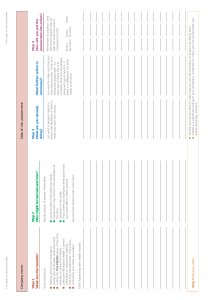

Introduction to Health and Safety in Construction. The handbook for construction professionals and students on NEBOSH and other construction courses ( PDFDrive )

advertisement