Number 2 · 2004 · 107-122 of the Egyptian projects’ owners contract a project manager who, with the help of a number of consultants, guides the construction of the project through its development cycle. With a licensed technology and new production line and probably with new and advanced equipment, all instructions for repair and service are supplied in a foreign language, which most of the time is incomplete in content and subject. Maintenance organization is always left out of sight. People start to think about maintenance after the commissioning and startup. At this stage a number of solutions may come into the picture such as: . hire a foreign company to carry out plant operation and maintenance; . contract maintenance experts with local technicians to manage maintenance operations; . introduce ready-made computerized maintenance packages with their associated technology as is; . use ready-made computerized maintenance packages with some customization; and . use a complete manual system with operators’ and maintenance technicians’ experience. The result is a vicious circle of frustration and failures as the project continues to age out, and more breakdowns and deterioration of quality will be expected. This scenario governs most of the maintenance operations in new and running projects and can be attributed to a lack of formal development methodology which integrates the technology with the human activity system and takes into account the cultural issues of our interacting systems (Samir, 1999b). This result contributes to the state of maintenance operations in Egypt as presented at the beginning of this article. Unfortunately, none of the previous approaches is expected to work due to the following reasons: . people need time to be acquainted with the management needs of the new technology; . the effect of the organization’s culture and values are missing with the introduction of the new ready packaged system; . engineers and technicians do not share in the evolution of the maintenance needs definition from the start; . applying successful ready-made packages in another environment does not always guarantee success in all environments; and . most of the time training is not always determined based on actual organizational needs. With this situation the following characterizes the nature of maintenance in such arrangements: . the maintenance organization grows in a random fashion, irrespective of the maintenance needs; . the nature of the maintenance operation will always be reactive to catch up with production demands; . maintenance budgets suffer more cuts, as data for budget justification is missing; . more staff with low managerial skills becomes the pattern of management; . deriving the plant production based on operation only will induce a weak planning vision; and . maintenance technology, if it exists, will never be fully utilized. 6. System approach to proactive maintenance (SAProM)q Proactive-based maintenance (ProM) as employed in this work is a systemic and holistic approach to building a maintenance system in such a way as to guarantee optimum safety, integrity, and to approach failure-free operation. 6.1. Concept Maintenance systems with their associated structure and procedures in any industrial plant, develop and evolve gradually over a period of time (Barasarba and Archer, 1995). This time period depends on many factors and the most important one is the commitment of the organization to the required change. As maintenance activities are always viewed to be based on technical tasks, the present approach emphasizes the importance of building a strong foundation of maintenance management in order to fulfill these tasks right first time, and every time. Without proper information channels, a unified data model, proper analytical capability and training based on actual and true needs, measurements of PCM become useless. Also, without proper interdepartmental interfaces the valuable data of product quality, equipment history, and cost, calculating a true and accurate cost of maintenance, will never be achieved. 6.2. Maintenance technology The present approach utilizes different technologies to monitor the cause of failure for the purpose of preventing the failure and extending the machine’s life. Based on the research results and supported by a field survey, 10 per cent of the cause of failure is responsible for 90 per cent of its occurrence (Fitch, 1995). Proper technology should be selected to monitor the cause of failure and to help in identifying the proper procedure for its prevention. 113 Implementation of proactive maintenance Journal of Quality in Maintenance Engineering Samir Ismail Mostafa Volume 10 · Number 2 · 2004 · 107-122 1998. It started its operation with a certain organization structure developed to satisfy the basic needs of its functions. Because of the high level of sophistication and accuracy required by the processing elements of the plant, conventional maintenance techniques appeared to be inefficient. A number of problems were found to exist with its operations, which showed itself in the following symptoms: . low operational performance; . frequent unscheduled faults; . frequent contamination of control elements; . frequent degradation in glass quality; . repeated spare parts availability problems; . weak information flow; and . frequent unplanned production demands. 6.3. Elements Implementation of ProM methodology as implemented in this work covers the following elements: . education and learning; . wide participation of employees; . management commitment; . technology full utilization; . maintenance system re-engineering; . full system integration; and . cost and return. These elements will be reviewed during the discussion of the following case study. 7. Proactive maintenance – the methodology The present method is an integrated structuredprototyping technique, specifically useful in maintenance system development in an illconditioned environment. The scope of structured approach, as applied here, can best be described through the following main phases: . program initiation; . feasibility analysis; . business area analysis; . logical system architecture; . system selection; . re-engineering and system design; . contracting and procurement; . construction; . implementation; and . post-implementation. A more detailed explanation of this methodology can be found in (Samir, 2002, p. 146). Prototyping is building a small model based on the basic system requirements, and, through a number of iterative steps, new requirements are added to the prototype and the model itself is extended to cover other areas of interest. Prototyping starts with logical system architecture and continues beyond system construction. During the last seven years, this methodology was used by the author in a number of projects, and the following sections shed more light on its elements and implementation as it is used with its full development cycle in the following particular case study. The EGC authority explored various means to enhance its managerial mechanisms, and maintenance management was one of the areas to be investigated when this program started in 1999. Preliminary analysis indicated that many of the problems encountered with the existing operations of EGC maintenance are related to inefficient maintenance organization, with its missing links and interfaces with other divisions, which are required to facilitate data flow between different sub-systems of the EGC. In order to enhance EGC maintenance organization structure, and to identify the type of maintenance strategy and technology suitable for its system, the first phase of the present study was initiated by adopting the following main activities: . assess the environment of the maintenance operations in the EGC; . identify problems and deficiencies of the EGC plant operations; . define new objectives to be achieved; and . develop requirements for a new arrangement, to help in achieving the set objectives. 8. Case study: implementation in the Egyptian Glass Company (EGC) 8.1. Problem definition To assess the environment and to identify EGC maintenance problems, a number of meetings, questionnaires, and brainstorming sessions were conducted with managers and personnel from maintenance departments and their interfacing sub-systems, in addition to EGC document flow and workflow review. Diagnosis of maintenance operations and practice were done by dividing the functions among the following major areas: . human resource and policy development; . maintenance management; . equipment availability and performance; and . preventive and predictive maintenance. The EGC officially started its production of high quality of flat glass, using a continuous fully automated process of float technology in January Each functional area was examined with its subdivisions, as identified through different levels of investigation. Table I summarizes basic 114 Implementation of proactive maintenance Journal of Quality in Maintenance Engineering Samir Ismail Mostafa Volume 10 · Number 2 · 2004 · 107-122 Table I Samples of findings with elements of investigation for EGC maintenance function area Human resource and policy development Function area Elements Training Organization and job description Policy and procedures Maintenance cost Spare parts and inventory Work order system Equipment reliability Equipment criticality Work shop Technology development Condition monitoring Diagnosis Trending and failure analysis Tools and devices Equipment availability and performance Maintenance management Preventive and predictive maintenance Findings and conclusions U U U U Technical training only Was not adequate Did not exist Model did not exist No parts coding, changes needed Did not exist Not calculated Based on experience Reactive No formal procedure Feeling and visual Based on experience Did not exist Only basic devices U U U U U U U U U U elements of investigation and findings. Direct effect between each element and functional area (as represented by U in the Table) was examined, as well as other indirect effects. A total of 80 elements of evaluation was used during the problem definition phase, and data collected were used in evaluation. It was concluded that the existing production line of the EGC provides an excellent opportunity for improvement of its layout, process monitoring and operations technology, besides its available documentation. Also, maintenance operations of the EGC needed a major enhancement to cope with the level of sophistication of the plant operation, and to be able to utilize all of its resources. New systems needed to be developed to overcome all of its existing difficulties, and to improve its level of maintenance activities. To guarantee successful implementation of the new system, development was carried out in phases. The first phase concentrated on developing a master plan for system development and the introduction of a small-scale maintenance system (prototype) based on the new basic requirements. This prototype was further expanded in the following phases: . a problem definition phase; . a design phase; . an implementation phase; . a predictive maintenance installation phase; and . a maintenance by information phase. As shown in Figure 1 these phases are overlapped and iterative; each is divided into a number of activities and tasks (350 tasks were implemented). Maintenance team members were trained to produce the required development information and to implement it at the same time. Information produced from each activity is used to feed the next phase and to set the stage for the team training and project management. During project implementation, a number of work groups and committees were formed to guide the development of requirements and to guarantee the proper interfaces of maintenance information with other departments of the EGC. It is important to note that during the development phases of the project, the author acted as a developer, implementer, coach and problem investigator (technical and non-technical) (see Samir, 2002, p. 146). 8.1.1. Functional analysis In order to be able to judge the effectiveness of EGC organization structure, job functions with samples of job description used in the licensing provider company (LPC), were used to construct a simplified float manufacturing organization model. This model was then compared with the existing functions in the EGC, and used to identify new areas and functions that needed to be covered. For this purpose a linear responsibility chart (Dougherty, 1989, p. 45) was used to relate each function with job position and duty, as described by the LPC. A total of 50 functions was examined with its corresponding job in the EGC, together with all of its supporting positions. Based on this analysis and with all other findings, a proposed EGC maintenance and technical organization structure was developed. 8.1.2. Mission statement Through a number of collective meetings with managers and engineers the following mission statement was defined: 115 Implementation of proactive maintenance Journal of Quality in Maintenance Engineering Samir Ismail Mostafa Volume 10 · Number 2 · 2004 · 107-122 Figure 1 Phases of maintenance system development EGC employs a sophisticated flat-glass continuous computer-controlled process to produce flat glass by utilizing float-bath technology. The production line should operate continuously around the clock for 24 hours, 7 days a week, to produce zero defect flat glass with production rate depends only on product specified geometry, density, and other physical parameters. The EGC maintenance mission is to guarantee continuous operation to produce the specified quantity of glass, with a specified quality. The mission only ends when production quantities are met. 8.1.3. New system objectives Based on the analysis results, new system objectives were derived and used to trigger all the subsequent development activities. Objectives were divided into short-term and long-term. The following gives examples for some of these objectives: . automatically generates training requirements for EGC technicians and engineers; . continuously enhances and improves technical skills required for critical operations; . fully utilizes information produced from process measurements and monitoring; . identifies equipment criticality based on actual plant operation; . provides clear identification of critical spare parts; . provides accurate estimate of materials, spare parts and consumables needed; . provides a detailed cost of maintenance for each piece of equipment; . continuously reduces maintenance costs while maintaining world-class operation; . uses equipment reliability models to improve the effectiveness of maintenance; . provides a learning mechanism for maintenance system implementation; . provides a means to predict failures of all critical equipment early enough and with no interruption to any of the planned operations; . . continuously reduces emergency repair or breakdown of all critical equipment and/or components to a minimum; and provides tools and mechanisms for enhancement and/or improvement of equipment performance. The new maintenance system was designed to remove all previously mentioned problems and satisfy the objectives defined above. 8.1.4. Maintenance and business objectives Linking maintenance objectives with EGC business objectives required close examination for its sub-systems functions, information flow, and outputs. For this purpose, EGC divisions which highly interact with maintenance, were identified as: . operation planning and control; . process engineering; . production; . technical; . inventory control; . purchasing; . training; . quality control; and . computer and information systems. Guaranteed smooth information flow between these divisions and maintenance was essential in the present project. For this purpose maintenance system interfaces were accurately defined (see Figure 2). 8.1.5. Organization structure Based on the comparison of the LPC organization model and considering the defined needs and objectives of EGC operations, a proposed organization structure was developed and submitted to EGC management for approval. Once this proposed organization was approved, job description, policy and procedures, with document flow, were formalized. Two new divisions, namely maintenance planning and 116 Implementation of proactive maintenance Journal of Quality in Maintenance Engineering Samir Ismail Mostafa Volume 10 · Number 2 · 2004 · 107-122 Figure 2 EGC sub-systems with interfaces . . increase effectiveness of maintenance operations; and improve energy management and control. A work plan was developed with 36 main activities, and each team member was asked to develop an action plan for specific systems or group of equipment in coordination with other members, and under the supervision of two team leaders (mechanical and electrical). Further, maintenance team members were trained to develop tasks in a number of collective and individualized sessions. 8.3. System design The system design phase concentrates on maintenance systems re-engineering, together with functional and data model development. Also, during the design phase equipment analysis was carried out, with real life failure data, to identify the proper monitoring and diagnostic technologies. The following highlights some of the important activities, which took place. technological studies, and machine health monitoring, were created. Functions and subdivisions for each of these divisions were developed based on actual workflow, and supported with real life data. 8.1.6. Maintenance planning The maintenance planning and technological study division is designed to carry out all planning and scheduling of maintenance, manage work order systems, perform the preliminary failure analysis and document and actually perform statistical analysis of component problems and maintainability factors. This division is considered as the first level of equipment enhancement and modification. Technical data about machine problems should be formulated here before passing to the next level of technical studies. Two levels of specialized technical studies were proposed: one at the Technical Office, and the other at the Research and Development department. Also, efforts of the maintenance planning division should be coordinated with the production planning and control as both represent two sides of the process support. 8.2. Planning for maintenance system development Data collected during the problem definition phase were used to build an integrated plan for both maintenance system development, and maintenance work to be performed on physical assets of the EGC facility, in addition to emergency procedures. Team members were trained to develop the plan through the following three main steps: (1) Define scope of work. (2) Develop a work plan. (3) Build an action plan. 8.3.1. Maintenance workflow Maintenance operations are planned based on the information generated by the new system. Effectiveness of this planning is highly dependent on the quality, accuracy, and recency of this information. Information is processed data captured from facts and events experienced by various operations taking place within the system. Forms and reports flowing with the physical work are the only elements used to capture these data. Without documenting all events happening within the system, no accurate information can be generated, and hence, all decisions will be questionable. For this reason, one of the essential works of this project was to activate a number of data-capturing elements designed specifically to suite the EGC environment, such as: (1) Service request – used mainly for unplanned maintenance. (2) Work order – initiated by the work request, and used for planned or repair work. (3) Shift register – used for plant zones/sub-systems to record its actual operations. (4) Job card – for recording actual work performed by each craftsman. (5) Inspection and repair procedure sheet – describes work required for repair. (6) History card – used for each machine and main component. (7) Spare parts list – to identify spare parts required for component maintenance. Scope of works was defined to cover the following main phases: . define availability of technical documents; . improve safety and work environment; To gain enough acceptance and support from those who will be using these forms, a number of meetings were conducted to get the full participation of the maintenance team in this 117 Implementation of proactive maintenance Journal of Quality in Maintenance Engineering Samir Ismail Mostafa Volume 10 · Number 2 · 2004 · 107-122 development process. Forms were produced in stages and each time people were invited to add to it. At the end, the final form was submitted to the plant manager for his review and approval. Maintenance planning engineers took an active part in transferring all the information between different parties: operators, production controllers, engineers and technicians. At the end of the development process a formal instruction (signed by one of the team members) was issued to all divisions to explain the form and its use. After two weeks of trials a collective meeting with all engineers and supervisors of the plant, was held to discuss their feedback, concerns and queries, and to formally set the forms in operation. Now, these forms are in place. purpose a maintenance cost model was developed and introduced in the computerized maintenance package designed and constructed during this project. The model is based on four fundamental costs associated with maintenance work as: (1) Direct cost. (2) Standby cost. (3) Lost production cost. (4) Degradation cost. 8.3.2. Equipment document and technical instruction In parallel with applying the work order system, technical instructions for equipment maintenance and inspection were made available to all engineers and technicians. Based on the information provided by the document survey, and from the examination of the process flow diagram, grouping of the equipment was identified in terms of system and functions in 33 different systems. Each of these elements includes a number of other cost items contributing to the total maintenance cost with various degrees. The model will be able to produce maintenance costs for each piece of equipment, each cost center, department, or plant, as specified in the system objectives. Using numerical values for these cost elements, the following maintenance cost indices are calculated: . ratio of maintenance-to-operation cost; . maintenance and operation man-hour ratio (taken from wage ratio); . ratio of contract cost to total maintenance cost; . overhead rate defined as the ratio of overheadto-maintenance cost; and . product maintenance cost defined as the cost of maintenance per 1,000 units produced. 8.3.3. Equipment database design Equipment and components within the 33 systems are grouped logically to facilitate EGC database design. There are a number of options for equipment grouping (August, 1998, p. 36), and the one used in the present model was chosen to enhance maintenance personnel specialization and to offer the required flexibility to trace component failures. Now, equipment with its sets of subequipment and components is grouped in terms of its physical location, systems and plants, and disciplines. Also, it is arranged in a hierarchy structure, and each is linked to its asset definition, and is related to a cost center with its cost accounts. Component spare parts and the standard repair list both serve as an interface with the inventory control subsystem. A database model with its corresponding data flow model, which constitute the base for the new computerized maintenance application, is under implementation now. 8.5. Installation of PCM Vibration measurements and oil analysis techniques were selected in the first phase of PCM of this project. For this purpose a number of steps were undertaken for its implementation. First, a recent graduate engineer, hired by the EGC for this particular project, was subjected to a training program on rotating equipment condition monitoring. The program was designed and administered by the author to qualify this new engineer to carry the required predictive measurements. Second, evaluation of different PCM packages was carried out. Third, procurement of the package with installation and implementation of the equipment database. Now, after 14 months since the installation of the monitoring package, it is possible to completely monitor 65 pieces of rotating equipment, and to carry out all diagnosis of measured data, in-house, with no external help. 8.4. Cost of maintenance Profitability and revenue increase, as the most important business objectives, can be achieved through various savings. Many studies indicated that savings in maintenance always have the largest and direct value in all savings (Barasarba and Archer, 1995, p. 3). To monitor and to control maintenance cost, elements of maintenance cost have to be defined and linked to the corresponding maintenance operation (Al-Najjar, 1996). For this 8.6. Maintenance information management Based on the new re-engineered maintenance system, a computer program was designed and constructed to automate all of its functions. The new computerized system is a Web-enabled application with six modules namely: setup (for production line and equipment), asset management, scheduling (preventive maintenance planning), failure analysis (implementing failure mode cause and effect analysis), analysis 118 Implementation of proactive maintenance Journal of Quality in Maintenance Engineering Samir Ismail Mostafa Volume 10 · Number 2 · 2004 · 107-122 (equipment performance and maintenance metrics), and security. It is believed that this application offers an integrated low-cost solution for all maintenance needs of the EGC. production loss hours (starting time and end time) with cause of loss (process or maintenance), and action taken. Figure 5 shows a trend of this loss during 11 months. The figure shows the total production loss in hours with its components (loss due to process and equipment malfunction loss) before maintenance system re-engineering (months 1 and 2 in 1999) and after implementation (starting from month 8 in the same year). It is clear that there is a decreasing trend during the project in all components. During the last two months in the graph (March and April, 2000) the average loss per month due to equipment malfunctions is 87 minutes, which represents 0.2 per cent of total production time per month, a value which changed very little. It is worth noting here that the impact of any change in the management function on system performance is nonlinear in nature with a number of delays (Forrester, 1969). We can only assess this impact with the proper collection of data, an accurate analytical model, and with a formal system in place. 9. Benefits and returns During the project implementation a number of performance indicators were used to measure its effectiveness and to justify its cost. The following represents samples of these indicators, and more parameters can be found in Dougherty (1989, p. 318). 9.1. Process through-put This is defined as the ratio between quantity of produced glass with the specified quality, and the tank load (total amount of line charge). This ratio is calculated automatically by the system DCS, and averaged for each shift and day. Figure 3 shows the yield distribution with time during 1999, during which time the system re-engineering took place, to be compared with Figure 4, which shows the distribution for the year 2001, after reengineering and PdM installation. It is clear that the introduction of the change brought the production loss to a controllable state. 9.2. Production loss One of the forms circulated in the system is the production loss survey form. This form collects Figure 3 Process rate at the start of change 9.3. Cost of maintenance per 1,000 units of product As the computerized package with the new maintenance cost model still in its implementation phase, cost of maintenance is calculated using data collected manually about spare parts, material, and average labor costs. Comparison of cost of maintenance with the cost before implementing the project will not give an accurate figure, as the EGC was supported by the LPC. For this reason we will compare the cost of maintenance to produce one ton of glass with the same cost in different industries in Egypt. This gives the following figures: . ratio of EGC maintenance cost per ton of glass to cost of maintenance to produce one ton of sugar (by Egyptian Sugar Integrated Industry ¼ 95 per cent; and . ratio of EGC maintenance cost per ton of glass to maintenance cost to produce ton of PVC (by a petrochemical company in Egypt) ¼ 44 per cent. Figure 5 Production loss in hours, before and after re-engineering Figure 4 Process rate after re-engineering and PdM 119 Implementation of proactive maintenance Journal of Quality in Maintenance Engineering Samir Ismail Mostafa Volume 10 · Number 2 · 2004 · 107-122 One should be very careful during this comparison because the cost of maintenance always depends on many factors, and comparison should be made only under standard conditions. becomes essential for computerized maintenance information systems definition. 9.4. Overall equipment effectiveness Overall equipment effectiveness (OEE), as defined by TPM, combines process rate with equipment availability, and quality rate. During the last six months (from 1/1/2002 to 30/6/2002) EGC average values for these parameters are 0.839, 0.99, and 0.87, respectively, which give: OEE ¼ (yield) 0.839 X (equipment availability) 0.99 X (quality rate) 0.87 ¼ 0.722. This value to be compared with that of the world class value of OEE ¼ 0.85. 9.5. Savings from failure prevention Part of PdM installation in the EGC is to calculate the savings and cost of the program. Each piece of the critical equipment diagnosed and analyzed is assessed by developing a number of scenarios for cause and consequence of failure. For each scenario the cost of failure effects is analyzed and recorded. It is hoped that by this procedure one can prove that maintenance is not just an overhead, but is a profit center (P/PM Technology, 1999 p. 19). To give an example, EGC’s nitrogen plants were monitored for motor bearing problems. The EGC maintenance department, with the help of the condition monitoring engineer, managed to operate this particular motor one year beyond its recommended replacement time by its vendor, and after two wrong diagnoses (one due to its control panel, and the other was a false alarm). It can be shown that two days of unplanned downtime for this plant would cost the factory the same amount of money required to buy the monitoring package, which is equal to an average of 4h 40min of lost production. 10. Conclusions The implementation of proactive maintenance (ProM), as presented here, offers a complete package for maintenance system development. The package contains a methodology, a software package, and a set of tested and verified procedures. The methodology is general enough to be used in various fields of application, as it was tested in different facilities, and service and production environments. It addresses the total corporate system, augmented by the new concepts of maintenance methods, and utilizes suitable approaches of information systems development. With the present approach process re-engineering References Al-Najjar, B. (1996), “Total quality maintenance: an approach for continuous reduction in costs of quality products”, Journal of Quality in Maintenance Engineering, Vol. 2 No. 3, pp. 4-20. August, J.K. (1998), “Equipment grouping for electric generating plants and process facilities”, P/PM Technology, Vol. 11 No. 5, p. 36. Avison, D.E. and Nandhakumar, J. (1995), “The discipline of information systems: let many flowers bloom, information system concepts, towards a consolidation of views”, Proceedings of the IFIP International Working Conference on Information Systems Concepts, Chapman & Hall, London. Barasarba, B.M. and Archer, J.A. (1995), IPT’S Rotary Equipment Handbook, Machinery Reliability and Condition Monitoring, IPT Publishing and Trading Ltd, London. Bond, T.H. (1994), “Implementing profit-centered maintenance”, P/PM Technology, p. 59. Bubenko, J.A. (1986), “Information system methodologies – a research view”, in Olle, T.W., Sol, H.C. and Verjn-Stuart, A. (Eds), Information System Design Methodologies: A Comparative Review, Elsevier, Amsterdam, pp. 4-92. Checkland, P. (1990), Systems Thinking, Systems Practice, 1981, 6th ed., John Wiley & Sons, New York, NY. Coetzee, J.L. (1999), “A holistic approach to the maintenance ‘problem’”, Journal of Quality in Maintenance Engineering, Vol. 5 No. 3, pp. 276-80. Cummings, T.G. and Worley, C.G. (1997), Organization Development and Change, 6th ed., South-West College Publishing, Cincinnati, OH. Donovan, A. (1998), “Improving business competitiveness through preactive maintenance management”, P/PM Technology, June, p. 54. Dougherty, D.C. (1989), Strategic Organization: Planning Downsizing for Survival, Quorum Books, New York, NY. Ebling, C.E. (1997), An Introduction to Reliability and Maintainability Engineering, McGraw-Hill, New York, NY. El-Mikkawy, N. and Handoussa, H. (2002), Institutional Reform and Economic Development in Egypt: an Economic Research Forum Edition, The American University in Cairo Press, Cairo. Fitch, C.J. (1995), Proactive Maintenance Can Yield More than 10Fold Savings over Conventional Predictive/Preventive Maintenance Programs, Diagentics Inc., Oklahoma City, OH. Forrester, J.W. (1969), Industrial Dynamics, MIT Press, Cambridge, MA. Hedderich, C. (2002), Navy Proactive Maintenance, available at: www.AMSEC.com (accessed 2002). Holmn, P. and Devane, T. (1999), The Change Handbook Group Methods for Shaping the Future, BK Publishing, Atlanta, GA. Huse, E.F. (1980), Organization Development and Change, 2nd ed., West Publishing, St Paul, MN. Jacobs, K. (2000), “Applying RCM principles in the selection of CBM-enabling technologies”, paper presented at the Predictive Maintenance Technology National Conference, Norman, OK, November 13-16, pp. 13-16. James, R. (2001), “Machine condition monitoring: a catalyst for change in industrial equipment maintenance”, P/PM Technology, Vol. 14 No. 6, p. 18. Juhasz, J.E. (1996), “Enterprise engineering in the systems age”, in Gaynor, G.H. (Ed.), Handbook of Technology Management, McGraw-Hill, New York, NY. 120 Implementation of proactive maintenance Journal of Quality in Maintenance Engineering Samir Ismail Mostafa Volume 10 · Number 2 · 2004 · 107-122 Kececioglu, D. (1994), Maintainability, Availability and Operational Readiness: Engineering Handbook, Prentice-Hall, Upper Saddle River, NJ, p. 335. Labib, A.W. (1998), “World-class maintenance using computerized maintenance management system”, Journal of Quality in Maintenance Engineering, Vol. 4 No. 1, pp. 66-75. Meador, R.J. (1997), “Technology advances for operation and maintenance”, paper presented at the Predictive Maintenance Technology National Conference, Dallas, TX, December 1-4, pp. 1-4. Mitchell, J.S. (1998), “Equipment asset management – a 21st century requirement for competitive success”, P/PM Technology, February, p. 24. Moubray, J. (1993), RCM Reliability-Centered Maintenance, Butterworth-Heinemann Ltd, Oxford. Nagarrur, N.N. (1999), “An object-oriented decision support system for maintenance management”, Journal of Quality in Maintenance Engineering, Vol. 5 No. 3, pp. 248-57. Nicholas, J.R. (2000), “Lessons learned from 100+ predictive condition monitoring program audit”, paper presented at the Predictive Maintenance Technology National Conference, Norman, OK, 13-16 November 2000. P/PM Technology (1999), “Reliability at what cost”, pannel discussion, December. Robinson, C.J. and Ginder, A.P. (1995), The North American Way, Productivity Press Inc., Cambridge, MA. Samir, I.M. (1996), Development of Maintenance Management System in Coral Beach Village (CBV), Problem Definition and Progress Report, Technical Report, November. Samir, I.M. (1998), “Development of maintenance management system in Armant Factory for reducing 30 per cent of maintenance cost”, final report submitted to Sugar Integrated Industry, Egypt, by DIP Fac. of Eng., Cairo University, Cairo, June. Samir, I.M. (1999a), EGC Maintenance System, Problem Definition and Prototype Development, submitted to the Egyptian Glass Company, 10th of Ramadan City, Egypt, April. Samir, I.M. (1999b), EPC Appraisal, Maintenance, Technical Report, prepared for Industry and Economic Consultants, January. Samir, I.M. (2002), Systems Analysis, Information Management System, Introduction to Analysis and Design Methodologies, available at: www.geocities.com/ analyst_corner/analyst.html Schermerhorn, J.R. Jr, Hunt, J.J. and Osborn, R.N. (1985), Managing Organization Behavior, John Wiley & Sons, New York, NY. Sherkhodaie, A. (2000), “Model-based expert system for fault diagnosis and prediction in rotary machninery”, P/PM Technology, December, p. 26. Smith, A.G.R. (1972), Science and Society in the 16th and 17th Centuries, Thames & Hudson, London. Talbott, C.M. (2001), “Prognosis of remaining life and related replacement decision”, P/PM Technology, April, p. 21. Toy, E.H. and Wogninrich, T.J. (2000), “Productive reliability through OM&E”, P/PM Technology, December, p. 44. Wang, S. (1999), “An object-oriented approach to plant configuration management information systems analysis”, Industrial Management & Data Systems, Vol. 99 No. 4, pp. 159-64. Ward, J. and Griffith, P. (1998), Strategic Planning of Information Systems, John Wiley & Sons, New York, NY. Wilson, B. (1990), Systems: Concepts, Methodologies, and Applications, 2nd ed. (original published 1984), John Wiley & Sons, New York, NY. Further reading Duffuaa, S.O., Raouf, A. and Campbell, J.D. (1999), Planning and Control of Maintenance Systems: Modeling and Analysis, John Wiley & Sons Inc., New York, NY. Mitchell, J.S. (1998), “Producer value – a proposed economic model for optimizing equipment (asset) management and utilization”, paper presented at MARCON 98, sponsored by the University of Tennessee, Maintenance and Reliability Center, Knoxville, TN. Murthy, D.N.P., Trens, A. and Eccleston, J.A. (2002), “Strategic maintenance management”, Journal of Quality in Maintenance Engineering, Vol. 8 No. 4, pp. 287-305. Oberg, C.P. (2000), “Managing maintenance as a business”, Plant Service, July, p. 53. Sherwin, D.J. (1999), “Age-based opportunity maintenance policy”, Journal of Quality in Maintenance Engineering, Vol. 5 No. 3, pp. 221-35. Tsang, A.H.C. (2002), “Strategic dimensions of maintenance management”, Journal of Quality in Maintenance Engineering, Vol. 8 No. 1, pp. 7-39. Appendix. Assessment of maintenance methods The following represents the basic elements used in examining each of the maintenance methods mentioned in the article. Other parameters were developed to help in the examination which spans areas of planning, organization development, methodology space, maintenance model, cost and finance, and maintenance engineering: No. Elements (1) Does it cover strategic planning? (2) Link maintenance objectives with business objectives? (3) Provide maintenance strategy development? (4) What basic strategy does it use? (5) Allow for maintenance system model development? (6) Is it a development methodology? (7) Does the methodology space have a life cycle? (8) Integrate information system organization with maintenance system development activities? (9) Does it help in CMMS selection, development, and implementation? (10) Allow for in-house development? (11) Allow for software customization? (12) Use on-the shelf package? (13) Provide requirements specification development? (14) Does the methodology cover: . social system; . activity system; and . maintenance technology selection? (15) Does the methodology provide tools for various phases of development? 121 Implementation of proactive maintenance Journal of Quality in Maintenance Engineering Samir Ismail Mostafa Volume 10 · Number 2 · 2004 · 107-122 (16) What its basic model is based on? (17) Does the model give specific indicators? (18) Do indicators cover: . system performance; . maintenance system effectiveness; and . machine health prediction? (19) Does it provide maintenance cost model? (20) Does the model consider: . asset cost; . preventive maintenance cost; . failure cost; and . outsourcing cost? (21) Does the model utilize data processing and information analysis? (22) Provide mechanism to update equipment life replacement? (23) Does it utilize economic indicators? (24) Integrate corporate financial subsystem including: . inventory; . fixed asset calculation; . general ledger; and . accounting? (25) Does it trace failure cause and effect? (26) What is its scope of maintenance? 122