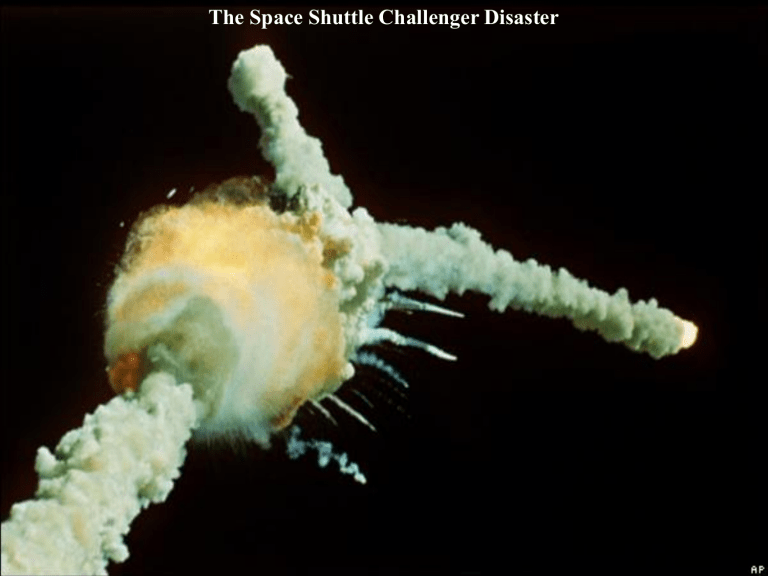

The Space Shuttle Challenger Disaster The Space Shuttle Challenger Disaster The “Teacher in Space” Mission At 11:38 am on January 28th 1986, the 25th Space Shuttle mission began with Challenger lifting off the launch pad at the Kennedy Space Center in Florida. Approximately 73 seconds later, the Challenger was engulfed in a fireball. Seven crew members lost their lives. The high profile nature of the “Teacher in Space” mission required an independent commission to review the accident and risk management processes that were in place at NASA and associates at the time. The Space Shuttle Challenger Disaster The NASA Space Program after Apollo When the Apollo program finished in the 1970s, NASA had begun planning for the next phase of space exploration, an interplanetary expedition to Mars. This involved three core projectsA Space Shuttle- A reusable transport vehicle A Space Station- The launch platform Manned Mars exploration Due to budgetary constraints, only one of these NASA projects could be supported. The Space Station concept was favoured by President Nixon. However, this required the development of the Space Shuttle to support the project. The Space Shuttle Challenger Disaster Feasibility study for the Space Shuttle concept An initial 1972 study by the Mathematica organisation found that the space shuttle could orbit payloads for as little as $100 US per pound, on sixty launches per year with the initial shuttle design specifications (69,000 pound payload capacity). This offered military, satellite deployment, scientific and medical research applications with a very cost effective option. However the Mathematica report was based on unrealistic costings provided by contractors to win NASA tenders. Additionally equipment performance shortfalls prevented the 109% of thrust required by NASA, further reducing payload capacities. The actual cost for payloads became 20 times the original estimate. The Space Shuttle Challenger Disaster The push to market the new technology During the development of the Space Shuttle, the European Space Agency began commercial satellite operations, increasing the market competition. NASA, in an attempt to remain market leader, partnered with the United States Air Force for the development of the Space Shuttle program With financial and political pressures in place, key engineering design compromises were made on the Space Shuttle. These were• Use of Solid Rocket Boosters (SRB) • Payload Bay size and shape adjustments • Removal of Air breathing engines • Removal of the Evacuation System These changes affected the weight and characteristics of the vehicle, reducing safety factors and versatility in the Space Shuttle. The Space Shuttle Challenger Disaster The push to market the new technology Solid Rocket Boosters NASA’s initial space shuttle design was with all liquid-fuelled rockets, following on from Apollo and the Saturn V rocket. Liquid based propulsion can be shut down in the event of catastrophe. However the decision was made to use cheaper, reusable Solid Rocket Boosters (SRB) for the shuttle program. Solid Rocket Boosters need to expend all fuel during liftoff to separation. The Rogers Commission found“The Space Shuttle System was not designed to survive a failure of the Solid Rocket Boosters. There are no corrective actions that can be taken if the boosters do not operate properly after ignition, i.e., there is no ability to separate an Orbiter safely from thrusting boosters and no ability for the crew to escape the vehicle during first-stage ascent.” The Space Shuttle Challenger Disaster The push to market the new technology Quality In 1973, after final design considerations of the Space Shuttle had taken place, NASA began the tendering process. This process was based primarily on cost considerations. Cost Time NASA considerations Rockwell International won the contract for the construction of the Space Shuttle (also known as the Orbiter Space Vehicle). This was despite the safety concerns that Rockwell’s proposal did not include any escape system. Morton-Thiokol Inc won the contract for the Solid Rocket Booster (SRB) component of the design. This was awarded due to the cost, $100 million cheaper than the next competitor, over the technical design and safety aspects. The Space Shuttle Challenger Disaster Risk management Safety testing The SRB did not have adequate safety testing and part replacement programs in place. Before reuse of the SRB, engineers would test the O ring seals for deterioration and failure. This involved blowing air into the seal to check integrity. The test was also responsible for doing some damage to the seal. At lower temperatures, it became evident that the materials used in the O ring design were less likely to seal correctly. The recent change to an asbestos-free putty, used as a backup to the seal, also became more brittle and less flexible during colder conditions. The lack of spare parts due to budget constraints further compounded the SRB safety. The Space Shuttle Challenger Disaster Risk management The risk management process at NASA and Morton-Thiokol Inc involved the followingA Flight Readiness Review (FRR) meeting which covered the following• Determine the overall mission status • Review significant problems • Review all constraints • Present all new waivers from the last flight Previous Space Shuttle missions had uncovered a flaw in the seal on the SRB, with damage to the O rings becoming more evident, especially in cooler conditions. Despite this a waiver was placed, allowing missions to continue unabated. The risk management process remained a qualitative process, whereby a low aggregate risk remained acceptable. The Space Shuttle Challenger Disaster Risk management Current risk management processes involve the following• Risk Identification • Risk Assessment • Risk Response Development • Risk Response Control NASA had a well established, albeit simple, risk classification system. The O ring component that failed in the launch of Challenger was initially classed as Criticality 1 in 1982, but later reclassified to C1R (redundancy in place) Morton Thiokol responsibility to mitigate this risk was poor, as reported by an internal memo from Richard Boisjoly 6 months previously. The Space Shuttle Challenger Disaster Politics, Infighting and Chain of Command NASA, without a permanent administrator for 4 months before the Challenger incident, were in management disarray. Additionally, the Flight Center Director in May 1985 imposed that NASA schedules would remain on target throughout the 1985-86 fiscal year. Despite this, delays were still occurring and media pressures were ever constant. This mounted a toll on NASA to deliver. The lower level employees at NASA were constrained through the bureaucracy to prevent the launch of Challenger. The Space Shuttle Challenger Disaster Politics, Infighting and Chain of Command At Morton-Thiokol Inc the management were also under considerable pressure. During a pre-flight meeting, NASA’s Mulloy, already stressed from previous mission delays, demanded Morton-Thiokol Inc reassess the position to stop the launch. Morton Thiokol then held a 30 minute conference with senior engineers. As there was no sustainable argument regarding the O ring seal problem in colder conditions, management made the decision to reverse its original position and give the all clear. NASA interpreted this as an acceptable risk and went to launch the mission. 16358573 Michael Monteleone , 16554131 Vijay Karigiri, 16569078 David Alexander The Space Shuttle Challenger Disaster The Rogers Commission Report Findings The Mechanical Cause of the Accident The consensus of the Commission was the mechanical cause of the accident was due to a joint failure in the lower two segments of the right Solid Rocket Motor (SRM). The failure was due to a faulty design unacceptably sensitive to a number of factors. These factors were the effects of temperature, the physical dimensions, the character of materials, the effects of reusability, processing and the reaction of the joint to dynamic loading. These factors in combination were considered to be the most likely causes of mechanical failure in the Space Shuttle Challenger destruction. The Space Shuttle Challenger Disaster The Rogers Commission Report Findings The investigation focussed on the followingEnvironmental conditionsThe ambient temperature was 36º F, 15º F colder than the next coldest launch. Additionally, water from previous rainfalls may have been present in the joints, freezing at the cooler temperatures and preventing proper seal performance Mechanical conditionsA combustion gas leak occurred in the right SRM during the ignition process which weakened the joint. No other Shuttle element or the payload contributed to this leak. Procedural complianceNo flight hardware at the launch site were outside Shuttle design specifications, launch site activities were conducted in accord with established procedures. The right SRM were assembled using approved procedures and sabotage was not a factor. The Space Shuttle Challenger Disaster The Rogers Commission Report Findings The Underlying Cause of the Accident The commission found the underlying cause of the accident was due to poor decision making regarding the mission launch. This is comprised of the following factors• The lack of a well structured and managed safety system • Waiving of launch constraints at the expense of flight safety • Containment of serious problems at Marshall Air Base • The reversal of the Morton Thiokol management decision regarding the launch. These factors created a complacent “flyfirst, safety later” attitude at NASA The TheSpace SpaceShuttle Shuttle Challenger Challenger Disaster Disaster The “Teacher in Space” mission had the following crew members on board the Challenger vehicle at the time of the disaster (pictured from left to right)Mission SpecialistPilotPayload SpecialistCommanderPayload SpecialistMission SpecialistMission Specialist- Ellison Onizuka Michael John Smith Sharon Christa McAuliffe Francis Richard Scobee Gregory Bruce Jarvis Ronald Erwin McNair Judith Arlene Resnik Their names are commemorated in a plaque at Arlington National Cemetery. After the Space Shuttle destruction, NASA consoled itself and the nation with the realization that all frontiers are dangerous and to a certain extent, such a disaster should be accepted as inevitable. However, this incident was avoidable, and a number of poor management decisions were made to launch in conditions that were hazardous and unprecedented at the time. This cost seven astronauts their lives. The TheSpace SpaceShuttle Shuttle Challenger Challenger Disaster Disaster Lessons learnt Risk management fundamentals The Challenger disaster became a textbook case of project failure and the lack of properly adhered to risk management procedures. The term “heterogeneous engineering” became synonymous with the Space shuttle program, as management and engineering decisions were made to meet organisational, political and economic needs rather than specific mission objectives. Finally, the Space Shuttle program was put on hold for 32 months for the investigation and repair process to be effected. Most senior NASA and Morton Thiokol personnel took early retirements after the incident.