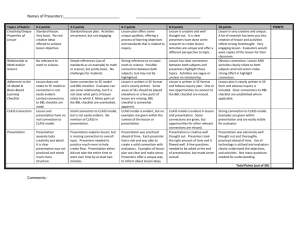

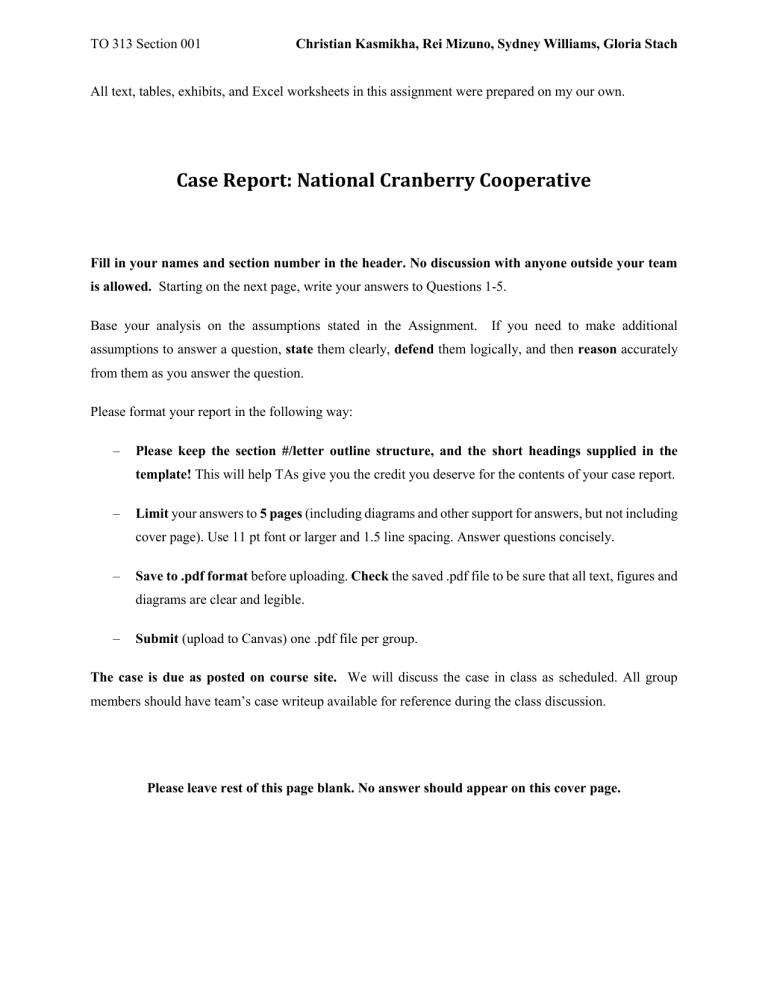

TO 313 Section 001 Christian Kasmikha, Rei Mizuno, Sydney Williams, Gloria Stach All text, tables, exhibits, and Excel worksheets in this assignment were prepared on my our own. Case Report: National Cranberry Cooperative Fill in your names and section number in the header. No discussion with anyone outside your team is allowed. Starting on the next page, write your answers to Questions 1-5. Base your analysis on the assumptions stated in the Assignment. If you need to make additional assumptions to answer a question, state them clearly, defend them logically, and then reason accurately from them as you answer the question. Please format your report in the following way: – Please keep the section #/letter outline structure, and the short headings supplied in the template! This will help TAs give you the credit you deserve for the contents of your case report. – Limit your answers to 5 pages (including diagrams and other support for answers, but not including cover page). Use 11 pt font or larger and 1.5 line spacing. Answer questions concisely. – Save to .pdf format before uploading. Check the saved .pdf file to be sure that all text, figures and diagrams are clear and legible. – Submit (upload to Canvas) one .pdf file per group. The case is due as posted on course site. We will discuss the case in class as scheduled. All group members should have team’s case writeup available for reference during the class discussion. Please leave rest of this page blank. No answer should appear on this cover page. TO 313 Section 001 Christian Kasmikha, Rei Mizuno, Sydney Williams, Gloria Stach All text, tables, exhibits, and Excel worksheets in this assignment were prepared on my (our) own. Question 1: (10 points) Analyze NCC’s Process: Capacity and implied utilization A. Labelled diagram. (use & edit diagram supplied below) B. Calculation detail. a. Dumpers i. Capacity= 3,000 bbl/hr (given in briefing) ii. Implied utilization= demand/capacity 1. Demand= 17,280/12= 1440 iii. 1440/3000= 48% b. Bins max contents i. Dry 1. Bins 1-16, each holds 250 250*16 = 4,000 bbl ii. Wet 1. Bins 17-27, 17-24 hold 250, 25-27 hold 500 = 8*250 + 3*400 = 3,200 bbl c. Destoning (dry only) i. Capacity 1. 1,500 per destoning unit (3 units). 1,500 * 3 = 4,500 bbl/hr ii. Implied utilization 1. Demand / capacity = 25% * 1,440 = 360/ 4,500 = 8% d. Dechaffing i. Dry 1. Capacity= 1,500 per unit, 1 unit 1,500 bbl/hr 2. Utilization= 360/1500= 24% ii. Wet 1. Capacity= 1,500 per dechaffing unit, 2 units 3000 bbl/hr 2. Utilization= 1080/3000 = 36% e. Drying (wet only) i. Capacity= 200 bbl/hr per unit, 3 units = 600 bbl/hr ii. Utilization = 1,080/600 = 180% f. Separating i. Capacity 1. Used average capacity of 400 bbl/hr per line, 3 lines = 1200 bbl/hr ii. Utilization 1. 1440/1200= 120% C. Maximum hourly throughput rate, & limiting resource area a. Maximum hourly throughput rate= bottleneck of wet process + bottleneck of dry= 600 + 360 = 960 bbl/hr b. Limiting resource= drying, highest implied utilization, lowest capacity Question 2 (15 points) Analyze expensive issues NCC faces in financial terms using operations tools. 1 TO 313 Section 001 Christian Kasmikha, Rei Mizuno, Sydney Williams, Gloria Stach All text, tables, exhibits, and Excel worksheets in this assignment were prepared on my (our) own. A. inventory buildup diagram o B. total truck waiting time in truck-hours. o Truck waiting time = (16.266-6.666) 9.6 hours C. costs of overtime operations o assuming seasonal workers, paid $8 per hour + 1.5x for overtime = $12/hr o case states that 8-9 workers usually work overtime, assume 8.5 workers o $12/hr * 8.5 workers on average * 5.6 hours $571.20 overtime operations cost per day 105 days $59,976 per season 2 TO 313 Section 001 Christian Kasmikha, Rei Mizuno, Sydney Williams, Gloria Stach All text, tables, exhibits, and Excel worksheets in this assignment were prepared on my (our) own. Question 3: (10 points) Analyze Capital Investment Decisions: Dryer and Dumper A. Fifth Kiwanee dumper a. 600 bbl/hr capacity per dumper b. Additional dumper costs $200,000 c. 600*4 = total dumping capacity of 2400 bbl/hr with 4 dumpers, compared to 3000 with 5 dumpers B. One new dryer C. Two new dryers D. Recommend best number of dryers to add and justify briefly. Question 4: (10 points) Analyze Capital Investment Decisions: Bin Conversions A. B. C. D. How many bins costs and benefits Recommend what would you choose? Question 5: (5 points) Analyze Capital Investment Decisions: Light Meter A. assumptions B. costs and benefits C. Should NCC buy? 3 TO 313 Section 001 Christian Kasmikha, Rei Mizuno, Sydney Williams, Gloria Stach All text, tables, exhibits, and Excel worksheets in this assignment were prepared on my (our) own. Trucks in Queue Dry berries bbl/hr C = 3,000 bbl/hr Wet berries bbl/hr Kiwanee Dumpers U = 48% Bins 1-16 storage = 4000 bbl Bins 17-27 storage = 3,200 bbl Destoners C = 4,500 bbl/hr U = 32% Dechaffers C = 1500bbl/hr U = 24% Dechaffers C = 3,000bbl/hr U= 36% Dryers C = 600 bbl/hr U = 180% C = 1200 bbl/hr Separators U = 120% Bulk and Bag 4