H - TIME PLANNING

management literature, however there has been much debate as to the

effectiveness of these methods.

The overall objectives of planning and scheduling systems are:

BACKGROUND

•

finish on time

Time planning involves converting the project's time objectives into an

operational plan. The process starts with the initiation of the project and

is not completed until handover.

•

continuous uninterrupted work flow

•

reduction of rework

•

reduce confusion and misunderstandings

•

increased knowledge of project status

•

aids reporting in meaning and timeliness to management

•

provides sense of control

•

provides cashflow information

•

provides guidance what should be occurring

Research has shown that one of the major causes for the project not

meeting cost objectives relate to the failure of achievement of the

necessary schedule objectives.

Clients realise the value of time in the execution of contracts and in many

cases use bonuses, penalties and specified planning requirements to

ensure that the time objectives are met.

Scheduling is the sequencing of activities on a project to ensure that the

plan is achieved. As with the WBS, schedules are often constructed in a

hierarchical fashion. For a typical engineering project this hierarchy may

consist of:

• Master Schedule - covering the major project milestones and

groups of activities required to achieve timely completion of the

project.

• Engineering, Procurement and Construction schedules.

Good plans should

• begin before work starts not during the works

• involve the people doing the work in the planning process

(ownership)

• Discipline schedules.

• include all aspects of the project in the plan, scope, budget,

schedule and quality

• Control logs.

• allow for changes and time for reviews and approvals

The level of detail shown on the schedule is a function of the use of the

schedule. The relevant time period for scheduling is also a function of

use.

There are a number of methods that can be used to schedule the work on

a project. Networks have occupied much of the recent project

• be simple and readable

• be communicated the plan to all parties.

Some different methods are as shown.

Page - H.1 -

!

"

"

#

!

$

#

%

&

"

'

(

)

*

*

"

Page - H.2 -

+

"

(

,

,

,

-

.

/

0

.

1

1

2

0

.

/

3

2

4

5

1

6

7

8

9

.

9

/

1

:

1

.

7

;

;

;

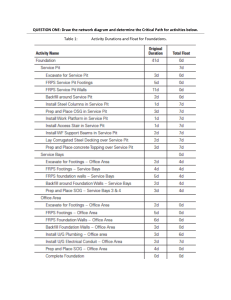

• Network - a diagram to represent the relationship of

activities to complete the project (see AON, AOA)

Network scheduling

Benefits of the technique

The method has the following benefits for controlling and

monitoring a project:

• Provides a consistent framework for planning,

scheduling, monitoring and controlling the project.

• Highlights the interdependence of work groups and

activities that make up the scope of the project.

• Assists in inter-functional communication.

• Maintains a relevant project completion date.

• Identifies activities that may jeopardise the project

completion date.

• Identifies activities that have some degree of flexibility

to allow more efficient work practices to be

implemented.

• Fixes starting and completion dates for activities.

• May be used to avoid timing and resource conflicts.

• Determines which activities may be run sequentially

and those activities that must run in parallel.

• Allow analysis of probabilistic completion dates.

Definitions

• Duration (D) - the estimated time taken to perform an

activity.

• Early Start (ES) - the earliest an activity can start.

• Early Finish (EF) - the earliest an activity can finish

EF = ES + D

• Late Finish (LF) - the latest an activity can be finished.

• Late Start (LS) - the latest time and activity can be started

without delaying the completion date of the project.

LS = LF - D

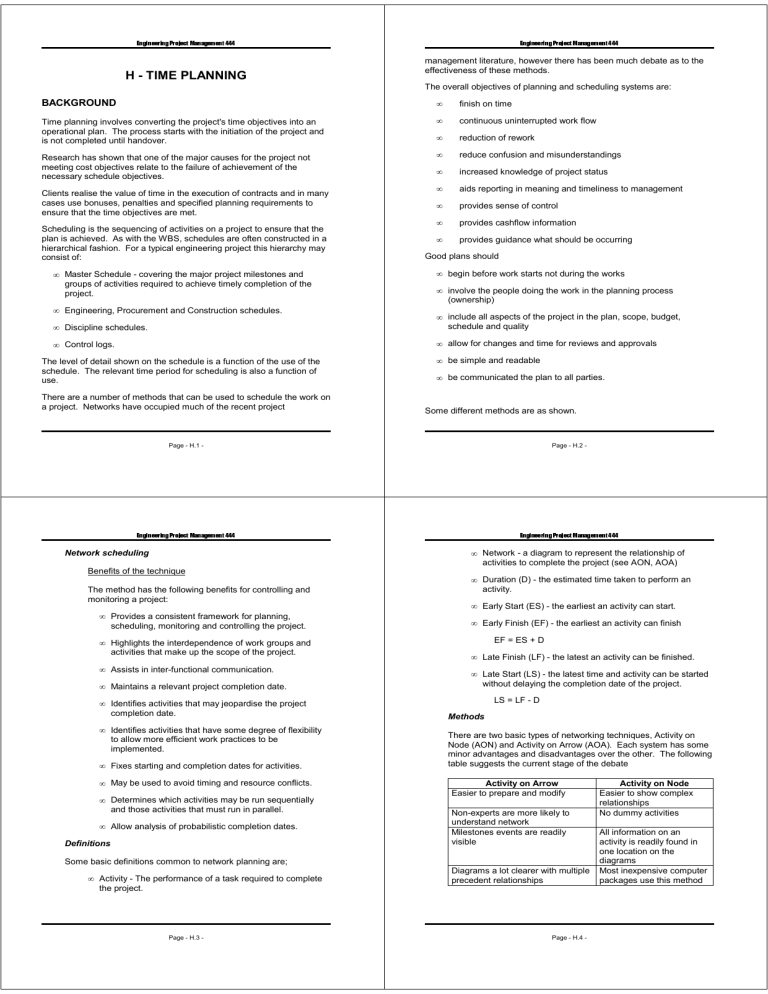

Methods

There are two basic types of networking techniques, Activity on

Node (AON) and Activity on Arrow (AOA). Each system has some

minor advantages and disadvantages over the other. The following

table suggests the current stage of the debate

Activity on Arrow

Easier to prepare and modify

Non-experts are more likely to

understand network

Milestones events are readily

visible

Some basic definitions common to network planning are;

• Activity - The performance of a task required to complete

the project.

Page - H.3 -

Diagrams a lot clearer with multiple

precedent relationships

Page - H.4 -

Activity on Node

Easier to show complex

relationships

No dummy activities

All information on an

activity is readily found in

one location on the

diagrams

Most inexpensive computer

packages use this method

<

=

>

?

=

@

@

A

?

=

>

B

A

C

D

@

E

F

G

H

=

H

>

@

I

@

=

F

J

J

J

K

There seems to be very little real differences to suggest that one

should be used over the other, it is largely a matter of choice. Most

modern programs allow both but are favoured for AON.

WBS Item

AX

A1

A2

BX

B1

B2

CX

C1

C2

C3

C4

C5

C6

C7

To illustrate the method, consider the following:

L

M

N

L

O

O

P

N

L

M

Q

P

R

S

O

T

U

V

W

L

W

M

O

X

O

L

U

Y

Y

Y

Description

Preparatory work

Wake up

Get disrobed

Personal hygiene and Ablutions

Take shower

Arrange hair

Dressing

Put on underwear

Put on pants/skirt

Put on socks

Put on shirt/blouse

Put on tie

Put on shoes

Put on jacket

Time (secs)

0

60

600

350

40

60

45

150

180

100

10

Unless you are unconventional you will possibly adopt the following

sequence:

A1 Wake up, A2 Get undressed, B1 Take a shower, B2 Arrange

hair after shower, C1 Put on underwear or C3 Put on socks or C4

Put on shirt/blouse after shower, C2 Put on pants/skirt after you C1

Underwear on, C6 Put on shoes after pants on and C3 socks on,

C5 put tie on after C4 shirt on, C7 Jacket on after C5 Tie on and B2

arrange hair.

In narrative form this logic is difficult to follow. There are two ways

to describe this logic. Firstly as shown on the following table

\

]

[

^

^

_

]

[

\

`

_

a

b

^

c

d

e

f

[

f

\

^

g

^

[

d

h

h

h

Description

Wake up

Get disrobed

Take shower

Arrange hair

Put on underwear

Put on pants/skirt

Put on socks

Put on shirt/blouse

Put on tie

Put on shoes

Put on jacket

Successors

A2

B1

C1,B2, C4, C3

C7

C2

C6

C6

C5

C7

C7

Get to work

ES

EF

C5 - Put on Tie

Dur 180

Activity

w

w

w

Or as a network diagram as shown over.

s

j

v

r

m

np

o

jk

l

n

m

jm

l

Page - H.7 -

ES

EF

C2 - Put on Pants/skirt

Dur 60

ES

EF

C1 - Put on Underwear

Dur 40

ES

EF

B2 - Arrange Hair

Dur 350.

jk

ES

EF

A2 - Get Disrobed

Dur 60.

i

ES

EF

C7 - Put on Jacket

Dur 10

u

q

ES

EF

C3 - Put on Sox

Dur 45

ES

EF

B1 - Take Shower

Dur 600.

j

s

ES

EF

C6 - Put on Shoes

Dur 100

m

uk

t

Page - H. 8 -

m

ES

EF

A1 - Wake Up

Dur 0.

A1

A2

B1

B2

C1

C2

C3

C4

C5

C6

C7

[

ES

EF

C4 - Put on Shirt/Blouse

Dur 150

Z

Page - H.6 -

8

Page - H.5 -

10

9

1100

1000

900

800

700

600

500

y

|

z

y

400

|

}

Page - H. 1 0 -

Page - H. 9 -

|

~

300

yz

{

}

|

y|

200

¡

¢

£

¤

20

Put on jacket

C7

200

Put on shoes

C6

360

Put on tie

C5

300

90

Put on shirt/blouse

Put on socks

C3

¢

C4

300

240

C2

C1

B2

Put on pants/skirt

Put on underwear

700

200

Arrange hair

Take shower

B1

0

Get disrobed

A2

300

Wake up

A1

Resource

Title

ID

This can be shown as a bar chart as below

yz

100

x

{

¤

¤

¥

§

¨

¦

©

©

ª

¨

¦

§

«

ª

¬

­

©

®

¯

°

±

¦

±

§

©

²

©

¦

¯

³

³

³

TE = (a + 4m + b)/6

Construction and calculations of networks

Network diagrams describe a project in terms of a sequence of

activities and events. An activity is a work task, that is something to

be done.

¦

In normal engineering projects, the first method is usually used due

to experience with the type of work. The second method has a use

when the work is unfamiliar, for example R&D projects.

Float and the critical path.

It is essential to determine what activities are required for the

network. The level of detail required is determined before

construction and the best guide is common sense.

An event represents an instant in time, a major event is usually

termed a milestone.

There are a number of different types of float on a network, the

most common type is total float. Total Float (TF) - the amount of

time an activity can be delayed without delaying the completion of

the project

TF = LF - EF = LS - ES = (LF - ES) - D

To construct the network, the relationships between activities also

need to be known. To determine these relationships for a subject

activity it is essential to:

• Determine what activities are predecessors.

ES

LF

D

• Determine what activities are successors.

• Determine what activities can be done at the same time.

For a network it is only necessary to determine the immediate

successors of an activity. If two activities have a

successor/predecessor relationship, they are termed sequential. If

two or more activities can be performed at the same time they are

parallel.

Calculation of activity times

Activity timing can come from a number of sources. Usually times

are calculated from an estimate of the manhours required to

complete an work item. The hours required are divided by a

notional gang that will undertaken the work. This gives the

duration.

Where probabilistic estimates are taken, the expected time may be

determined from the following formula

Page - H.11 -

Total Slack

If the difference is zero, the activities are deemed to be critical, that

is any change in the duration of the activities will affect the network

completion date as this is the longest path through the network.

The float is in effect the duration that an activity can be increased

before it becomes critical.

In project planning there is much dispute as to who owns the float.

For example a client may suggest a scope change that affects non

critical activities. The debate is to whether the contractor is able to

Page - H.12 -

´

µ

¶

·

µ

¸

¸

¹

·

µ

¶

º

¹

»

¼

¸

½

¾

¿

À

µ

À

¶

¸

Á

¸

µ

¾

Â

Â

Â

Ã

claim a time extension for these changes. Many cases have

investigated this issue, the results are not conclusive, however the

general trends are that the float belongs to the project. Making

judgements on this type of ruling is difficult.

Ä

Å

Æ

Ä

Ç

Ç

È

Æ

Ä

Å

É

È

Ê

Ë

Ç

Ì

Í

Î

Ï

Ä

Ï

Å

Ç

Ð

Ç

Ä

Í

Ñ

Ñ

Ñ

where i = preceding activities.

LF

The total float on a network is often used to determine the tradeoff

between costs and time on a network. The float analysis can be

used to select activities that should be "crashed" at a cost penalty.

LF

Free Float (FF) - the amount of time an activity may be delayed

without delaying the early start times of the immediate following

activity.

D

FFi = ESj min - EFi

Safety

Slack

LF

where i = preceding activity and i = following

activities.

ES

Independent Slack (IS) is the unconditional float on an activity. It is

independent of any other decisions regarding starting times made

elsewhere in the network.

ES

D

ES

IS = max{(ES k min - LF i max -D),0}

Free Slack

ES

Safety Slack (SS) - the amount of time you can delay an activity

given that all preceding activities have been delayed.

SS = LF - LFi max

Page - H.13 -

Ó

Ô

Õ

Ó

Ö

Ö

×

Õ

Ó

Ô

Ø

×

Ù

Ú

Ö

Û

Ü

Ý

Þ

Ó

Þ

Ô

Ö

ß

Ö

Ó

Ü

à

à

à

H o lid a y

Ò

Page - H.14 -

LF

200

190

180

D

LF

Independent

Slack

T a rg e t F in ish

ES

ES

170

160

150

140

130

ï

ï

120

ï

ë

â

î

å

íã

â

100

ì

í

ë

å

æè

ç

Line of Balance

âã

ä

æ

å

A number of other methods exist. Of these, the Line of

Balance is particularly useful for repetitive projects. These

type of projects include roadworks, transmission lines and

pipelines. The method comes from production line

scheduling.

ä

âå

á

âã

90

80

70

60

50

40

The Line of Balance looks at methods to achieve an output by

crew sizes, equipment and other techniques that will match

the schedule time objectives.

30

20

Page - H.15 T im e

W eek 1

W eek 2

W eek 3

W eek 4

W eek 5

W eek 6

W eek 7

W eek 8

W eek 9

W eek 10

W eek 11

W eek 12

W eek 13

W eek 14

W eek 15

10

S ta g e

é

D if ic u lt W o rk

ê

Other time planning methods

Page - E.16 -

110

å

Pre-shutdown

Shutdown

Post Shutdown

2 weeks

Less than 10 hours

1 month

2 months

1 to 5 days

1 month

6 months

6 to 30 days

1 month

ô

ñ

ü

ø

ö

ú

ù

ô

õ÷

ñò

ñô

ñò

ÿ

õ

ô

Page - E.18 -

Monitor Progress Ensure

Daily against

resources

work sheets

properly utilized

Schedule Scope

Changes

Forecast

completion

Identify changes

to planned scope

Determine if

scope change is

necessary

If forecast

completion is

overrun- revisit

costs and

necessity

ý

Shutdown

ñ

Resourcing

Determine

manning for all

disciplines

Determine Tools

and Equipment

required

Detail

Manufactured

Items

ú

Scheduling

Develop work

packs for each

item

Determine

maximum time

frame for

shutdown

þ

Planning

Identify

equipment to be

serviced

Determine Work

Detail

Estimate time for

each item

Identify Critical

Path(s)

ô

Page - E.17 -

þ

Phase

Pre-Shutdown

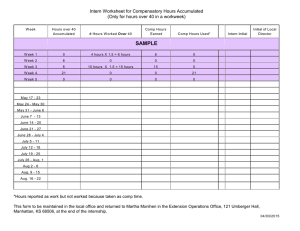

See AON Solver Spreadsheet.

üò

Page - E.19 -

1 month

10 hours to one day

1 month

Duration of Phase in relation to Shutdown

Close out costs

ð

Three stages and durations shown below

Phase

Close out all

contracts

Demobilize

labour

ó

Monitor schedule Determine any

and correct

losses of tools or

sequencing of

equipment

work

ó

Recommissionin

g sequence for

each item

û

Post-Shutdown

þ

Costing

Direct labour

Indirect labour

Tool hire

Equipment Hire

Manufactured

items

Consumables

Travel Expenses

Meals and

Accommodation

Contingency

Allowances

Ensure all

Collect and log

controls are

all costs on a

being maintained daily basis

Timesheets

prepared and

checked for

labour and

Equipment

Organization

Ormganize

mobilization,

Accommodation

and meals

Tools and

Equipment Hire

Tender for offsite

manufacture