Pilot

CNC PILOT

4290

Software version 6.4/7.0

English (en)

6/2003

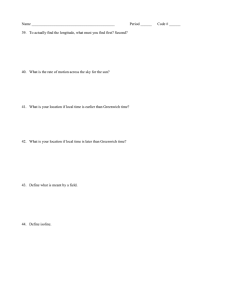

CNC PILOT 4290V7.0—Keyboard

CNC PILOT 4290 V7.0—Keyboard

Manual operating mode

INS (insert)

■ Insert list element

■ Close dialog box, save data

Automatic operating mode

Programming modes (DIN PLUS,

Simulation, TURN PLUS)

Organization modes (Parameter,

Service, Transfer)

Numerals (0...9)

For entering numbers and selecting soft keys

...

Minus

For entering an algebraic sign

Decimal point

Display error status

Call info system

ESC (escape)

■ Go back by one menu level

■ Close dialog box, do not save data

“Continue key”

For special functions (e.g. marking)

DEL (delete)

■ Deletes the list element

■ Deletes the selected character or the character

to the left of the cursor

ALT (alter)

■ Edit the list element

Enter

To confirm your input

Cursor keys

Moves the cursor by one position

in the direction of the arrow (one

character, one field, one line, etc.)

Page Up, Page Down

■ Go to previous/next screen page

■ Go to previous/next dialog box

■ Switch between input windows

...

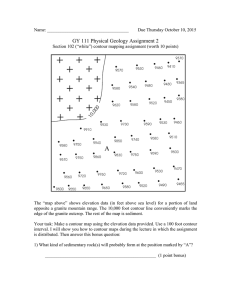

CNC PILOT 4290V6.4—Keyboard

CNC PILOT 4290V6.4—Keyboard

Operating modes key

Call the selection of operating modes

Numerals (0...9)

For entering numbers and selecting soft keys

Display error status

Minus

For entering an algebraic sign

Call the info system

Decimal point

ESC

■ Go back by one menu level

■ Close dialog box, do not save data

Enter

To confirm your input

>> (“continue” key)

For special functions (e.g. marking)

DEL

Delete key

ALT (alter)

■ Edit the list element

INS (insert)

■ Insert list element

■ Close dialog box, save data

...

Cursor keys

Moves the cursor by one position

in the direction of the arrow (one

character, one field, one line, etc.)

Page Up, Page Down

■ Go to previous/next screen page

■ Go to previous/next dialog box

■ Switch between input windows

...

4

The Pilot

Contents

... is your concise programming guide for the HEIDENHAIN

CNC PILOT 4290 contouring control. For more comprehensive information on programming and operating, refer to the

CNC PILOT User's Manual.

DIN Programming ..............................................................

Overview: G Functions for Contour Description ................

6

6

Program Section Codes .....................................................

8

Certain symbols are used in the Pilot to denote specific types

of information:

G Functions for Contour Description ................................. 10

Front, Rear and Lateral Surface Contours .......................... 26

Important note!

Warning: Danger for the user or the machine!

Chapter in User's Manual. Here you will find more

detailed information on the current topic.

The information in this Pilot applies to the CNC PILOT with

the software number 340 340 460-xx (release 6.4) and the

CNC PILOT with the software number 368 650-xx (release

7.0).

Overview: G Functions for the Machining Part ..................

Simple Linear and Circular Movements .............................

Feed Rate, Spindle Speed ..................................................

Tool-Tip and Cutter Radius Compensation (TRK) ................

Datum Shifts, Oversizes ...................................................

Tools, Compensation .........................................................

Turning, Drilling and Threading Cycles ...............................

C-Axis Machining ..............................................................

Other G Functions .............................................................

Subprograms .....................................................................

42

45

48

50

51

57

59

82

90

94

5

DIN Programming

DIN Programming

Program section codes

Page

NC blocks start with the letter “N” followed by a block

number (with up to four digits).

Program section codes

8

Comments are enclosed in parentheses „[...]“. They are

located either at the end of an NC block or in a separate NC

block.

G20-Geo

G21-Geo

Instructions for operation

During editing, the CNC PILOT shows programmed contours

in a maximum of two simulation windows. You can select

the windows from the DIN PLUS main menu (Menu item

”Graphics—Windows”).

■ The starting point of the contour will be marked with a

”small box”

■ If the cursor is located on a block from ”blank or finished

part”, the corresponding contour element will be indicated in

red in the simulation window (”Contour display”)

• Additions/changes to the contour will only be

considered if the ”Graphics” menu item is

reactivated.

• Unambiguous NC block numbers are a prerequisite

for the contour display!

• For programming variables, see ”CNC PILOT 4290

User's Manual”

• For programming in the Y axis, see

”CNC PILOT 4290 with Y Axis User's Manual”

6

Definition of blank

Chuck part, cylinder/tube

Cast part

Basic elements for contour description

G0-Geo

G1-Geo

G2-Geo

G3-Geo

G12-Geo

G13-Geo

Starting point of contour

Line segment

Arc with incr. center dimensioning

Arc with incr. center dimensioning

Arc with abs. center dimensioning

Arc with abs. center dimensioning

Contour form elements

G22-Geo

G23-Geo

G24-Geo

G25-Geo

G34-Geo

G37-Geo

G49-Geo

Recess (standard)

Recess/relief turn

Thread with undercut

Undercut contour

Thread (standard)

Thread (general)

Bore hole at turning center

Page

10

10

Page

11

11

12

12

12

12

Page

13

14

15

16

19

20

22

Overview:

G7-Geo

G8-Geo

G9-Geo

G10-Geo

G38-Geo

G39-Geo

G52-Geo

G95-Geo

G149-Geo

Help commands for contour definition

Precision stop ON

Cycle stop OFF

Precision stop blockwise

Peak-to-valley height

Feed rate reduction

Attributes of superimposed elements

Blockwise oversize

Feed per revolution

Additive compensation

Superimposed contours

G308-Geo

G309-Geo

Beginning of pocket/island

End of pocket/island

Elements of the end face contour

G100-Geo

G101-Geo

G102-Geo

G103-Geo

G300-Geo

G301-Geo

G302-Geo

G303-Geo

G304-Geo

G305-Geo

G307-Geo

G401-Geo

G402-Geo

Starting point of face contour

Line segment on face

Circular arc on face

Circular arc on face

Bore hole on face

Linear slot on face

Circular slot on face

Circular slot on face

Full circle on face

Rectangle on face

Eccentric polygon on face

Linear pattern on face

Circular pattern on face

Page

23

23

23

23

23

24

24

25

25

25

Page

26

26

Elements of the lateral surface contour

G110-Geo

G111-Geo

G112-Geo

G113-Geo

G310-Geo

G311-Geo

G312-Geo

G313-Geo

G314-Geo

G315-Geo

G317-Geo

G411-Geo

G412-Geo

Starting point of lateral surface contour

Line segment on lateral surface

Circular arc on lateral surface

Circular arc on lateral surface

Bore hole on lateral surface

Linear slot, lateral surface

Circular slot on lateral surface

Circular slot on lateral surface

Full circle on cylindrical surface

Rectangle on lateral surface

Eccentric polygon on lateral surface

Linear pattern, lateral surface

Circular pattern, lateral surface

Page

34

34

35

35

36

37

37

37

38

38

39

40

41

Overviesw: Contour description

Help commands for contour description

Page

27

27

28

28

29

30

30

30

31

31

32

32

33

Circular arc on lateral surface

7

Program section codes

Program section codes

When you create a new DIN program, certain program section codes are already entered. Delete or

add codes, depending on the task. A DIN program

must include the codes ”MACHINING” and ”END.”

Overview of program section codes

PROGRAMMKOPF [ PROGRAM HEAD ]

TURRET

CLAMPING DEVICE

ROHTEIL [ BLANK ]

FERTIGTEIL [ FINISHED PART ]

FRONT END

REAR END

CYLINDER SURFACE

AUXILIARY CONTOUR

BEARBEITUNG [ MACHINING ]

ENDE [ END ]

SUBPROGRAM

RETURN

■ SLIDE: NC program is only executed for the indicated slide – No in-

put: NC program is executed for every slide (input: “$1, $2, ...”)

■ UNIT: unit of measurement ”metric/inches”—No input: the unit set

in control parameter 1 is used

The ”Unit” can be programmed only when a new program is

being created (set under PROGRAM HEAD). It is not possible

to post-edit this entry.

TURRET x

contains the assignment for the tool carrier x (x: 1..6). If the tool is described in the data bank, enter the T number and the ID number. Alternately, you can define the tool parameters in the NC program.

Tool data input:

Call the tool input: INS key

T-number: position in the tool carrier

ID (identification number): reference to the tool database– No input: tool data is not included in the tool database.

Simple tool:

■ Only suitable for simple traverse paths and turning cycles (G0...G3,

G12, G13; G81...G88).

PROGRAMMKOPF [ PROGRAM HEAD ]

The PROGRAM HEAD comprises:

■ Organizational information (does not influence

program execution)

■ Setup information (does not influence program

execution)

8

■ There is no regeneration of the contour.

■ Cutter radius compensation is carried out.

■ Data are not stored in the tool database (”Simple tools” have no ID).

Continued

Enhanced input: No limitations for use of the tool (data is transferred

to the tool database during program conversion.)

■ LATERAL SURFACE X.. : section ”Lateral surface

contour” – ”X..”

■ AUXILIARY CONTOUR: indicates further contour

CLAMPING DEVICE x

Defines the type of clamping device X used on the spindle (x: 1..4).

If you do not program CLAMPING DEVICE, the machining simulation

assumes there is no clamping device (see also G65).

Parameters

H:

Clamping device number (reference for G65) – Range: 1 H 9

ID:

Identification number of clamping device

X:

Clamping diameter

Q:

Chucking shape – defines the position of the clamping device reference point (see G65)

ROHTEIL [ BLANK ]

Program section for the definition of the blank.

FERTIGTEIL [ FINISHED PART ]

Program section for the contour definition of the finished part.

Additional program section codes within the finished part definition:

■ FRONT END Z.. : Section ”Front end contour” – ”Z..” defines the position of the front contour.

■ REAR SIDE Z.. : Section ”Rear side contour” – ”Z..” defines the position of the rear side contour.

definitions

If you have several independent contour definitions, then repeated use of the program

section codes (FRONT END, REAR END,

etc.) is permitted.

BEARBEITUNG [ MACHINING ]

Program section for the machining of the workpiece.

MACHINING must be included in your program.

ENDE [ END ]

Ends your NC program. The code END must be

included in your program (replaces M30).

Program section codes

If you do not program TURRET, the tools entered in the turret

table will be used.

SUBPROGRAM ”12345678”

If you define a subprogram within your NC program

(within the same file), it is identified with

SUBPROGRAM, followed by the name of the

subprogram (max. 8 characters).

RETURN

Ends your NC subprogram.

9

Blank material for cylinder/pipe G20-Geo

Definition of blank

G20 defines the contour of a cylinder/hollow cylinder.

Parameters

■ Diameter of cylinder/hollow cylinder

X:

■ Diameter of circumference of polygonal blank

Z:

Length of blank

K:

Right edge (distance between workpiece datum and right edge)

I:

Inside diameter for hollow cylinders

Cast part G21-Geo

G21 generates the contour of the blank part from the contour of the

finished part – plus the ”equidistant allowance P.”

Parameters

P:

Equidistant finishing allowance (reference: finished part contour)

Q:

Bore holes yes/no – default: Q=0

■ Q=0: without bore holes

■ Q=1: with bore holes

10

Starting point of turning contour G0 Geo

G0 defines the starting point of a turning contour.

Basic elements for

contour description

Parameters

X, Z: Starting point of the contour (X diameter value)

Line segment in a contour G1-Geo

G1 defines a line segment in a turning contour.

Parameters

X, Z: End point (X diameter value)

A:

Angle to rotary axis – for angle direction see illustration

Q:

Select point of intersection – default: 0

■ Q=0: Near intersection

■ Q=1: Far intersection

B:

Chamfer/rounding

■ B is undefined: Tangential transition

■ B=0: Nontangential transition

■ B>0: Rounding radius

■ B<0: Chamfer width

E:

Special feed-rate factor (0 < E 1) – default: 1

(special feed rate = active feed rate * E)

11

Circular arc in a contour

Basic elements for

contour description

G2/G3-Geo – incremental, G12/G13-Geo – absolute center

coordinates

G2/G3 or G12/G13 defined a circular arc in a contour. The direction of

rotation is visible in the help graphic.

Parameters

X, Z: End point (X diameter value)

R:

Radius

Q:

Selection of intersection – default: 0

■ Q=0: Far intersection

■ Q=1: Near intersection

B:

Chamfer/ rounding at end of circular arc

■ B no entry: tangential transition

■ B=0: no tangential transition

■ B>0: Radius of rounding

■ B<0: Width of chamfer

E:

Special feed-rate factor (0 < E 1) – default: 1

(special feed rate = active feed rate * E)

Example: G2-Geo

With G2/G3:

I:

Center point incremental (distance from starting point to center

as radius)

K:

Center point incremental (distance from starting point to center)

With G12/G13:

I:

Absolute center (radius)

K:

Absolute center

12

Example: G12-Geo

Recess (standard) G22-Geo

Parameters

X:

Starting point of recess on the end surface (diameter)

Z:

Starting point of recess on lateral surface

I, K: Inside corner

■ I for recess on front face: recess end point (diameter value)

■ K for recess on end face: recess base

■ I for recess on lateral surface: recess base (diameter value)

■ K for recess on lateral surface: recess end point

Ii, Ki: Inside corner – incremental (pay attention to sign !)

■ Ii for recess on end face: recess width

■ Ki for recess on end face: recess depth

■ Ii for recess on lateral surface: recess depth

■ Ki for recess on lateral surface: end point of recess (recess

width)

B:

Outside radius/chamfer (at both ends of the recess) – default: 0

■ B>0: Radius of the rounding

■ B<0: Width of the chamfer

R:

Inside radius (in both corners of recess) – default: 0

Form elements

for contour description

G22 defines a recess on an axis-parallel reference element (G1). G22 is

assigned to the previously programmed reference element.

Program either X or Z.

13

Form elements

for contour description

Recess (general) G23-Geo

G23 defines a recess on a linear reference element (G1). G23 is

assigned to the previously programmed reference element. On the lateral surface the recess can be positioned on an inclined reference

straight.

Parameters

H:

Recess type – default: 0

■ H=0: symmetrical recess

■ H=1: free rotation

X:

Center point of recess on end surface (diameter)

Z:

Center point of recess on lateral surface

I:

Recess depth and position

■ I>0: recess to right of reference element

■ I<0: recess to left of reference element

K:

Recess width (without chamfer/rounding)

U:

Recess diameter (diameter of recess floor) – use only if the

reference element runs parallel to the Z axis.

A:

Recess angle – default: 0

■ with H=0: 0° A < 180° (angle between edges of recess)

■ with H=1: 0° < A 90° (angle between reference straight and

recess edge)

B:

Outside radius/corner. Starting point near corner - default: 0

■ B>0: Radius of rounding

■ B<0: Width of chamfer

P:

Outside radius/corner. Starting point distant from corner - default: 0

■ P>0: Radius of rounding

■ P<0: Width of chamfer

R:

Inside radius (in both corners of recess) – default: 0

Simple recess

The CNC PILOT refers the recess depth to the reference

element. The recess base runs parallel to the reference

element.

14

Recess or free rotation

Thread with undercut G24-Geo

Calling the contour macro:

N..G1 X..Z..B..

/Starting point for thread

N..G24 F..I..K..Z.. /Contours for thread and undercut

N..G1 X..

/Next surface element

Parameters

F:

Thread pitch

I:

Depth of undercut (radius)

K:

Width of undercut

Z:

End point of the undercut

Form elements

for contour description

G24 defines a linear base element, a linear thread (external or internal

thread; metric ISO fine-pitch thread DIN 13 Part 2, Series 1) and a subsequent thread undercut (DIN 76).

• G24 can be used only if the thread is cut in the direction of

contour definition.

• The thread is machined with G31.

15

H:

Undercut contour G25-Geo

Form elements

for contour description

G25 generates the following undercut contours in paraxial contour

corners. The meaning of the parameters depends on the type of

undercut.

If you program G25

■ after the reference element, the undercut is turned at the end of the

reference element.

■ before the reference element, the undercut is turned at the

beginning of the reference element.

Type of undercut – default: 0

■ H=4: undercut form U

■ H=0, 5: undercut form DIN 509 E

■ H=6: undercut form DIN 509 F

■ H=7: thread undercut DIN 76

■ H=8: undercut form H

■ H=9: undercut form K

Calling the contour macro (example):

N..G1 Z..

/Linear element as reference

N..G25 H..I..K.. .. /Undercut contour

N..G1 X..

/Next surface element

Parameters

Undercut form U (H=4)

Parameters

I:

Depth of undercut (radius)

K:

Width of undercut

R:

Inside radius (in both corners of recess) – default: 0

P:

Outside radius/chamfer – default: 0

■ P>0: radius of the rounding

■ P<0: width of the chamfer

Continued

16

Undercut form U (H=4)

Parameters

I:

Depth of undercut (radius)

K:

Width of undercut

R:

Undercut radius (in both corners of the undercut)

W:

Undercut angle

If you do not enter any parameters the CNC PILOT calculates

the values from the diameter (see User's Manual, section

“Undercut Parameters DIN 509 E”).

Undercut DIN 509 E (H=0, 5)

Undercut DIN 509 F (H=6)

Form elements

for contour description

Undercut DIN 509 E (H=0, 5)

Parameters

I:

Depth of undercut (radius)

K:

Width of undercut

R:

Undercut radius (in both corners of the undercut)

P:

Transverse depth

W:

Undercut angle

A:

Transverse angle

If you do not enter any parameters the CNC PILOT calculates

the values from the diameter (see User's Manual, section

“Undercut Parameters DIN 509 F”).

Continued

Undercut DIN 509 F (H=6)

17

Form elements

for contour description

Undercut DIN 76 (H=7)

Parameters

I:

Depth of undercut (radius)

K:

Width of undercut

R:

Undercut radius (in both corners of the undercut) – default:

R=0.6*I

W:

Undercut angle – default: 30°

Undercut DIN 76 (H=7)

Undercut form H (H=8)

If you do not enter W, it will be calculated on the basis of K and R. The

final point of the undercut is then located at the ”final point contour.”

Parameters

K:

Width of undercut

R:

Undercut radius – no value: the circular element is not machined

W:

Plunge angle – no value: W is calculated

Continued

18

Undercut form H (H=8)

Parameters

I:

Undercut depth

R:

Undercut radius – no value: the circular element is not machined

W:

Undercut angle

A:

Angle to linear axis – default: 45°

Undercut form K (H=9)

Form elements

for contour description

Undercut form K (H=9)

Thread (standard) G34-Geo

G34 defines a simple or an interlinked external or internal thread (metric

ISO fine-pitch thread DIN 13 Series 1). Threads are interlinked by

programming several G01/G34 blocks after each other.

Parameters

F:

Thread pitch – no value: pitch from the standard table

• You need to program a linear contour element as a reference

before G34 or in the NC block containing G34.

• The thread is cut with G31.

19

Thread (general) G37-Geo

Form elements

for contour description

G37 defines the different types of thread. Threads are interlinked by

programming several G01/G34 blocks after each other.

20

Parameters

Q:

Type of thread – default: 1

■ Q=1: metric ISO fine-pitch thread (DIN 13 Part 2, Series 1)

■ Q=2: metric ISO thread (DIN 13 Part 1, Series 1)

■ Q=3: metric ISO taper thread (DIN 158)

■ Q=4: metric ISO tapered fine-pitch (DIN 158)

■ Q=5: metric ISO trapezoid thread (DIN 103 Part 2, Series 1)

■ Q=6: flat metric trapezoid thread (DIN 308 Part 2, Series 1)

■ Q=7: metric buttress thread (DIN 13 Part 2, Series 1)

■ Q=8: cylindrical round thread (DIN 405 Part 1, Series 1)

■ Q=9: cylindrical Whitworth thread (DIN 259)

■ Q=10: tapered Whitworth thread (DIN 2999)

■ Q=11: Whitworth pipe thread (DIN 2999)

■ Q=12: nonstandard thread

■ Q=13: UNC US coarse thread

■ Q=14: UNF US fine-pitch thread

■ Q=15: UNEF US extra-fine-pitch thread

■ Q=16: NPT US taper pipe thread

■ Q=17: NPTF US taper dryseal pipe thread

■ Q=18: NPSC US cylindrical pipe thread with lubricant

■ Q=19: NPFS US cylindrical pipe thread without lubricant

F:

Thread pitch – must be entered for Q=1, 3..7, 12.

P:

Thread depth – enter only for Q=12.

K:

Runout length (for threads without undercut) –

default: 0

Continued

• Program a linear contour element as a

reference before G37.

• The thread is cut with G31.

• For standard threads, the parameters P, R,

A and W are defined by the CNC PILOT.

• Use Q=12 if you wish to use individual

parameters.

The thread is generated to the length of the

reference element. For the machining of

threads without an undercut, it is necessary

to program an additional linear element so

that the overrun can be executed by the CNC

PILOT without danger of collision.

H:

A:

W:

R:

E:

Reference point (position of thread runout) – default: 0

■ D=0: runout at end of reference element

■ D=1: runout at beginning of reference element

Number of grooves – default: 1

Edge angle left – enter only for Q=12.

Edge angle right – enter only for Q=12.

Thread width – enter only for Q=12.

Variable pitch (increases/reduces the pitch per revolution by E) –

default: 0

Form elements

for contour description

D:

21

Bore hole (centered) G49-Geo

Form elements

for contour description

G49 defines a single bore hole with countersink and thread at the

turning center (front or end face).

Parameters

Z:

Starting position for hole (reference point)

B:

Bore hole diameter

P:

Depth of hole (excluding point)

W:

Point angle – default: 180°

R:

Countersinking diameter

U:

Countersinking depth

E:

Countersinking angle

I:

Thread diameter

J:

Thread depth

K:

Thread runout length

F:

Thread pitch

V:

Left-hand or right-hand thread - default: 0

■ V=0: Right-hand thread

■ V=1: Left-hand thread

A:

Angle (position of bore hole) – default: 0

■ A=0: front end

■ A=180: tail end

O:

Centering diameter

• G49 is programmed in the FINISHED PART section (not in

the FRONT or REAR SIDE section).

• The contour defined with G49 is machined with G71...G74.

22

Accurate stop ON

Accurate stop OFF

Accurate stop blockwise

influences finishing feed rate for total contour

influences finishing feed rate for basic contour elements block

by block

G39 Only for form elements:

■ influences finishing feed rate

■ additive compensation values

■ equidistant finishing allowances

G52 Equidistant finishing allowances – blockwise

G95 defines finishing feed rate for total contour

G149 additive compensation values for total contour

Accurate stop ON G7-Geo

G7 switches the ”precision stop” on modally. In a ”precision stop,” the

CNC PILOT does not start the next block until the ”tolerance window”

around the end point is reached (for tolerance window, see machine

parameters 1106, 1156, ...).

• The NC block containing G7 is also executed with a precision

stop.

• ”Precision stop” is used for basic contour elements that are

executed with G890 or G840.

Precision stop OFF G8-Geo

G8 switches the precision stop off. The block containing G8 is executed

without a precision stop.

Blockwise accurate stop G9-Geo

G9 activates a precision stop for the NC block in

which it is programmed (see also ”G7 Geo”).

Peak-to-valley height (surface texture)

G10-Geo

G10 influences the finishing feed rate of G890 and

thus determines the surface roughness of the

workpiece.

Basics of programming

■ The peak-to-valley height activated with G10 is modal.

■ G10 without parameters deactivates peak-to-valley

height.

■ G95 Geo deactivates peak-to-valley height.

■ G10 RH... (without ”H”) overwrites the valid peakto-valley roughness block by block.

■ G38 Geo overwrites the valid peak-to-valley

roughness block by block.

Help commands for

contour description

Overview: Help commands for contour description

G7

G8

G9

G10

G38

Parameters

H:

Type of surface texture (see also DIN 4768)

■ H=1: general roughness (profile depth) Rt1

■ H=2: average roughness Ra

■ H=3: mean roughness Rz

RH: Peak-to-valley roughness (in µm, inches: µinch)

The peak-to-valley height applies only for

basic contour elements.

23

Feed rate reduction factor G38-Geo

Help commands

for contour description

G38 defines a special feed rate for G890.

24

Parameters

E:

Special feed-rate factor (0 < E 1) – default: 1

(special feed rate = active feed rate * E)

Basics of programming

■ G38 is a non-modal function.

■ G38 is programmed before the contouring

element for which it is destined.

■ G38 replaces another special feed rate or a

programmed peak-to-valley height.

The ”special feed rate” applies only for basic

contour elements.

Attributes for superimposed elements G39-Geo

G39 influences the machining of G890 for the superimposed

elements (form elements):

✲■ Chamfers/rounding arcs (for connecting base elements)

■ Undercuts

■ Recesses

Influence on machining:

■ Special feed rate

■ Peak-to-valley height

■ Additive D compensation

■ Equidistant oversizes

Parameters

F:

Feed per revolution

V:

Type of surface texture (see also DIN 4768)

■ V=1: general roughness (profile depth) Rt1

■ V=2: average roughness Ra

■ V=3: mean roughness Rz

RH: Peak-to-valley height (µm, inch mode: µinch)

D:

Number of the additive compensation (901 D 916)

P:

H:

E:

Finishing allowance (radius)

(Translation of P) absolute / additive – default: 0

■ H=0: P replaces G57/G58 allowances

■ H=1: P is added to G57/G58 allowances

Special feed-rate factor (0 < E 1) – default: 1

(special feed rate = active feed rate * E)

Basics of programming

■ G39 is a non-modal function.

■ G39 is programmed before the contour element

for which it is destined.

■ G50 before a cycle (MACHINING section) switches

G39 oversizes for this cycle off.

Only use peak-to-valley height (”V, RH”),

finishing allowance (”F”) and special feed

rate (”E”) alternately!

Additive compensation G149-Geo

G52 defines an equidistant finishing allowance which is taken into

consideration in G810, G820, G830, G860 and G890.

The CNC PILOT manages 16 tool-independent

correction values.

Basics of programming

■ G52 is a non-modal function.

■ G52 is programmed in the NC block containing the contour element

for which it is destined.

■ G50 before a cycle (MACHINING section) switches G52 oversizes for

this cycle off.

To activate the additive correction function, program

G149 followed by a „D number“ (for example, G149

D901). ”G149 D900” resets the additive

compensation function.

Parameters

P:

Finishing allowance (radius)

H:

(Translation of P) absolute / additive – default: 0

■ H=0: P replaces G57/G58 allowances

■ H=1: P is added to G57/G58 allowances

Basics of programming

■ Additive compensation is effective from the block

in which G149 is programmed.

■ An additive compensation remains active until:

• the next ”G149 D900”

• the end of the finished part description

Parameters

D:

Additive compensation - Default: D900

Range: 900 to 916

Help commands for

contour description

Blockwise finishing allowance G52-Geo

Feed rate per revolution G95-Geo

G95 influences the finishing feed rate of G890.

Note the direction of contour description!

Basics of programming

■ G95 is a modal function

■ G10 switches the G95 finishing feed rate off.

Parameters

F:

Feed per revolution

• Use peak-to-valley height and finishing feed rate alternatively.

• The G95 finishing feed rate replaces a finishing feed rate

defined in the machining program.

25

Start of pocket/island G308-Geo

G308 defines a new reference level/reference diameter for

hierarchically nested front face or lateral surface contours.

Overlapped contours

Parameters

P:

Depth for pocket, height for islands

The algebraic sign of ”Depth P” defines the position of the milling

contour:

■ P<0: Pocket

■ P>0: Island

Section

P

Surface

Milling floor

FRONT END

FRONT END

REAR END

REAR END

CYLINDER SURFACE

CYLINDER SURFACE

P<0

P>0

P<0

P>0

P<0

P>0

Z

Z+P

Z

Z–P

X

X+(P*2)

Z+P

Z

Z–P

Z

X+(P*2)

X

The milling cycles machine from the ”surface” toward the ”milling

floor.”

X:

Z:

P:

Reference diameter from the section code

Reference plane from the section code

”Depth” from G308 or from the cycle parameters

End pocket/island G309-Geo

G309 ends a reference level. Every reference plane defined with G308

must be ended with G309!

26

• Note with ”P”: the addition of a negative

number reduces the result, and the

subtraction of a negative number increases

the result.

• Island: The area-milling cycles machine

the complete area specified in the contour

definition. Islands that are defined within

this area are not considered.

Starting point of end face contour G100-Geo

Parameters

X, C: Starting point in polar coordinates (diameter, starting angle)

XK,YK: Starting point in Cartesian coordinates

Base elements for

front/end face contour

G100 defines the starting point of an end face contour.

Linear segment in end face contour G101-Geo

G101 defines a line segment in an end face contour.

Parameters

X, C: End point in polar coordinates (diameter, end angle)

XK,YK: End point in Cartesian coordinates

A:

Angle to positive XK-axis

B:

Chamfer/rounding

■ B is undefined: Tangential transition

■ B=0: Nontangential transition

■ B>0: Rounding radius

■ B<0: Chamfer width

Q:

Select point of intersection – default: 0

■ Q=0: Near intersection

■ Q=1: Far intersection

27

Circular arc in front end contour G102-/G103-Geo

Base elements for

front/end face contour

G102/G103 defines a circular arc in a front/end face contour. The

direction of rotation is visible in the help graphic.

Parameters

X, C: End point in polar coordinates (diameter, end angle)

XK,YK: End point in Cartesian coordinates

R:

Radius

I, J: Center in Cartesian coordinates

Q:

Selection of intersection – default: 0

■ Q=0: Far intersection

■ Q=1: Near intersection

B:

Chamfer/ rounding at end of circular arc

■ B no entry: tangential transition

■ B=0: no tangential transition

■ B>0: Radius of rounding

■ B<0: Width of chamfer

G102-Geo

The end point may not be the same as the starting point (not a

full circle).

28

G103-Geo

G300 defines a bore hole with countersink and thread on the front/end

face.

Parameters

XK,YK: Center of hole

B:

Hole diameter

P:

Depth of hole (excluding point)

W:

Point angle – default: 180°

R:

Countersinking diameter

U:

Countersinking depth

E:

Countersinking angle

I:

Thread diameter

J:

Thread depth

K:

Thread runout length

F:

Thread pitch

V:

Left-hand or right-hand thread - default: 0

■ V=0: Right-hand thread

■ V=1: Left-hand thread

A:

Angle (reference: Z-axis)

■ Front end – default: 0° (range: –90° < A < 90°)

■ Rear end – default: 180° (range: 90° < A < 270°)

O:

Centering diameter

Figures on end face contour

Bore hole on end face G300-Geo

Use G71...G74 to machine bore holes defined with G300-Geo.

29

Figures on end face contour

Linear slot on the end face G301-Geo

G301 defines a linear slot on the front/rear end face.

Parameters

XK,YK: Center of slot

A:

Angle of slot length (reference: XK-axis) – default: 0°

K:

Slot length

B:

Slot width

P:

Depth/height – no entry: ”P” from G308

■ P<0: Pocket

■ P>0: Island

Circular slot on the front end G302-/G303-Geo

G302/G303 defines a circular slot on the front/rear end face.

Parameters

I, J: Center of slot curvature

R:

Curvature radius (reference: center point path of the slot)

A:

Angle of slot starting point (reference: XK-axis) – default: 0

W:

Angle of slot end point (reference: XK-axis)

B:

Slot width

P:

Depth/height – no entry: ”P” from G308

■ P<0: Pocket

■ P>0: Island

30

Example: G302-Geo

G304 defines a full circle on the front/rear end face.

Parameters

XK,YK: Circle center

R:

Circle radius

P:

Depth/height – no entry: ”P” from G308

■ P<0: Pocket

■ P>0: Island

Figures on end face contour

Full circle on front end face G304-Geo

Rectangle on end face G305-Geo

G305 defines a rectangle on the front/rear end face.

Parameters

XK,YK: Center of rectangle

A:

Angle to longitudinal axis of rectangle (reference: XK-axis) – default:

0°

K:

Length of rectangle

B:

(Height) width of rectangle

R:

Chamfer/rounding - default: 0

■ R>0: Radius of rounding

■ R<0: Width of chamfer

P:

Depth/height – no entry: ”P” from G308

■ P<0: Pocket

■ P>0: Island

31

Figures on end face contour

Regular polygon on end face G307-Geo

G307 defines a regular polygon on the front/rear end face.

Parameters

XK,YK: Polygon center point

Q:

Number of edges (Q3)

A:

Angle to a polygon side (reference: XK-axis) – default: 0°

K:

Edge length

■ K>0: Edge length

■ K<0: Key width (inside diameter)

R:

Chamfer/rounding - default: 0

■ R>0: Radius of rounding

■ R<0: Width of chamfer

P:

Depth/height – no entry: ”P” from G308

■ P<0: Pocket

■ P>0: Island

Linear pattern on end face G401-Geo

G401 defines a linear pattern on the front/rear end face. G401 is

effective for the bore hole/figure defined in the following block

(G300..305, G307).

Parameters

Q:

Number of figures

XK,YK: Starting point of pattern

I, J: End point of pattern

Ii, Ji: Distance between two figures (in XK, YK direction)

A:

Angle to the longitudinal axis of the pattern (reference: XK-axis)

R:

Total length of pattern

Ri:

Distance between two figures (pattern distance)

32

G402 defines a circular pattern on the front/rear end face. G402 is

effective for the figure defined in the following block (G300..305, G307).

Programming notes

■ Program the hole/figure in the following block without a center –

exception: circular slot.

■ The milling cycle (MACHINING section) calls the hole/figure in the

following block - not the pattern definition.

Parameters

Q:

Number of figures

K:

Pattern diameter

A, W: Starting angle, end angle – position of first/last figure (reference:

XK-axis) – default: A=0°; W=360°

Wi: Angle between two figures

V:

Direction (orientation) – default: 0

■ V=0 – without W: Distribution over complete circle

■ V=0 – with W: Distribution over long arc

■ V=0 – with Wi: Algebraic sign of Wi defines the direction

(Wi<0: Pattern in clockwise direction)

■ V=1 – with W: Pattern in clockwise direction

■ V=1 – with Wi: Pattern in clockwise direction (algebraic sign of

Wi is without meaning)

■ V=2 – with W: Pattern counterclockwise

■ V=2 – with Wi: Pattern counterclockwise (algebraic sign of Wi

has no effect)

XK,YK: Center of pattern

H:

Position of figures – default: 0

■ H=0: Normal position – figures are rotated about the circle

center (rotation)

■ H=1: Original position – position of figure remains the

unchanged with respect to the coordinate system (translation)

Figures on end face contour

Circular pattern on end face G402-Geo

33

Starting point of lateral surface contour G110-Geo

Basic elements of

lateral surface contour

G110 defines the starting point of a lateral surface contour.

Parameters

Z, C: Starting point of contour (starting point, starting angle)

CY: Starting angle as linear dimension

Program either Z, C or Z, CY.

Straight line in a lateral surface contour G111-Geo

G111 defines a line segment in a lateral surface contour.

Parameters

Z, C: End point, end angle

CY: End angle as linear dimension

A:

Angle (reference: negative Z axis)

B:

Chamfer/rounding

■ B is undefined: Tangential transition

■ B=0: Nontangential transition

■ B>0: Rounding radius

■ B<0: Chamfer width

Q:

Select point of intersection – default: 0

■ Q=0: Near intersection

■ Q=1: Far intersection

Program either Z, C or Z, CY.

34

Circular arc in lateral surface contour G112-/G113-Geo

Parameters

Z, C: End point, end angle

CY: End angle as linear dimension

R:

Radius

K:

Center point (in Z direction)

W:

Angle of the center point

J:

Angle of the center point as a linear value

Q:

Selection of intersection – default: 0

■ Q=0: Far intersection

■ Q=1: Near intersection

B:

Chamfer/rounding

■ B is undefined: Tangential transition

■ B=0: Nontangential transition

■ B>0: Rounding radius

■ B<0: Chamfer width

G112-Geo

Basic elements of

lateral surface contour

G112/G113 defines a circular arc in a lateral surface contour. The

direction of rotation is visible in the help graphic.

G113-Geo

35

• Program either Z, C or Z and CY, or K, W or K and J.

• Program either center or radius.

• For radius: only arcs 180° possible

Bore hole on lateral surface G310-Geo

Figures on the

lateral surface

G310 defines a bore hole with countersink and thread on the lateral

surface.

Parameters

Z, C: Center point of bore hole (position, angle)

CY: Angle as linear dimension

B:

Hole diameter

P:

Depth of hole (excluding point)

W:

Point angle – default: 180°

R:

Countersinking diameter

U:

Countersinking depth

E:

Countersinking angle

I:

Thread diameter

J:

Thread depth

K:

Thread runout length

F:

Thread pitch

V:

Left-hand or right-hand thread - default: 0

■ V=0: Right-hand thread

■ V=1: Left-hand thread

A:

Angle (reference: Z axis) – default: 90° = vertical hole (range:

0° < A < 180°)

O:

Centering diameter

Use G71...G74 to machine contours defined with G310.

36

Linear slot on lateral surface G311-Geo

G311 defines a linear slot on the lateral surface.

Figures on the

lateral surface

Parameters

Z, C: Center point of slot (position, angle)

CY: Angle as linear dimension

A:

Angle to longitudinal axis of slot (reference: Z-axis) – default: 0°

K:

Slot length

B:

Slot width

P:

Pocket depth – no entry: ”P” from G308

Circular groove on lateral surface G312-/G313-Geo

G312/G313 defines a circular slot on the lateral surface.

Parameters

Z, C: Center of curvature of slot (position, angle)

CY: Angle as linear dimension

R:

Curvature radius (reference: center point path of the slot)

A:

Angle of slot starting point (reference: Z axis)

W:

Angle of slot end point (reference: Z axis)

B:

Slot width

P:

Pocket depth – no entry: ”P” from G308

Example: G312-Geo

37

Full circle on lateral surface G314-Geo

G314 defines a full circle on the lateral surface.

Figures on the

lateral surface

Parameters

Z, C: Circle center (position, angle)

CY: Angle as linear dimension

R:

Circle radius

P:

Pocket depth – no entry: ”P” from G308

Rectangle on lateral surface G315-Geo

G315 defines a rectangle on the lateral surface.

Parameters

Z, C: Center point of rectangle (position, angle)

CY: Angle as linear dimension

A:

Angle to longitudinal axis of rectangle (reference: Z-axis) – default: 0°

K:

Length of rectangle

B:

Width (height) of the rectangle

R:

Chamfer/rounding - default: 0

■ R>0: Radius of rounding

■ R<0: Width of chamfer

P:

Pocket depth – no entry: ”P” from G308

38

Regular polygon on lateral surface G317-Geo

Parameters

Z, C: Center point of polygon (position, angle)

CY: Angle as linear dimension

Q:

Number of edges (Q3)

A:

Angle to a polygon side (reference: Z-axis) – default: 0°

K:

Edge length

■ K>0: Edge length

■ K<0: Key width (inside diameter)

R:

Chamfer/rounding - default: 0

■ R>0: Radius of rounding

■ R<0: Width of chamfer

P:

Pocket depth – no entry: ”P” from G308

Figures on the

lateral surface

G317 defines a regular polygon on the lateral surface.

39

Linear pattern on lateral surface G411 Geo

Figures on the

lateral surface

G411 defines a linear pattern on the lateral surface. G411 is effective for

the bore hole/figure defined in the following block (G310..315, 317).

40

Parameters

Q:

Number of figures

Z, C: Starting point, starting angle of pattern

K, W: End point, end angle of pattern

Ki:

Distance between the figures (in Z-direction)

Wi: Angular distance between the figures

A:

Angle of pattern length axis (reference: Z axis)

R:

Total length of pattern

Ri:

Distance between two figures (pattern distance)

If you program Q, Z and C, the bore holes/figures will be

ordered in a regular manner along the circumference.

Circular pattern on lateral surface G412 Geo

G412 defines a circular pattern on the lateral surface. G412 is effective

for the bore hole/figure defined in the following block (G310..315, 317).

Parameters

Q:

Number of figures

K:

Diameter of circle

A, W: Starting angle, end angle – position of first/last figure (reference:

Z-axis) – default: A=0°; W=360°

Wi: Distance between two figures

V:

Direction (orientation) – default: 0

■ V=0 – without W: Distribution over complete circle

■ V=0 – with W: Distribution over long arc

■ V=0 – with Wi: Algebraic sign of Wi defines the direction

(Wi<0: Pattern in clockwise direction)

■ V=1 – with W: Pattern in clockwise direction

■ V=1 – with Wi: Pattern in clockwise direction (algebraic sign of

Wi is without meaning)

■ V=2 – with W: Pattern counterclockwise

■ V=2 – with Wi: Pattern counterclockwise (algebraic sign of Wi

has no effect)

Z, C: Position, angle to midpoint of pattern

H:

Position of figures – default: 0

■ H=0: Normal position – figure is rotated about the circle center

(rotation)

■ H=1: Original position – position of figure remains the

unchanged with respect to the coordinate system (translation)

Figures on the

lateral surface

Programming notes

■ Program the hole/figure in the following block without a center –

exception: circular slot.

■ The milling cycle (MACHINING section) calls the hole/figure in the

following block - not the pattern definition.

41

Overview: machining part

G Functions for Machining

The following functions must be preceded with the section

code MACHINING.

For contour-based turning cycles define the reference to the

contour description in ”NS, NE.” You can determine this

reference as follows:

Activate contour display (menu item ”Graphic”).

Place the cursor on the ”NS/NE” field and press the

Continue key.

Select the desired contour element with the left/right arrow

key.

The up/down arrow keys can be used to switch between

several contours (also end face contours, etc.)

Transfer the block number of the contour element (”Enter”

key).

If you activate the up/down arrow keys, the

CNC PILOT also considers contours that are not

displayed on the screen.

Tool positioning without machining

G0

Positioning in rapid traverse

G14 Approach to the tool change position

G701 Rapid traverse to machine coordinates

Page

45

45

46

Simple Linear and Circular Paths

G1

Linear path

G2

Circular path

G3

Circular path

G12 Circular path

G13 Circular path

Page

46

47

47

47

47

Feed rate and spindle speed

Gx26 Speed limit *

G48 Acceleration (slope)

G64 Discontinuous feed rate

Gx93 Feed rate per tooth *

G94 Feed per minute

Gx95 Feed in revolutions

Gx96 Constant surface speed

Gx97 Spindle speed

Page

48

48

49

49

49

49

49

49

Cutter radius compensation (TRC/MCRC)

G40 Switch off TRC/MCRC

G41 TRC/MCRC left

G42 TRC/MCRC right

Page

50

50

50

* ”x” = number of the spindle (0...3)

42

Page

51

51

52

52

52

52

63

54

82

Allowances, safety clearances

G47 Set safety clearances

G50 Switch off allowance

G57 Paraxial allowance

G58 Contour-parallel allowance

G147 Safety clearance (milling)

Page

55

55

56

56

55

Tools, types of compensation

T

Tool change

G148 (Changing the) correction of cut

G149 Additive correction

G150 Compensate right tool tip

G151 Compensate left tool tip

Page

57

57

58

58

58

Simple turning cycles

G80 End of cycle

G81 Simple longitudinal roughing

G82 Simple face roughing

G83 Simple contour-parallel roughing

G85 Undercuts

G86 Simple recessing cycle

G87 Transition radii

G88 Chamfers

Page

59

59

59

60

61

63

64

64

Contour-determined turning cycles

G810 Longitudinal roughing cycle

G820 Face roughing cycle

G830 Contour-parallel roughing cycle

G835 Contour-parallel with neutral tool

G860 Universal recessing cycle

G866 Simple recessing cycle

G869 Recess turning cycle

G890 Finishing cycle

Page

65

65

67

68

69

70

71

72

Thread cycle group

G31 Thread cycle

G32 Single thread cycle

G33 Single thread cut

Page

74

75

76

Drilling cycle group

G36 Tapping

G71 Simple drilling cycle

G72 Boring, sinking, etc.

G73 Tapping cycle

G74

Deep drilling cycle

Page

77

78

79

80

81

C axis

G120 Reference diameter for cylinder

surface machining

G152 Datum shift C-axis

G153 Standardize C-axis

Page

End face machining

G100 Rapid traverse, front/rear face

G101 Linear movement, front/rear face

G102 Circular arc, front/rear face

G103 Circular arc, front/rear face

Page

83

83

84

84

Overview: machining part

Datum shift

Overview Datum shifts

G51 Datum shift (relative)

G53 Parameter-dependent datum shift

G54 Parameter-dependent datum shift

G55 Parameter-dependent datum shift

G56 Additive datum shift (relative)

G59 Datum shift (absolute)

G121 Contour mirroring/shifting

G152 Datum shift C-axis

82

82

82

43

Overview:

G-functions for machining part

44

Cylindrical surface machining

G110 Rapid traverse, cylindrical surface

G111 Linear movement, cylindrical surface

G112 Circular arc, cylindrical surface

G113 Circular arc, cylindrical surface

G120 Reference diameter for cylinder

surface machining

Page

85

85

86

86

Milling Cycles

G840 Contour milling

G845 Pocket milling – roughing

G846 Pocket milling – finishing

Page

87

89

89

Other G Functions

G4

Dwell time

G7

Accurate stop ON

G8

Accurate stop OFF

G9

Block precision stop

G60 Deactivate protection zone

G65 Chucking equipment for graphics

G98 Assignment spindle – workpiece

G121 Contour mirroring/shifting

G702 Regeneration of contour storing/loading

G703 Regeneration of contour ON/OFF

G720 Spindle synchronization

G905 Measuring C-angle offset

G918 Feedfor ward control ON/OFF

G919 Spindle override 100%

G920 Deactivate datum shift

G921 Deactivate datum shift and tool

dimensions

Page

90

90

90

90

90

91

91

54

92

92

92

92

93

93

93

82

93

Other G Functions

G980 Activate datum shift

G981 Activate datum shift and tool

dimensions

Page

93

Subprograms

Subprogram call

Page

94

See User's Manual

G15 Moving a rotary axis

G30 Converting

G62 One-sided synchronization

G63 Synchronous start of slide

G119 Select C axis

G162 Set synchronizing mark

G192 Minute feed rate for rotary axes

G204 Wait for moment

G600 Tool preselection in magazine/chain

G601 Inserting tool from magazine into carrier

G710 Linking tool dimensions

G711 Activate magazine tool

G717 Update nominal values

G718 Servo lag

G900..999 Special G functions

93

Rapid traverse G0

The tool moves at rapid traverse along the shortest path to the ”target

point.”

Tool positioning

without machining

Parameters

X, Z: Diameter, length to target point (X diameter)

Tool change point G14

The slide moves in rapid traverse to the tool change position. In setup

mode, define permanent coordinates for the tool change.

Parameters

Q:

Sequence – default: 0

0:

Diagonal path of traverse

1:

First in X axis, then in Z

2:

First in Z axis, then in X

3:

X axis only

4:

Z direction only

45

Rapid traverse to machine coordinates G701

The slide moves at rapid traverse on the shortest path to the ”target

point.”

Simple linear

and circular paths

Parameters

X, Z: End point (X diameter value)

”X, Z” refer to the machine datum and the slide datum.

Linear path G1

The tool moves at the programmed feed rate on a line to the ”end point.”

46

Parameters

X, Z: Diameter, length to end point (X diameter)

A:

Angle (angular direction: see graphic support window)

Q:

Selection of intersection – default: Q=0

■ Q=0: Near intersection

■ Q=1: Far intersection

B:

Chamfer/rounding

■ B is undefined: Tangential transition

■ B=0: Nontangential transition

■ B>0: Rounding radius

■ B<0: Chamfer width

E:

Special feed-rate factor (0 < E 1) – default: 1

(special feed rate = active feed rate * E)

Circular path

G2, G3 – incremental, G12, G13 – absolute center coordinates

The tool moves in a circular arc at the feed rate to the ”end point.” The

direction of rotation of G2/G3 or G12/G13 is shown in the graphic

support window.

Parameters

X, Z: Diameter, length to end point (X diameter)

R:

Radius (0 < R 200 000 mm)

Q:

Selection of intersection – default: Q=0

■ Q=0: Far intersection

■ Q=1: Near intersection

B:

Chamfer/rounding

■ B is undefined: Tangential transition

■ B=0: Nontangential transition

■ B>0: Rounding radius

■ B<0: Chamfer width

E:

Special feed-rate factor (0 < E 1) – default: 1

(special feed rate = active feed rate * E)

Example: circular path G2

Simple linear

and circular paths

The special feed rate applies to chamfer/rounding.

Example: circular path G12

47

With G2, G3:

I, K: Center point incremental (distance starting point – center point;

I radius)

With G12, G13:

I, K: Absolute center (I radius)

Feed rate and spindle speed

Speed limitation

G26: Spindle; Gx26: Spindle x (x: 1...3)

G26/Gx26 limits the speed of spindle x. The speed limit remains in

effect until program end or until it is replaced by a new G26/Gx26.

Parameters

S:

(Maximum) speed

Acceleration (slope) G48

G48 specifies the approaching acceleration, braking acceleration, and

the maximum feed rate. G48 is a modal function.

Without G48 the following parameter values apply:

■ Acceleration at approach/deceleration at departure: Machine

parameter 1105 ff ”Acceleration/deceleration of linear axis”

■ and the maximum feed rate from: Machine Parameter 1101 ff ”Maximum axis speed”

Parameters

E:

Acceleration at approach – no input: the parameter values take

effect.

F:

Deceleration at departure – no input: the parameter values take

effect

H:

Programmed acceleration On/Off

■ H=0: switch off programmed acceleration after next traverse

■ H=1: switch on programmed acceleration

P:

Maximum feed rate – no input: Parameter value

48

The ”absolute maximal speed” is specified

in machine parameter 805 and following.

If S > parameter value, the parameter value

takes applies.

• If P > parameter value, the parameter

value applies.

• ”E, F and P” refer to the X or Z axis. The

acceleration/feed rate for the slide is not

higher with axis-parallel traverses.

Feed rate per revolution Gx95

G64 interrupts the programmed feed for a short period of time.

G95: Spindle; Gx95: Spindle x (x: 1...3)

G95/Gx95 defines the feed rate as a function of

drive.

■ For switch-on, program G64 with E and F.

■ For switch-off, program G64 without parameters.

Parameters

E:

Duration of pause (range: 0.01 s < E < 99.99 s)

F:

Parameters

F:

Feed rate in mm/revolution or inch/revolution

Duration of feed rate (range: 0.01 s < E < 99.99 s)

Feed rate per tooth spindle x Gx93

Constant cutting speed Gx96

Gx93 (x: spindle 1...3) defines the feed rate drive-dependent,

depending on the number of teeth of the cutter.

G96: spindle; Gx96: spindle x (x: 1...3)

G96/Gx96 defines a constant cutting speed. The

spindle speed is dependent on the X position of the

tool tip or on the tool diameter (with driven tools).

Parameters

F:

Feed rate per tooth (mm/tooth or inch/tooth)

The actual value display shows the feed rate in mm/rev.

Parameters

S:

Cutting velocity (in m/min or ft/min)

Feed rate constant G94 (minute feed)

Speed Gx97

G94 defines the feed rate as a function of drive.

G97: spindle; Gx97: spindle x (x: 1...3)

G97/Gx97 defines a constant spindle speed.

Parameters

S:

Speed (in revolutions per minute)

Parameters

F:

Feed rate per minute (in mm/min or inch/min)

Feed rate and spindle speed

Interrupted (intermittent) feed G64

49

Tooth and cutter radius

compensation (TRC)

Tooth and cutter radius compensation (TRC/MCRC)

G40, G41, G42

G40: Switch off TRC/MCRC

■ The TRC is effective up to the block before G40.

■ In the block with G40, or in the block after G40, only one straight line

segment permitted (G14 is not permitted).

G41/G42: switch on TRC/MCRC

■ In the block with G41/G42 or after the block with G41/G42, one

straight line segment (G0/G1) is to be programmed.

■ The TRC/MCRC is included after the next contour element.

G41: Switch on TRC/MCRC – displacement of the tool radius in the

direction left of the contour.

G42: Switch on TRC/MCRC – displacement of the tool radius in the

direction right of the contour.

Parameters

Q:

Machining plane – default: 0

■ Q=0: TRC on the turning plane (X-Z plane)

■ Q=1: MCRC on the end face (X-C plane)

■ Q=2: MCRC on the cylindrical surface (Z-C plane)

■ Q=3: MCRC on the end face (X-Y plane)

■ Q=4: MCRC on the cylindrical surface (Y-Z plane)

H:

Output (only with MCRC) – default: 0

■ H=0: Intersecting areas which are programmed in directly

successive contour elements are not machined.

■ H=1: The complete contour is machined – even if certain areas

are intersecting.

O:

Feed rate reduction – default: 0

■ O=0: Feed rate reduction active

■ O=1: No feed rate reduction

50

• If the tool radii > contour radii, it can result

in tool path loops during CRC/MCRC.

Recommendation: Use the finishing cycle

G890 / milling cycle G840.

• Never select MCRC during a perpendicular

approach to the plane.

• Note when calling subprograms with

active TRC/MCRC:

Switch the TRC/MCRC off in the main program if it was switched on in the main program. – Switch the TRC/MCRC off in the

subprogram in which it was switched on.

G51

■ Relative shift

■ Programmed shift

■ Reference: set workpiece datum

G53, G54, G55

■ Relative shift

■ Shift from parameters

■ Reference: set workpiece datum

G56

■ Additive shift

■ Programmed shift

■ Reference: current workpiece datum

G59

■ Absolute shift

■ Programmed shift

■ Reference: machine datum

Zero point shift

Overview

Zero point shift G51

G51 displaces the workpiece datum by ”Z” (or ”X”). The shift is

referenced to the workpiece datum defined in setup operation.

Even if you shift the zero point several times with G51, the

displacement is still always referenced to the workpiece zero point

from the setup mode.

The zero point shift applies until the end of the program or until it is

canceled by another zero point shift.

Parameters

X, Z: Displacement (X radius value) – default: 0

51

Parameter-dependent zero point shift G53, G54, G55

G53, G54, G55 displace the workpiece zero point by the value defined

in the setup parameters 3, 4, 5. The shift is referenced to the workpiece

zero point defined in setup operation.

Zero point shift

Even if you shift the zero point several times with G53, G54, G55, the

displacement is still always referenced to the workpiece datum from

the setup mode.

The datum shift applies until the end of the program or until it is

canceled by another datum shift.

A shift in X must be indicated as a radius value.

Additive zero point shift G56

G56 shifts the workpiece zero point by ”Z” (or ”X”). The displacement

is referenced to the currently active workpiece zero point.

If you shift the workpiece zero point several times with G56, the

displacement is always added to the currently active zero point.

Parameters

X, Z: Shift (X radius value) – default: 0

52

Absolute zero point shift G59

G59 sets the workpiece datum to ”X, Z”. The new datum is valid to the

end of the program.

G59 cancels all previous zero point shifts (with G51, G53..G55

or G59).

Zero point shift

Parameters

X, Z: Datum shift (X radius dimension)

53

G121 contour mirror and shift

Datum shift

G121 mirrors and/or shifts the position of roughed and finished part

contours. The contour is mirrored in the X axis and shifted in the Z

direction. The workpiece datum is not affected.

Parameters

H:

Mirroring – default: 0

■ H=0: Contour shift – no mirroring

■ H=1: Contour shift, mirroring, and reversal of the direction of

contour description

Q:

Mirroring the coordinate system (direction of the Z axis) - default: 0

■ Q=0: No mirroring

■ Q=1: Mirroring

Z:

Shift – default: 0

D:

Mirroring XC/XCR (mirroring/shifting the front and rear face

contours) - default: 0

■ D=0: No mirroring/shifting

■ D=1: Mirroring/shifting

• Lateral surface contours are mirrored/shifted like turning

contours.

• Auxiliary contours are not mirrored.

• Please note for Q=1: The coordinate system including the

contour is mirrored – H=1 mirrors only the contour.

54

Switch off allowance with G50

G47 defines the safety clearance for the turning cycles: G810, G820,

G830, G835, G860, G869, G890; drilling cycles G71, G72, G74 and

milling cycles G840...G846. G47 without parameters activates the

parameter values (machining parameters 2, ... – safety clearances).

G50 switches off allowances defined with G52/G39Geo for the following cycle.

Parameters

P:

Safety clearance

G47 replaces safety clearance set in the machining parameters

or that set in G147.

Allowances, safety clearances

Safety clearance G47

Safety clearance (drilling and milling cycles) G147

G147 defines the safety clearance for milling operations with

G840...G846. Parameter ”K” influences the safety clearance for drilling

operations (G71, G72, G74). G147 replaces the safety clearance set in

”;Machining parameter 2, ... – safety clearances.”

Parameters

I:

Safety clearance in milling direction

K:

Safety clearance in approach direction (feed)

G147 replaces safety clearance set in the machining

parameters or that set in G47.

55

Allowances, safety clearances

Axis-parallel allowance G57

G57 defines different allowances in X and Z. G57 is programmed before

the cycle.

After cycle execution, allowances are

■ deleted: G810, G820, G830, G835, G860, G869, G890

■ not deleted: G81, G82, G83

Parameters

X, Z: Allowance (X diameter value)

If the allowances are programmed with G57 and in the cycle

itself, the cycle allowances are used.

Contour-parallel allowance (equidistant) G58

G58 defines a contour-parallel allowance. A negative allowance is

permitted with G890. G58 is programmed before the cycle.

After cycle execution, allowances are

■ deleted: G810, G820, G830, G835, G860, G869, G890

■ not deleted: G81, G82, G83

Parameters

P:

Allowance

If an offset is programmed with G58 and in the cycle, the

offset from the cycle is used.

56

The ”T” is followed by the WAPP number. You can enter the T number

directly or select it from the tool list (switch with the CONTINUE key).

WAPP number:

W: Tool carrier number

A: Number of the location group

PP: Pocket number in the tool carrier

If you are working with multi tools, program

”T PP.S” or ”T WAPP.S” (S = number of the side tooth).

Tools, types of compensation

Tool call T

(Changing the) cutter compensation G148

”O” defines the wear and tear compensation values to be

compensated. DX and DZ become effective after program start and

after a T command.

Parameters

O:

Selection – default: 0

■ O=0: DX, DZ active – DS inactive

■ O=1: DS, DZ active – DX inactive

■ O=2: DX, DS active – DZ inactive

The recessing cycles G860, G866 automatically take the

”correct” wear compensation into account.

57

Tools, types of compensation

Additive compensation G149

The CNC PILOT manages 16 tool-independent compensation values. To

activate the additive compensation function, program G149 followed by

a „D number“ (for example, G149 D901). ”G149 D900” resets the additive compensation function.

Parameters

D:

Additive compensation - default: D900

Range: 900 to 916

Compensate right tool tip G150

Compensate left tool tip G151

G150/G151 defines the workpiece datum for recessing and button

tools.

G150: datum is on right tip

G151: datum is on left tip

G150/G151 is effective from the block in which it is programmed and

remains in effect up to

■ the next tool change

■ end of the program

• The displayed actual values always refer to the tool tip

defined in the tool data.

• Be sure to switch the direction when you work with TRC

58

Basics of programming

■ The compensation becomes effective only after the

tool has actually moved in the compensation

direction by the compensation value. You must

therefore program G149 one block before the block

in which you want the compensation to apply.

■ An additive compensation remains effective until:

■ The next ”G149 D900”

■ The next tool change

■ The end of the program

End of cycle G80

Simple turning cycles

G80 concludes fixed cycles.

Simple longitudinal roughing G81

Simple face roughing G82

G81/G82 machines (roughs) the contour area described by the current

tool position and ”X, Z”. If you wish to machine an oblique cut, you can

define the angle with I and K.

The tool moves to clearance at the end of the cycle:

■ G81: X – last lift-off coordinate; Z – cycle start point

■ G82: X – cycle start point; Z – last lift-off coordinate

Parameters

X/Z: Contour target point (X diameter)

Q:

G-function Infeed – default: 0

■ 0: infeed with G0 (rapid traverse)

■ 1: infeed with G1 (feed rate)

G81:

I:

Maximum infeed distance in the X direction

■ I<0: with machining the contour line

■ I>0: without machining the contour line

K:

Offset in Z direction – default: 0

G82:

I:

Offset in X direction – default: 0

K:

Maximum infeed distance in the Z direction

■ K<0: with machining the contour line

■ K>0: without machining the contour line

Simple longitudinal roughing G81

• Cutter radius compensation: is not

carried out

• Offsets (G57): are calculated and remain

effective after end of cycle.

• Safety clearance after each step: 1 mm.

59

Simple contour repeat cycle G83

Simple turning cycles

G83 carries out the functions programmed in the following blocks (simple traverse or cycles without contour description) more than once.

G80 ends the machining cycle.

If the number of infeeds differs for the X- and Z axes, the tool first

advances in both axes with the programmed values. The infeed is set to

zero if the target value for one direction is reached.

Notes on programming G83

■ Stands alone in the block

■ Must not be programmed with K variables

■ Must not be nested, not even by calling subprograms

Tool position at end of cycle: Cycle starting point.

Parameters

X/Z: Contour target point (X diameter) - no input: transfer the last X/Z

coordinate

I/K: Maximum infeed (I: radius) – default: 0

• Cutter radius compensation: is not carried out – You can

program the TRC separately with G40..G42.

• Offsets: G57-offsets are calculated; G58-offsets only have

effect if you are working with TRC. Allowances remain in

effect after the end of cycle.

• Safety clearance after each step: 1 mm.

60

Danger of collision !

After each pass, the tool returns on a diagonal path before it advances for the next pass.

If required, program an additional rapid traverse path to avoid a collision.

With the function G85, you can machine undercuts according to DIN

509 E, DIN 509 F and DIN 76 (thread undercut). The CNC PILOT

decides the type of undercut using ”K.” For undercut parameters, see

table.

The adjoining cylinder is machined if the tool is positioned at the

cylinder diameter (”X”) ”in front of” the cylinder.

The undercut roundings are executed with the radius 0.6 * I.

Parameters

X, Z: Destination point (X as diameter value)

I:

Depth/wear allowance (radius)

■ DIN 509 E, F: wear allowance – default: 0

■ DIN 76: undercut depth

Undercut DIN 76 (thread undercut)

K:

Undercut width and type

■ K no input: DIN 509 E

■ K=0: DIN 509 F

■ K>0: undercut length for DIN 76

E:

Reduced feed (for machining the undercut) – no input: active

feed rate

Simple turning cycles

Undercut cycle G85

• Cutter radius compensation: is not carried out

• Allowances: are not considered

Continued

Undercut DIN 509 E

61

Simple turning cycles

62

Undercut angle for undercuts according to DIN 509 E and F: 15°

Transverse angle for an undercut according to DIN 509 F: 8°.

where:

I = depth of undercut

K = width of undercut

R = undercut radius

P = depth of end face

Undercut according to DIN 509 E

Diameter

I

K

R

18

0.25

2

0.6

> 18 – 80

0.35

2.5

0.6

> 80

0.45

4

1

Undercut DIN 509 F

Undercut according to DIN 509 F

Diameter

I

K

R

P

18

0.25

2

0.6

0.1

> 18 – 80

0.35

2.5

0.6

0.2

> 80

0.45

4

1

0.3

Recessing G86

G86 machines simple radial and axial recesses with chamfers. From the

tool position the CNC PILOT calculates a radial/axial or an inside/outside

recess.

Simple turning cycles

If you program an allowance, the control always rough-machines the

recess first. In the second step, the recess is then finish-machined.

G86 machines chamfers at the sides of the recess. If you do not wish

to cut the chamfers, you must position the tool at a sufficient distance

from the workpiece. Calculation of the starting position XS (diameter):

XS = XK + 2 * (1,3 – b)

XK: Contour diameter

b: Chamfer width

Tool position at end of cycle:

■ Radial recess:

X – Starting position; Z – last recess position

■ Axial recess:

X – last recess position; Z – start position

Parameters

X, Z: Target point (X diameter)

Radial recess:

I:

Allowance

■ I>0: Allowance (roughing and finishing)

■ I=0: No finishing

K:

Recess width – no input: a single cut is machined (recess width

= tool width)

Axial recess:

I:

Recess width – no input: a single cut is

machined (recess width = tool width)

K:

Allowance

■ K>0: Allowance (roughing and finishing)

■ K=0: No finishing

E

Period of dwell (dwell time for chip breaking) –

default: Duration of on revolution

■ With finishing allowance: Only for finishing

■ Without finishing allowance: for every

recess

• Cutter radius compensation: is not

carried out

• Allowances are not considered.

63

Transition radii G87

Simple turning cycles

G87 machines transition radii at orthogonal, paraxial inside and outside

corners. The direction for the rounding is taken from the ”position/

machining direction” of the tool.

A preceding longitudinal or transverse element is machined if the tool is

located at the X or Z coordinate of the corner before the cycle is executed.