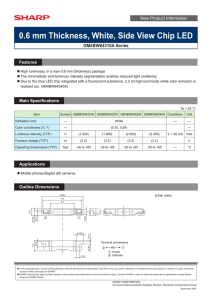

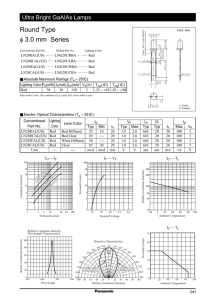

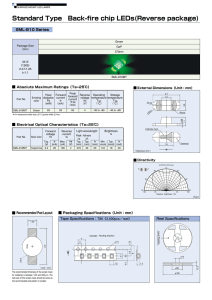

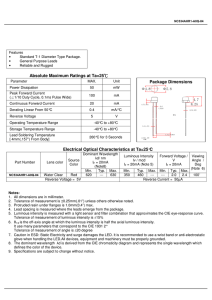

www.osram-os.com Produktdatenblatt | Version 1.1 LA T676 LA T676 TOPLED ® TOPLED, SMT LED with integrated reflector. With our great experience in SMT LED we are able to offer a high quality product for all kind of applications. Applications —Cluster, Button Backlighting —Interior Illumination (e.g. Ambient Map) —Electronic Equipment —White Goods Features —Package: white PLCC-2 package, colorless clear resin —Chip technology: InGaAlP —Typ. Radiation: 120° (Lambertian emitter) —Color: λdom = 615 nm (● amber) —Corrosion Robustness Class: 3B —Qualifications: AEC-Q102 Qualified —ESD: 2 kV acc. to ANSI/ESDA/JEDEC JS-001 (HBM) 1 Version 1.5 | 2022-02-02 LA T676 Ordering Information Type Luminous Intensity 1) IF = 20 mA Iv LA T676-Q2T1-24 90 ... 355 mcd 2 Version 1.5 | 2022-02-02 Ordering Code Q65110A9273 LA T676 Maximum Ratings Parameter Symbol Operating Temperature Top min. max. -40 °C 100 °C Storage Temperature Tstg min. max. -40 °C 100 °C Junction Temperature Tj max. 125 °C Forward current TS = 25 °C IF max. 30 mA Forward current pulsed t ≤ 10 µs; D = 0.005 ; TS = 25 °C IF pulse max. 250 mA Surge current Single pulses; t ≤ 10µs; TS = 25 °C IFS max. 1000 mA Reverse voltage 2) TS = 25 °C VR max. 12 V ESD withstand voltage acc. to ANSI/ESDA/JEDEC JS-001 (HBM) VESD 3 Version 1.5 | 2022-02-02 Values 2 kV LA T676 Characteristics IF = 20 mA; TS = 25 °C Parameter Symbol Peak Wavelength λpeak typ. 625 nm Dominant Wavelength 3) IF = 20 mA λdom min. typ. max. 612 nm 615 nm 624 nm Spectral Bandwidth at 50% Irel,max ∆λ typ. 16 nm Viewing angle at 50% IV 2φ typ. 120 ° Forward Voltage 4) IF = 20 mA VF min. typ. max. 1.83 V 2.00 V 2.33 V Reverse current 2) VR = 12 V IR typ. max. 0.01 µA 10 µA Temperature Coefficient of Peak Wavelength -10°C ≤ T ≤ 100°C TCλpeak typ. Real thermal resistance junction/ambient 5)6) RthJA real max. 500 K / W Real thermal resistance junction/solderpoint 5) RthJS real typ. max. 200 K / W 280 K / W 4 Version 1.5 | 2022-02-02 Values 0.13 nm / K LA T676 Brightness Groups Group Luminous Intensity 1) IF = 20 mA min. Iv Luminous Intensity. 1) IF = 20 mA max. Iv Luminous Flux 7) IF = 20 mA typ. ΦV Q2 90 mcd 112 mcd 300 mlm R1 112 mcd 140 mcd 380 mlm R2 140 mcd 180 mcd 480 mlm S1 180 mcd 224 mcd 610 mlm S2 224 mcd 280 mcd 760 mlm T1 280 mcd 355 mcd 950 mlm Wavelength Groups Group Dominant Wavelength 3) IF = 20 mA min. λdom Dominant Wavelength 3) IF = 20 mA max. λdom 2 612 nm 616 nm 3 616 nm 620 nm 4 620 nm 624 nm 5 Version 1.5 | 2022-02-02 LA T676 Group Name on Label Example: Q2-2 Brightness Wavelength Q2 2 6 Version 1.5 | 2022-02-02 LA T676 Relative Spectral Emission 7) Irel = f (λ); IF = 20 mA; TS = 25 °C I LA T676 1.0 : Vλ : amber 0.8 0.6 0.4 0.2 0.0 350 400 450 500 550 600 650 700 750 800 λ/ Radiation Characteristics 7) Irel = f (ϕ); TS = 25 °C LA T676 ϕ/ -40° -50° -20° -10° 0° 10° 20° 30° 40° 50° 60° 70° 80° 90° 1.0 -30° 0.8 0.6 -60° -70° -80° -90° -100° 7 Version 1.5 | 2022-02-02 0.4 0.2 0.0 I LA T676 Forward current Relative Luminous Intensity 7) IF = f(VF); TS = 25 °C IF / mA 7), 8) Iv/Iv(20 mA) = f(IF); TS = 25 °C LA T676 30 IV LA T676 1.6 IV(20mA) 1.4 25 1.2 20 1.0 0.8 15 0.6 10 0.4 0.2 5 VF / V 8 Version 1.5 | 2022-02-02 30 2.1 25 2.0 20 1.9 15 1.8 10 1.7 5 0.0 1.6 1 1 1.5 IF / mA LA T676 Forward Voltage Relative Luminous Intensity 7) ΔVF = VF - VF(25 °C) = f(Tj); IF = 20 mA ∆VF / V Iv/Iv(25 °C) = f(Tj); IF = 20 mA LA T676 0.3 7) Iv LA T676 1.6 Iv(25°C) 1.4 0.2 1.2 0.1 1.0 0.0 0.8 0.6 -0.1 0.4 -0.2 0.2 -0.3 -40 -20 0 20 40 60 80 100 120 Tj / °C Dominant Wavelength 7) λdom = f(Tj); IF = 20 mA ∆λ dom / nm LA T676 10 5 0 -5 -10 -40 -20 0 20 40 60 80 100 120 Tj / °C 9 Version 1.5 | 2022-02-02 0.0 -40 -20 0 20 40 60 80 100 120 Tj / °C LA T676 Max. Permissible Forward Current IF = f(T) IF / mA 30 25 20 : Ts 15 10 5 0 0 20 40 60 80 100 T / °C Permissible Pulse Handling Capability IF = f(tp); D: Duty cycle LA T676 TS = 0°C ... 100°C IF / A 0.30 0.25 : D = 1.0 : D = 0.5 : D = 0.2 : D = 0.1 : D = 0.05 : D = 0.02 : D = 0.01 : D = 0.005 0.20 0.15 0.10 0.05 10-6 10-5 10-4 10-3 0.01 0.1 1 10 / 10 Version 1.5 | 2022-02-02 LA T676 Dimensional Drawing 9) 2.1 (0.083) 3.0 (0.118) 2.6 (0.102) 2.3 (0.091) 1.7 (0.067) 0.1 (0.004) (typ.) A 3.7 (0.146) 3.3 (0.130) 4˚±1 3.4 (0.134) 3.0 (0.118) (2.4) (0.095) 2.1 (0.083) 0.9 (0.035) 0.7 (0.028) Cathode marking 0.5 (0.020) 1.1 (0.043) C 0.18 (0.007) 0.12 (0.005) 0.6 (0.024) 0.4 (0.016) GPLY6724 Further Information: Approximate Weight: 34.0 mg Corrosion test: Class: 3B Test condition: 40°C / 90 % RH / 15 ppm H2S / 14 days (stricter than IEC 60068-2-43) 11 Version 1.5 | 2022-02-02 LA T676 Recommended Solder Pad 9) 4.5 (0.177) 2.6 (0.102) 1.5 (0.059) 1.5 (0.059) 4.5 (0.177) 2.6 (0.102) Padgeometrie für verbesserte Wärmeableitung Paddesign for improved heat dissipation Lötstopplack Solder resist Cu-Fläche > 16 mm 2 Cu-area > 16 mm 2 OHLPY970 For superior solder joint connectivity results we recommend soldering under standard nitrogen atmosphere. Package not suitable for ultra sonic cleaning. 12 Version 1.5 | 2022-02-02 LA T676 Reflow Soldering Profile Product complies to MSL Level 2 acc. to JEDEC J-STD-020E OHA04525 300 ˚C T 250 Tp 245 ˚C 240 ˚C tP 217 ˚C 200 tL 150 tS 100 50 25 ˚C 0 0 50 100 150 200 250 s 300 t Profile Feature Symbol Pb-Free (SnAgCu) Assembly Minimum Recommendation Maximum Ramp-up rate to preheat*) 25 °C to 150 °C tS Time tS TSmin to TSmax Ramp-up rate to peak*) TSmax to TP Liquidus temperature 60 2 3 100 120 2 3 Unit K/s s K/s TL 217 Time above liquidus temperature tL 80 100 s Peak temperature TP 245 260 °C Time within 5 °C of the specified peak temperature TP - 5 K tP 20 30 3 6 Ramp-down rate* TP to 100 °C 10 Time 25 °C to TP All temperatures refer to the center of the package, measured on the top of the component * slope calculation DT/Dt: Dt max. 5 s; fulfillment for the whole T-range 13 Version 1.5 | 2022-02-02 °C 480 s K/s s LA T676 Taping 9) 14 Version 1.5 | 2022-02-02 LA T676 Tape and Reel 10) Reel Dimensions A W Nmin W1 W2 max Pieces per PU 180 mm 8 + 0.3 / - 0.1 mm 60 mm 8.4 + 2 mm 14.4 mm 2000 330 mm 8 + 0.3 / - 0.1 mm 60 mm 8.4 + 2 mm 14.4 mm 8000 15 Version 1.5 | 2022-02-02 LA T676 Barcode-Product-Label (BPL) Dry Packing Process and Materials 9) Moisture-sensitive label or print L E E V l e be sela ). k, H de L If an bl r co ba (R id m ity . H R hu 0% e e /6 tiv ˚C la ared ag ck re fr 30 _ < in pa % k of to 90 rs ea s d ). rs ou or te (p on rs H de , ou iti H an bjec ng ou rs co ˚C 72 si nd H ou 5 te 48 ˚C su es e H co ± 24 6 da e y 40 be oc tim ˚C e or < ith tim ill pr). or ct w O w nt 23 tim e at lo or fa M TO F s al tim at le ˚C at lo at or e. P th F l tic th va lo or ur O F lo s ui on be if: read en w ed l 4 5 F m la ce eq id lo g, n oc l ve vi 5a is in or be 24 de pr ve l 6 Le de , nt whe e te co g: , w e Le ve l ke r ou se da ba ed flo ur e Le ve m % ba e ba al st ur e Le r en re ed e re> 10 oi st e e fo tim ur se al op fo M se oi st ur as k, is or . 33 se is M oi st bed k, lo H an , g ph -0 M oi in an in F R ng ar rbl D M e ba T r po If bl ith % lif ki r C. (if S is p. w ea r ks lf J10 ba to et th va Y ea m rs m _ r w, < he ed 1 ee te Y d, EC iredicat S fte at nt > 1 W Hou D A flody qu In no ire 1. d e ou 4 8 re reity is qu/JE re 2. bo e M tim to es id 2b re C 16 : e a) S tim is IP ic ed loor tim e b) ev Humor or e en F tim lo or D 2a king nc te F op a) lo or 3. b) ba re F lo da e fe l 1 2 F If al re tim ve l 4. se d l 2a ve Le 3 an ve l ag e Le e B ve ur e Le at st ur e Le D oi st ur e M oi st ur M oi st M oi M N E RS s in IV O IT T S C nta N U TIO U coSEND Ais bUagRMEICO T E CThIS S d Barcode label < M RA OS Humidity indicator Barcode label Please check the HIC immidiately after bag opening. Discard if circles overrun. Avoid metal contact. Do not eat. Comparator check dot WET If wet, examine units, if necessary bake units 15% If wet, examine units, if necessary bake units 10% 5% If wet, parts still adequately dry. change desiccant Humidity Indicator MIL-I-8835 Desiccant AM OSR OHA00539 Moisture-sensitive product is packed in a dry bag containing desiccant and a humidity card according JEDEC-STD-033. 16 Version 1.5 | 2022-02-02 LA T676 Type Designation System Wavelength (λdom typ.) A: 617 nm S: 633 nm T: 528 nm Y: 587 nm O: 606 nm G: 570 nm P: 560 nm R: 625 nm B: 470 nm H: 645 nm V: 505 nm L: Emission Color amber super red true green yellow orange green pure green red blue hyper-red verde green Color coordinates according CIE 1931/Emission color: W: white UW: ultra white C B: color on demand blue CG: color on demand green CL: color on demand lagune Package Type T: TOPLED Light emitting diode L A T 6 ´ Lead / Package Properties 6: folded leads 7: reverse gullwing leads T: folded leads, improved corrosion stability Au-LF), w/o TiO2 jetting V: folded leads and UX:3 w/ improved corrosion stability (Au-LF), TiO2 jetting Encapsulant Type / Lens Properties 7: Colorless clear or white volume conversion (resin encapsulation) S: Silicone (with or without diffuser) Chip Technology: 1: TSN 3: standard InGaN 4: AlGaAs 5: HOP 2000 6: Standard InGalP 9: TSN low current B: HOP 2000 C: ATON D: Small ThinGaN/ Thinfilm (e.g. 6mil) F: Thinfilm InGaAlP G: ThinGaN(Thinfilm InGaN) K: InGaAlP low current S: standard InGaN low current 0: TSN 17 Version 1.5 | 2022-02-02 7 6 LA T676 Notes The evaluation of eye safety occurs according to the standard IEC 62471:2006 (photo biological safety of lamps and lamp systems). Within the risk grouping system of this IEC standard, the device specified in this data sheet fall into the class exempt group (exposure time 10000 s). Under real circumstances (for exposure time, conditions of the eye pupils, observation distance), it is assumed that no endangerment to the eye exists from these devices. As a matter of principle, however, it should be mentioned that intense light sources have a high secondary exposure potential due to their blinding effect. When looking at bright light sources (e.g. headlights), temporary reduction in visual acuity and afterimages can occur, leading to irritation, annoyance, visual impairment, and even accidents, depending on the situation. Subcomponents of this device contain, in addition to other substances, metal filled materials including silver. Metal filled materials can be affected by environments that contain traces of aggressive substances. Therefore, we recommend that customers minimize device exposure to aggressive substances during storage, production, and use. Devices that showed visible discoloration when tested using the described tests above did show no performance deviations within failure limits during the stated test duration. Respective failure limits are described in the IEC60810. For further application related information please visit www.osram-os.com/appnotes 18 Version 1.5 | 2022-02-02 LA T676 Disclaimer Attention please! The information describes the type of component and shall not be considered as assured characteristics. Terms of delivery and rights to change design reserved. Due to technical requirements components may contain dangerous substances. For information on the types in question please contact our Sales Organization. If printed or downloaded, please find the latest version on the OSRAM OS website. Packing Please use the recycling operators known to you. We can also help you – get in touch with your nearest sales office. By agreement we will take packing material back, if it is sorted. You must bear the costs of transport. For packing material that is returned to us unsorted or which we are not obliged to accept, we shall have to invoice you for any costs incurred. Product and functional safety devices/applications or medical devices/applications OSRAM OS components are not developed, constructed or tested for the application as safety relevant component or for the application in medical devices. OSRAM OS products are not qualified at module and system level for such application. In case buyer – or customer supplied by buyer – considers using OSRAM OS components in product safety devices/applications or medical devices/applications, buyer and/or customer has to inform the local sales partner of OSRAM OS immediately and OSRAM OS and buyer and /or customer will analyze and coordinate the customer-specific request between OSRAM OS and buyer and/or customer. 19 Version 1.5 | 2022-02-02 LA T676 Glossary 1) Brightness: Brightness values are measured during a current pulse of typically 25 ms, with an internal reproducibility of ±8 % and an expanded uncertainty of ±11 % (acc. to GUM with a coverage factor of k = 3). 2) Reverse Operation: This product is intended to be operated applying a forward current within the specified range. Applying any continuous reverse bias or forward bias below the voltage range of light emission shall be avoided because it may cause migration which can change the electro-optical characteristics or damage the LED. 3) Wavelength: The wavelength is measured at a current pulse of typically 25 ms, with an internal reproducibility of ±0.5 nm and an expanded uncertainty of ±1 nm (acc. to GUM with a coverage factor of k = 3). 4) Forward Voltage: The forward voltage is measured during a current pulse of typically 8 ms, with an internal reproducibility of ±0.05 V and an expanded uncertainty of ±0.1 V (acc. to GUM with a coverage factor of k = 3). 5) Thermal Resistance: Rth max is based on statistic values (6σ). 6) Thermal Resistance: RthJA results from mounting on PC board FR 4 (pad size 16 mm² per pad) 7) Typical Values: Due to the special conditions of the manufacturing processes of semiconductor devices, the typical data or calculated correlations of technical parameters can only reflect statistical figures. These do not necessarily correspond to the actual parameters of each single product, which could differ from the typical data and calculated correlations or the typical characteristic line. If requested, e.g. because of technical improvements, these typ. data will be changed without any further notice. 8) Characteristic curve: In the range where the line of the graph is broken, you must expect higher differences between single devices within one packing unit. 9) Tolerance of Measure: Unless otherwise noted in drawing, tolerances are specified with ±0.1 and dimensions are specified in mm. 10) Tape and Reel: All dimensions and tolerances are specified acc. IEC 60286-3 and specified in mm. 20 Version 1.5 | 2022-02-02 LA T676 Revision History Version Date Change 1.4 2021-02-12 Features Schematic Transportation Box Dimensions of Transportation Box Notes Disclaimer Glossary 1.5 2022-02-02 Maximum Ratings Derating (Diagrams) Electro - Optical Characteristics (Diagrams) Characteristics 21 Version 1.5 | 2022-02-02 LA T676 Published by OSRAM Opto Semiconductors GmbH Leibnizstraße 4, D-93055 Regensburg www.osram-os.com © All Rights Reserved. 22 Version 1.5 | 2022-02-02