Improving Low Power and Shutdown PSA Methods and Data to Permit Better Risk Comparison and Trade-off Decision Making - Responses to the COOPRA Survey

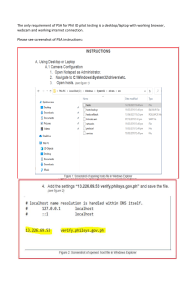

advertisement