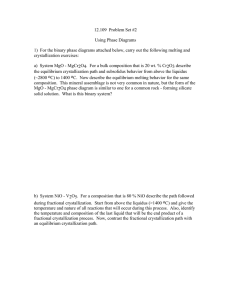

Useful Method to Analyze Data on Overall Transformation Kinetics I. Avramov, K. Avramova Institute of Physical Chemistry, Bulg. Acad. Sci., 1113 Sofia, Bulgaria E-mail for correspondence: avramov@ipc.bas.bg Keywords: crystallization, glass-ceramics, relaxation ABSTRACT We propose an easy and reliable method for analyzing data from DTA and DSC studies of crystallization at constant heating rate, q. It is demonstrated that important information can be obtained in log-log coordinates of plot of heating rate, log q , against peak temperature , log Tp . The slope of the corresponding straight line is proportional to the dimensionless activation energy p that there is a simple relation E E RT . It is demonstrated Tp q E 1 between the characteristic crystallization time τ, the heating rate the the heating rate heating the heating rate rate the heating rate q the heating rate and the heating rate the the heating rate peak the heating rate temperature the heating rate Tp. the heating rate Keywords: overall crystallization kinetics, thermal analyses, DSC, DTA Introduction It seems that Verhulst first postulated that the transformation fraction (t) , int) , in a media being subject to exhaustion, can be describes by sigmoid function [1,2]. Later on, it was assumed [3-5] that the transformation rate is a product of two functions, one of them representing the reaction mechanism, f(), being explicitly dependent on while the other one, k(t) is reliant on time t. So, the rate equation is (t) , int ) k (t) , int ) f t 11\* MERGEFORMAT (t) , in) In the following we use the reciprocal of k(t) , int), the characteristic time 1 k t . It is more appropriate as the dimension of is [time]. The overall crystallization rate kinetics has a long history of research. Usually, the experimental results are analyzed in the framework of the Kolmogorov-Johnson-Mehl-Avrami (t) , inKJMA) theoretical model [6-8]. According to it the time dependence of degree of transformation α is: 1-e t - n 22\* MERGEFORMAT (t) , in) Here n is the dimensionless power which depends on crystallization mechanism as well as on wherever nucleation takes place or crystals are developing around existing active centers. It is easily seen that Eq.2 is solution of Eq.1 for the properly chosen explicit form of the f(α) the heating rate and the heating rate k(t) the heating rate functions. The crystallization process, that takes place during the widespread methods of thermal analyses, DTA and DSC, starts frequently from the surface [9-11]. Although the KJMA approach is discussed in many books and review articles [12-16], the interpretation of experimental results is relatively easy (t) , insee [13,14]) only when crystallization time is constant, const. In this case the corresponding derivative form (t) , insee Eq.1) is: 1 d t 1 1 n 1 ln 1 n dt 33\* MERGEFORMAT (t) , in) Nowadays there are experimental data on the derivative form d/dt (mainlydt (t) , inmainly from DSC and DTA studies) [15,16]. Earlier the experiments were focused on the integral forms, i.e. the dependencies of on time t. It was considered unreliable to interpret the differential form, d/dt (mainlydt, because it is well known that negligible deviations in integral forms lead to important errors in differentiated ones. For the isothermal case (t) , inτ=constconst) the most popular approach was to plot the experimental results in bilogarithmic coordinates, log(t) , in log(t) , in1 )) against log t . The slope of the expected straight line is the dimensionless power n. The problem is that the estimation of the term log(t) , in log(t) , in1 )) is very inaccurate for both α→0 and for α→1. Recently, we proposed [17,18] to plot the data in coordinates α against log t. Thus d the derivative d log t is determined and through it the n value is obtained in a reliable way. The situation is much more complicated when τ is not a constant (t) , infor instance in non-isothermal conditions). Although there are many approaches (t) , insee [13,19-21] and literature cited there), and all of the treatments are based on the formal theory of transformation kinetics, they differ greatly in their assumptions. This leads to contradictions in results interpretation. The aim of the present study is to find a way to interpret experimental data in an easy and reliable way. New method of interpretation of experimental data If is not constant, Eq.2 is no more valid. However, we can still use an expression similar to Eq. 3 for the transformation rate 1 1 d n n 1 ln 1 dt t 44\* MERGEFORMAT (t) , in) So that the transformation rate can be presented as 1 1 d n n 1 ln 1 dT q (t) , inT ) 55\* MERGEFORMAT (t) , in) where q dT dt is the heating rate. Since at low temperatures the value of (t) , inT) is very large, the process is frozen and we can assume that the heating at constant rate q starts at T=const0 K. The corresponding solution of Eq.5 is T dT n 1 exp 0 q T 66\* MERGEFORMAT (t) , in) It is useful to note that the integral in Eq.6 is n T dT ln 1 0 q T 77\* MERGEFORMAT (t) , in) To solve properly Eqs.67, we need a sufficiently accurate, and in the same time friendly to use, formula for the temperature dependence of characteristic time τ.The most popular hypothesis is that it is a result of thermally activated process; i.e. E o exp RT 88\* MERGEFORMAT (t) , in) Introduction of Eq.8 yields to rather complicated solution of the integral in Eq.6 because an exponential integral function, Ei, appears. The attempts to find suitable method to interpret the experimental result lead to the so-called “Kissinger” coordinates [10,16,17], namely to plot the temperatures T p of the maximums of the Tp2 1 d ln dT against temperature T curves in coordinates q against Tp . From the slope of the corresponding straight line the activation energy E is estimated. Unfortunately, the value of the activation energy obtained in this way is always overestimated. We expect that the upper limit is E 37 RT otherwise, according to Eq.8, the corresponding crystallization time would be unreasonably large (t) , insee for instance E 37 [10]). Thus, for RT the exponential term in Eq.8 is about 1016, so the characteristic time τ should be too large as compared with the expected experimental ones, no matter how small is the preexponential constant τo. Actually, the expected crystallization time is of the order of minutes at the temperatures of the maximum of d the dT against T curves. Therefore here we start here new approach. Let at a given reference heating rate qr the characteristic time is τr at the temperature of the maximum of the crystallization peak Tr. We assume that at any temperature T the characteristic time is T T r Tr E 99\* MERGEFORMAT (t) , in) In Appendix 1 we demonstrate that Eq.9 is equivalent to assumption made by the Eq.8 E with E RTr . The advantage of Eq. 9 is that the integral in Eq.6 is easily solved. T T dT T q T q r E 1 Tr 0 E 1010\* MERGEFORMAT (t) , in) So that the solution of Eq.6 is 1 exp E T T q r E 1 Tr n 1111\* MERGEFORMAT (t) , in) Discussion Note that Eqs.8,9 are oversimplifications, despite they accounts for the temperature dependence of the crystallization time. Additionally, the activation energy for crystallization could depend on the degree of transformation as the composition of the amorphous phase at the crystallization front changes (t) , insee for instance [22.23]). So, the present treatment is just a step in solving the problem. Further steps are needed as the limits of validity of the present approach are experimentally tested. d Appendix 2 provides detailed analyses of the peak position of the dT against T curve It is shown that at any heating rate q the peak temperature Tp(q) is determines by the condition TpE1 E r q r E 1 T 1 ; or TpE1 q r E 1 TrE 1212\* MERGEFORMAT (t) , in) A straight line is expected if the heating rate q is plotted against the peak temperature Tp in log-log coordinates. log q E 1 log Tp E log Tr log(t) , inE 1) log(t) , in r ) 1313\* MERGEFORMAT (t) , in) E The dimensionless activation energy E RTr can be determined from the slope of this line. The characteristic crystallization time τr remains the only unknown and is easily determined from the intercept. Since there are no limitations for the choice of the reference heating rate qr the characteristic crystallization time τp(q) is determined through Eq.12 as p q Tp q E 1 1414\* MERGEFORMAT (t) , in) In other words, there is an universal relation between the peak temperature T p , the corresponding crystallization time τ and heating rate q Tp q p E 1 1515\* MERGEFORMAT (t) , in) To illustrate the use of this method we analyze crystallization results of one of the samples studied in [10]. Powder samples of composition 5.2Al2O3 19.6 CaO 17.9 MgO 53.5 SiO2 with fraction size between 75 and 125 [m] were used. The heating rates of 5, 7.5, 10 and 20 [K/dt (mainlymin] were applied. The relationship [10] between the heating rate lg q and the peak temperature lg Tp is demonstrated in Fig.1 in log-log coordinates. From the corresponding slope the dimensionless activation energy is E E 31 RTp . The heating rates, the peak temperatures and the corresponding crystallization times calculated according to Eq.14 are summarized in Table 1. With E 31 and τ≈4 [min] the Eq.8 will be satisfied for τo≈1 10-13 [min]≈ 9 10-12 [s]. Thus, for the first time, the value of the preexponential constant τo is well within the expected limits. The proposed method of analysis gives an activation energy of around 250 [kJ/dt (mainly mol]. The analysis of the same DTA data in [10], using the Kissinger equation, gave an activation energy of ~400 [kJ/dt (mainlymol]. The reason for overestimated values obtained from analyses of Kissinger equation is because the activation energy is not constant. In Kissinger coordinates the corresponding slope depends on the activation energy plus its first derivative in respect to temperature. Some examples could be seen for instance in [24]. The present method estimates the activation energy without involving its temperature derivative. According to Eqs. 1112 the degree of crystallinity p at the maximum of the d dT against temperature T curve has an universal value p 1 1 0.63 e , independent on the power n. It is useful to determine the dimensionless Avrami d parameter n from the maximal slope of the dT against ln T curve. d d ln T p n E 1 e 1616\* MERGEFORMAT (t) , in) with e2.718. One can draw a tangent to the highest slope of the experimentally determined sigmoid curve. This straight line will intercept abscissa at a given onset point ln T1. The intercept with =const 1 gives the end point ln T2 of the process. According to Eq.16 , the parameter n is determined as follows n e ln T2 -ln T1 E 1 MERGEFORMAT (t) , in) Conclusions 1717\* The activation energy can be obtained from the slope of the dependence of heating rate , log q, against the temperature of the maximal crystallization rate , log Tp. The characteristic crystallization time τp(q) can be determined either from Eq.14 or from the intercept of the mentioned above straight line. Tp It is demonstrated that the product q p is constant depending on the activation energy. Appendix 1 Note that crystallization appears in a relatively narrow temperature interval, so, if the reference heating rate is chosen in a way that Tr is about the middle of the temperature interval in which the transformation takes place, the dimensionless temperature is Tr 1, with accuracy of 3% T . Therefore, a fairly accurate Tr T 1 ln r T so that we can make the following transformation: approximation is T E E E Tr T o exp ln r 1 1 exp RTr RTr T RTr T 1818\* MERGEFORMAT (t) , in) E In this way Eq.9 is satisfied with E RTr . Appendix 2 The first derivative of Eq.11 is d n E 1 T E1 dT T q 1 E 1 Tr MERGEFORMAT (t) , in) n n T E1 exp q 1 E 1 TrE 1919\* Correspondingly, the second derivative is 2 d 2 T E1 n E 1 q E 1 T dT 2 r r n n 1 T E1 1 exp n E 1 q r E 1 TrE T E1 E q r E 1 Tr 2020\* MERGEFORMAT (t) , in) Therefore the extreme condition d 2 dT 2 0 p shows that the temperature of the peak T p is determines by the condition n T E1 1 ; or TpE1 q r E 1 TrE E q E 1 T r r 2121\* MERGEFORMAT (t) , in) E As soon as the value of the dimensionless activation energy is about one can neglect the term 1 1 1 n E 1 30n E 30 RTr . Table 1 Crystallization time τ in dependence (Eq.14) of the [19] heating rate q and the corresponding peak temperature Tp q [K/dt (mainlymin] 5 7.5 10 20 Tp [K] 988 1000 1009 1032 τ [min] 6.4 4.3 3.1 1.7 n 1,3 1,2 lg q [K/min] 1,1 1,0 0,9 0,8 0,7 2,995 3,000 3,005 3,010 3,015 lg Tp Fig.1 Dependence between the heating rate lg q and the peak temperature lg Tp. References 1. Verhulst PF. Notice sur la loi que la population poursuit dans son accroissement.Correspondancemathématiqueet physique 1838 ; X: 113-121. 2. Verhulst PF. Recherches mathématiques sur la loi d'accroisement de la population.Mem.Acad. R. Bruxelles, 1844; 18 : 1 3. Young DA, Decomposition of Solids, Pergamon Press, Oxford, 1966 4. Šesták J. Modelling of reaction mechanism: use of Euclidian and fractal geometry, Chapter 10 in his book: Science of Heat and Thermophysical Studies: a generalized approach to thermal analysis. pp.276-314,Elsevier, Amsterdam 2005A.Kolmogorov , Izv. Acad. Sci. USSR, ser Math., 1 (t) , in1937) 355 5. Isak Avramov, Jaroslav Šesták, “Generalized kinetics of overall phase transition explicit to crystallization” Journal of Thermal Analysis and Calorimetry 2014, Volume 118, Issue 2, pp 1715-1720 6. W. Johnson, R. Mehl, Trans. AIME 135 (t) , in1939) 416 7. M. Avrami, J. Chem. Phys. 7 (t) , in1939) 1103 8. M. Avrami, J. Chem. Phys. 8 (t) , in1940) 212 9. R. Muller, E. Zanotto, V. Fokin, J. Non-Cryst. Sol. 274 (t) , in2000) 208 10. K. Avramova , A. Karamanov, I. Avramov, Journal of Non-Crystalline Solids 428 (t) , in2015) 49–53 11. A. Karamanov, I. Avramov, L. Arrizza, R. Pascova, I. Gutzow, Journal of Non-Crystalline Solids 358 (t) , in2012) 1486 12. Koga N, Šimon P, Šesták J. Some fundamental and historical aspects of phenomenological kinetics in solid-state studied by thermal analysis. Chapter 1 in book: Thermal analysis of micro-, nano- and non-crystalline materials (t) , inJ. Šesták, P. Šimon. Editors), pp. 1-28, Springer Berlin 2013, 13. Yinnon H., Uhlmann D. Application of thermoanalytical techniques to the study of crystallization kinetics in glass-forming liquids, Part I: Theory. J. Non-Cryst. Solids 1983; 54: 253-275. 14. Weinberg MC, Birnie III DP.Avrami exponents for transformations producing anisotropic particles. J. Non-Cryst. Solids 1996 ; 202: 290-296. 15. Málek J, Applicability of KJMA model in the thermal analysis of crystallization kinetics of glasses. Thermochim Acta 1995; 267: 61-73 16. C. S. Ray, D.E Day, In Nucleation and Crystallization in Liquids and Glasses, Am. Ceram. Soc. 30 (t) , in1992) 207-224. 17. I.Avramov, C. Russel, K. Avramova J. of Non-Cryst. Sol. 337 (t) , in2004) 220-225 “Conditions for metastable crystallization from undercooled melts” 18. I.Avramov, K. Avramova, C. Rüssel J. Cryst. Growth 285 (t) , in2005) 394 19. H. Kissinger, Res. Natl. Bur. Stand. 57 (t) , in1956). 20. H. Kissinger, Anal. Chem. 29 (t) , in1957). 21. Avramov, Ch. Tzvetkova, Ts. Vassilev, Journal of Non-Crystalline Solids 355 (t) , in2009) 23–28 22. Bocker C, Russel C., Avramov I Intern. J. of Applied Glass Science 4 (t) , in2013)174 23. K. Thieme, I. Avramov, C. Rüssel, Scientific Reports | 6:25451 | DOI: 10.1038/dt (mainlysrep25451 (t) , inNature.com/dt (mainly scientificreports) 24. I. Avramov, G. Guinev, A.C.M. Rodrigues, J. Non-Cryst. Sol. 271 (t) , in2000) 12