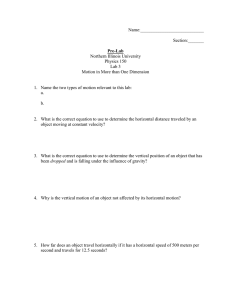

29-11-2022 Operations Strategy Prof.dr. Jan de Vries Department of Operations 29-11-2022 Programme › › › › Introduction Overview lectures Characterizing Processes - complexity Some final remarks Methodology of Operations Management Horizontal structure – – – – Vertical structure – – – – location of stockpoints design (physical) processes the way products and services are made .... levels of planning decisions that have to be made trade-off’s between different performance objectives ..... Organizational structure – – – – nr. 3 what organizational entities can be distinguished allocation of tasks/responsibilities and competences how is co-ordination achieved ..... Horizontal structure Focus of Operations Management Transformation processes performance Organisational embedding nr. 4 Planningand Control systems |5 Operations Strategy Operations strategy is • • • • • • the total pattern of decisions that shape the long term capabilities of any type of operation and their contribution to overall strategy through the ongoing reconciliation of market requirements and operations resources. Operations strategy is the strategic reconciliation of market requirements with operations resources Tangible and Intangible Resources Operations Capabilities Customer Needs Decision Areas Performance Objectives Operations Processes Understanding resources and processes Market Positioning Competitors’ Actions Strategic decisions Required performance Understanding markets |6 Methodology of Operations Management Horizontal structure – – – – Vertical structure – – – – location of stockpoints design (physical) processes the way products and services are made .... levels of planning decisions that have to be made trade-off’s between different performance objectives ..... Organizational structure – – – – nr. 7 what organizational entities can be distinguished allocation of tasks/responsibilities and competences how is co-ordination achieved ..... Horizontal structure Describing/Analysing the horizontal structure High Level of detail Low nr. 8 Horizontal structure Layout of the process Process schemes Basic form (grondvorm) Example of a Basic Form Basic Form: • • • nr. 9 sequence of the flow of materials location of stock points dominant transformation processes (subprocesses) Horizontal structure Some important questions regarding the horizontal structure Do the (sub) processes support the strategic intentions of the operation? Do the sub processes add value Is each subprocess in control? Are the stockpoints necessary? Why are there stockpoints? Who ‘owns’ and has responsibility for the (sub)process What are potential problems within each subprocess How contributes each subprocess to the necessary performance requirement(s)? nr. 10 Horizontal structure Example basic form Patient flows Poliprocess Nurseryprocess X-ray process nr. 11 Horizontal structure Surgeryprocess Understanding the horizontal structure character of the overall process and subprocesses sequence of materials flow location of stock points character of the technology being used scale/the capacity of each unit (are there any bottlenecks??) How are specific performance objectives met – quality – speed – dependability – flexibility – Cost degree of complexity of the horizontal structure . . . . . . . .. nr. 12 Characterizing processes Characterizing complexity Some important characteristics nr. 13 Product-variety Material structure Manufacturing structure Specific character of resources Commonality of raw material Capacity cohesion Uncertainty Characterizing Processes Can be applied for both production and service settings Characterizing the horizontal structure Why are these characteristics so important? In one way or the other the planning and control structure is influenced by these characteristics nr. 14 Characterizing Processes Characterizing transformation processes Product variety – number of different products that can be manufactured Material structure – is related to the complexity of the product itself. Relates for instance to the different types of materials the products are made of (including the materials being used) Manufacturing structure – is related to the complexity of the manufacturing process itself (number of operations, complexity of operations, necessity of using special equipment. . . .). nr. 15 Characterizing Processes Characterizing the transformation process Specific character of the resources being used – flexibility of machines, multi purpose of machines. Flexibility of employees, etc. Commonality of raw material – can raw material/parts be applied for different products (specific versus generic) Capacity cohesion – physical relations between capacities (coupled versus decoupled equipment) Uncertainty – the degree of lacking information in order to make decisions (for example demand, performance within the production process, the supply of materials, …..) nr. 16 Characterizing Processes And again ... companies in one way or the other have to deal with complexity and in many cases complexity heavily affects the planning and control structure of the company nr. 17 Characterizing Processes