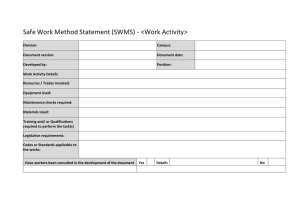

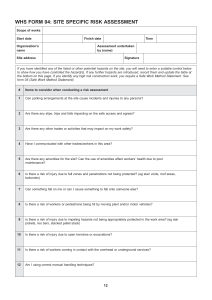

CPCCBC4002A: Assessment 4 Please type your answers in black font. (Calibri 12 point) STUDENT DETAILS Student Name: Fabiano Salas UNIT AND ASSESSMENT DETAILS Unit Number: 4002A TAFE ID: 880988486 Assessment No: 4 LA Number: 023622 DECLARATION X I hold a copy of this assessment X I have completed all parts of the assessment. X I hereby certify that no part of this assessment or product has been copiedfrom any other student’s work or from any other source except where due acknowledgement is made in the assessment. Student’s signature: Fabiano Salas FAB FORM PTY LTD ABN 93627500261 Address: 5 gertude St wolli creek, NSW, 2205 fabformconstructions@gmail.com 1- Introduction 2- WHS Policy 3- Roles and Responsibilities of site personnel 4- Hazard Identification and Risk Control 5- Safe Work Method Statement 6- Information, training, instruction and supervision 7-Consultation, co-operation and co-ordination 8- Incident Management 9- Site Safety Rules 10- Subcontractor Management 11- Health and Safety Site Inspections 1 Introduction The following WHS plan was prepared by Fab Form Construction group and applies to any construction work done under its name as the main contractor. At Fab Form Construction PTY LTD we ensure that all workers follow the right process and procedures to prevent accidents and with that guarantee all workers safety is our main goal. The document that follows, adopted by Fab Form, sets the strategy and procedures to ensure Work Health and Safety of all workers This includes but not exclusively to the program of the building of Strathfield Apartment block. 2 WHS policy At Fab Form Construction we believe that the well-being of people employed at work, or people affected by our work is a priority and must be taken under consideration during all work performed on our behalf. Work health and safety is everyone’s responsibility and people are our most important asset. The safety of the public has also equal priority to that of our workers. The main objectives of this policy are to: • achieve a 100% safe and incident free workplace • apply WHS in project planning and work activities • Include all employees and subcontractors in the decision-making process through regular communication and consultation within them • ensure all employees and subcontractors identify and control risks in the workplace • Eliminate potential risks by monitoring and reviewing them • Getting employees WHS knowledge better through a program of education and training. The success of this WHS management depends on: • • • All personnel commitment to achieve this policy objectives by planning their work activities taken consideration the WHS plan. Applying the risk management process in an effective manner Enhancing the communication and consultation between our workers and subcontractors. 3 Roles and Responsibilities of site personnel Site Manager: Gilmar Telles Duties: • • • • • • • Keep monitoring workers health and conditions at the workplace. Provide training, instruction, supervision and information necessary. Maintenance of a safe site and structures. Obtain up to date knowledge on WSH matter. Provide safe handling, storage and material use for all materials and substances used on site. Provide a safe space and system of work procedures. Provide adequate facilities as washrooms, toilets, lockers and dining areas. Site supervisor: Jack Daniels Duties: • Provide a safe work plan • Making sure OHS requirements are met according to legislative requirements. • Investigate hazard reports and ensure corrective actions are taken place • Supervising all work during the process of construction • Provide assistance taken consideration OHS procedures. • Supervising workers be sure that all work is conducted in a manner that is safe and with no risk to employees and personnel health and safety. • Ensuring that safe work is at practice all times. • Conduct all inductions, toolbox talks and briefings. • To participate on the planning and design of trade activities stages. • Caring workplace inspections and safety reports. • To participate on accident and incident investigations. • To lead by example according to safe practices Site Safety Officer: Bon Boniere • • • • • • • • • • • • To provide advice and assistance on OHS. Conduct accident/incident reports investigation. Conducting a high level of safety awareness to all employees. Participate in regular workplace inspections to ensure improvements resulting from prior inspections made. Reviewing inspections and safe reports Participate in Toolbox talks Managing rehabilitation for injured employees. Getting up to date information about safety performance to the site manager. Assisting and helping the site supervisor to develop and implement OHS. Participate in safety meetings and programs. Preparing and applying project safety inductions Monitoring and supervising compliance with safe work procedures. 4 Hazard Identification and Risk Control OHS Legislation requires any personnel in control of the workplace to identify the potential hazards of the related work, assess the risks involved and develop controls to eliminate or minimise the risk. Identification of Hazards: By inspecting the workplace, you can imagine what might go wrong just by regularly walking around the jobsite and observing how things are being done. Things to look out for includes but not only the following: • • • • • Is the work environment safe for workers to carry out work without risking their health and safety? (Lighting, ventilation, obstructions) Is there appropriate behaviours between workers, managers, supervisors and other personnel that interact? Is all work performed, including mental and physical work, in an appropriate manner? Are all the tools used on site checked and assured to be working in proper condition? Were any changes occurred recently that may affect health and safety? Eliminating hazards during the design phase is the best chance to avoid them at the first place. The effective design of a work task or system considers the task before it’s taken place, so the safe design of structures, equipment’s and vehicles accounts for all construction stages during the work. Consulting workers: You should always ask your workers about any health and safety problems they might have encountered during their work and any ''near misses'' or incidents that have not been reported. Workers questioning and surveys may also be undertaken to obtain information about such matters as workplace bullying, as well as chronic muscular pains that can signal potential hazards Risk Assessment: A Risk Class is determined for each potential workplace hazard by referring to the categories below. The following Risk Management chart can be used to determine the procedure taken to manage the risk identified. HIGH RISK – Class 1: For hazards that have the potential to kill or permanently disable a person. MEDIUM RISK - Class 2: For the hazards that have the potential to cause a serious Injury or illness that can temporarily disable a person. LOW RISK – Class 3: For hazards that have the potential to cause minor injuries. • • • After identified, all risks class 1 and 2 will be recorded in detail on the Safe Work Method Statement. All class 3 risks will be checked and resolved but will not be recorded on the SWMS. The above risk class will be used to determine the control required to minimize or eliminate the risk. The higher the class the more controls are required to be provided. Risk Control: WHS regulation require specific control measures to be implemented in certain circumstances. As an example, the risk of trenching collapse of 1.5 or above in depth must be controlled with battering or shoring. Where a specific control is prescribed, it must be implemented before work proceeds. Hierarchy of control measures: Some control measures can be more efficient than others. They are ranked from the highest level of protection to the lowest. This is known as hierarchy of control, the higher order controls are always considered first. Risk Elimination: To completely remove the hazard from the workplace. This is definitely the most effective control measure and must always be considered first. As an example, the risk of falling from working at heights can be eliminated by doing the work at ground level. Is the risk cannot be eliminated within reasonably practicable, substitution, isolation or engineering controls must be considered, or a combination of those. Risks can be minimised by using one of the following control measures: Substitution: Minimise by replacing or substituting a hazard or hazardous work practice for a less hazardous one. E.g.: • Substituting an ordinary brick cutting saw blade with a noise reduced blade can minimise exposure to noise. • Using a step latter instead of stepping on a milk crate. • Using water-based paint instead of a solvent-based paint • Isolating a mobile work zone area from public with physical barriers to minimize the risk. Engineering controls: Using physical control measures to minimise risk as: • • Using a hoist to crane materials can minimize risk of workers musculoskeletal injuries by caring their tools from one level to another. Shoring sides of excavations to minimize risk of collapsing and getting a person trapped. Administrative controls: • • • Implementing training programs to instruct workers how to use new equipment. Making a schedule to complete tasks outside peak UV radiation levels to reduce exposure. Implementing job rotation system. Using Protective equipment: The usage of PPE (Personal Protective Equipment) has the lowest order in the control hierarchy, although PPE should also be considered as a practice to increase protection and therefore reduce hazards. It is valuable to remind that the usage of PPE does not change the nature of the hazard itself but increases protection in case other methods fail. Examples of PPE are: • Safety cap boots. • Hi-vis clothing • Hard-hats • Earplugs or earmuffs • Sunglasses Example of PPE form: 5- Safe Work Method Statement SWMS involves identifying hazards and assessing their risk in order to eliminate or minimize their occurrence. Where potential Class 1 or 2 risks are identified, Safe Work Method Statement will be filled and completed using a template given next. After filling out and submitting the template, steps and control measures will be taken to eliminate or minimize the risk. Prior to commencement of work on site, the Safe Work Method Statement submitted will be reviewed. The Form provides record to demonstrate fulfilment and compliance to OHSL. The person who is responsible for implementing the particular control and cation in order to eliminate or minimise the risk of the hazard is nominated above, which ensures responsibility on compliance and resolution that can be followed up. The Safe Work Method Statement will provide an ongoing evaluation on how well both Class 1 and 2 hazards are correctly being identified for the proposed activity to be undertaken and whether the controls used for it eliminated the potential hazard or minimized the risk of injury. A few examples of controls and how they can be applied are: Removing the Hazard: Enclosing machinery that is too noisy Using Engineered control: Use machinery to do heavy lifting Change practices: Train personnel do lift objects properly Providing PPE: Hearing protectors PROCEDURE OF SWMS: The following Safe Work Method Statement must be completed and signed by appointed qualified personnel representing Fab Form Construction who is fully competent in the work or activity to be undertaken. After, the statement will be reviewed and again signed by the contractor representative of the current project. All employees will have access to the statement which will be used and reviewed during toolbox meetings and signed off at the end to induce implementation of the desired controls to carry out the work safely. Work will not commence until the above have been done. 6- Information, training, instruction and supervision Providing knowledge like general construction induction training and other specific areas training can assist in ensuring people gain the necessary knowledge and skills to perform safe work. Information like the identification of nature of work to be carried out and the risks associated with the task as well as the health and safety guides and procedures are extremely important for a safe work environment. This information must be clear and easy to understand to any personnel to whom it may be important, being that in a verbal and/or written form. Supervisors will often provide such information during instruction, induction or toolbox talks. They are also responsible to provide workers with supervision to ensure that all work is being carried with a great level of safety and that their competency match their task. ANY tradesperson, including labourers, supervisors, engineers and so on, are required to achieve competency on a General Construction Induction Training (commonly known as white card). This induction training provides minimum knowledge of construction work and health and safety laws. All personnel must successfully complete this training, which is only carried out in Australia by a registered training organisation which follows the specifics points that need to be part of such program. After completion the person who has successfully graduated from the course must present the card received as a proof of completion during the site induction of any workplaces before commencement of work. Site Induction training: A training to provide information specifically about the workplace • Site safety • First Aid location services and materials • Amenities • Evacuation Procedures • Security measures • Hazards and their Controls Site Induction form: Specialized training: All induction and training necessary for a specific task that require a more specialized activity and/or personnel • • • Training for confined spaces Training for certain specific equipment or tool Training for working with heights 7- Consultation, co-operation and co-ordination Consultation: The involvement of workers in an essential to be able to identify hazards and therefore have the ability to eliminate or minimize them before accidents occur. With toolbox meetings where all participants sign off on the development of controls to do so we are able to meet this goal. These meetings will be used to help managers and supervisors to manage safety and to provide a space where workers can have their opinion about the matter, creating better safety awareness and maintaining safety throughout the project. The procedures and controls used in the SWMS will be seen, discussed and signed off by participants to confirm their understanding about the matter. Example of Toolbox meeting record. The cooperation between different professionals also must be carried out. An architect for example must carry out his calculations and planning altogether with the professionals on the field to make sure that the safety of the design is achievable, although it is also required to constantly check with other workers about their methods of building such a project in case of not knowing the procedure and process of achieving the design. By getting feedbacks from the builder and formworkers/concreters this can be achieved. 8 Incident Management: In the occurrence of and Incident, the following procedure should be followed: In required, contact emergency services immediately (dial 000) Ensure that the place of incident is closed off and no other personal can access it. If safe to do so, provide first aid to personal affected (first aid ticket holders only) Make notes and acquire all incident information (names, location, time and description of occurrence). 9 Site safety rules: Absolutely no aggressive behaviour or bulling is accepted. All tools and electrical equipment must be properly tagged and tested by a professional. No domestic leads of power supply are allowed. No alcohol or illegal drugs on the jobsite and no one under the influence is allowed to work. Workers will be tested periodically. Work areas must be clean and tidy during all process of construction. All incident, injuries and near misses must be reported immediately to supervisor. All PPE must be worn at all times during work according to manufactures instructions. No children or pets allowed in the workplace No person should enter the site without passing through site office and obtaining a visitor pass. All personal performing and activities that requires a license should provide such to site office where a copy will be kept (e.g. excavators, scaffolders, etc) All workers and visitor should sign in and out every day at the site office. 10 Subcontractor management: Fab Form construction ensures that all subcontractors under its controls have the same attitude towards Health and Safety while performing their duties. All subcontractors will also participate on toolbox meetings and have their say on safety matters. They are also required proper training and equipment to be use in our premisses. Sub-contractors should provide their own equipment and PPE and it must follow within guidelines of OHS laws. They must also appoint a responsible person to represent their interest and to guide their work during the construction period. All subcontractors must fill the register (sign in sheet) and the SWMS documentation provided. 11 Health and Safety Site Inspections: Site Inspections will be carried out regularly as it gives everyone the opportunity to identify hazards and assess their risk in accordance with OHS laws These inspections are aimed to better everyone’s safety and compliance in order to make improvements to the quality of work environment and to get everyone safe at home every day. The inspection program includes: Inspection of tools and equipment’s before their use and regularly after that. Daily supervisor walks throughout the site to check conditions and PPE usage. Checking of machinery and its usage. Checks with personal about their mental health Checking of material handling These checks are meant to fix unsafe work practices immediately and to keep hazards to a minimum and a follow up procedure will be taken place after the initial assessment. This includes recording all action taken and letting all personal informed about it. WORK SAFE!