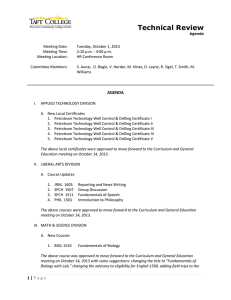

ALWAYS ALMANSOORI Petroleum Industry Overview (PIO) www.almansoori.biz VISION To achieve SUSTAINABLE EXCELLENCE in SERVICE with World Class Health, Safety, Environment & Quality. 2 History & Introduction___________ 2 Main Functions of Petroleum Industry Upstream Downstream •Exploration •Drilling •Well Completion •Production •Oil Treatment •Storage •Transportation •Refining •Petrochemical 3 History & Introduction___________ • Petroleum industry plays a significant role in our life. • The word ‘Petroleum’ is originally a combination of two Latin words: Petr, meaning stone or rock and Oleum, meaning Oil. Therefore, the word Petroleum meant Oil of the Rock. • Petroleum differs in its color, viscosity and purity from one place to another. It may be dark brown, light brown or greenish to blackish brown, while gas has no color. 4 History & Introduction___________ The first well was drilled in the North West of Pennsylvania, USA in 1859 by Edwin Drake. His name was used to help name the drilling rig as “derrick” in his honor. After 9 years, in1868, the second well was drilled in Gemmsa, Egypt. 5 History & Introduction___________ Oil & Gas are of a combination of different percentages of Carbon and Hydrogen in addition to smaller percentages of Sulphur, Oxygen and Nitrogen. There are both light crude oil and heavy crude oil. Petroleum migrates from high pressure to low pressure until trapped. It gets separated from any water that is there and floats above it. 6 History & Introduction___________ Oil and Gas are formed by decaying remains of dead marine animals and plants. Oil and Gas reservoirs buried deep underground were once large oceans and lakes where animals and plants lived and died millions of years ago. The remains of these animals and plants sank to the bottom of oceans and lakes. With the passing of time, it decomposed and was covered by layers of sand and silt brought by rivers and winds. Layers upon layers of deposits turned into sedimentary rocks. Heat, bacteria and pressure from these layers helped the remains turn into hydrocarbons (Oil and Gas) which were trapped in pores and grooves in the sedimentary rocks. 7 History & Introduction___________ Petroleum can be discovered by studying the degree of Permeability or Porosity of sedimentary rocks. Permeability can be measured by taking cylindrical rock samples and then inject specific gases or liquids into them. It can also be measured by microscopic testing of drilling samples. 8 EXPLORATION________________ • • Geologist and Geophysics do the exploration. Crude Oil migrate from high pressure to low pressure until it is trapped . 3 types of exploration 1. Surface 2. Sub surface 3. Satellite 9 CONTINUED… EXPLORATION________________ 10 EXPLORATION_______________ Seismic Method (most commonly used): it is where a grid of lines is plotted over a wide area and geophones are then placed along the grid lines so that the results of the seismic testing can be recorded. The seismic data that is collected is a measurement of the time it takes sound waves to travel from the vibration source to different rock layers and back to the geophones located at the surface. This data is recorded and sent to the geophysicist. The geophysicist will then analyze the data turning it into time and depth charts. These show the location of the reservoir and the depth and properties of layers of rock in which oil and gas are trapped. 11 EXPLORATION_____________ Types of Trap: Anticline Syncline Faults Salt Dome 12 CONTINUED… Oil Production When producing oil from the well, it needs emulsion treatment. Emulsion means oil-in-water or water-in-oil. Emulsion can be treated by ‘breakthrough’ and ‘coalescing’. 13 Oil Production There are 5 Methods of Oil Treatment: 1. Gravity 2. Heat (heater-treater) 3. Mechanically (separators) 4. Chemically (demulsifier) 5. Electrically (electrostatic heatertreater) 14 Oil Production Oil and Gas is brought from the reservoirs to the well surface by installing a number of valves to the wellhead, these valves are called ‘Christmas Trees’. They link the production pipes and the flow pipes. The size of the flow line and a choke regulate the rate at which the Oil and Gas flow in accordance with the production plans. As long as the natural pressure inside the reservoir is high enough, the Oil will flow automatically from the well. If the natural pressure drops or if the amount of Oil in the well drops to a point where production will stop, then we use pumps or inject Gas and water into 15 the reservoir to resume production. Oil Production The next step is to collect all the Oil produced by several wells in one gathering station, that is where Associated Gas is separated. The Oil is then sent to processing plants where salt and water is removed. Density of Crude Oil- API Gravity API Gravity ( Degrees)= (141.5/Relative Density ( g/cm3)- 131.5 Eg: If light crude oil relative density is 0.83 g/cm3, then API Gravity = 40 degrees The higher the API gravity better the value 16 Offshore Oil and Onshore Oil Gas Fields Offshore oil & gas fields: • Umm Al Sheif • Upper Zakum • Lower Zakum • Umm Al-Dalkh • Satah • Bunduq • Abu al Bokush • Umm Al-Lulu • Mubarra • ArzanahUmm Al Anbar • Naser • Bu Haseer • Bun Dana • Ghasha Onshore oil & gas fields: • Bab • Bu Hasa • Asab • Sahil • Shah • Dabbiya • Shanayel • Rumaitha • Habshan 17 CLIENTS LIST United Arab Emirates OIL OPERATING CO. SERVICE CO. ADCO ADMA ADOC (Japan) Bunduq Crescent Petroleum Dubai Petroleum Establishment Total Zadco Margham NDC Weatherford GOSS Sperry Sun/Halliburton Schlumberger Arabian Drilling ENSCO Noble Drilling Precision Drilling Baker Atlas Baker Hughes Inteq Appexindo COR Pathfinder CLIENTS LIST Qatar OIL OPERATING CO. RAS GAS Qatar Gas 3 & 4 QP SERVICE CO. Gulf Drilling International Noble Drilling International ENSCO Nabors Weatherford Sperry Sun/Halliburton Specialized Oil Services Corelab CLIENTS LIST Kuwait OIL OPERATING CO. Kuwait Oil Company Joint Operations SERVICE CO. United Precision Drilling Kuwait Drilling Company Burgan Drilling Weatherford Sperry Sun/Halliburton Nabors Baker Hughes Weatherford Drilling Intl. Sinopec CLIENTS LIST Yemen OIL OPERATING CO. Hunt Oil Company Canadian Nexen Safer Dove Energy Ltd. SERVICE CO. Nabors HTC Yemen Int’l Ltd. MB Petroleum Services Al Hashdi Schlumberger JOECO CLIENTS LIST Oman OIL OPERATING CO. PDO Occidental SERVICE CO. Nabors Drilling National Drilling & Services Co. Deutag Sperry Sun/Halliburton Sea & Land Weatherford Schlumberger Dalma Energy Abraj Energy Ensign Baker Hughes CLIENTS LIST Saudi Arabia OIL OPERATING CO. SERVICE CO. Saudi Aramco Pool Arabia Arabian Oil Co. (AlKhafji) ZP Arabia Drilling Co. Precision Drilling Rawabi Dalma Sinope SA Luksar SA Sino Saudi Gas Weatherford SA Sinopec SA Al Rashed Fastners Saipem Halliburton / Sperrysun Schlumberger Baker Hughes Precision Energy Pathfinder Odfjell CLIENTS LIST Iran OIL OPERATING CO. Agip Total SERVICE CO. Weatherford Naftkav Schlumberger Precission Drilling CLIENTS LIST Egypt OIL OPERATING CO. Agiba South Dabaa Geisum Gupco Suco Scimitar SERVICE CO. Valve & Tools Schlumberger EDC Transocean Pathfinder Napesco Tenaris Sinotharwa CLIENTS LIST Libya OIL OPERATING CO. Total AGOCO DRILLING CO. Challenger KCA Deutag Tahara Songa CLIENTS LIST Turkmenistan OIL OPERATING CO. Dragon Oil Lukoil DRILLING CO. Continental MSE Main Clients • • • • • • • • • ADNOC ADCO ADMA OPCO ADGAS BUNDUQ NDC BP SHARJAH TOTAL ABK ENOC • • • • • • • • • ZADCO AUH GAS DEV. DUBAI PETROLEUM TAKREEER DANAGAS SHELL DRAGON OIL CRESCENT PETROLEUM Al Hosn 28 OIL GAS PRODUCTION OIL AND NATURAL GAS PRODUCTION ( approximate by 2012) COUNTRRY CRUDE OIL IN 1000 BPD Natural gas In billion cubic feet SAUDI ARABIA OMAN IRAQ KUWAIT QATAR UAE BAHRAIN EGYPT IRAN RUSSIA USA 9475 885 2625 2530 1295 2687 35 511 4054 9773 5672 3095 957 46 414 4121 1810 432 2165 5161 20915 21577 World consume about 30 million. Barrel oil per day 29 AlMansoori Petroleum Services___ PRODUCTION TESTING AND PRODUCTION FACILITIES WIRELINE AND COMPLETION INSPECTION SERVICES DIRECTIONAL DRILLING LOGGING AND PERFORATING TUBING-CONVEYED PERFORATING COREX ALMANSOORI (JV) MSE KEY ENERGY (JV) H2S AND SAFETY SERVICES 30 AlMansoori Petroleum Services___ PRODUCTION TESTING & EARLY PRODUCTION FACILITIES • WELL TESTING SERVICE • MARINE SERVICES • EARLY PRODUCTION SERVICES • WATER TREATMENT SERVICES • MULTI PHASE SERVICES • INTEGRATED WELL SERVICES • ENVIRONMENTAL SERVICES • DRILL STEM TESTING 31 AlMansoori Petroleum Services PRODUCTION TESTING & EARLY PRODUCTION FACILITIES WELL TESTING CHRISTMAS TREE An assembly of valves, spools, press. gauges & chokes fitted to the wellhead of a completed well is used to control production. This is used to direct and control the flow of fluids from the well. A series of valves composing the following swab valve, master valve, wing valve and kill valve (injection) make up this piece of equipment. EMERGENCY SHUTDOWN VALVE (ESD) A device used to immediately stop the well flow stream during emergencies. ESD's shut down the well within 6 seconds and is located on or near the Christmas tree It is activated by a control panel. 32 AlMansoori Petroleum Services PRODUCTION TESTING & EARLY PRODUCTION FACILITIES WELL TESTING CHOKE MANIFOLD Used to control the well flow stream. Sizes include 5k, 10k, 15k psi chokes, adjustable and positive type. DATA HEADER Is connected to upstream and downstream side of the choke manifold to provide pressure gauge, well temperature, sample point and injection equipment. It allows connection of pressure and temperature monitoring equipment as well as injection equipment 33 AlMansoori Petroleum Services PRODUCTION TESTING & EARLY PRODUCTION FACILITIES SEPARATOR •A cylindrical or spherical vessel used to separate gas from liquid and water from oil in the total fluid stream producing well. Separator Process The production separation begins with well flow stream entering a vessel horizontally and hitting a series of perpendicular plates (deflector), this cause liquid to drop to the bottom of the vessel where gas rises to the top. Gravity then separates liquids into the oil and water phases. The oil floats on the water and overflows the weir into the oil chamber in the right section. The gas, oil and water phases are metered individually as they exit the unit through separate outflow lines. Mechanical meters measure the liquid and an orifice meter measures the gas. 34 AlMansoori Petroleum Services PRODUCTION TESTING & EARLY PRODUCTION FACILITIES SWEETENING UNIT A process used to remove hydrogen sulfide (H2S) and carbon dioxide (CO2) from gas stream; these compounds are removed because they can form acidic solutions when they contact water. FLARE STACK An arrangement consisting of a vertical tower and burners used to burn combustible vapors. A flare is usually situated near a producing well or at a gas plant. 35 AlMansoori Petroleum Services PRODUCTION TESTING & EARLY PRODUCTION FACILITIES Surge Tank Designed to store liquid hydrocarbons after separation. This surge tank is used to measure liquid flow rates as well as combined shrinkage and meter factor. Storage Tank: Pipeline: Sweet Gas: Sour Gas: Meter Factor: storage tank for oil production after the oil has been treated. a tube or systems of tubes used for transportation of crude oil and natural gas. Pipes come in different ratings such as 602, 1002, and 1502. Natural gas that contain small amount of hydrogen sulphide and carbon dioxide. a gas containing hydrogen sulfide and carbon dioxide and of which a re extremely harmful. a correction number of the meter. It is determined by calibrating the meter using incompressible fluid (liquid) 36 AlMansoori Petroleum Services WIRELINE AND COMPLETION The suitable tubing must meet the bottom hole pressure and temperature and is run inside the production casing with the production packer, tail pipe and downhole assembly (i.e. re-entry guide, perforated joint, no-go nipple, packers, sliding side doors (SSD) or sliding sleeves, selective nipples and landing nipples of surface control – sub surface safety valve (SC – SSV) . 37 AlMansoori Petroleum Services WIRELINE AND COMPLETION • Open Hole Completion – the production casing is above the payzone. • Cased Perforation Completion – production casing is front of the payzone and then perforated. • Liner Hanger 38 AlMansoori Petroleum Services WIRELINE AND COMPLETION The suitable tubing must meet the bottom hole pressure and temperature and is run inside the production casing with the production packer, tail pipe and downhole assembly (i.e. re-entry guide, perforated joint, no-go nipple, packers, sliding side doors (SSD) or sliding sleeves, selective nipples and landing nipples of surface control – sub surface safety valve (SC – SSV) . 39 AlMansoori Petroleum Services___ WIRELINE OPERATIONS • BOTTOM HOLE PRESSURE AND TEMPERATURE SURVEYS • ELECTRONIC BHP/BHT MEMORY GAUGE SERVICES • RUNNING & PULLING DOWNHOLE PLUGS & SAFETY VALVES • SHIFTING SLIDING SLEEVES • LOCATING TUBING ENDS BOTTOM OF HOLE & OBSTRUCTIONS • BOTTOM HOLE SAMPLING • TUBING CALIPER SURVEYS Well Miller Well Cleaner Well Key • PARAFFIN & SCALE CUTTING • FISHING OPERATIONS Well Stroker Well Tractor 40 CONTINUED… AlMansoori Petroleum Services___ WIRELINE OPERATIONS • FLUID LEVEL MEASUREMENT • DOWNHOLE VIDEO CAMERA • GAS LIFT OPERATIONS • MEMORY PLT • TUBULAR PERFORATIONS (MECHANICAL) • HIGH PRESSURE EXPANDABLE GAUGE HANGERS • SLICKLINE CONVEYED CEMENT PLUGS (EXTREME) • SLICK CONVEYED BRIDGE PLUGS (SEAL-TITE) • RUNNING & TESTING LINER HANGERS (SMITH/LINDSEY) GAUGE HANGER 41 CONTINUED… AlMansoori Petroleum Services___ WIRELINE OPERATIONS • RENTAL OF SLICKLINE EQUIPMENT • COMPLETION ENGINEER SERVICES 42 AlMansoori Petroleum Services WIRELINE AND COMPLETION • Open Hole Completion – the production casing is above the payzone. • Cased Perforation Completion – production casing is front of the payzone and then perforated. • Liner Hanger 43 AlMansoori Petroleum Services___ INSPECTION SERVICES • PIPE MANAGEMENT SYSTEM • CRANE AND LOOSE LIFTING EQUIPMENT INSPECTION • ASNT LEVEL III SERVICES • SURVEILLANCE AND THIRD PARTY MONITORING • NDT SERVICES (ET, MT, PT, RT, UT, VT) • DRILL STEM INSPECTION (API, DS-1, NS-2, SOP, CLIENT) • OCTG EXAMINATIONS (API 5A5, 5CT, 4-FUNCTIONAL EMI) • TUBULAR RENOVATION (CLEANING & PROTECTION) • RIG PARTS AND HANDLING TOOLS INSPECTION 44 CONTINUED… AlMansoori Petroleum Services___ INSPECTION SERVICES • QA/QC TECHNICAL AUDITING • MECHANICAL TESTING AND ANALYSIS • CLIENT CARE COURSES AND SEMINAR • DEMAGNITISATION • EDDY CURRENT • ELECTROMAGNETIC INSPECTION • RADIOGRAPHIC TESTING • RATTLING • RE-FACING 45 CONTINUED… AlMansoori Petroleum Services___ INSPECTION SERVICES • EXTERNAL AND INTERNAL CLEANING • HARDNESS TESTING • HOT SPOT UNITS/EXAMINATION • MAGNETIC PARTICLE INSPECTION • OPTICAL EXAMINATIONS • PACKAGING SYSTEMS • PENETRANT TESTING • PIPE STRAIGHTENING • PROTECTIVE COATING 46 CONTINUED… AlMansoori Petroleum Services___ INSPECTION SERVICES • ULTRASONIC TESTING • THREADING UNITS • VISUAL TESTING • WELD INSPECTION 47 DEFECTS ON DRILLING TOOL 48 Six Most Common NDT Methods Visual Liquid Penetrant Magnetic Ultrasonic Eddy Current X-ray Elect + rons - Exposure Recording Device Visual Inspection Most basic and common inspection method. Tools include fiberscopes, borescopes, magnifying glasses and mirrors. Portable video inspection unit with zoom allows inspection of large tanks and vessels, railroad tank cars, sewer lines. Robotic crawlers permit observation in hazardous or tight areas, such as air ducts, reactors, pipelines. Liquid Penetrant Inspection • A liquid with high surface wetting characteristics is applied to the surface of the part and allowed time to seep into surface breaking defects. • The excess liquid is removed from the surface of the part. • A developer (powder) is applied to pull the trapped penetrant out the defect and spread it on the surface where it can be seen. • Visual inspection is the final step in the process. The penetrant used is often loaded with a fluorescent dye and the inspection is done under UV light to increase test sensitivity. Magnetic Particle Inspection The part is magnetized. Finely milled iron particles coated with a dye pigment are then applied to the specimen. These particles are attracted to magnetic flux leakage fields and will cluster to form an indication directly over the discontinuity. This indication can be visually detected under proper lighting conditions. Ultrasonic Inspection (Pulse-Echo) High frequency sound waves are introduced into a material and they are reflected back from surfaces or flaws. Reflected sound energy is displayed versus time, and inspector can visualize a cross section of the specimen f showing the depth of features that reflect sound. initial pulse crack echo back surface echo crack 0 2 4 6 8 10 Oscilloscope, or flaw detector screen plate Radiography The radiation used in radiography testing is a higher energy (shorter wavelength) version of the electromagnetic waves that we see as visible light. The radiation can come from an X-ray generator or a radioactive source. High Electrical Potential Electrons + - X-ray Generator or Radioactive Source Creates Radiation Radiation Penetrate the Sample Exposure Recording Device Eddy Current Testing Coil Coil's magnetic field Eddy current's magnetic field Eddy currents Conductive material DRILL PIPE RELATED STANDARDS AND SPECIFICATIONS DS-1 STANDARD DRILL STEM DESIGN AND INSPECTION API RP 7G-2 Recommended Practice for Inspection and Classification of used Drill Stem Elements API SPEC 7-2 SPECIFICATION FOR ROTARY DRILL STEM ELEMENTS API SPEC 5DP SPECIFICATION FOR DRILL PIPE ( NEW ) ASTM SECTION-3 STANDARD FOR NON DESTRUCTIVE TESTING AlMansoori Petroleum Services___ Is the Drilling of a Wellbore to a Predetermined Target Through Preplanned Trajectory To be sure 100% that oil traps have hydrocarbon, you have to drill a deviated well. 57 Reasons for Directional Drilling Drilling Multiple Wells From a Single Structure or Pad Most Offshore Development Would Not Be Possible Without Directional Drilling Drilling in Towns, From Land to Offshore and Under Production Facilities Inaccessible Surface Location One of the Primary Uses of Directional Drilling is to Sidetrack a Well Even If It Was to Go Around a Stuck BHA Using Old Well to Explore for New Oil by Sidetracking Out the Casing and Drilling Directionally Sometimes Multiple Sidetracks Are Used to Better Understand Geology or to Place the Wellbore in a More Favorable Portion of the Reservoir Drilling Around Salt Domes Drilling Around Faults Relief well drilling where directional well is drilled into the blowout well target when the surface location is no longer accessible Horizontal drilling Increasing exposure of the reservoir to increase productivity Multilateral drilling where drilling more than one wellbore from a single parent wellbore 58 Applications of Directional Drilling Type I is a build and hold – Drilled to a relatively shallow KOP – Deflected to a maximum inclination – The inclination is held relatively constant to TD Type II Is a Build Hold and Drop Often Termed an “S” Curve – Multiple Targets – Around Salt Domes – More Torque and Drag for the Same Departure Type III Is a Continuous Build to Target – Deeper Kickoff Point – Small Horizontal Departure – Less Expensive Type IV Is a Horizontal Wellbore – Build Rates May Be High – Hold Inclination Is Near 90 Degrees 59 AlMansoori Petroleum Services___ DIRECTIONAL DRILLING • Air / UBD MWD guidance and logging • Casing / Liner reaming • Specialized drilling tools design and manufacture • Rotary tools • Fishing and milling • Casing drilling and reaming 60 AlMansoori Petroleum Services___ Types & Methods of Drilling Methods • Rotary Drilling • Turbo Drilling or (MM) • Top Drive Operation Types • Vertical • Directional or Deviated • Horizontal 61 AlMansoori Petroleum Services___ DIRECTIONAL DRILLING • WELL PLANNING, ENGINEERING AND FEASIBILITY STUDIES • WELL BORE CONSTRUCTION MANAGEMENT • DIRECTIONAL DRILLING • MWD GAMMA-RESISTIVITY-PRESSURE LWD • COIL TUBING/SLIM HOLE/TTRD DRILLING 62 CONTINUED… AlMansoori Petroleum Services ALMANSOORI LOGGING SERVICES utilizes the WARRIOR Data Acquisition System in its Wireline Units. The system allows a real time surface readout of the down hole tools and allows us to provide our clients with Prints, Film and Digital copies of the Data recorded. The system comprises of a P.C., Colour Monitor, Signal Recovery Panel, Perforating Panel and Printer. The Perforation Panel is complete with a Removable Key Safety Switch and Double Lockout Firing switches. This system has been tried and tested throughout the Wireline Industry and is fully capable of supporting our needs for Data Acquisition. 63 AlMansoori Petroleum Services___ LOGGING & PERFORATING • Production Logging • Cement Evaluation • Casing Inspection and Evaluation Services • Correlation and Depth Determination • Pipe Recovery Services including Radial cutting torch 64 CONTINUED… AlMansoori Petroleum Services___ LOGGING & PERFORATING • Expendable Hollow Carrier Perforation Services • Through Tubing Strip Gun Type Perforation Services • Plug and Packer Setting Services • Casing Patch Services 65 AlMansoori Petroleum Services___ TUBING-CONVEYED PERFORATING • VARIOUS SIZES OF GUNS FROM 2 INCHES UP TO 7 INCHES • PENETRATION UP TO 63 INCHES • ENTER HOLE UP TO 1 INCH • DIFFERENT TYPES OF FIRING TECHNIQUE, SUITABLE FOR ALL APPLICATION INCLUDING HORIZONTAL/ORIENTED PERFORATION • DUAL COMPLETION 66 AlMansoori Petroleum Services ALMANSOORI LOGGING SERVICES offers open hole and cased hole services. The key Cased hole offerings are as below •Production Logging (Wireline, Tractor or Coiled Tubing conveyed) •Pulsed Neutron Log ( Reservoir Monitoring) •Casing Inspection and Evaluation Services Flowmeter (various Line speeds) •Cement Evaluation •Perforation Services •Pipe recovery services 67 Cased Hole Logging Services Various Production Problems Water production started from one of the zones Cross Flow – Flow from one zone to another zone. Casing Leak , Channeling Corrosion Initiation due to different methods. 68 Cased Hole Logging Services • Simultaneous measurement of: – – – – Pressure Temperature Fluid Density Capacitance (Water Hold-up) – Flow-meter (Spinner) – Gamma Ray/CCL PLT Sensors • Additional: – MAPS – Noise-Temperature PLT Tool String 69 TCP Services ALMANSOORI LOGGING & TCP SERVICES offers a complete range of perforation services and systems to meet the client requirements. •VARIOUS SIZES OF GUNS FROM 2 INCHES UP TO 7 INCHES • PENETRATION UP TO 63 INCHES, ENTER HOLE UP TO 1 INCH 70 TCP Services PERFORATING • TCP Operations in Egypt & Kurdistan • Through Tubing Strip Gun Type Perforation • Plug and Packer Setting Services • Casing Patch Services • Free Point and Back off 71 TCP Services Wireline Conveyed Perforating Tubing Conveyed Perforating (TCP) 72 AlMansoori Petroleum Services___ H2S AND SAFETY SERVICES • CONSULTING AND SERVICES • EQUIPMENT RENTAL • TRAINING • PRODUCTS 73 AlMansoori Petroleum Services___ SAFETY SERVICES - H2S & HSE INTRODUCTION H2S is one of the leading cause of death in the oil field industry and is an ever-increasing problem for workers involved in oil and gas exploration and production. H2S, However, is not just an oil field problem. This gas is found in many areas unrelated to the oil filed, such as land fills, sewers, waste treatment plants and septic systems. 74 AlMansoori Petroleum Services___ SAFETY SERVICES - H2S & HSE OVERVIEW: • Hydrogen sulfide often results from the bacterial breakdown of organic matter in the absence of oxygen, such as in swamps and sewers; this process is commonly known as anaerobic digestion. • H2S also occurs in volcanic gases, natural gas, and some well waters. The human body produces small amounts of H2S and uses it as a signaling molecule. • Dissolved in water, hydrogen sulfide is known as hydrosulfuric acid or sulphydric acid, a weak acid. 75 AlMansoori Petroleum Services___ SAFETY SERVICES - H2S & HSE OVERVIEW: H2S is highly TOXIC & Colorless gas – VERY DANGEROUS Belongs to the inorganic Sulphide family Consists of 2 Hydrogen and 1 Sulphur atom Known by many names, including: - Stink Damp - Rotten Egg Gas - Sulphurated Hydrogen - Hydrosulphuric Acid - Sewer Gas - Sour Crude/Sour Gas - Sulphur Hydride - Swamp Gas - Devil’s Breath 76 AlMansoori Petroleum Services___ SAFETY SERVICES - H2S & HSE SOURCES OF H2S Natural Sources > Produced in nature by decomposition of organic materials by bacteria. > May develop in low oxygen areas - swamps, polluted water > Can be found in unstabilised crude oil and gas streams 77 AlMansoori Petroleum Services___ SAFETY SERVICES - H2S & HSE Industrial Sources > A product or by-product of waste material: * As a by-product, often recovered and converted to elemental sulphur/sulphuric acid * As a waste material, often flared or disposed of by burning 78 AlMansoori Petroleum Services___ SAFETY SERVICES - H2S & HSE COMMON LOCATIONS WHERE H2S MIGHT BE PRESENT ON DRILLING OPERATIONS: Drilling and Well Service operations: 1. Rig Floor 2. Bell Nipple 3. Mud Pits 4. Shale Shakers Production Operations: 1. Test Separator 2. Choke Manifold 3. Well Head 4. Heater 79 AlMansoori Petroleum Services___ SAFETY SERVICES - H2S & HSE Basic Equipment used for H2S Safety & Protection 1. 2. 3. 4. 5. 6. 7. Breathing Apparatus with Hoseline Connection Air Breathing Cascade System & Breathing Air Compressor Portable Gas Detectors Fixed Gas Sensor, AV Alarms and Display Monitor Wind Sock Bug Blower / Air Mover PPE 80 AlMansoori Petroleum Services___ SAFETY SERVICES - H2S & HSE IMPORTANT: It is mandatory that all personnel working in the H2S environment must attend and pass H2S Awareness, Safety & Use of Breathing Apparatus (Theoretical & Practical) Training Certification prior to work on site. 81 ALMANSOORI PETROLEUM INDUSTRIES AlMansoori Petroleum Industries (AMPI) is a subsidiary of AlMansoori Specialized Engineering (MSE). AMPI was established in October 2008 and is involved in establishing manufacturing facilities of Oil & Gas related products, on the basis of joint ventures. The Company is based in Abu Dhabi and supported by competent professional staff for the management of the current established industrial companies and joint ventures. The staff are also qualified and dedicated to access and evaluate any new opportunities of manufacturing. AMPI carry MSE’s 30 years experience in forming successful joint ventures and facilitating licensing agreements as well as key acquisitions. Its intention is to further increase the share in the business and territorial coverage through strategic joint ventures or licensing arrangements with international partners who will be interested in establishing an arrangement and networking opportunities with AMPI and its alliances and offices throughout the MENA region. 82 AlMansoori Petroleum Services___ COREX ALMANSOORI (JV) • ROUTINE CORE ANALYSIS * ANALYTICAL MEASUREMENTS * ANCILLARY SERVICES • SPECIAL CORE ANALYSIS • FORMATION DAMAGE AND STIMULATION TESTING 83 AlMansoori Petroleum Services AlMansoori-Key Energy Services LLC (JV) AlMansoori and Key Energy Services, U.S.A. signed a joined venture agreement and formed the JV Company ‘AlMansoori Key Energy Services LLC’ in March 2010. It has 4 primary Lines of Business (LOB’s), all of which are covered under our JV agreement. RIG SERVICES Rig Services is Key’s Flagship LOB. Our Service-rig fleet is the largest, most capable in the industry, with rigs rated from 150Hp to 1000Hp for well work at any depth. Our fleet includes rigs with the patented KeyView® and HydraWalk® Pipe Handling systems. Our Rig services include: Workover land rig & auxiliary equipment Pumps Top drives Anchor trucks Downhole and Rental tools Hyperclean units Re-entries on existing wells: deepening, sidetracks and horizontal drilling 84 AlMansoori Petroleum Services AlMansoori-Key Energy Services LLC (JV) FISHING & RENTAL SERVICES Key provides fishing services both onshore and offshore, and also provides whipstock and side tracking services through this LOB. Key Rental Services offers a complete line of services and equipment for both on- and offshore, including our exclusive SmartTongSM Rod Connection Service. Premium tubing and drill pipe rentals Foam air units Whip stock and casing exits Handling tools Power swivels Cutting and wash over services Jars Pressure control equipment 85 AlMansoori Petroleum Services AlMansoori-Key Energy Services LLC (JV) INTERVENTION SERVICES Key Energy Services currently operates the worlds’ 3rd largest fleet of Coiled-Tubing Units (CTU’s), at over 40+ units. Sizes range from 1.25” to 2.5”, some at over 20,000’, with up to 100k snubbing/pull capacity At present all of these units are located in the USA, however, one or more units could be deployed for the right opportunity. 86 AlMansoori Petroleum Services AlMansoori-Key Energy Services LLC (JV) FLUID MANAGEMENT SERVICES A significant part of any oilfield operation is fluid handling. Key has 150 service locations in the US, and our fleet of vehicles can extract fluids from pits, tanks and other storage facilities; transport brine and other drilling fluids to and from well locations; transport produced water to salt water to disposal wells; and haul equipment to and from the well site. We also own and lease permitted disposal wells for the disposal of salt water and incidental nonhazardous oil and gas-wastes. 87 AlMansoori Petroleum Industry___ (JOINT VENTURE COMPANIES ) FLOWSERVE ALMANSOORI SERVICES Repair, Maintenance of ESPs, Control Valves & Mechanical Seals. MICODA PROCESS SYSTEM INTERNATIONAL Manufacturing of Process Equipments. VINCOTTE INTERNATIONAL MIDDLE EAST VARCO ALMANSOORI SERVICES Repair, Service & Certification of Hoisting & Rig Floor Equipments. 88 CONTINUED… AlMansoori Petroleum Industry___ Flowserve AlMansoori Services Flowserve AlMansoori Services is a Joint Venture company established between AlMansoori Petroleum Industries and Flowserve International based in USA. The Company was established in 1993 and is based in Mussafah, Abu Dhabi. The Company provides repair and maintenance services of submersible pumps, mechanical seals and control valves manufactured by Flowserve and other international similar brands or products. Vincotte Int’l. Middle East Vincotte International Middle East is a Joint Venture company established between AlMansoori Petroleum Industries and Vincotte International based in Belgium. The Company provides nondestructive & destructive testing, third party inspection, design review, management system certification, product certification, civil engineering services, training, specialized assistance and consultancy in Health & Safety. The Company is based in Mussafah, Abu Dhabi 89 CONTINUED… AlMansoori Petroleum Industry___ VARCO AlMansoori Services Varco AlMansoori Services LLC is a Joint Venture Company between AlMansoori Petroleum Industries and National Oil Well VARCO, established in 1992. The Company provides repair, maintenance and certifications of all hoisting and rig floor equipment manufactured by National Oil Well VARCO. The Company is based in Mussafah, Abu Dhabi. 90 CONTINUED… AlMansoori Petroleum Industry___ MICODA PROCESS SYSTEMS INTERNATIONAL LLC Micoda Process Systems International LLC (MPSI) was established in 2006 to develop and manufacture specialized equipment for the Oil & Gas industry. MPSI has the ability to undertake projects of all sizes. Micoda is an National Board ASME “U-Stamp” facility certified to Design, Manufacture, Alter & Repair pressure vessels in accordance with ASME Sec VIII, Div 1. Products & Services Include: Underbalanced Drilling Systems Production Testing Systems Oil & Gas Processing Equipment Pressure Vessels & Storage Tanks Flare Stacks & Burner Booms 91 AlMansoori Petroleum Industry___ INDUSTRIES WHOLLY OWNED BY ALMANSOORI PETROLEUM INDUSTRIES SPECIALIZED OILFIELD PRODUCTS Manufacturing of Wireline Units Specialized Oilfield Products is a company established in 2004 and wholly owned by AlMansoori Petroleum Industries. The company manufactures all range and types of wireline equipment and other related oilfield equipment built in accordance to customer specifications and expectations. The Company is based in ICAD 1, Abu Dhabi. GLOBAL CHEMICAL COMPANY Manufacturing of Drilling Chemicals & Sulphonated Asphalt Global Chemical Company is a company wholly owned by AlMansoori Petroleum Industries and was formed in 2006. The Company is involved in the manufacture of high quality speciality drilling mud additives & Sodium Asphalt Sulphonate used in all drilling operations. The Company is based in ICAD 1, Abu Dhabi 92 Thank You