Solutions to Case Problems Manual to Accompany

An Introduction To

Management Science

Quantitative Approaches

To Decision Making

Twelfth Edition

David R. Anderson

University of Cincinnati

Dennis J. Sweeney

University of Cincinnati

Thomas A. Williams

Rochester Institute of Technology

R. Kipp Martin

University of Chicago

South-Western

Cincinnati, Ohio

Contents

Preface

Chapter 1: Introduction

♦ Scheduling a Golf League

Chapter 9: Project Scheduling: PERT/CPM

♦ R.C. Coleman

Chapter 2: An Introduction to Linear Programming

♦ Workload Balancing

♦ Production Strategy

♦ Hart Venture Capital

Chapter 10: Inventory Models

♦ Wagner Fabricating Company

♦ River City Fire Department

Chapter 3: Linear Programming: Sensitivity Analysis

and Interpretation of Solution

♦ Product Mix

♦ Investment Strategy

♦ Truck Leasing Strategy

Chapter 4: Linear Programming Applications in

Marketing, Finance and Operations Management

♦ Planning an Advertising Campaign

♦ Phoenix Computer

♦ Textile Mill Scheduling

♦ Workforce Scheduling

♦ Duke Energy Coal Allocation

Chapter 6: Distribution and Network Models

♦ Solution Plus

♦ Distribution Systems Design

Chapter 11: Waiting Line Models

♦ Regional Airlines

♦ Office Equipment, Inc.

Chapter 12: Simulation

♦ Tri-State Corporation

♦ Harbor Dunes Golf Course

♦ County Beverage Drive-Thru

Chapter 13: Decision Analysis

♦ Property Purchase Strategy

♦ Lawsuit Defense Strategy

Chapter 14: Multicriteria Decision Problems

♦ EZ Trailers, Inc.

Chapter 15: Forecasting

♦ Forecasting Sales

♦ Forecasting Lost Sales

Chapter 7: Integer Linear Programming

♦ Textbook Publishing

♦ Yeager National Bank

♦ Production Scheduling with Changeover Costs

Chapter 16: Markov Processes

♦ Dealer’s Absorbing State Probabilities in

Black Jack

Chapter 8: Nonlinear Optimization Models

♦ Portfolio Optimization with Transaction Costs

Chapter 21: Dynamic Programming

♦ Process Design

Preface

The purpose of An Introduction to Management Science is to provide students with a sound

conceptual understanding of the role management science pays in the decision-making process.

The text emphasizes the application of management science by using problem situations to

introduce each of the management science concepts and techniques. The book has been

specifically designed to meet the needs of nonmathematicians who are studying business and

economics.

The Solutions to Case Problems Manual contains solutions to the case problems.

Note: The solutions to the end-of-chapter problems and learning objectives for each chapter are

included in the Solutions Manual.

Acknowledgements

We would like to provide a special acknowledgement to Catherine J. Williams for her efforts in

preparing the Instructor's Manual. We are also indebted to our acquisitions editor Charles E.

McCormick, Jr. and our developmental editor Alice C. Denny for their support during the

preparation of this manual.

David R. Anderson

Dennis J. Sweeney

Thomas A. Williams

R. Kipp Martin

Chapter 1

Introduction

Case Problem: Scheduling a Golf League

Note to Instructor: This case problem illustrates the value of the rational management science approach.

The problem is easy to understand and, at first glance, appears simple. But, most students will have trouble

finding a solution. The solution procedure suggested involves decomposing a larger problem into a series

of smaller problems that are easier to solve. The case provides students with a good first look at the kinds

of problems where management science is applied in practice. The problem is a real one that one of the

authors was asked by the Head Professional at Royal Oak Country Club for help with.

Solution: Scheduling problems such as this occur frequently, and are often difficult to solve. The typical

approach is to use trial and error. An alternative approach involves breaking the larger problem into a

series of smaller problems. We show how this can be done here using what we call the Red, White, and

Blue algorithm.

Suppose we break the 18 couples up into 3 divisions, referred to as the Red, White, and Blue divisions.

The six couples in the Red division can then be identified as R1, R2, R3, R4, R5, R6; the six couples in the

White division can be identified as W1, W2,…, W6; and the six couples in the Blue division can be

identified as B1, B2,…, B6. We begin by developing a schedule for the first 5 weeks of the season so that

each couple plays every other couple in its own division. This can be done fairly easily by trial and error.

Shown below is the first 5-week schedule for the Red division.

Week 1

R1 vs. R2

R3 vs. R4

R5 vs. R6

Week 2

R1 vs. R3

R2 vs. R5

R4 vs. R6

Week 3

R1 vs. R4

R2 vs. R6

R3 vs. R5

Week 4

R1 vs. R5

R2 vs. R4

R3 vs. R6

Week 5

R1 vs. R6

R2 vs. R3

R4 vs. R5

Similar 5-week schedules can be developed for the White and Blue divisions by replacing the R in the

above table with a W or a B.

To develop the schedule for the next 3 weeks, we create 3 new six-couple divisions by pairing 3 of the

teams in each division with 3 of the teams in another division; for example, (R1, R2, R3, W1, W2, W3),

(B1, B2, B3, R4, R5, R6), and (W4, W5, W6, B4, B5, B6). Within each of these new divisions, matches

can be scheduled for 3 weeks without any couples playing a couple they have played before. For instance,

a 3-week schedule for the first of these divisions is shown below:

Week 6

R1 vs. W1

R2 vs. W2

R3 vs. W3

Week 7

R1 vs. W2

R2 vs. W3

R3 vs. W1

Week 8

R1 vs. W3

R2 vs. W1

R3 vs. W2

A similar 3-week schedule can be easily set up for the other two new divisions. This will provide us with a

schedule for the first 8 weeks of the season.

For the final 9 weeks, we continue to create new divisions by pairing 3 teams from the original Red, White

and Blue divisions with 3 teams from the other divisions that they have not yet been paired with. Then a 3week schedule is developed as above. Shown below is a set of divisions for the next 9 weeks.

CP - 1

Chapter 1

Weeks 9-11

(R1, R2, R3, W4, W5, W6)

(W1, W2, W3, B1, B2, B3)

(R4, R5, R6, B4, B5, B6)

(W1, W2, W3, B4, B5, B6)

(W4, W5, W6, R4, R5, R6)

(W1, W2, W3, R4, R5, R6)

(W4, W5, W6, B1, B2, B3)

Weeks 12-14

(R1, R2, R3, B1, B2, B3)

Weeks 15-17

(R1, R2, R3, B4, B5, B6)

This Red, White and Blue scheduling procedure provides a schedule with every couple playing every other

couple over the 17-week season. If one of the couples should cancel, the schedule can be modified easily.

Designate the couple that cancels, say R4, as the Bye couple. Then whichever couple is scheduled to play

couple R4 will receive a Bye in that week. With only 17 couples a Bye must be scheduled for one team

each week.

This same scheduling procedure can obviously be used for scheduling sports teams and or any other kinds

of matches involving 17 or 18 teams. Modifications of the Red, White and Blue algorithm can be

employed for 15 or 16 team leagues and other numbers of teams.

CP - 2

Chapter 2

An Introduction to Linear Programming

Case Problem 1: Workload Balancing

1.

Model

DI-910

DI-950

Production Rate

(minutes per printer)

Line 1

Line 2

3

4

6

2

Profit Contribution ($)

42

87

Capacity: 8 hours × 60 minutes/hour = 480 minutes per day

D1 = number of units of the DI-910 produced

D2 = number of units of the DI-950 produced

Let

Max

s.t.

42D1

+ 87D2

3D1 + 6D2

4D1 + 2D2

D 1, D 2 ≥ 0

≤ 480

≤ 480

Line 1 Capacity

Line 2 Capacity

Using The Management Scientist, the optimal solution is D1 = 0, D2 = 80. The value of the optimal

solution is $6960.

Management would not implement this solution because no units of the DI-910 would be produced.

2.

Adding the constraint D1 ≥ D2 and resolving the linear program results in the optimal solution D1 =

53.333, D2 = 53.333. The value of the optimal solution is $6880.

3.

Time spent on Line 1: 3(53.333) + 6(53.333) = 480 minutes

Time spent on Line 2: 4(53.333) + 2(53.333) = 320 minutes

Thus, the solution does not balance the total time spent on Line 1 and the total time spent on Line 2.

This might be a concern to management if no other work assignments were available for the

employees on Line 2.

4.

Let

T1 = total time spent on Line 1

T2 = total time spent on Line 2

Whatever the value of T2 is,

T1 ≤ T2 + 30

T1 ≥ T2 - 30

Thus, with T1 = 3D1 + 6D2 and T2 = 4D1 + 2D2

3D1 + 6D2 ≤ 4D1 + 2D2 + 30

3D1 + 6D2 ≥ 4D1 + 2D2 − 30

CP - 3

Chapter 2

Hence,

−1D1 + 4D2 ≤ 30

−1D1 + 4D2 ≥ −30

Rewriting the second constraint by multiplying both sides by -1, we obtain

−1D1 + 4D2 ≤ 30

1D1 − 4D2 ≤ 30

Adding these two constraints to the linear program formulated in part (2) and resolving using The

Management Scientist, we obtain the optimal solution D1 = 96.667, D2 = 31.667. The value of the

optimal solution is $6815. Line 1 is scheduled for 480 minutes and Line 2 for 450 minutes. The

effect of workload balancing is to reduce the total contribution to profit by $6880 - $6815 = $65 per

shift.

5.

The optimal solution is D1 = 106.667, D2 = 26.667. The total profit contribution is

42(106.667) + 87(26.667) = $6800

Comparing the solutions to part (4) and part (5), maximizing the number of printers produced

(106.667 + 26.667 = 133.33) has increased the production by 133.33 - (96.667 + 31.667) = 5 printers

but has reduced profit contribution by $6815 - $6800 = $15. But, this solution results in perfect

workload balancing because the total time spent on each line is 480 minutes.

Case Problem 2: Production Strategy

1.

Let

Max

s.t.

BP100 = the number of BodyPlus 100 machines produced

BP200 = the number of BodyPlus 200 machines produced

371BP100 +

8BP100

5BP100

2BP100

-0.25BP100

+

+

+

+

461BP200

12BP200

10BP200

2BP200

0.75BP200

≤

≤

≤

≥

600

450

140

0

BP100, BP200 ≥ 0

CP - 4

Machining and Welding

Painting and Finishing

Assembly, Test, and Packaging

BodyPlus 200 Requirement

Solutions to Case Problems

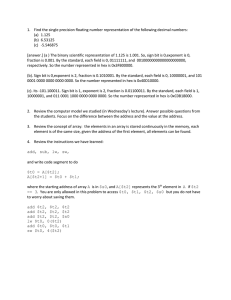

BP200

80

Number of BodyPlus 200

.

70

Assembly, Test, and Packaging

60

50

Machining and Welding

40

BodyPlus 200 Requirement

30

20

10

Painting and Finishing

BP100

30 40 50 60 70 80 90 100

Number of BodyPlus 100

Optimal Solution

0

10

20

Optimal solution: BP100 = 50, BP200 = 50/3, profit = $26,233.33. Note: If the optimal

solution is rounded to BP100 = 50, BP200 = 16.67, the value of the optimal solution will differ

from the value shown. The value we show for the optimal solution is the same as the value that

will be obtained if the problem is solved using a linear programming software package such as

The Management Scientist.

2.

In the short run the requirement reduces profits. For instance, if the requirement were reduced

to at least 24% of total production, the new optimal solution is BP100 = 1425/28, BP200 =

225/14, with a total profit of $26,290.18; thus, total profits would increase by $56.85. Note: If

the optimal solution is rounded to BP100 = 50.89, BP200 = 16.07, the value of the optimal

solution will differ from the value shown. The value we show for the optimal solution is the

same as the value that will be obtained if the problem is solved using a linear programming

software package such as The Management Scientist.

3.

If management really believes that the BodyPlus 200 can help position BFI as one of the

leader's in high-end exercise equipment, the constraint requiring that the number of units of the

BodyPlus 200 produced be at least 25% of total production should not be changed. Since the

optimal solution uses all of the available machining and welding time, management should try

to obtain additional hours of this resource.

CP - 5

Chapter 2

Case Problem 3: Hart Venture Capital

1.

Let S = fraction of the Security Systems project funded by HVC

M = fraction of the Market Analysis project funded by HVC

Max

s.t.

1,800,000S

+

1,600,000M

600,000S

600,000S

250,000S

S

+

+

+

500,000M

350,000M

400,000M

S,M

≥

M

0

≤

≤

≤

≤

≤

800,000

700,000

500,000

1

1

Year 1

Year 2

Year 3

Maximum for S

Maximum for M

The solution obtained using The Management Scientist software package is shown below:

OPTIMAL SOLUTION

Objective Function Value =

2486956.522

Variable

-------------S

M

Value

--------------0.609

0.870

Reduced Costs

-----------------0.000

0.000

Constraint

-------------1

2

3

4

5

Slack/Surplus

--------------0.000

30434.783

0.000

0.391

0.130

Dual Prices

-----------------2.783

0.000

0.522

0.000

0.000

OBJECTIVE COEFFICIENT RANGES

Variable

-----------S

M

Lower Limit

--------------No Lower Limit

No Lower Limit

Current Value

--------------1800000.000

1600000.000

Upper Limit

--------------No Upper Limit

No Upper Limit

Current Value

--------------800000.000

700000.000

500000.000

1.000

1.000

Upper Limit

--------------822950.820

No Upper Limit

No Upper Limit

No Upper Limit

No Upper Limit

RIGHT HAND SIDE RANGES

Constraint

-----------1

2

3

4

5

Lower Limit

--------------No Lower Limit

669565.217

461111.111

0.609

0.870

CP - 6

Solutions to Case Problems

Thus, the optimal solution is S = 0.609 and M = 0.870. In other words, approximately 61% of the

Security Systems project should be funded by HVC and 87% of the Market Analysis project should

be funded by HVC.

The net present value of the investment is approximately $2,486,957.

2.

Security Systems

Market Analysis

Total

Year 1

$365,400

$435,000

$800,400

Year 2

$365,400

$304,500

$669,900

Year 3

$152,250

$348,000

$500,250

Note: The totals for Year 1 and Year 3 are greater than the amounts available. The reason for this is

that rounded values for the decision variables were used to compute the amount required in each

year. To see why this situation occurs here, first note that each of the problem coefficients is an

integer value. Thus, by default, when The Management Scientist prints the optimal solution, values

of the decision variables are rounded and printed with three decimal places. To increase the number

of decimal places shown in the output, one or more of the problem coefficients can be entered with

additional digits to the right of the decimal point. For instance, if we enter the coefficient of 1 for S

in constraint 4 as 1.000000 and resolve the problem, the new optimal values for S and D will be

rounded and printed with six decimal places. If we use the new values in the computation of the

amount required in each year, the differences observed for year 1 and year 3 will be much smaller

than we obtained using the values of S = 0.609 and M = 0.870.

3.

If up to $900,000 is available in year 1 we obtain a new optimal solution with S = 0.689 and M =

0.820. In other words, approximately 69% of the Security Systems project should be funded by HVC

and 82% of the Market Analysis project should be funded by HVC.

The net present value of the investment is approximately $2,550,820.

The solution obtained using The Management Scientist software package follows:

OPTIMAL SOLUTION

Objective Function Value =

Variable

-------------S

M

Constraint

-------------1

2

3

4

5

2550819.672

Value

--------------0.689

0.820

Slack/Surplus

--------------77049.180

0.000

0.000

0.311

0.180

Reduced Costs

-----------------0.000

0.000

Dual Prices

-----------------0.000

2.098

2.164

0.000

0.000

OBJECTIVE COEFFICIENT RANGES

Variable

-----------S

M

Lower Limit

--------------No Lower Limit

No Lower Limit

Current Value

--------------1800000.000

1600000.000

CP - 7

Upper Limit

--------------No Upper Limit

No Upper Limit

Chapter 2

RIGHT HAND SIDE RANGES

Constraint

-----------1

2

3

4

5

4.

Lower Limit

--------------822950.820

No Lower Limit

No Lower Limit

0.689

0.820

Upper Limit

--------------No Upper Limit

802173.913

630555.556

No Upper Limit

No Upper Limit

If an additional $100,000 is made available, the allocation plan would change as follows:

Security Systems

Market Analysis

Total

5.

Current Value

--------------900000.000

700000.000

500000.000

1.000

1.000

Year 1

$413,400

$410,000

$823,400

Year 2

$413,400

$287,000

$700,400

Year 3

$172,250

$328,000

$500,250

Having additional funds available in year 1 will increase the total net present value. The value of the

objective function increases from $2,486,957 to $2,550,820, a difference of $63,863. But, since the

allocation plan shows that $823,400 is required in year 1, only $23,400 of the additional $100,00 is

required. We can also determine this by looking at the slack variable for constraint 1 in the new

solution. This value, 77049.180, shows that at the optimal solution approximately $77,049 of the

$900,000 available is not used. Thus, the amount of funds required in year 1 is $900,000 - $77,049 =

$822,951. In other words, only $22,951 of the additional $100,000 is required. The differences

between the two values, $23,400 and $22,951, is simply due to the fact that the value of $23,400 was

computed using rounded values for the decision variables. The value of $22,951 is computed

internally in The Management Scientist output and is not subject to this rounding. Thus, the most

accurate value is $22,951.

CP - 8

Chapter 3

Linear Programming: Sensitivity Analysis and Interpretation

of Solution

Case Problem 1: Product Mix

Note to Instructor: The difference between relevant and sunk costs is critical. The cost of the shipment of

nuts is a sunk cost. Practice in applying sensitivity analysis to a business decision is obtained. You may

want to suggest that sensitivity analyses other than the ones we have suggested be undertaken.

1.

Cost per pound of ingredients

Almonds

$7500/6000 = $1.25

Brazil $7125/7500 = $.95

Filberts $6750/7500 = $.90

Pecans $7200/6000 = $1.20

Walnuts $7875/7500 = $1.05

Cost of nuts in three mixes:

Regular mix: .15($1.25) + .25($.95) + .25($90) + .10($1.20) + .25($1.05) = $1.0325

Deluxe mix

.20($1.25) + .20($.95) + .20($.90) + .20($1.20) + .20($1.05) = $1.07

Holiday mix: .25($1.25) + .15($.95) + .15($.90) + .25($1.20) + .20($1.05) = $1.10

2.

Let R = pounds of Regular Mix produced

D = pounds of Deluxe Mix produced

H = pounds of Holiday Mix produced

Note that the cost of the five shipments of nuts is a sunk (not a relevant) cost and should not affect

the decision. However, this information may be useful to management in future pricing and

purchasing decisions. A linear programming model for the optimal product mix is given.

The following linear programming model can be solved to maximize profit contribution for the nuts

already purchased.

Max

s.t.

1.65R

+

2.00D

+

2.25H

0.15R

0.25R

0.25R

0.10R

0.25R

R

+

+

+

+

+

0.20D

0.20D

0.20D

0.20D

0.20D

+

+

+

+

+

0.25H

0.15H

0.15H

0.25H

0.20H

D

H

R, D, H ≥ 0

CP - 9

≤

≤

≤

≤

≤

≥

≥

≥

6000

7500

7500

6000

7500

10000

3000

5000

Almonds

Brazil

Filberts

Pecans

Walnuts

Regular

Deluxe

Holiday

Chapter 3

The solution found using The Management Scientist is shown below.

Objective Function Value =

61375.000

Variable

-------------R

D

H

Value

--------------17500.000

10624.999

5000.000

Reduced Costs

-----------------0.000

0.000

0.000

Constraint

-------------1

2

3

4

5

6

7

8

Slack/Surplus

--------------0.000

250.000

250.000

875.000

0.000

7500.000

7624.999

0.000

Dual Prices

-----------------8.500

0.000

0.000

0.000

1.500

0.000

0.000

-0.175

OBJECTIVE COEFFICIENT RANGES

Variable

-----------R

D

H

Lower Limit

--------------1.500

1.892

No Lower Limit

Current Value

--------------1.650

2.000

2.250

Upper Limit

--------------2.000

2.200

2.425

Current Value

--------------6000.000

7500.000

7500.000

6000.000

7500.000

10000.000

3000.000

5000.000

Upper Limit

--------------6583.333

No Upper Limit

No Upper Limit

No Upper Limit

7750.000

17500.000

10624.999

9692.307

RIGHT HAND SIDE RANGES

Constraint

-----------1

2

3

4

5

6

7

8

Lower Limit

--------------5390.000

7250.000

7250.000

5125.000

6750.000

No Lower Limit

No Lower Limit

-0.000

3.

From the dual prices it can be seen that additional almonds are worth $8.50 per pound to TJ.

Additional walnuts are worth $1.50 per pound. From the slack variables, we see that additional

Brazil nut, Filberts, and Pecans are of no value since they are already in excess supply.

4.

Yes, purchase the almonds. The dual price shows that each pound is worth $8.50; the dual price is

applicable for increases up to 583.33 pounds.

CP - 10

Solutions to Case Problems

Resolving the problem by changing the right-hand side of constraint 1 from 6000 to 7000 yields the

following optimal solution. The optimal solution has increased in value by $4958.34. Note that

only 583.33 pounds of the additional almonds were used, but that the increase in profit contribution

more than justifies the $1000 cost of the shipment.

Objective Function Value =

66333.336

Variable

-------------R

D

H

Value

--------------11666.667

17916.668

5000.000

Reduced Costs

-----------------0.000

0.000

0.000

Constraint

-------------1

2

3

4

5

6

7

8

Slack/Surplus

--------------416.667

250.000

250.000

0.000

0.000

1666.667

14916.667

0.000

Dual Prices

-----------------0.000

0.000

0.000

5.667

4.333

0.000

0.000

-0.033

OBJECTIVE COEFFICIENT RANGES

Variable

-----------R

D

H

Lower Limit

--------------1.000

1.976

No Lower Limit

Current Value

--------------1.650

2.000

2.250

Upper Limit

--------------1.750

3.300

2.283

Current Value

--------------7000.000

7500.000

7500.000

6000.000

7500.000

10000.000

3000.000

5000.000

Upper Limit

--------------No Upper Limit

No Upper Limit

No Upper Limit

6250.000

7750.000

11666.667

17916.668

15529.412

RIGHT HAND SIDE RANGES

Constraint

-----------1

2

3

4

5

6

7

8

5.

Lower Limit

--------------6583.333

7250.000

7250.000

4210.000

7250.000

No Lower Limit

No Lower Limit

0.002

From the dual prices it is clear that there is no advantage to not satisfying the orders for the Regular

and Deluxe mixes. However, it would be advantageous to negotiate a decrease in the Holiday mix

requirement.

CP - 11

Chapter 3

Case Problem 2: Investment Strategy

1.

The first step is to develop a linear programming model for maximizing return subject to constraints

for funds available, diversity, and risk tolerance.

Let G = Amount invested in growth fund

I = Amount invested in income fund

M = Amount invested in money market fund

The LP formulation and optimal solution found using The Management Scientist are shown.

MAX .18G +.125I +.075M

S.T.

1)

2)

3)

4)

5)

6)

7)

G + I + M < 800000

.8G -.2I -.2M > 0

.6G -.4I -.4M < 0

-.2G +.8I -.2M > 0

-.5G +.5I -.5M < 0

-.3G -.3I +.7M > 0

.05G + .02I -.04M < 0

Funds Available

Min growth fund

Max growth fund

Min income fund

Max income fund

Min money market fund

Max risk

OPTIMAL SOLUTION

Objective Function Value =

94133.336

Variable

-------------G

I

M

Value

--------------248888.906

160000.000

391111.094

Reduced Costs

-----------------0.000

0.000

0.000

Constraint

-------------1

2

3

4

5

6

7

Slack/Surplus

--------------0.000

88888.898

71111.109

0.000

240000.000

151111.109

0.000

Dual Prices

-----------------0.118

0.000

0.000

-0.020

0.000

0.000

1.167

OBJECTIVE COEFFICIENT RANGES

Variable

-----------G

I

M

Lower Limit

--------------0.150

-0.463

0.015

Current Value

--------------0.180

0.125

0.075

CP - 12

Upper Limit

--------------No Upper Limit

0.145

0.180

Solutions to Case Problems

RIGHT HAND SIDE RANGES

Constraint

-----------1

2

3

4

5

6

7

Lower Limit

--------------0.188

No Lower Limit

-71111.109

-106666.641

-240000.000

No Lower Limit

-8000.000

Current Value

--------------800000.000

0.000

0.000

0.000

0.000

0.000

0.000

Upper Limit

--------------No Upper Limit

88888.898

No Upper Limit

133333.313

No Upper Limit

151111.109

6399.999

Rounding to the nearest dollar, the portfolio recommendation for Langford is as follows.

Fund:

Growth

Income

Money Market

Total

Amount

Invested

$248,889

160,000

391,111

$800,000

Yield = 94,133 / 800,000 = .118

The portfolio yield is .118 or 11.8%.

Note that the portfolio yield equals the dual price for the funds available constraint.

2.

If Langford’s risk index is increased by .005 that is the same as increasing the right-hand side of

constraint 7 by .005 (800,000) = 4000. Since this amount of increase is within the right-hand-side

range, we would expect an increase in return of 1.167 (4000) = 4668. The revised formulation and

new optimal solution are shown below. Except for rounding, the value has increased as predicted;

the new optimal allocation is

Fund:

Growth

Income

Money Market

Total

Amount

Invested

$293,333

160,000

346,667

$800,000

The portfolio yield becomes 98,800/800,000 = .124 or 12.4%

MAX .18G +.125I +.075M

S.T.

1)

2)

3)

4)

5)

6)

7)

G + I + M < 800000

.8G -.2I -.2M > 0

.6G -.4I -.4M < 0

-.2G +.8I -.2M > 0

-.5G +.5I -.5M < 0

-.3G -.3I +.7M > 0

.045G + .015I-.045M < 0

CP - 13

Chapter 3

OPTIMAL SOLUTION

Objective Function Value =

3.

98800.000

Variable

-------------G

I

M

Value

--------------293333.313

160000.000

346666.656

Reduced Costs

-----------------0.000

0.000

0.000

Constraint

-------------1

2

3

4

5

6

7

Slack/Surplus

--------------0.000

133333.328

26666.666

0.000

240000.000

106666.664

0.000

Dual Prices

-----------------0.124

0.000

0.000

-0.020

0.000

0.000

1.167

Since .16 is in the objective coefficient range for the growth fund return, there would be no change

in allocation. However, the return would decrease by (.02) ($248,889) = $4978.

A decrease to .14 is outside the objective function coefficient range forcing us to resolve the

problem. The new formulation and optimal solution is as follows.

MAX .14G +.125I +.075M

S.T.

1)

2)

3)

4)

5)

6)

7)

G + I + M < 800000

.8G -.2I -.2M > 0

.6G -.4I -.4M < 0

-.2G +.8I -.2M > 0

-.5G +.5I -.5M < 0

-.3G -.3I +.7M > 0

.05G + .02I-.04M < 0

OPTIMAL SOLUTION

Objective Function Value =

Variable

-------------G

I

M

85066.664

Value

--------------160000.016

293333.313

346666.688

CP - 14

Reduced Costs

-----------------0.000

0.000

0.000

Solutions to Case Problems

Constraint

-------------1

2

3

4

5

6

7

4.

Slack/Surplus

--------------0.000

0.000

160000.000

133333.313

106666.688

106666.688

0.000

Dual Prices

-----------------0.106

-0.010

0.000

0.000

0.000

0.000

0.833

Since the current optimal solution has more invested in the growth fund than the income fund,

adding this requirement will force us to resolve the problem with a new constraint. We should

expect a decrease in return as is shown in the following optimal solution.

MAX .18G +.125I +.075M

S.T.

1)

2)

3)

4)

5)

6)

7)

8)

G + I + M < 800000

.8G -.2I -.2M > 0

.6G -.4I -.4M < 0

-.2G +.8I -.2M > 0

-.5G +.5I -.5M < 0

-.3G -.3I +.7M > 0

.05G + .02I-.04M < 0

G - I < 0

OPTIMAL SOLUTION

Objective Function Value =

93066.656

Variable

-------------G

I

M

Value

--------------213333.313

213333.313

373333.313

Reduced Costs

-----------------0.000

0.000

0.000

Constraint

-------------1

2

3

4

5

6

7

8

Slack/Surplus

--------------0.000

53333.324

106666.664

53333.324

186666.656

133333.328

0.000

0.000

Dual Prices

-----------------0.116

0.000

0.000

0.000

0.000

0.000

1.033

0.012

Note that the value of the solution has decreased from $94,133 to $93,067. This is only a decrease

of 0.2% inyield. Since the yield decrease is so small, Williams may prefer this portfolio for

Langford.

5.

It is possible a model such as this could be developed for each client. The changed yield estimates

would require a change in the objective function coefficients and resolving the problem if the change

was outside the objective coefficient range.

CP - 15

Chapter 3

Case Problem 3: Truck Leasing Strategy

1.

xij = number of trucks obtained from a short term lease signed in month i for a period of j

Let

months

yi = number of trucks obtained from the long-term lease that are used in month i

Monthly fuel costs are 20 ($100) = $2000.

Monthly Costs for Short-Term Leased Trucks

Note: the costs shown here include monthly fuel costs of $2000.

Cost

$4000 + $2000 = $6000

2 ($3700) + $2000 = $9400

3 ($3225) + $2000 = $11,675

4 ($3040) + $2000 = $14,160

Decision Variables

x11, x21, x31, x41

x12, x22, x32

x13, x23

x14

Monthly Costs for Long-Term Leased Trucks

Since Reep Construction is committed to the long-term lease and since employees cannot be

laid off, the only relevant cost for the long-term leased trucks is the monthly fuel cost of $2000.

MIN 6000X11 + 9400X12 + 11675X13 + 14160X14 + 6000X21 + 9400X22 +

11675X23 + 6000X31 + 9400X32 + 6000X41 + 2000Y1 + 2000Y2 + 2000Y3 +

2000Y4

S.T.

1)

2)

3)

4)

5)

6)

7)

8)

X11 + X12

X21 + X22

X31 + X32

X41 + X32

Y1 < 1

Y2 < 2

Y3 < 3

Y4 < 1

+

+

+

+

X13

X23

X23

X23

+

+

+

+

X14

X14

X22

X14

+

+

+

+

Y1

X13

X14

Y4

CP - 16

=

+

+

=

10

X12 + Y2 = 12

X13 + Y3 = 14

8

Solutions to Case Problems

Objective Function Value =

151660.000

Variable

-------------X11

X12

X13

X14

X21

X22

X23

X31

X32

X41

Y1

Y2

Y3

Y4

Value

--------------0.000

0.000

3.000

6.000

0.000

0.000

1.000

1.000

0.000

0.000

1.000

2.000

3.000

1.000

Reduced Costs

-----------------3515.000

3725.000

0.000

0.000

2810.000

210.000

0.000

0.000

915.000

3515.000

0.000

0.000

0.000

0.000

Constraint

-------------1

2

3

4

5

6

7

8

Slack/Surplus

--------------0.000

0.000

0.000

0.000

0.000

0.000

0.000

0.000

Dual Prices

------------------2485.000

-3190.000

-6000.000

-2485.000

485.000

1190.000

4000.000

485.000

OBJECTIVE COEFFICIENT RANGES

Variable

-----------X11

X12

X13

X14

X21

X22

X23

X31

X32

X41

Y1

Y2

Y3

Y4

Lower Limit

--------------2485.000

5675.000

10760.000

13950.000

3190.000

9190.000

10485.000

3190.000

8485.000

2485.000

No Lower Limit

No Lower Limit

No Lower Limit

No Lower Limit

Current Value

--------------6000.000

9400.000

11675.000

14160.000

6000.000

9400.000

11675.000

6000.000

9400.000

6000.000

2000.000

2000.000

2000.000

2000.000

CP - 17

Upper Limit

--------------No Upper Limit

No Upper Limit

11885.000

15075.000

No Upper Limit

No Upper Limit

11885.000

6915.000

No Upper Limit

No Upper Limit

2485.000

3190.000

6000.000

2485.000

Chapter 3

RIGHT HAND SIDE RANGES

Constraint

Lower Limit

-------------------------1

4.000

2

11.000

3

13.000

4

2.000

5

0.000

6

1.000

7

0.000

8

0.000

Current Value

--------------10.000

12.000

14.000

8.000

1.000

2.000

3.000

1.000

Upper Limit

--------------11.000

13.000

No Upper Limit

11.000

7.000

3.000

4.000

7.000

2.

The total cost associated with the leasing plan is $151,660.

3.

If Reep Construction is willing to consider the possibility of layoffs, we need to include driver

costs of $3200 per month. Replacing the coefficients for y1, y2, y3, and y4 in our previous linear

program with $5200 and resolving resulted in the following leasing plan:

Month

Length of Lease (Months)

Leased

1

2

3

4

1

0

0

4

6

2

0

0

2

_

3

0

0

_

_

4

0

_

_

_

In addition, in month 3, two of the trucks from the long-term leases were used. The total cost of this

leasing plan is $165,410.

To see what effect a no layoff policy has, we can set y1 = 1, y2 = 2, y3 = 3, y4 = 1 and

resolve the linear program using objective coefficients of $5200 for y1, y2, y3, and y4. The new

optimal solution forces us to use all the available trucks from the long-term lease; the optimal

leasing plan is shown below.

Month

Length of Lease (Months)

Leased

1

2

3

4

1

0

0

3

6

2

0

0

1

_

3

1

0

_

_

4

0

_

_

_

The total cost associated with this solution is $174,060. Thus, if Reep maintains their current policy

of no layoffs they will incur an additional cost of $174,060 - $165,410 = $8,650.

CP - 18

Chapter 4

Linear Programming Applications in Marketing, Finance and

Operations Management

Case Problem 1: Planning an Advertising Campaign

The decision variables are as follows:

T1 = number of television advertisements with rating of 90 and 4000 new customers

T2 = number of television advertisements with rating of 40 and 1500 new customers

R1 = number of radio advertisements with rating of 25 and 2000 new customers

R2 = number of radio advertisements with rating of 15 and 1200 new customers

N1 = number of newspaper advertisements with rating of 10 and 1000 new customers

N2 = number of newspaper advertisements with rating of 5 and 800 new customers

The Linear Programming Model and solution using The Management Scientist follow:

MAX 90T1+55T2+25R1+20R2+10N1+5N2

S.T.

1)

2)

3)

4)

5)

6)

7)

8)

9)

10)

1T1<10

1R1<15

1N1<20

10000T1+10000T2+3000R1+3000R2+1000N1+1000N2<279000

4000T1+1500T2+2000R1+1200R2+1000N1+800N2>100000

-2T1-2T2+1R1+1R2>0

1T1+1T2<20

10000T1+10000T2>140000

3000R1+3000R2<99000

1000N1+1000N2>30000

OPTIMAL SOLUTION

Objective Function Value =

Variable

-------------T1

T2

R1

R2

N1

N2

2160.000

Value

--------------10.000

5.000

15.000

18.000

20.000

10.000

CP - 19

Reduced Costs

-----------------0.000

0.000

0.000

0.000

0.000

0.000

Chapter 4

Constraint

-------------1

2

3

4

5

6

7

8

9

10

Slack/Surplus

--------------0.000

0.000

0.000

0.000

27100.000

3.000

5.000

10000.000

0.000

0.000

Dual Prices

-----------------35.000

5.000

5.000

0.006

0.000

0.000

0.000

0.000

0.001

0.000

OBJECTIVE COEFFICIENT RANGES

Variable

-----------T1

T2

R1

R2

N1

N2

Lower Limit

--------------55.000

No Lower Limit

20.000

16.500

5.000

No Lower Limit

Current Value

--------------90.000

55.000

25.000

20.000

10.000

5.000

Upper Limit

--------------No Upper Limit

66.667

No Upper Limit

25.000

No Upper Limit

5.500

Current Value

--------------10.000

15.000

20.000

279000.000

100000.000

0.000

20.000

140000.000

99000.000

30000.000

Upper Limit

--------------15.000

33.000

30.000

294000.000

127100.000

3.000

No Upper Limit

150000.000

109000.000

40000.000

RIGHT HAND SIDE RANGES

Constraint

-----------1

2

3

4

5

6

7

8

9

10

1.

Lower Limit

--------------0.000

0.000

0.000

269000.000

No Lower Limit

No Lower Limit

15.000

No Lower Limit

93375.000

20000.000

Summary of the Optimal Solution

T1 + T2 = 10 + 5 = 15 Television advertisements

R1 + R2 = 15 + 18 = 33 Radio advertisements

N1 + N2 = 20 + 10 = 30 Newspaper advertisements

Advertising Schedule:

Media

Television

Radio

Newspaper

Totals

Number of Ads

15

33

30

78

Total Exposure Rating:

Total New Customers Reached:

Budget

$150,000

99,000

30,000

$279,000

2,160

127,100 (Surplus constraint 5)

CP - 20

Solutions to Case Problems

2.

The dual price shows that total exposure increases 0.006 points for each one dollar increase in the

advertising budget. Right Hand Side Ranges show this dual price applies for a budget increase of up

to $294,000 - $279,000 = $15,000. Thus the dual price applies for the $10,000 increase.

Total Exposure Rating would increase by 10,000(0.006) = 60 points

A $10,000 increase in the advertising budget is a 3.6% increase. But, it only provides a 2.8%

increase in total exposure. Management may decide that the additional exposure is not worth the

cost. This is a discussion point.

3.

The ranges for the exposure rating of 90 for the first 10 television ads show that the solution remains

optimal as long as the exposure rating is 55 or higher. This indicates that the solution is not very

sensitive to the exposure rating HJ has provided. Indeed, we would draw the same conclusion after

reviewing the next four ranges. We could conclude that Flamingo does not have to be concerned

about the exact exposure rating. The only concern might be the newspaper exposure rating of 5. A

rating of 5.5 or better can be expected to alter the current optimal solution.

4.

Remove constraint #5 for the linear programming model and use it to develop the objective function:

MAX 4000T1+1500T2+2000R1+1200R2+1000N1+800N2

Solving provides the following Optimal Solution

T1 + T2 = 10 + 4 = 14 Television advertisements

R1 + R2 = 15 + 13 = 28 Radio advertisements

N1 + N2 = 20 + 35 = 55 Newspaper advertisements

Advertising Schedule:

Media

Television

Radio

Newspaper

Totals

Number of Ads

14

28

55

97

Total New Customers Reached:

Budget

$140,000

83,000

55,000

$279,000

139,600

Total Exposure Rating

90(10) + 55(4) + 25(15) + 20(13) + 10(20) + 5(35) = 2130

5.

The solution with the objective to maximize the number of potential new customers reached looks

attractive. The total number of ads is increased from 78 to 97 (24%) and the number of potential

new customers reached is increased by 139,600 – 127,100 = 12,500 (9.8%).

Maximizing total exposure may seem to be the preferred objective because it is a more general

measure of advertising effectiveness. Exposure includes issues of image, message recall and appeal

to repeat customers. However, in this case, many more potential new customers will be reached

with the objective of maximizing reach, and the total exposure is only reduced by 2160 – 2130 = 30

points (1.4%).

At this point, we would expect some discussion concerning which solution is preferred: the one

obtained by maximizing total exposure or the one obtained by maximizing potential new customers

reached. Expect students to have differing opinions on the final recommendation. Basically, there

are two good media allocation solutions for this problem.

CP - 21

Chapter 4

Case Problem 2: Phoenix Computer

1.

The monthly cost of a new employee is $2,250 = $27,000/12. The training program is 3 months for

a new employee and costs $1,500. So the total cost of hiring a new employee and training her/him

to be a laptop specialist is $8,250 = 3($2,250) + $1,500.

2.

The training program is only 2 months for current employees and costs $1,000. So a replacement

employee will only need to be hired 2 months before the laptop specialist is needed in this case. So

the incremental cost of putting a current employee through the training program is $5,500 =

2($2,250) + $1,000.

3.

It is clear that 100 new employees will need to be hired either to become laptop specialists

themselves or to replace current employees who will become laptop specialists. So the company's

monthly payroll cost will increase by $225,000 = 100($2,250) in September over January.

A linear program can be formulated and solved to minimize the cost of hiring and training over the

period from February to August. The following variable definitions are used:

Feb 3

•

•

•

Jun 3

Mar 2

•

•

•

Jul 2

= No. of new employees entering the 3-month program in February

= No. of new employees entering the 3-month program in June

= No. of current employees entering the 2-month program in March

= No. of current employees entering the 2-month program in July

IdleMay = No. of trained laptop specialists in excess of those needed in May

•

•

•

IdleSep = No. of trained laptop specialists in excess of those needed in September

There are 16 constrains needed. The first 5 deal with meeting the needs for laptop specialists.

Constraints (6) through (10) restrict the number of current employees that may enter the program

while Constraints (11) through (16) deal with the capacity of the training center.

The following output from The Management Scientist shows a model and solution that can be used

to answer the questions in part 3.

LINEAR PROGRAMMING PROBLEM

MIN

8250Feb3+5500Mar2+2250IdleMay+8250Mar3+5500Apr2+2250IdleJun+8250Apr3+55

00May

2+2250IdleJul+8250May3+5500Jun2+2250IdleAug+8250Jun3+5500Jul2+2250IdleS

ep

CP - 22

Solutions to Case Problems

S.T.

1)

2)

3)

4)

5)

1Feb3+1Mar2-1IdleMay=20

1Feb3+1Mar2+1Mar3+1Apr2-1IdleJun=30

1Feb3+1Mar2+1Mar3+1Apr2+1Apr3+1May2-1IdleJul=85

1Feb3+1Mar2+1Mar3+1Apr2+1Apr3+1May2+1May3+1Jun2-1IdleAug=85

1Feb3+1Mar2+1Mar3+1Apr2+1Apr3+1May2+1May3+1Jun2+1Jun3+1Jul2-IdleSep

=100

6) 1Mar2<15

7) 1Mar2+1Apr2<35

8) 1Mar2+1Apr2+1May2<35

9) 1Mar2+1Apr2+1May2+1Jun2<40

10) 1Mar2+1Apr2+1May2+1Jun2+1Jul2<50

11) 1Feb3<25

12) 1Mar2+1Mar3<25

13) 1Apr2+1Apr3<25

14) 1May2+1May3<25

15) 1Jun2+1Jun3<25

16) 1Jul2<25

OPTIMAL SOLUTION

Objective Function Value =

Variable

-------------Feb3

Mar2

IdleMay

Mar3

Apr2

IdleJun

Apr3

May2

IdleJul

May3

Jun2

IdleAug

Jun3

Jul2

IdleSep

698750.000

Value

--------------10.000

10.000

0.000

15.000

0.000

5.000

25.000

25.000

0.000

0.000

0.000

0.000

0.000

15.000

0.000

CP - 23

Reduced Costs

-----------------0.000

0.000

2250.000

0.000

2250.000

0.000

0.000

0.000

4500.000

2250.000

0.000

2250.000

0.000

0.000

10500.000

Chapter 4

Constraint

-------------1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

Slack/Surplus

--------------0.000

0.000

0.000

0.000

0.000

5.000

25.000

0.000

5.000

0.000

15.000

0.000

0.000

0.000

25.000

10.000

Dual Prices

-----------------0.000

2250.000

-2250.000

0.000

-8250.000

0.000

0.000

0.000

0.000

2750.000

0.000

0.000

2250.000

2250.000

0.000

0.000

Case Problem 3: Textile Mill Scheduling

Let X3R = Yards of fabric 3 on regular looms

X4R = Yards of fabric 4 on regular looms

X5R = Yards of fabric 5 on regular looms

X1D = Yards of fabric 1 on dobbie looms

X2D = Yards of fabric 2 on dobbie looms

X3D = Yards of fabric 3 on dobbie looms

X4D = Yards of fabric 4 on dobbie looms

X5D = Yards of fabric 5 on dobbie looms

Y1 = Yards of fabric 1 purchased

Y2 = Yards of fabric 2 purchased

Y3 = Yards of fabric 3 purchased

Y4 = Yards of fabric 4 purchased

Y5 = Yards of fabric 5 purchased

Profit Contribution per Yard

Fabric

1

2

3

4

5

Manufactured

0.33

0.31

0.61

0.73

0.20

Purchased

0.19

0.16

0.50

0.54

0.00

1

2

3

4

5

Regular

—

—

0.1912

0.1912

0.2398

Dobbie

0.21598

0.21598

0.1912

0.1912

0.2398

Production Times in Hours per Yard

Fabric

Model may use a Max Profit or Min Cost objective function.

CP - 24

Solutions to Case Problems

Max

0.61X3R + 0.73X4R + 0.20X5R

+ 0.33X1D + 0.31X2D + 0.61X3D + 0.73X4D + 0.20X5D

+ 0.19Y1 + 0.16Y2 + 0.50Y3 + 0.54Y4

or

Min

0.49X3R + 0.51X4R + 0.50X5R

+ 0.66X1D + 0.55X2D + 0.49X3D + 0.51X4D + 0.50X5D

+ 0.80Y1 + 0.70Y2 + 0.60Y3 + 0.70Y4 + 0.70Y5

Regular Hours Available

30 Looms x 30 days x 24 hours/day = 21600

Dobbie Hours Available

8 Looms x 30 days x 24 hours/day = 5760

Constraints:

Regular Looms:

0.192X3R + 0.1912X4R + 0.2398X5R ≤ 21600

Dobbie Looms:

0.21598X1D + 0.21598X2D + 0.1912X3D + 0.1912X4D + 0.2398X5D ≤ 5760

Demand Constraints

X1D + Y1

X2D + Y2

X3R + X3D + Y3

X4R + X4D + Y4

X5R + X5D + Y5

= 16500

= 22000

= 62000

= 7500

= 62000

OPTIMAL SOLUTION

Objective Function Value =

Variable

-------------X3R

X4R

X5R

X1D

X2D

X3D

X4D

X5D

Y1

Y2

Y3

Y4

Y5

62531.91797

Value

--------------27711.29297

7500.00000

62000.00000

4669.13672

22000.00000

0.00000

0.00000

0.00000

11830.86328

0.00000

34288.70703

0.00000

0.00000

CP - 25

Reduced Costs

-----------------0.00000

0.00000

0.00000

0.00000

0.00000

0.01394

0.01394

0.01748

0.00000

0.01000

0.00000

0.08000

0.06204

Chapter 4

Constraint

-------------1

2

3

4

5

6

7

Slack/Surplus

--------------0.00000

0.00000

0.00000

0.00000

0.00000

0.00000

0.00000

Dual Prices

-----------------0.57531

0.64821

0.19000

0.17000

0.50000

0.62000

0.06204

OBJECTIVE COEFFICIENT RANGES

Variable

-----------X3R

X4R

X5R

X1D

X2D

X3D

X4D

X5D

Y1

Y2

Y3

Y4

Y5

Lower Limit

--------------0.50000

0.71606

0.18252

0.31426

0.30000

No Lower Limit

No Lower Limit

No Lower Limit

0.18000

No Lower Limit

0.48606

No Lower Limit

No Lower Limit

Current Value

--------------0.61000

0.73000

0.20000

0.33000

0.31000

0.61000

0.73000

0.20000

0.19000

0.16000

0.50000

0.54000

0.00000

Upper Limit

--------------0.62394

No Upper Limit

No Upper Limit

0.34000

No Upper Limit

0.62394

0.74394

0.21748

0.20574

0.17000

0.61000

0.62000

0.06204

Current Value

--------------21600.00000

5760.00000

16500.00000

22000.00000

62000.00000

7500.00000

62000.00000

Upper Limit

--------------28156.00000

8315.23047

No Upper Limit

26669.13672

No Upper Limit

35211.29297

84095.07813

RIGHT HAND SIDE RANGES

Constraint

-----------1

2

3

4

5

6

7

Lower Limit

--------------16301.60059

4751.55957

4669.13672

10169.13672

27711.29297

0.00000

34660.54688

Production/Purchase Schedule (Yards)

Regular

Looms

Fabric

1

2

3

4

5

27711

7500

62000

Projected Profit: $62,531.92

CP - 26

Dobbie

Looms

4669

22000

Purchased

11831

34289

Solutions to Case Problems

Value of 9th Dobbie Loom

Dual Price (Constraint 2) = 0.64821 per hour dobbie

Monthly Value of 1 Dobbie Loom

(30 days)(24 hours/day)($0.64821) = $466.71

Note: This change is within the Right-Hand Side Ranges for Constraint 2.

Discussion of Objective Coefficient Ranges

For example, fabric one on the dobbie loom shares ranges of 0.31426 to 0.34 for the profit

maximization model or 0.64426 to 0.67 for the cost minimization model.

Note here that since demand for the fabrics is fixed, both the profit maximization and cost

minimization models will provide the same optimal solution. However, the interpretation of the

ranges for the objective function coefficients differ for the two models. In the profit maximization

case, the coefficients are profit contributions. Thus, the range information indicates how price per

unit and cost per unit may vary simultaneously. That is, as long as the net changes in price per unit

and cost per unit keep the profit contributions within the ranges, the solution will remain optimal. In

the cost minimization model, the coefficients are costs per unit. Thus, the range information

indicates that assuming price per unit remains fixed how much the cost per unit may vary and still

maintain the same optimal solution.

Case Problem 4: Workforce Scheduling

1.

Let tij = number of temporary employees hired under option i (i = 1, 2, 3) in month j (j = 1 for

January, j = 2 for February and so on)

The following table depicts the decision variables used in this case problem.

Option 1

Option 2

Option 3

Jan.

t11

t21

t31

Feb.

t12

t22

t32

Mar.

t13

t23

t33

Apr.

t14

t24

t34

May

t15

t25

June

t16

Costs: Contract cost plus training cost

Option

1

2

3

Contract Cost

$2000

$4800

$7500

Training Cost

$875

$875

$875

Min. 2875(t11 + t12 + t13 + t14 + t15 + t16)

+ 5675(t21 + t22 + t23 + t24 + t25)

+ 8375(t31 + t32 + t33 + t34)

One constraint is required for each of the six months.

CP - 27

Total Cost

$2875

$5675

$8375

Chapter 4

Constraint 1: Need 10 additional employees in January

t11 = number of temporary employees hired under Option 1 (one-month contract) in January

t21 = number of temporary employees hired under Option 2 (two-month contract) in January

t31 = number of temporary employees hired under Option 3 (three-month contract) in January

t11 + t21 + t31 = 10

Constraint 2: Need 23 additional employees in February

t12 , t22 and t32 are the number of temporary employees hired under Options 1, 2 and 3 in

February.

But, temporary employees hired under Option 2 or Option 3 in January will also be available to

satisfy February needs.

t21 + t31 + t12 + t22 + t32 = 23

Note: The following table shows the decision variables used in this constraint

Jan.

Option 1

Option 2

Option 3

t21

t31

Feb.

t12

t22

t32

Mar.

Apr.

May

June

Constraint 3: Need 19 additional employees in March

Option 1

Option 2

Option 3

Jan.

Feb.

t31

t22

t32

Mar.

t13

t23

t33

Apr.

May

June

t31 + t22 + t32 + t13 + t23 + t33 = 19

Constraint 4: Need 26 additional employees in May

Jan.

Option 1

Option 2

Option 3

Feb.

Mar.

t32

t23

t33

Apr.

t14

t24

t34

May

June

t32 + t23 + t33 + t14 + t24 + t34 = 26

Constraint 5: Need 20 additional employees in May

Jan.

Feb.

Option 1

Option 2

Option 3

Mar.

Apr.

t33

t24

t34

t33 + t24 + t34 + t15 + t25 = 20

CP - 28

May

t15

t25

June

Solutions to Case Problems

Constraint 6: Need 14 additional employees in June

Jan.

Feb.

Mar.

Option 1

Option 2

Option 3

Apr.

May

June

t16

t25

t34

t34 + t25 + t16 = 14

Optimal Solution: Total Cost = $313,525

Option 1

Option 2

Option 3

Jan.

0

3

7

Feb.

1

0

12

Mar.

0

0

0

Apr.

0

0

14

May

6

0

June

0

2.

Option

1

2

3

3.

Number Hired

7

3

33

Total:

Contract Cost

$14,000

$14,400

$247,500

$275,900

Training Cost

$6,125

$2,625

$28,875

$37,625

Total Cost

$20,125

$17,025

$276,375

$313,525

Hiring 10 full-time employees at the beginning of January will reduce the number of temporary

employees needed each month by 10. Using the same linear programming model with the righthand sides of 0, 13, 9, 16, 10 and 4, provides the following schedule for temporary employees:

Option 1

Option 2

Option 3

Option

1

2

3

Total:

Jan.

0

0

0

Feb.

4

0

9

Number Hired

7

3

13

23

Mar.

0

0

0

Apr.

0

3

4

May

3

0

Contract Cost

$14,000

$14,400

$97,500

June

0

Training Cost

$6,125

$2,625

$11,375

Total Cost

$20,125

$17,025

$108,875

$146,025

Full-time employees cost:

Training cost: 10($875) = $8,750

Salary: 10(6)(168)($16.50) = $166,320

Total Cost = $146,025 + $8750 + $166,320 = $321,095

Hiring 10 full-time employees is $321,095 - $313,525 = $7,570 more expensive than using

temporary employees. Do not hire the 10 full-time employees. Davis should continue to contract

with WorkForce to obtain temporary employees.

CP - 29

Chapter 4

4.

With the lower training costs, the costs per employee for each option are as follows:

Option

1

2

3

Cost

$2000

$4800

$7500

Training Cost

$700

$700

$700

Total Cost

$2700

$5500

$8200

Resolving the original linear programming model with the above costs indicates that Davis should

hire all temporary employees on a one-month contract specifically to meet each month's employee

needs. Thus, the monthly temporary hire schedule would be as follows: January - 10; February - 23;

March - 19; April - 26; May - 20; and June - 14. The total cost of this strategy is $302,400. Note

that if training costs were any lower, this would still be the optimal hiring strategy for Davis.

Case Problem 5: Duke Energy Coal Allocation

A linear programming model can be used to determine how much coal to buy from each of the

mining companies and where to ship it. Let

xij = tons of coal purchased from supplier i and used by generating unit j

The objective function minimizes the total cost to buy and burn coal. The objective function

coefficients, cij , are the cost to buy coal at mine i, ship it to generating unit j, and burn it at

generating unit j. Thus, the objective function is ∑ ∑ cij xij . In computing the objective function

coefficients three inputs must be added: the cost of the coal, the transportation cost to the generating

unit, and the cost of processing the coal at the generating unit.

There are two types of constraints: supply constraints and demand constraints. The supply

constraints limit the amount of coal that can be bought under the various contracts. For the fixedtonnage contracts, the constraints are equalities. For the variable-tonnage contracts, any amount of

coal up to a specified maximum may be purchased. Let Li represent the amount that must be

purchased under fixed-tonnage contract i and Si represent the maximum amount that can be

purchased under variable-tonnage contract i. Then the supply constraints can be written as follows:

∑x

ij

= Li

for all fixed-tonnage contracts

≤ Si

for all variable-tonnage contracts

j

∑x

ij

j

The demand constraints specify the number of mWh of electricity that must be generated by each

generating unit. Let aij = mWh hours of electricity generated by a ton of coal purchased from

supplier i and used by generating unit j, and Dj = mWh of electricity demand at generating unit j.

The demand constraints can then be written as follows:

∑a x

ij ij

= Dj

for all generating units

i

Note: Because of the large number of calculations that must be made to compute the objective

function and constraint coefficients, we developed an Excel spreadsheet model for this problem.

Copies of the data and model worksheets are included after the discussion of the solution to parts (a)

through (f).

CP - 30

Solutions to Case Problems

1.

The number of tons of coal that should be purchased from each of the mining companies and where

it should be shipped is shown below:

Miami Fort #

5

Miami Fort # 7

Beckjord

East Bend

Zimmer

0

0

61,538

288,462

0

Peabody

217,105

11,278

71,617

0

0

American

0

0

0

0

275,000

Consol

0

0

33,878

0

166,122

Cyprus

0

0

0

0

0

Addington

0

200,000

0

0

0

Waterloo

0

0

98,673

0

0

RAG

The total cost to purchase, deliver, and process the coal is $53,407,243.

2.

The cost of the coal in cents per million BTUs for each generating unit is as follows:

Miami Fort #5

111.84

3.

Miami Fort #7

136.97

Beckjord

127.24

East Bend

103.85

Zimmer

114.51

The average number of BTUs per pound of coal received at each generating unit is shown

below:

Miami Fort #5

13,300

Miami Fort #7

12,069

Beckjord

12,354

East Bend

13,000

Zimmer

12,468

4.

The sensitivity report shows that the shadow price per ton of coal purchased from American Coal

Sales is -$13 per ton and the allowable increase is 88,492 tons. This means that every additional ton

of coal that Duke Energy can purchase at the current price of $22 per ton will decrease cost by $13.

So even paying $30 per ton, Duke Energy will decrease cost by $5 per ton. Thus, they should buy

the additional 80,000 tons; doing so will save them $5(80,000) = $400,000.

5.

If the energy content of the Cyprus coal turns out to be 13,000 BTUs per ton the procurement plan

changes as shown below:

Miami Fort # 5 Miami Fort # 7 Beckjord

Zimmer

0

0

61,538

288,462

0

Peabody

36,654

191,729

71,617

0

0

American

0

0

0

0

275,000

Consol

0

0

33,878

0

166,122

Cyprus

0

0

85,769

0

0

Addington

200,000

0

0

0

0

Waterloo

0

0

0

0

0

RAG

6.

East Bend

The shadow prices for the demand constraints are as follows:

Miami Fort #5

21

Miami Fort #7

20

Beckjord

20

CP - 31

East Bend

18

Zimmer

19

Chapter 4

The East Bend unit is the least cost producer at the margin ($18 per mWh), and the allowable

increase is 160,000 mWh. Thus, Duke Energy should sell the 50,000 mWh over the grid. The

additional electricity should be produced at the East Bend generating unit. Duke Energy’s profit will

be $12 per mWh.

The Excel data and model worksheets used to solve the Duke Energy coal allocation problem are as

follows:

Duke Energy Coal Allocation Model (Data)

Duke Energy Coal Allocation Model (Solution)

CP - 32

Chapter 6

Distribution and Network Models

Case Problem 1: Solution Plus

1.

This case can be formulated as a transportation problem with the Cincinnati and Oakland production

facilities as the origins. The locations of the railway stations are the destinations. Each objective

function coefficient is the sum of the production cost at an origin and the freight cost to ship from

the origin to a destination. The minimum cost solution has a value of $1,318,985 and 773,522

gallons of cleaning fluid are produced and shipped. So, the average cost per gallon of producing the

cleaning fluid and shipping it to the railway stations is $1.705168. Shown below is the optimal

shipping plan.

Santa Ana

El Paso

Pendleton

Houston

Kansas City

Los Angeles

Glendale

Jacksonville

Little Rock

Bridgeport

Sacramento

Cincinnati

0

6800

39636

100447

24570

0

0

68486

148586

111475

0

500000

Total

Oakland

22418

0

40654

0

0

64761

33689

0

0

0

112000

273522

From the shipping plan it can be seen that the Cincinnati plant is at capacity. The dual price for the

Cincinnati capacity constraint indicates that if more capacity can be made available the total cost can

be decreased by $.11 for every additional gallon up to 40,654.

2.

Since it costs Solutions Plus $1.705168 per gallon to produce and deliver the cleaning fluid to the

railroad, this is the breakeven point. If Mr. Miller bids any less, Solutions Plus will lose money on

the contract.

3.

A 15% profit margin corresponds to a price of 1.15($1.705168) = $1.9609432 per gallon. Rounding

up, we would recommend the president bid $1.97 per gallon if a 15% profit margin is desired.

4.

If management of Solutions Plus expects oil prices to go up, they can also expect freight rates to go

up. The breakeven point found by solving the minimum cost transportation problem is using freight

rates for the first year. So, management should perhaps bid a bit higher to allow for an increase in

freight rates in the second year of the contract. You might offer to resolve the problem assuming,

say, a 10% increase in freight rates to see what the breakeven point would be in this situation. On

the other hand, if freight rates are expected to go down in the second year, management might want

to bid a bit lower to increase the chances of winning the contract.

CP - 33

Chapter 6

Solutions Plus

Production Cost

Santa Ana

Origin

Cincinnati

10

Oakland

0.22

22418

Demand

CP - 34

Santa Ana

Origin

Cincinnati

11.2

Oakland

1.87

22418

Demand

Cincinnati Oakland

1.2

1.65

El Paso

Pendleton

0.84

0.83

0.74

0.49

6800

80290

FREIGHT COST

Destination

Houston

Kansas City Los Angeles Glendale Jacksonville Little Rock Bridgeport Sacramento Supply

0.45

0.36

10

10

0.34

0.34

0.34

10 500000

10

10

0.22

0.22

10

10

10

0.15 500000

100447

24570

64761

33689

68486

148586

111475

112000

El Paso

Pendleton

2.04

2.03

2.39

2.14

6800

80290

FREIGHT + PRODUCTION COST

Destination

Houston

Kansas City Los Angeles Glendale Jacksonville Little Rock Bridgeport Sacramento Supply

1.65

1.56

11.2

11.2

1.54

1.54

1.54

11.2 500000

11.65

11.65

1.87

1.87

11.65

11.65

11.65

1.8 500000

100447

24570

64761

33689

68486

148586

111475

112000

Model

Total

Per Gallon

Min Cost 1318984.93 1.705167959

Santa Ana

Origin

0

Cincinnati

Oakland

22418

22418

Total

=

22418

El Paso

Pendleton

6800

39636

0

40654

6800

80290

=

=

6800

80290

Destination

Houston

Kansas City Los Angeles Glendale Jacksonville Little Rock Bridgeport Sacramento

100447

24570

0

0

68486

148586

111475

0

0

0

64761

33689

0

0

0

112000

100447

24570

64761

33689

68486

148586

111475

112000

=

=

=

=

=

=

=

=

100447

24570

64761

33689

68486

148586

111475

112000

Total

500000 <= 500000

273522 <= 500000

773522

Solutions to Case Problems

Case Problem 2: Distribution Systems Design

Three related linear programming models were developed and solved to answer the questions in this case.

First, we developed a linear programming formulation of the network model shown on the following page;

we refer to this network model and the corresponding linear program as the Part 2 Network Model and the

Part 2 Linear Program, respectively. Variations of the Part 2 Linear Program were then used to answer the

questions in parts 1 and 3. For instance, to answer the question concerning the existing system in part 1 we

added constraints to the Part 2 Linear Program which set the flow equal to 0 over the distribution centercustomer arcs that Darby does not currently use. For Part 3, we added three plant to customer arcs to the

Part 2 Network Model and corresponding linear program: El Paso - San Antonio, San Bernardino - Los

Angeles, and San Bernardino - San Diego.

The decision variables used in each of the linear programs use 4 letters to describe the amount of flow over

each arc. The first two letters in each variable name identify the “from” node and the second two letters

identify the “to” nodes. For instance, EPFW represents the amount shipped from El Paso to Ft. Worth and

LVDE represents the amount shipped from Las Vegas to Denver.

A description of the LP models that provide the basis for answering the questions in the managerial report

follows the network model for the questions in part 2.

CP - 35

Chapter 6

Part 2 Network Model:

Dallas

6300

San

Antonio

4880

Wichita

2130

Kansas

City

1210

Denver

6120

Salt

Lake

City

4830

Phoenix

2750

0.3

2.1

Ft. Worth

3.1

4.4

6.0

3.20

30,000

5.4

El Paso

2.20

4.5

5.2

6.0

4.20

2.7

Santa Fe

4.7

3.90

20,000

3.4

3.3

2.7

San

Bernardino

1.20

5.4

3.3

Las Vegas

2.4

2.1

2.5

Los

Angeles

San Diego

CP - 36

8580

4460

Solutions to Case Problems

LP Model and Solution for Part 2

MIN 13.7EPFW + 12.7EPSF + 14.7EPLV + 13.9SBSF + 11.2SBLV + .3FWDA +

2.1FWSA + 3.1FWWI + 4.4FWKC + 6.0FWDE + 5.2SFDA + 5.4SFSA + 4.5SFWI +

6.0SFKC + 2.7SFDE + 4.7SFSL + 3.4SFPH + 3.3SFLA + 2.7SFSD + 5.4LVDE +

3.3LVSL + 2.4LVPH + 2.1LVLA + 2.5LVSD

S.T.

1)

2)

3)

4)

EPFW

SBSF

FWDA

SFDA

+

+

+

+

5)

6)

7)

8)

9)

10)

11)

12)

13)

14)

LVDE

FWDA

FWSA

FWWI

FWKC

FWDE

SFSL

SFPH

SFLA

SFSD

+

+

+

+

+

+

+

+

+

+

SFSD

EPSF

SBLV

FWSA

SFSA

LVSL

SFDA

SFSA

SFWI

SFKC

SFDE

LVSL

LVPH

LVLA

LVSD

+ EPLV < 30000

< 20000

+ FWWI + FWKC + FWDE - EPFW = 0

+ SFWI + SFKC + SFDE + SFSL + SFPH + SFLA +

EPSF - SBSF = 0

+ LVPH + LVLA + LVSD - EPLV - SBLV = 0

= 6300

= 4880

= 2130

= 1210

+ LVDE = 6120

= 4830

= 2750

= 8580

= 4460

Objective Function Value =

Variable

-------------EPFW

EPSF

EPLV

SBSF

SBLV

FWDA

FWSA

FWWI

FWKC

FWDE

SFDA

SFSA

SFWI

SFKC

SFDE

SFSL

SFPH

SFLA

SFSD

LVDE

LVSL

600942.000

Value

--------------14520.000

6740.000

0.000

0.000

20000.000

6300.000

4880.000

2130.000

1210.000

0.000

0.000

0.000

0.000

0.000

6120.000

0.000

0.000

0.000