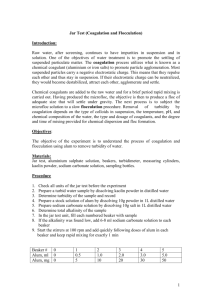

A Look at the Basics Coagulation and flocculation are fundamental to drinking water treatment. Here’s a look at the chemical and physical processes at work. A small community water system asked the staff at Florida Gateway College how to remove color and organic materials from the surface water system that was the drinking water supply. College personnel explained that after the source water is screened and passed through the optional steps of prechlorination and aeration, it is ready for coagulation and flocculation. In theory and at the chemical level, coagulation/flocculation is a three-step process, consisting of flash mixing, coagulation and flocculation. However, in practice in the treatment plant, there are only two steps: The water first flows into the flash mixing chamber and then enters the flocculation basin. Taking out turbidity The primary purpose of the coagulation/flocculation process is to remove turbidity, the cloudiness caused by small suspended particles. Coagulation and flocculation describe the charge neutralization and aggregation of colloidal particles in raw water. Coagulation reduces turbidity, color, organic substances, phosphorous and trace metal precipitates, such as iron, manganese and chromium. Turbidity is more than an aesthetic problem in water. Water with a high turbidity can be difficult or impossible to disinfect properly. As a result, the maximum allowable level of turbidity in water is 0.5 NTU, while the recommended level is about 0.1 NTU. Coagulation and flocculation have benefits beyond removing turbidity. The process also removes suspended bacteria and can be used to remove color and heavy metals from raw water. Turbidity and color are much more common in surface water than in groundwater. When surface water flows over the ground to streams and rivers, the water picks up large quantities of particles. As a result, while aeration is more commonly required for groundwater, treatment involving coagulation and flocculation is typical for surface water. Subscribe: If you don't want to bring your iPad into the bathroom, we can send you a magazine subscription for free! Three steps The chemistry of coagulation and flocculation consists of three processes. In the flash mixer, coagulant chemicals are added, and the water is mixed quickly and violently to distribute the chemicals evenly. Flash mixing typically lasts a minute or less. If the water is mixed for less than 30 seconds, the chemicals will not properly mix into the water. On the other hand, if mixing lasts more than 60 seconds, the mixer blades will shear the newly forming floc into small particles. After flash mixing, coagulation occurs. During coagulation, the coagulant chemicals neutralize the electrical charges of the fine particles in the water, allowing the particles to come closer together and form large clumps. The final step is flocculation, in which gentle mixing brings the fine particles formed by coagulation into contact with each other. Flocculation typically lasts 30 to 45 minutes. The flocculation basin often has a number of compartments with decreasing mixing speeds as the water advances through the basin. This compartmentalization allows increasingly larger floc to form without being broken apart by the mixing blades. Testing for dosage The product of a well-regulated coagulation and flocculation process is water in which the majority of turbidity has collected into floc: clumps of bacteria and particulate impurities that have formed clusters. The floc settles out in the sedimentation basin, and remaining floc is removed in the filter. The best floc size is 0.1 to 3 mm. Larger floc does not settle as well and is more subject to breakup in the flocculation basin. Smaller floc may not settle. We explained to the community staff that jar tests are used to determine dosage requirements for chemicals added to remove particulates. Coagulation is always considered along with flocculation; the process removes particles that cannot be removed by sedimentation or filtration alone. These particles, usually less than 1 μm in diameter, are called colloids. They have poor settling characteristics and are responsible for the color and turbidity of the water. Related: Product Spotlights - Wastewater: November 2021 Colloids include clays, metal oxides, proteins, microorganisms and organic substances from peaty catchment areas that give the brown color to water. The important property they all share is a negative charge which, along with the interaction between the colloidal particles and the water, prevents the particles from aggregating and settling in still water. The particles can be aggregated by adding either multivalent ions or colloids with an opposite (positive) charge. The positive charges are added as chemical coagulants. Adding coagulants Chemicals commonly used as coagulants are aluminum and ferric salts, in the form of Al3+ and Fe3+ ions. These positively charged multivalent ions neutralize the negatively charged particles, allowing the particles to aggregate. At high concentrations of aluminum or ferric salts, and in the presence of sufficient alkalinity, insoluble hydroxides of aluminum or iron are formed. In the precipitation reaction, the colloidal particles are enmeshed within the precipitate and removed. Most facilities use ferric salts. There must be about 50 mg/L of alkalinity in the water for coagulation and flocculation to be effective. If alkalinity is inadequate, it can be added as lime, calcium hydroxide or soda ash. n some waters, even with the optimum coagulant dose, coagulation is poor, and extra substances known as coagulant aids must be added. These include clay, silica and polyelectrolytes, which are long-chain organic molecules with chemical groups attached along the length of the chain. These become charged when the molecule is dissolved in water. The negative colloidal particles are attracted to positively charged polymer groups on the polyelectrolyte and settle.