इंटरनेट

मानक

Disclosure to Promote the Right To Information

Whereas the Parliament of India has set out to provide a practical regime of right to

information for citizens to secure access to information under the control of public authorities,

in order to promote transparency and accountability in the working of every public authority,

and whereas the attached publication of the Bureau of Indian Standards is of particular interest

to the public, particularly disadvantaged communities and those engaged in the pursuit of

education and knowledge, the attached public safety standard is made available to promote the

timely dissemination of this information in an accurate manner to the public.

“जान1 का अ+धकार, जी1 का अ+धकार”

“प0रा1 को छोड न' 5 तरफ”

“The Right to Information, The Right to Live”

“Step Out From the Old to the New”

Mazdoor Kisan Shakti Sangathan

Jawaharlal Nehru

IS/IEC 60947-2 (2003): Low-Voltage Switchgear and

Controlgear, Part 2: Circuit Breakers [ETD 7: Low Voltage

Switchgear and Controlgear]

“!ान $ एक न' भारत का +नम-ण”

Satyanarayan Gangaram Pitroda

“Invent a New India Using Knowledge”

“!ान एक ऐसा खजाना > जो कभी च0राया नहB जा सकता ह”

है”

ह

Bhartṛhari—Nītiśatakam

“Knowledge is such a treasure which cannot be stolen”

lS/lEC 60947-2:2003

[Superseding

IS 13947 (Part 2): 1993]

lndkm Standard

LOW-VOLTAGE

SWITCHGEAR

PART 2

AND CONTROLGEAR

CIRCUIT BREAKERS

ICS 29.130.20

@ BIS 2007

BUREAU

MANAK

December 2007

OF

BHAVAN,

INDIAN

STANDARDS

9 BAHADUR

SHAH

NEW DELHI

11 OOO2

ZAFAR

MARG

Price Rs. 1580.00

lS/lEC 60947-2:2003

CONTENTS

1

General ................ .................... ......................................... ............. ....... ... ....... ....... ......... 1

1.1

Scope andobject

1.2

Normative

.... ............................................................ ..... ...... ....... ..... ........ .... 1

references

................. ................................... ...... ..... ..... ..... ...... ....... ....... 2

2

Definitions

3

Classification

4

Characteristics

of circuit-breakers

............................... ........... ...... ........... ....... ............ .... 8

of characteristics

... ...................................... ...... ............ .......... .......... ..... 8

5

........ ........ ..... ............. .... .... .... .... ... .. ...... ... ....... .......... ........... ..... ...... ....... ......... 4

4.1

Summary

4.2

Type ofcircuit.breaker

4,3

Rated andlimiting

4.4

Utilization

4,5

Control

4.6

Auxiliaw

Releases

4,8

integral

Product

..... ........... .. ................................ ........... ... ......... .... ..... ...... ........... ........... 14

fuses

(integrally

MarKng

instructions

7

Constructional

fused circuit-breakers)

........ ......... .......... .. ...... ........... ... ...l5

............ ......................................... ........... ........ ...... ....... ................... 15

of the information

5,2

Normal

of the main circuit .................. .... ...... ..... ..... ....... ............. 9

,,, ,,, ,, !.,,, ...............,.,.,,,,,,, ,,, ,,, ,,, ,,, ,,,, ,..,,,.,,, ,.,,.,,,,,,,, ,.,, ,, ..... ..,, 13

circuits ............... ......................... ....... ............. ...... ..... .......... ........ ... ........ 14

5.3

6

values

categories

information

Nature

.................................. ... .............. ...... .... ....... ..... .... ............. 9

circuits ............ ........... ............... .................. ....... ........ ... ..... ................ .......l3

4.7

5,1

8

....... ...................... ........................................... ............ .... ...... .................... 7

.................. ........................ .............. ....... ................ .. .. ....l5

... ..... .... ..... ........ .......................... ............ .............. ............ .............. ... ......l6

service,

forinstallation,

mounting

operation

and transport

and performance

7,1

Constructional

7.2

Performance

requirements

7,3

Electromagnetic

requirements

and maintenance

conditions

requirements

..... ... ...... .. ..... ..... ........ ..... ..l7

..................... ....... .......... ...................l7

................. .. ....... .... ...... ..... ......... ....... .......l7

........................... .............. .... ........... ..... ........ ............l7

........ ..... .................... ........... ..... ........... ...... ..................lg

compatibility

(EMC) ........ .. .............. ....... ........... .............. ... ..........25

Tests .... ...... .... ..... ... .... ........... ..................................... .......... ............ ..... ........ .. ..............25

8.1

Kind of tests .. ... ..... .... .. ....... .. ................. ... .... .... ........ ... ........... ..... ....... .............. .....25

8.2

compliance

8.3

Type tests ..... ... ........... .................. .............................. ........ .... .............. ................26

8.4

Routine

With Constructional

requirements

........ ........... .......... ....... ............. .......26

tests . .... ...... ...... ........................................... ........ ...... ............................. 53

Annex A (normative)

Coordination

under short-circuit

conditions between

a circuit-breaker

and another short-circuit

protective device associated in

the same circuit ..... ..... ....... ....... ....... ................................................ ........... ........... ........ ..... 58

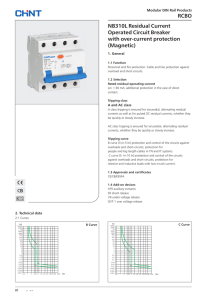

Annex B (normative)

Circuit-breakers

Annex C (normative)

Individual

Annex

D

Vacant

incorporating

pole short-circuit

residual

current

test sequence

protection

.. .....

..... 67

....... ..... ...... .................... .. 100

... ............... ........ ........ ....... ........ ... ..................... ........... ........... ........ ........ 101

Annex E (informative)

Items subject

to agreement

between

manufacturer

and user ........ ....l O2

Annex F (normative)

Additional tests for circuit-breakers

with electron ic over-current

protection .............................. .. ..................... ............................l O3

Annex

G (normative)

Power loss ...... ...................... .............. ........ ......... ..... .......... .............l26

Annex

H (normative)

Test sequence

for circuit-breakers

for IT systems

...... .......................129

lS/lEC 60947-2:2003

Annex J (normative)

Electromagnetic

compatibility

(EMC) – Requirements

and

test methods for circuit-breakers

............................................. ........... ........ ............ .. .... .... ...l3l

Annex K (informative)

Glossary of symbols related to products covered

by this standard ....... .......... ................................................... .... ........ ............ .......................l52

Annex L (normative)

Circuit-breakers

not fulfilling the requirements

for overcurrent

protection .......... .... .............. ...... ......... ........................ ....... ........ ..................l54

Annex M (normative)

Modular residual current devices

(without integral current breating

device) ....................................... ........ .. ....... ........ .......... ...l59

Annex N (normative)

Electromagnetic

compatibility

(EMC) - Additional

requirements

and test methods for devices not covered by annexes B, F and M ......... ........ ....... ................2O2

Figure

1 – Test arrangement

(connecting

cables

not shown) for short-circuit

tests ................ 57

Figure A.1 – Over-current

coordination

between a circuit-breaker

and a fuse

or back-up protection

by a fuse: operating characteristics

................ ........... ........... .............

63

Figure A.2 and Figure A.3 – Total discrimination

64

between

two circuit-breakers

........

Figure A.4 and Figure A.5 - Back-up protection by a circuit-breaker

–

Operating characteristics

. ....... .................. ...... ...................... ............ .... ......... ...... ...............

65

Figure A.6 - Example of test circuit for conditional short-circuit

breaking capacity tests

showing cable connections

fora 3-pole circuit. breaker (Cl) ........... ......... .......................... ..

66

Figure

(see B.8.2) .........

92

Figure B.2 – Test circuit for the verification

of the limiting value

of the non-operating

current under over-current

conditions (see 6.8.5 ) ..... ........... .... ............

B.1 – Test circuit

93

Figure B.3 – Test circuit for the verification

of the behaviour of CBRS classified

under B.3.1 ,2.2 (see B.8.9) ....................... ....... ................................ ............... ....................

94

Figure

95

B.4–

Current

Figure B,5 – Example

Figure

B.6–

for the verification

ring wave 0,5ps/100

of the operating

kHz ............................. .. ............. ..... ..................

of test circuit for the verification

Surge current

characteristic

of resistance

to unwanted

tripping ........ 96

wave 8/2 O~s .............. .... ..... ....... ........... ...................................

96

Figure B.7 – Test circuit for the verification

of resistance to unwanted tripping in case

of flashover without follow-on current (B.8.6.2) ............ .......... ................................. .............

97

Figure B.8 – Test circuit for the verification

of the correct operation of CBRS,

in the case of residual pulsating direct currents (see 6.8.7.2.1, B.8.7.2.2 and B.8.7.2.3)

......

98

Figure 6.9 – Test circuit for the verification

of the correct operation of CBRS,

in the case of a residual pulsating direct current superimposed

by a smooth direct residual current (see 6.8.7.2.4) .................... ....... ... ...............................

99

Figure F. 1 – Representation

of test current produced by back-to-back

thyristors

in accordance

with F.4.1 .......... .................................................. ... ...... ........... .. .. ............... .. 113

Figure F.2 – Test circuit for emission tests, immunity to harmonics, current dips,

electrostatic

discharges

and radiated electromagnetic

fields in accordance

with F.4. I.3, F.4.2.1, F,4.3, F,4.4, F.5.4 and F.6.2. –Two phase poles in series .................. 114

Figure F.3 – Test circuit for emission tests, immunity to harmonics,

current dips,

electrostatic

discharges

and radiated electromagnetic

fields in accordance

with F.4,1 .3, F.4.2,1, F,4.3, F.4.4, F.5.4 and F.6.2. –Three

phase poles in series .. .. ........... 115

lS/lEC 60947-2:2003

Figure F.4 – Test circuit for emission tests, immunity to harmonics,

current dips,

electrostatic

discharges

and radiated electromagnetic

fields in accordance

with F.4. I.3, F.4.2.1, F.4,3, F,4.4, F.5.4 and F.6.2. –Three-phase

connection .... ..................ll6

Figure F,5 - Test current for the verification

of the influence of the current dips

and interruptions

in accordance with F.4.2.1 .............. .. ............ ..... ...... ....... ..... .............. .......ll7

Figure F.6 – Circuit for electrical fast transients/bursts

(EFT/B) immunity test

in accordance with F.4.5 -Two

phase poles in series ..... ........... ...... ..... ..... .. ......... ...... ..... ....ll8

Figure F.7 – Circuit for electrical fast transients/bursts

(EFT/B) immunity test

in accordance with F.4.5– Three phase polesin series ... .......... ........ ........... ..... ..... ..............ll9

Figure F.8 - Circuit for electrical fast transients/bursts

(EFT/B) immunity test

inaccordance

with F.4.5-Three-phase

connection .,, ........ ........... .... ... ........... ... ..................l2O

Figure F,9 – Test circuit for the verification

of the influence of surges in the main circuit

(line-to-earth)

in accordance

with F,4,6– Two phase poles in series ... . .... ....... ...... ....... .. ......121

Figure F.10 - Test circuit for the verification

of the influence of surges in the main

circuit (line-to-earth)

in accordance

with F.4.6 – Three phase poles in series.., ... ....... ........... 122

Figure F.11 – Test circuit for the verification

circuit (line-to-earth)

in accordance

of the influence

with F.4.6 - Three-phase

of surges in the main

connection ......... ..... ............... 123

Figure F.12 - Test circuit for the verification

of the influence of current surges

in the main circuit in accordance with F.4,6– Two phase poles in series,,.,.,,

..... ........ .. .. ...... 124

Figure F.13 – Test circuit for the verification

of the influence of current surges

in the main circuit in accordance

with F.4.6– Three phase poles in series..,, ... .... .............. .. . 124

Figure F.14 – Test circuit for the verification

of the influence of current surges

in the main circuit in accordance

with F,4,6– Three-phase

connection .. ........... ....... .......... ... 125

Figure F.15 – Temperature

variation cycles at a specified rate of change

in accordance with F.9.1 ............ .... .......................................... ............. ......... .. .............. ...... 125

Figure G,l –Example

of power loss measurement

according

to G.2,1 .. ........... ..... .......... .....128

Figure G.2–

of power loss measurement

according

to G,2.2 and G,2.3 .................128

Example

Figure J.1 – EUT mounted

in metallic

enclosure

–Two

Figure J.2 – EUT mounted

in metallic

enclosure

– Three

Figure J.3 – EUT mounted

in metallic

enclosure

- Three-phase

Figure J,4 – Test set-up

for the verification

phase poles in series .... ...... .. ........... 140

of immunity

phase poles in series

connection

to electrostatic

to radiated

..

....

. 142

... ..... ........ ..........l44

discharges

electromagnetic

........... ...145

Figure J.5 – Test set-up for the verification

of immunity

fields .......146

Figure J.6 – Test set-up for the verification

toelectrical

fast transients/bursts

(EFT/B)

of immunity

..... ...... .................. ........ .... ....... ........................ ...l47

Figure J.7 – Test set-up for the verification

induced by radio-frequency

fields (common

of immunity to conducted disturbances

mode) – Two. phase poles in series ..,,, ...... .. ......148

Figure J.8 – Test set-up for the verification

Induced by radio-frequency

fields (common

of immunity to conducted disturbances

mode) – Three phase poles in series ................149

Figure J,9 – Test set-up for the verification

induced by radio-frequency

fields (common

of immunity to conducted disturbances

mode) – Three-phase

connection .... ..................l5O

Figure J.l O. Test set.upfor

Figure K.1 - Relationship

radiated

between

emissions

symbols

............ .............. ........... ........... ........... .......l5l

and tripping

characteristics

.... ............. ...... ... .....l53

lS/lEC 60947-2:2003

Figure M.1 – Test circuits for the verification

of operation in the case

of a steady increase of residual current ............................................. ...................... .............l83

Figure M.2 – Test circuits for the verification

of operation in the case

of a sudden appearance

of residual current (with breaking device) ........ ........................... .. ..l84

Fiflure M.3 – Test circuits for the verification

of a sudden appearance

of residual current

of operation in the case

(without breaking device) ........... ......... ....... ....... 185

Figure M.4 – Test circuits for the verification

of the limiting value

of non-operating

current under overcurrent

conditions ............ .. ........ .. ......... ............... ..........l86

Figure M.5 – Test circuits for the verification

of the resistance to unwanted tripping

In the case of loading of the network capacitance

........ .... ................. .......... ........ .... .............l87

Figure M.6 – Test circuit for the verification

of the resistance to unwanted tripping

In the case of flashover without follow. on current ............................. ....... ........ ...... ...............l88

Figure M.7 – Test circuits for the verification

of operation in the case

of a continuous

rise of a residual pulsating direct current ........ ....... ........ ....... .......................l89

Figure

M.8 – Test circuits

for the verification

of operation

in the case of a sudden

appearance of residual pulsating direct current (without breaking device) ............................. 190

Figure M.9 – Test circuits for the verification

of operation in the case of a sudden

appearance

of residual pulsating direct current (with breaking device) ........ ...... ................ ....l9l

Figure M. 10 – Test circuits for the verification

of operation in the case of a residual

pulsatlng direct current superimposed

by smooth direct current of 6 mA,,,, ...... ....... ...192........l92

Figure M.11 – Test circuits for the verification

of operation in the case

of a slowly rising residual smooth direct current ........... .. .......... .. ...... ... ............ .. ....... ............l93

Figure M.12 – Test circuits for the verification

of operation in the case

of a sudden appearance

of residual smooth direct current (without breaking

Figure M. 13 – Test circuits for the verification

of operation

of a sudden appearance

of residual smooth direct current

in the case

(with breaking

device)

............194

device) .... .............195

Figure M.14 – Test circuits for the verification

of operation in the case

of a slowly rising residual current resulting from a fault in a circuit fed

by athree-pulse

star ora six-pulse bridge connection ............ ........ ....... ......... .................. ....lg6

Figure M.15 – Test circuits for the verification

of operation in the case

of a slowly rising residual current resulting from a fault in a circuit fed

by a two-pulse bridge connection

line. to.line ........................ ... ........................... ..................lg7

Figure M.16 – Test circuit for the verification

of the behaviour of MRCDS

with separate sensing means in the case of a failure of the sensor means

connection

.......... 198

Figure M. 17 – Test circuit for the verification

of the behaviour of MRCD

with separate sensing means under short-circuit

conditions . .. ......... .. ....... ........ .......... ..........199

Figure M.18 – Test circuit for the verification

with Integral sensing means undershirt-circuit

of the behaviour of MRCD

conditions .......... ............. ............. ...............2OO

Figure M. 19 – Test circuit for the verification

of the behaviour

ofterm!nal

type MRCD under short. circuit conditions ............ ......... ....... ............. ......... ... ......2Ol

Table 1 –Standard

ratios

between

/cS and /Cu............ ............... ...... ........ ......... .. ....................ll

Table 2 – Ratio n between short-circuit

making capacity and short-circuit

breaking capacity and related power factor (for a.c. circuit-breakers)

!V

12

lS/lEC 60947-2:2003

Table 3– Minimum

Table

values

4– Utilization

of rated short-time

categories

withstand

current ...... ............. ........ ..... ........... 12

..... ...................................... .............. ...... .... ........ ................. 13

Table 5 – Preferred values of the rated control supply voltage, if different from that

of the main circuit . ............... ...... .......... ................... ....... ........ ....... ....... ..... ....... .... ............... . 13

Table 6 – Characteristics

of the opening operation of inverse time-delay

over-current

opening releases at the reference temperature

........ .......... ........ ....... .......... ........... .............. 21

Table 7–Temperature-rise

Table

8– Number

Table

9–Overall

Iimits for terminals

of operating

schema

and accessible

parts ........ ............. ...... .......... 23

cycles ... ......................... .. ......... ..... ..... ..... ............... ........... .. 24

of test sequences

................ .. ......... ...... .......... ..... ..... ..... ...... ........ 28

Table 9a - Applicability

of test sequences according to the relationship

between ICS, lCuandlCW . .... .. ..... ............ ... ....... .... .... .... ........... ....... .......... ..... .... ...... ...... ... ...... 29

Table

10.

Number

Table

11-

Values

Table

12–Test

ofsamples

for test .............................. ........ ....... .......... .... .... ....... ...... .... 32

of power factors

circuit

Table B.1 .Operating

and time constants

characteristics

characteristic

Table B.2 – Operating characteristic

non-actuating

time of 0,06s

....

Table B.3 – Requirements

Table B.4.

Additional

for overload

corresponding

performance

fornon.time.delay

to test currents

type .................... ..... ...... .. ..... .......... 72

for time-delay-type

having a limiting

... ............ .........

.. .... ...... ......... ... . . ...

for CBRS functionally

test sequences

34

..... .......... .......... .......... ....... 44

dependent

... 73

on line voltage .. ........................ 77

............ .. .......................... ...... .......... .... ...... ............ ... 80

Table 6.5 – Tripping current

of an earth fault comprising

range for CBRS in case

d.c. component ......... ........... .......... ..... ...... .... ....... ..... .. ........... 85

Table F.1 –Test

for current

parameters

Table J.1 –EMC–lmmunity

Table J,2 – Reference

Table J.3.

EMC.

Ml

Table

M.2 – Requirements

Table

M.3.

Alphabetical

–PrcJduct

information

Test sequences

of the figures

for immunity

tests ..,,,, ..............l34

tests ........ .. ..................... .. .... ............ ...... .... .......... .. .......... .. ....l37

cam for the application

Table

... ...... .... ..... ...... ...... ...............l O7

tests .............................. .................. ...... .... ....... ......................l33

data for the application

Emission

Table J.4 – Reference

dips and interruptions

of the figures

for emission

tests .... ................l37

..... ....... ...................... ... ...... ........ ...... .... ....... ..... .......... .......l65

for MRCDs with voltage

source

.......... ...... ..... .... .. ..... ..................I67

......................... ............................. ...... ..... .... ....... .... ................l6g

index of tests .... .... ....... ............... ....... ........... ............... .......... ........ ...... ............ 27

lS/lEC

60947-2:2003

Low-Voltage

Switchgear

NATIONAL

FOREWORD

and Controlgear

Sectional

Committee,

ETD 07

This Indian Standard

(Part 2) which is identical with IEC 60947-2:2003

‘Low-voltage

switchgear

and

controlgear

— Part 2: Circuit breakers’

issued by the International

Electrotechnical

Commission

(lEC)

was adopted

by the Bureau

of Indian

Standards

on the recommendation

of the Low-Voltage

Swltchgear

and Controlgear

Sectional

Committee

and approval

of the Electrotechnical

Division

Council.

This standard

supersedes

controlgear:

Part 2 Circuit

IS 13947

breakers’.

(Part

The text of IEC Standard

has been approved

2) : 1993

as suitable

dewations.

Certain

conventions

are, however,

Attention is particularly

drawn to the following:

in this

a)

Wherever

the words ‘International

be read as ‘Indian Standard’,

b)

Comma

practice

adopted

Standards

respective

not

Standard’

‘Specification

reference

appears

low-voltage

switchgear

appear

to certain

referring

while

to this standard,

in Indian

International

Standards,

Standards

for

they should

the current

which

Indian

also exist.

The corresponding

Indian Standards,

which are to be substituted

in their

places, are listed below along with their degree of equivalence

for the editions indicated:

/nfernafional

Standard

IEC 60050

(441) (1984)

Electrotechnical

Vocabulary

Chapter

441:

Switchgear,

and fuses

International

(IEV)

—

controlgear

Corresponding

Indian

Standard

IS 1885 (Part 17) : 1979 Electrotechnical

vocabulary:

Part

17 Switchgear

and

controlgear

(first revision)

Degree of

Equivalence

Technically

Equivalent

IEC

60051

(all

parts)

Direct

acting

indicating

analogue

electrical

measuring

instruments

and their accessories

IS 1248 : 2003 (all parts) Direct acting

indicating

analogue

electrical

measuring

instruments

and their accessories

do

IEC 60068-2-14

testing — Part

IS 9000 (Part 14/See 1 to 3) :1988 Basic

Environmental

testing

procedures

for

electronic

and electrical

items: Part 14

Test N: Change

of temperature

(first

revision)

do

IEC 60068-2-30

(1 980)

Environmental

testing — Part 2-30: Tests — Test Db

and guidance:

Damp heat, cyclic (12+12

hour cycle)

IS 9000 (Part 5/See 1 and 2) : 1981

Basic environmental

testing

procedures

for electronic

and electrical

items: Part 5

Damp heat (cyclic) test

do

IEC

(1 982)

Electric

60364-4-41

installations

of buildings

—

Part

4:

Protection

for safety

— Chapter

41:

Protection against shock

SP 30:1985

do

Change

and

for publication

as an Indian Standard without

Identical

to those used in Indian Standards.

(,) has been used as a decimal marker,

is to use a point (.) as the decimal marker.

standard,

for

(1 984)

Environmental

2-14: Tests — Test N

of temperature

vi

National

electrical

code

lS/lEC

/nternationa/

IEC

60898

over-current

and similar

(1995)

Circuit-breakers

protection

installations

IEC

60947-1

switchgear

and

General rules

Corresponding

Standard

for

(1999)’)

for

household

Low-voltage

controlgear

—

Part

1:

Indian

Degree of

Equivalence

Standard

IS 8828

: 1996

Circuit-breakers

overcurrent

protection

for household

similar installations

lS/l EC 60947-1

switchgear

and

General rules

60947-2:2003

for

and

: 2004

Low-voltage

Part

1

controlgear:

Identical

Technically

Equivalent

IEC

60947-4-1

(2000)2)

Low-voltage

switchgear

and controlgear

— Part 4:

Contractors and motor-starters

— Section

1: Electromechanical

contractors

and

motor-starters

lS/lEC

60947-4-1

: 2002

Low-voltage

swltchgear

and

controlgear:

Part

4

Contractors and motor-starters,

Section 1

Electromechanical

contractors and motorstarters

do

IEC

IS

do

61000-3-2

(2000)

Electromagnetic

(EMC) — Part 3: Limits —

Section 2: Limits for harmonic current

emissions (equipment input current s 16 A

compatibility

14700

(Part

Electromagnetic

Part 3 Limits,

3/See

2)

:

1999

compatibility

(EMC):

2 Limits

for

Section

per phase)

harmonic

current

emissions

(equipment

input current s 16 A per phase)

IEC 61000-3-3

(1994)

Electromagnetic

compatibility

(EMC) — Part 3: Limits —

voltage

3:

Limitation

of

Section

fluctuations

and flicker

in low-voltage

supply systems for equipment

with rated

currents

16 A

IS

14700

(Part

3/See

3)

: 1999

Electromagnetic

compatibility

(EMC):

Part 3 Limits,

Section

3 Limitation

of

voltage

fluctuations

and flicker

in lowvoltage

supply

systems

for equipment

with rated current <16 A

IEC 61000-4-2

(1 995) Electromagnetic

compatibility

(EMC) — Part 4: Testing

and measurement

techniques

— Section

2: Electrostatic

discharge

immunity test

IS

14700

(Part

4/See

2)

: 1999

Electromagnetic

compatibility

(EMC):

Part

4

Testing

and

measurement

techniques,

Section,

2

Electrostatic

discharge

immunity test

do

IEC 61000-4-3

(2002)

Electromagnetic

compatibility

(EMC) — Part 4: Testing and

measurement

techniques

— Section

3:

Radiated, radio-frequency,

electromagnetic

field immunity test

IS

14700

(Part

4/See

3)

: 2005

Electromagnetic

compatibility

(EMC): Part

4 Testing and measurement

techniques,

Section

3

Radiated,

radio-frequency,

electromagnetic

field immunity test

do

IEC 61000-4-4

(1 995)

Electromagnetic

compatibility

(EMC) — Part 4: Testing

and measurement

techniques

— Section

4: Electrical fast transient/burst

immunity

test

IS

14700

(Part

4/See

4)

: 1999

Electromagnetic

compatibility

(EMC):

Part

4

Testing

and

measurement

techniques,

Section

4 Electrical

fast

transient/burst

immunity test

do

IEC 61008-1

(1 990)

Residual

current

operated circuit-breakers

without integral

over-current

protection for household

and

similar uses (RCCB’S) — Part 1: General

rules

IS 12640 (Part 1) :2000 Residual current

operated

circuit-breaker

for household

and similar uses: Part 1 Circuit-breakers

without

integral

over-current

protection

(RCCB’S)

do

IEC

IS 12640 (Part 2) :2001 Residual current

operated circuit-breaker

far household

and similar uses: Part 2 Circuit-breakers

do

61009-1

(1991)

Residual

current

operated

circuit-breakers

with

integral

over-current

protection

for household

and

similar uses (RCBO’S) — Part 1: General

rules

with

integral

(RCBO’S)

1)$3nce;evised in 2004.

2)Since revised in 2002.

vii

over-current

protection

Identical

lS/lEC

60947-2:2003

International

Standard

Corresponding

Indian

CISPR 11 (1997) Industrial,

scientific

and

medical (ISM) radio-frequency

equipment

—

disturbance

Electromagnetic

characteristics

— Limits and methods

of

measurement

IS 6873

(Part 4) : 1999

methods

of

measurement

disturbance

characteristics:

CISPR 22 (1997) Information

technology

Radio

disturbance

equipment

—

characteristics

— Limits and methods

of

measurement

IS 6873

methods

Industrial,

scientific

and

radio-frequency

equipment

Degree of

Equivalence

Standard

Limits

and

of

radio

Part

4

Identical

medical

(ISM)

(first revision)

(Part 7) : 1999

Limits

and

of

measurement

of

radio

characteristics:

Part

7

disturbance

Information

technology

equipment

(first

revision)

do

The technical committee

responsible

for the preparation

of this standard

has reviewed the provisions

of the following

International

Standards

referred in this adopted standard

and has decided that they

for use in conjunction

are acceptable

International

Title

Standard

0 (2000)

IEC 60695 -2-

Fire hazard

based

test methods

—

Fire hazard testing — Part 2-11: Glowing/hot-wire

based

Glow-wire

flammability

test method for end products

test methods

—

Fire hazard testing — Part 2-12: Glowing/hot-wire

Glow-wire

flammability

test method for materials

based

test methods

—

Fire hazard testing — Part 2-13:

based

test methods

—

Glow-wire

1 (2000)

IEC 60695 -2-

IEC 60695 -2- 2 (2000)

IEC 60695-2-13

(2000)

Glow-wire

IEC 60755

with this standard:

— Part 2-10:

ignitability

General requirements

(1 983)

IEC 60934(1

testing

appai”atus

988)

Circuit-breakers

and common

test procedure

Glowing/hot-wire

test method

for residual

for equipment

Glowing/hot-wire

for materials

current

operated

protective

devices

(CBE)

IEC 61000-4-5

(1 995)

Electromagnetic

compatibility

(EMC) — Part 4: Testing

techniques

— Section 5: Surge immunity test

IEC 6 000-4-6

(1 996)

Electromagnetic

compatibility

(EMC) — Part 4: Testing and measurement

techniques

— Section 6: Immunity to conducted

disturbances,

induced by

radio frequency

fields

IEC 6 000-4-11

IEC 61000-5-2

(1 994)

(1 997)

and measurement

Electromagnetic

compatibility

(EMC) — Part 4: Testing and measurement

techniques

— Section 11: Voltage dips, short interruptions

and voltage

variations

immunity tests

Electromagnetic

compatibility

(EMC) — Part 5: Installation

guidelines

— Section 2: Earthing and cabling

Only the English text of the International

Standard, and as such the page numbers

and mitigation

Standard

has been retained while adopting

it as an Indian

given here are not same as in the IEC Publication.

For the purpose of deciding

whether

a particular

requirement

of this standard

is complied

with, the

final value, observed

or calculated,

expressing

the result of a test or analysis,

shall be rounded off in

accordance

with

significant

places

this standard.

IS 2 : 1960 ‘Rules for rounding

retained

in the rounded off value

VIII

off numerical

values

(revised’.

The number

should be same as that of the specified

value

of

in

lS/lEC 60947-2:2003

Indian Standard

LOW-VOLTAGE

SWITCHGEAR

PART 2

1

AND CONTROLGEAR

CIRCUIT BREAKERS

General

The provisions of the general rules dealt with in IEC 60947-1 (hereinafter

referred to as Part 1)

are applicable to this standard, where specifically

called for. Clauses and subclauses,

tables,

figures and appendices

of the general rules thus applicable

are identified

by reference

to

Part 1, for example, 1.2.3 of Part 1, table 4 of Part 1, or annex A of Part 1.

1,1

Scope and object

This standard

applies to circuit-breakers,

the main contacts

of which are intended

to be

connected to circuits, the rated voltage of which does not exceed 1 000 V a.c. or 1 500 V d.c.;

it also contains additional requirements

for integrally fused circuit-breakers.

it applies whatever the rated currents,

of the circuit-breakers

may be,

The requirements

for

protection are contained

circuit-breakers

in annex B.

The additional

requirements

contained in annex F.

The additional

the method

requirements

for

which

The requirements

and test

contained in annex J.

methods

with

test methods

in annex N.

current

for

or the proposed

intended

to

electronic

for IT systems

not fulfilling

The requirements

for modular

residual

device) are contained in annex M.

Supplementary

IEC 60947-4-1,

also

for electromagnetic

The requirements

for circuit-breakers

are contained in annex L.

The requirements

and

auxiliaries are contained

are

circuit-breakers

for circuit-breakers

of construction

The requirements

for circuit-breakers

contained in IEC 60934.

earth-leakage

over-current

are contained

compatibility

protection

the requirements

for overcurrent

devices

integral

electromagnetic

(without

compatibility

for the protection

of wiring

for use by uninstructed

for equipment

are

in annex H.

of circuit-breakers

requirements

for circuit-breakers

used as direct-on-line

applicable to low-voltage

contractors and starters.

The requirements

for circuit-breakers

similar

applications,

and designed

IEC 60898,

provide

applications

protection

current

of

are

breaking

circuit-breaker

starters

are given

in

installations

in buildings and

persons,

are contained

in

(for example

electrical

appliances)

are

lS/lEC 60947-2:2003

For certain specific applications

(for example

additional

requirements

may be necessary.

traction,

rolling

mills,

marine

service)

particular

or

NOTE

Circuit-breakers

which are dealt with in this standard may be provided with devices for automatic opening

under predetermined

conditions other than those of over-current

and undervoltage

as, for example,

reversal of

power or current. This standard

does not deal with the verification

of operation

under such pre-determined

conditions.

The object

a)

of this standard

the characteristics

b) the conditions

is to state:

of circuit-breakers;

with which

circuit-breakers

and behaviour

in normal

1)

operation

2)

operation

and behaviour

in case of overload

short-circuit,

including co-ordination

in service

3)

dielectric

tests intended for confirming

adopted for these tests;

d)

information

Normative

to:

service;

and operation

(discrimination

and behaviour

in case

and back-up protection);

of

properties;

c)

1.2

shall comply with reference

to be marked

that these

conditions

have been

met and the methods

to be

on or given with the apparatus

references

The following referenced

documents

are indispensable

for the application

of this document. For

dated references,

only the edition cited applies. For undated references,

the latest edition of

the referenced document (including any amendments)

applies.

IEC 60050(44 1): 1984,

Switchgear,

controlgear

International

and fuses

IEC 60051 (all parts)

their accessories

Direct

acting

IEC 60068-2-14:1984,

Environmental

Electrotechnical

indicating

IEC 60068-2-30:1980,

Environmental

heat, cyclic (12+ 12-hour cycle)

IEC 60364

( all parts),

IEC 60364-4-41:1982,

Chapter 41: Protection

E/ectric

testing

Electric

installations

against shock

analogue

electrical

– Part 2: Tests.

testing

insfa//ations

Vocabulary

(IE V)

–

measuring

Test N: Change

– Part 2: Tests -

Chapter

441:

instruments

and

of temperature

Test Db and guidance:

Damp

of bui/dings

of buildings

– Part

4: Protection

for

safety

-

Fire hazard testing - Part 2-10:

and common test procedure

Glowing/hot-

wire based

test methods

-

IEC 60695-2-11:2000,

Glow-wire flammability

Fire hazard testing - Part 2-11:

test method for end-products

Glowing/hot-

wire based

test methods

-

IEC 60695-2-12:2000,

Glow-wire flammability

Fire hazard testing - Part 2-12: G/owing/hot-wire

test method for materials

based

test methods

-

based

test methods

–

IEC 60695-2-10:2000,

G/ow-wire apparatus

IEC 60695-2-13:2000,

Glow-wire ignitability

I EC 60755:1983,

Fire hazard testing - Part 2-13:

test method for materials

General

requirements

for residual

2

Glowing/hot-wire

current

operated

protective

devices

lS/lEC 60947-2:2003

IEC 60898,

Circuit-breakers

for over-current

IEC 60934,

Circuit-breakers

for equipment

IEC 60947-1:1999,

Low-voltage

Amendment

1 (2000)

Amendment

2 (2001)

and con frolgear

s witchgear

contractors

IEC 61000-3-2:2000,

Electromagnetic

harmonic current emissions (equipment

for household

and similar

installations

(CBE)

switchgear

IEC 60947-4-1:2000,

Low-voltage

motor-starters

– Electromechanical

protection

– Part 1: General

and controlgear

and motor-starters

compatibility

input current

– Part

rules

4-1:

(EMC) – Part 3-2:

S16 A per phase)

Contractors

Limits

– Limits

and

for

IEC 61000-3-3:1994,

Limitation of voltage

rated current S16 A

Electromagnetic

compatibility

(EMC) – Part 3: Limits – Section

3:

fluctuations

and flicker in low-voltage

supply systems for equipment

with

IEC 61000-4-2:1995,

techniques – Section

Amendment

1 (1998i

Amendment

2 (2000)

Electromagnetic

2: Electrostatic

compatibility (EMC) – Part 4: Testing

discharge immunity test

Electromagnetic

IEC 61000-4-3:2002,

measurement

techniques

- Radiated

Amendment

1 (2002)

,

compatibility

radio-frequency

(EMC)

–

Part

electromagnetic

and measurement

4-3:

field

Testing

immunity

and

test

IEC 61000-4-4:1995,

Electromagnetic

compatibility

techniques – Section 4: Electrical fast transient/burst

Amendment

1 (2000)

Amendment

2 (2001)

(EMC) – Part 4: Testing

immunity test

and measurement

IEC 61000-4-5:1995,

Electromagnetic

compatibility

techniques – Section 5: Surge immunity test

Amendment

1 (2000)

(EMC) – Part 4: Testing

and measurement

IEC 61000-4-6:1996,

techniques – Section

Amendment

1 (2000)

Electromagnetic

compatibility

(EMC) – Part 4.’ Testing and measurement

6: Immunity to conducted disturbances,

induced by radio frequency fields

IEC 61000-4-11:1994,

techniques – Section

Amendment

1 (2000)

Electromagnetic

compatibility

(EMC) – Part 4: Testing

11: Voltage dips, short interruptions

and voltage variation

IEC 61000-5-2:1997,

guidelines – Section

Electromagnetic

compatibility

2: Earthing and cabling

and measuring

immunity tests

(EMC) – Part 5: installation

and mitigation

IEC 61008-1:1990,

Residual

current operated

circuit-breakers

without integral

protection for household

and similar uses (RCCB ‘s) ~ Part 1: General rules

over-current

IEC 61009-1:1991,

Residual

current

operated

circuk-breakers

with integral

protection for household

and similar uses (RCBO ‘s) – Part 1. General rules

over-current

lS/lEC 60947-2:2003

Cl SPR 11:1997, industrial,

scientific

magnetic disturbance

characteristics

Amendment

1 (1999)

and medical (ISM) radio-frequency

equipment

– Limits and methods of measurement

Cl SP R 22:1997, Information

technology

and methods of measurement

2

equipment

– Radio disturbance

characteristics

– Electro-

– Limits

Definitions

For the majority

Part 1,

For the purpose

NOTE

Where

IEC 60050(441),

of the definitions

of this standard,

required

in connection

the following

additional

these definitions

are taken unchanged

the IEV reference is given in brackets.

from the

with this standard,

definitions

International

see Clause

2 of

shall apply:

.E/actrotachrrica/

Vocabulary

(//EV),

2.1

circuit-breaker

a mechanical

switching

device, capable

normal circuit conditions

and also making,

under specified abncirmal circuit conditions

of making,

carrying

and breaking

currents

under

carrying for a specified time and breaking currents

such as those of short-circuit

[IEV 441-14-20]

2.1.1

frame size

a term designating

a group of circuit-breakers,

the external physical dimensions

of which are

common to a range of current ratings. Frame size is expressed

in amperes corresponding

to

the highest current rating of the group. Within a frame size, the width may vary according to the

number of poles

NOTE

This definition

does not imply dimensional

2.1.2

construction

break

a significant

difference

addfiional type testing

in construction

(see 7.1 .5)

standardization.

between

circuit-breakers

of a given frame

2.2

integrally

fused circuit-breaker

a combination,

in a single device, of a circuit-breaker

and fuses,

series with each pole of the circuit-breaker

intended to be connected

size, recwiring

one fuse being placed

to a phase conductor

in

[IEV 441-14-22]

2.3

current-limiting

circuit-breaker

a circuit- breake~ with a break-time

otherwise attainable

peak value

short enough

to prevent

[IEV 441-14-21]

4

the short-circuit

current

reaching

its

lS/lEC 60947-2:2003

2.4

plug-in circuit-breaker

a circuit-breaker

which,

enable the circuit-breaker

in addition to its interrupting

to be removed

contacts,

NOTE Some circuit-breakers may be of the plug-in type on the line

has a set of contacts

side only, the load terminals

being

which

usually

suitable for wiring connection.

2.5

withdrawable

circuit-breaker

a circuit-breaker

which, in addition to its interrupting

contacts, has a set of isolating contacts

which enable the circuit-breaker

to be disconnected

from the main circuit, in the withdrawn

position, to achieve an isolating distance in accordance with specified requirements

2.6

moulded-case

circuit-breaker

a circuit-breaker

having a supporting

part of the circuit-breaker

housing

of moulded

insulating

material

forming

an integral

[IEV 441-14-24]

2.7

air circuit-breaker

a circuit-breaker

in which the contacts

open and close in air at atmospheric

pressure

[IEV 441-14-27]

2.8

vacuum circuit-breaker

a circuit-breaker

in which the contacts

open and close within

a highly evacuated

envelope

[IEV 441-14-29]

2.9

gas circuit-breaker

a circuit-breaker

in which the contacts

higher pressure

open and close in a gas other than air at atmospheric

or

2.10

making-current

release

a release which permits a circuit-breaker

to open, without any intentional

time-delay,

during a

closing operation, if the making current exceeds a predetermined

value, and which is rendered

inoperative when the circuit-breaker

is in the closed position

2.11

short-circuit

release

an over-current

release

intended

for protection

2.12

short-time

delay short-circuit

release

an over-current

release intended to operate

of Part 1)

2.13

alarm switch

an auxiliary switch

it is associated

which

operates

only

upon

against

short circuits

at the end of the short-time

the tripping

of the

delay

circuit-breaker

(see

2.5.26

with

which

lS/lEC 60947-2:2003

2.14

circuit-breaker

with lock-out device preventing

closing

a c!rcuit-breaker

in which each of the moving contacts is prevented

be capable of passing current if the closing command

is initiated

remain established

2.15

short-circuit

breaking

a breaking (or making)

(or making) capacity

capacity for which the prescribed

conditions

from closing sufficiently

to

while specified

conditions

include

a short circuit

2.15.1

ultimate short-circuit

breaking capacity

a breaking capacity for which the prescribed conditions according to a specified test sequence

do not include the capability of the circuit-breaker

to carry its rated current continuously

2.15.2

service short-circuit

breaking capacity

a breaking capacity for which the prescribed

conditions

according to a specified

include the capability of the circuit-breaker

to carry its rated current continuously

2.16

opening

subclause

test sequence

time

2.5.39

of Part

1 applies,

with

the following

additions:

.

In the case of a directly operated circuit-breaker,

the instant of initiation of the opening time

is the instant of initiation of a current large enough to cause the circuit-breaker

to operate;

.

in the case of a circuit-breaker

operated

by any form of auxiliary

power, the instant of

initiation of the opening time is the instant of application

or removal of the auxiliary power to

the opening release.

NOTE

For circuit-breakers

“opening time” is commonly referred to as “tripping time”, although,

tripping time applies to the time between the instant of initiation of the opening time and the

opening command becomes irreversible.

strictly speaking,

instant when the

2.17

over-current

protective

co-ordination

subclause 2.5.22 of Part 1 applies

2.17.1

over-current

discrimination

subclause 2,5.23 of Part 1 applies

[IEV 441-17-15]

2.17.2

total discrimination

(total selectivity)

over-current

discrimination

where, in the presence of two over-current

protective

devices in

series, the protective

device on the load side effects the protection

without causing the other

protective device to operate

2.17.3

partial discrimination

(partial selectivity)

over-current

discrimination

where, in the presence of two over-current

protective

devices in

series, the protective

device on the load side effects the protection

up toa given level of overcurrent, without causing the other protective device to operate

6

lS/lEC 60947-2:2003

2.17.4

selectivity

limit current (IJ

the selectivity limit current is the current co-ordinate

of the intersection

between the total timecurrent characteristic

of the protective device on the load side and the pre-arcing

(for fuses),

or tripping (for circuit-breakers)

time-current

characteristic

of the other protective device

The selectivity

limit current

(see figure Al)

is a limiting

value of current

below which, in the presence of two over-current

protective devices in series, the protective

device on the load side completes

its breaking

operation

in time to prevent the other

protective device from starting its operation (i.e. selectivity is ensured);

●

.

above which, in the presence of two over-current

protective devices in series, the protective

device on the load side may not complete its breaking operation in time to prevent the other

protective device from starting its operation (i.e. selectivity is not ensured),

2.17.5

back-up protection

subclause 2.5,24 of Part 1 applies

2.17.6

take-over current (/B)

subclause 2.5.25 of Part 1 is amplified as follows:

For the purpose of this standard, 2.5.25 of Part 1 applies to two over-current

protective

in series for operating times 20,05 s. For operating times <0,05 s the two over-current

in series are considered

as an association,

see annex A.

NOTE

The take-over

current characteristics

current is the current co-ordinate

of the intersection

of two over-current protective devices in series.

between

the

maximum

devices

devices

break

time

2.18

/2t characteristic

of a circuit-breaker

information (usually a curve) giving the maximum

values of /2f related to break time as a

function of prospective

current (r.m.s. symmetrical

for a.c.) up to the maximum

prospective

current corresponding

to the rated short-circuit

breaking capacity and associated voltage

2.19

resetting

time

time elapsed between a circuit-breaker

tripping

reaching a condition where it can be reclosed

3

due to an overcurrent

Classification

Circuit-breakers

may be classified:

3.1

According to their utilization category, A or B (see 4.4)

3.2

According

to the interrupting

medium,

for example:

air-break;

— vacuum

–

break;

gas-break.

7

and subsequently

lS/lEC 60947-2:2003

3.3

According

to the design,

for example:

— open construction;

—

3.4

mouided

case,

According

–

dependent

—

independent

–

to the method

manual

3.5

—

3.6

viz:

operation;

power operation;

energy

According

suitable

mechanism,

power operation;

independent

— stored

the operating

operation;

manual

dependent

of controlling

operation.

to the suitability

for isolation:

for isolation;

not suitable

for isolation

According

to the provision

for maintenance:

— maintainable;

—

3.7

non-maintainable

According

–

fixed;

–

plug-in;

to the method

of installation,

to the degree

of protection

for example:

— withdrawable

3.8

4

4.1

According

Characteristics

Summary

(see 7.1.11

of Part 1).

of characteristics

of a circuit-breaker

-

type of circuit-breaker

–

rated and limiting

-

utilization

–

control

-

auxiliary

circuits

–

releases

(4.7);

circuits

shall be stated

in terms of the following,

(4.2);

values

categories

fuses

by the enclosure

of circuit-breakers

The characteristics

— integral

provided

of the main circuit

(4,3);

(4,4);

(4,5);

(4.6);

(integrally

fused

circuit-breakers)

(4.8);

as applicable:

lS/lEC 60947-2:2003

4.2

Type of circuit-breaker

The following

shall be stated:

4.2.1

Number

4.2.2

Kind

of current

Kind of current

4.3

Rated

of poles

(a. c. or d.c. ) and, in the case of a.c., number

and limiting

values

of the main

of phases

circuit

The rated values established

for a circuit-breaker

shall be stated

to 4.4, but it is not necessary to establish all the rated values listed.

A circuit-breaker

is defined

4.3.3.1

Rated

Subclause

4.31.1

Ue is generally

voltage

of Part 1 applies

covered

stated

In Canada

by the following

operational

— Circuit-breakers

with the following

as the voltage

between

b)

the voltage

systems.

between

phases

(for example

Circuit-breakers

for unearthed

according to annex H.

Circuit-breakers

U, shall be stated

phases.

and the USA, the rated operational

covered

These c!rcuit-breakers

amplification:

by item a) of note 2:

between phases and earth, together

four-wire neutral earthed systems;

additional

4.3.1,2

4.3.1.3

Rated impulse

Subclause

4.31.3

earthed

tests according

between

According to present practice in Canada

by the voltage between phases only.

Subclause

U, is stated as

voltage

phases

(l-Ji)

withstand

voltage

(Uirrlp)

of Part 1 applies

4.3.2.1

Conventional

Subclause

4,3.2.1

systems

(for example

unearthed

(IT)

277/480

or impedance

require

additional

V)

for

earthed

tests

by the following

free-air

thermal

to annex C.

by the letter C.

and the USA, circuit-breakers

of Part 1 applies.

is defined

phases

three-wire

preceded

Currents

A circuit-breaker

between

480 V) for three-phase

or impedance

as the voltage

Rated insulation

voltage

with the voltage

by item b) of note 2:

require

4.3.1.2

4.3.2

4.3,1

(Ue)

the voltage

three-phase

NOTE B

identified

with

rated voltages:

a)

—

in accordance

Rated voltages

4.3.1

NOTE A

and rated frequency

currents:

current

of Part 1 applies.

9

(/th)

covered

by item b) of note 2 are

lS/lEC 60947-2:2003

4.3.2.2

Conventional

enclosed

Subclause

4.3.2.2

of Part 1 applies.

4.3.2.3

Rated

current

thermal

4.3.2.4

Current

Subclause

7.1.8 of Part 1 applies.

rating

43.3

for four-pole

considered

as normal

Eight-hour

:~ubclause

4.3 4.1 of Part 1 applies.

4.3.4.2

Uninterrupted

Subclause

4.3.4.2

circuit-breakers

duty

duty

of Part 1 applies.

Short-circuit

Rated

are as follows:

characteristics

short-circuit

making

The rated short-circuit

making capacity

ca~acltv assianed to that circuit-breaker

at rated freq; ency and at a specified

expressed as the maximum prospective

capacity

(Icm)

making

of a circuit-breaker

is the value of short-circuit

voltaqe

bv the manufacturer

for the rated o~erational

pdwer factor for a,c., or time constant

for d.c. It-is

peak current.

For a c the rated short-circuit

making capacity of a circuit-breaker

rated ulhmate short-circuit

breaking capacky, multiplied by the factor

For d c the rated short-circuit

making capacity

rated ultlmate short-circuit

breaking capacity.

A rated short-circuit

making capacity implies

current corresponding

to that rated capacity

rated operational

voltage.

4.3.5.2

of

Rated duty

4.3.4,1

4.3.5.1

(/U) (see 4.3.2.4

of Part 1 applies.

The rated duties

4.3.5

is the rated uninterrupted

current

free-air thermal current (/th).

Rated frequency

Subclause

4.3.4

(/~h~)

(/n)

For circuit-breakers,

the rated current

Part 1) and is equal to the conventional

4.3.3

current

Rated

short-circuit

breaking

of a circuit-breaker

shall be not less than its

n of table 2 (see 4.3.5.3).

shall

be not less than its

that the circuit-breaker

shall be able to make the

at the appropriate

applied voltage related to the

capacities

The rated short-circuit

breaking capacities

of a circuit-breaker

are the values of short-circuit

breaking capacity assigned to that circuit-breaker

by the manufacturer

for the rated operational

voltage, under specified conditions.

10

lS/lEC 60947-2:2003

A rated short-circuit

breaking capacity requires that the circuit-breaker

shall be able to break

any value of short-circuit

current up to and including

the value corresponding

to the rated

capacity at a power-frequency

recovery voltage corresponding

to the prescribed

test voltage

values and:

-

for a.c., at any power factor

not less than that of table

-

for d.c,, with any time constant

not greater

11 (see 8.3.2.2.4);

than that of table

11 (see 8.3.2.2.5).

For power-frequency

recovery

voltages

in excess of the prescribed

(see 8.3.2.2,6),

no short-circuit

breaking capacity is guaranteed

test

voltage

values

For a,c., the circuit-breaker

shall be capable of breaking a prospective

current corresponding

to

its rated short-circuit

breaking

capacity

and the related

power factor given in table 11,

irrespective

of the value of the inherent

d.c. component,

on the assumption

that the a c,

component

is constant.

The rated short-circuit

—

rated ultimate

—

rated service

4.3.5.2.1

breaking capacities are stated as

short-circuit

short-circuit

Rated

ultimate

breaking

breaking

capacity;

capacity.

short-circuit

breaking

capacity

(Icu)

The rated ultimate short-circuit

breaking capacity of a circuit-breaker

is the value of ultimate

short-circuit

breaking capacity (see 2,1 5,1) assigned to that circuit-breaker

by the manufacturer

for the corresponding

rated operational

voltage, under the conditions

specified

in 8,3.5. It is

expressed

as the value of the prospective

breaking cWrrent, in kA (r, m.s. value of the a.c.

component in the case of a,c. ),

4.3.5.2.2

Rated service

short-circuit

breaking

capacity

(/=.)

The rated service short-circuit breaking capacity of a circuit-breaker

is the value of service

short-circuit

breaking capacity (see 2,15.2) assigned to that circuit-breaker

by the manufacturer

for the corresponding

rated operational

voltage, under the conditions

specified

in 8.3.4 It is

expressed

as a value of prospective

breaking

current, in kA, corresponding

to one of the

specified percentages

of the rated ultimate short-circuit

breaking capacity, in accordance

with

table 1, and rounded up to the nearest whole number. It may be expressed

as a ‘A of /CU

(for example /C~ = 25 % /cU).

Alternatively,

when the rated service short-circuit

breaking capacity is equal to the rated shorttlme withstand current (see 4.3.5,4), it may be stated as that value, in kA, provided that it is not

less than the relevant minimum value of table 1.

Where /CU exceeds 200 kA for utilization

category A (see 4.4),

category B, the manufacturer

may declare a value /C~ of 50 kA.

Table

Utilization

1 - Standard

category

ratios between

/=S and I=u

Utilization

A

rrlr

11

or 1000

category

B

kA for

utilization

lS/lEC 60947-2:2003

4.3.5.3

Standard

relationship

between short-circuit

making

and related power factor, for a.c. circuit-breakers

The standard relationship

between

capacity is given in table 2.

short-circuit

breaking

and breaking

capacity

capacities

and short-circuit

making

Table 2 -f?atio

n between short-circuit

making capacity and short-circuit

breaking capacity and related power factor (for a.c. circuit-breakers)

Short-c~r~uit\@

reaking

capacity

I

I

Power

Minimum

short

n.

kA r.m.s.

short

NOTE

factor.

value

required

- circuit

making

- circuit

4,5

s/<6

0,7

</<10

0,5

1,7

10

</s20

0,3

2,0

20

<(s50

0,25

50

</

0,2

2,1

2,2

of breaking

capacity

I

capacity

breaking

6

For values

for n

factor

capacity

1,5

lower than 4,5 kA, for certain

applications,

see table

I

11 for the power

The rated short-circuit

making and breaking capacities are only valid when the circuit-breaker

is operated

in accordance

with the requirements

of 7.2.1,1 and 7.2. i.2.

For special requirements,

the manufacturer

capacity higher than that required by table

subject of agreement

between manufacturer

4.3.5.4

Rated short-time

withstand

The rated short-time

withstand

current

current assigned to that circuit-breaker

In 8.3.6.2.

may assign a value of rated short-circuit

making

2. Tests to verify these rated values shall be the

and user.

current

(Icw)

of a circuit-breaker

by the manufacturer

is the value of short-time

under the test conditions

For a.c., the value of this current is the r.m.s value of the a,c. component

short-circuit

current, assumed constant during the short-time delay.

The short-time

delay associated

with the rated

0,05 s, preferred values being as follows:

0,05 –0,1

The rated short-time

table 3

Table

withstand

3-

Rated

current

Minimum

current

In

short-time

–0,25–0,5–1

of the prospective

current

values

of rated short-time

Rated

short-time

withstand

be at least

withstand

current

12 In or 5 kA, whichever

30 kA

values

current

Jcw -

Minimum

values

kA

12

shall

S

shall be not less than the appropriate

A

/n <2500

In >2500

withstand

withstand

specified

is the greater

shown

in

lS/lEC 60947-2:2003

4.4

Utilization

categories

The utilization category of a circuit-breaker shall be stated with reference to whether or not it is

specifically intended for selectivity by means of an intentional time delay with respect to other

circuit-breakers

in series”dn the load side, under short-circuit

conditions (see figure A.3),

Attention is drawn to the differences

of the tests applying

table 9 and 8.3.4, 8.3.5, 8.3.6 and 8.3.8),

Utilization

categories

are defined

categories

(see

in table 4.

Table 4Utilization

to the two utilization

Utilization

categories

Application

category

with

respect

to selectivity

Circuit-breakers

not specifically

intended for selectivity

under shortcircuit conditions with respect to other short-circuit protective devices in

series on the load side, i.e. without an intentional

short-time

delay

provided for selectivity

under short-circuit

conditions,

and therefore

without a short-time withstand current rating according to 4.3.5.4.

A

Circuit-breakers

specifically

intended for selectivity

under short-circuit

conditions with respect to other short-circuit protective devices in series

on the load side, i.e. with an intentional short-time delay (which may be

adjustable),

provided for selectivity under short-circuit conditions. Such

circuit-breakers

have a short-time withstand current rating according to

4.3.5.4.

B

NOTE

Selectivity is not necessarily

ensured up to the ultimate shortcircuit breaking capacity of the circuit-breakers

(for example in the case

of operation of an instantaneous

release)

but at least up to the value

specified in table 3.

NOTE 1 The power factor or time constant

table 11 (see 8.3.2.2.4

and 8,3.2,2.5),

associated

with each value

NOTE 2 Attention

is drawn to the different

requirements

utilization categories A and B, in accordance with table 1.

for the

of rated short-circuit

minimum

required

current

percentage

is given in

of lc~ for

NOTE 3 A circuit-breaker

of utilization

category

A may have an intentional

short-time

delay provided for

selectivity under conditions other than those of short circuit, with a short-time withstand current less than that

according to table 3. In that case, the tests include test sequence

IV (see 8.3.6) at the assigned short-time

withstand current.

4.5

4.5.1

Control

circuits

Electrical

Subclause

control

circuits

4.5.1 of Part 1 applies, with the following addition:

If the rated control supply voltage is different

that its value be chosen from table 5.

Table

from that of the main circuit,

5 – Preferred values of the rated control supply

if different from that of the main circuit

d.c.

Single-phase

v

it is recommended

voltage,

a.c.

v

24-48-110–125–220-250

NOTE

The manufacturer

should be prepared to state the value or values

control circuits at the rated control supply voltage,

24-48--

13

of the current taken

by the

lS/lEC 60947-2:2003

4.5.2

Air-supply

Subclause

4.6

control

circuits

(pneumatic

or electro-pneumatic)

4.5.2 of Part 1 applies

Auxiliary

Subclause

circuits

4,6 of Part 1 applies

Releases

4.7

4.7.1

Types

1) Shunt release;

2)

Over-current

release:

a)

instantaneous;

b)

definite

time delay;

c)

Inverse

time delay:

independent

—

of previous

dependent

on previous

load;

load (for example

thermal

type release).

NOTE 1 The term “overload