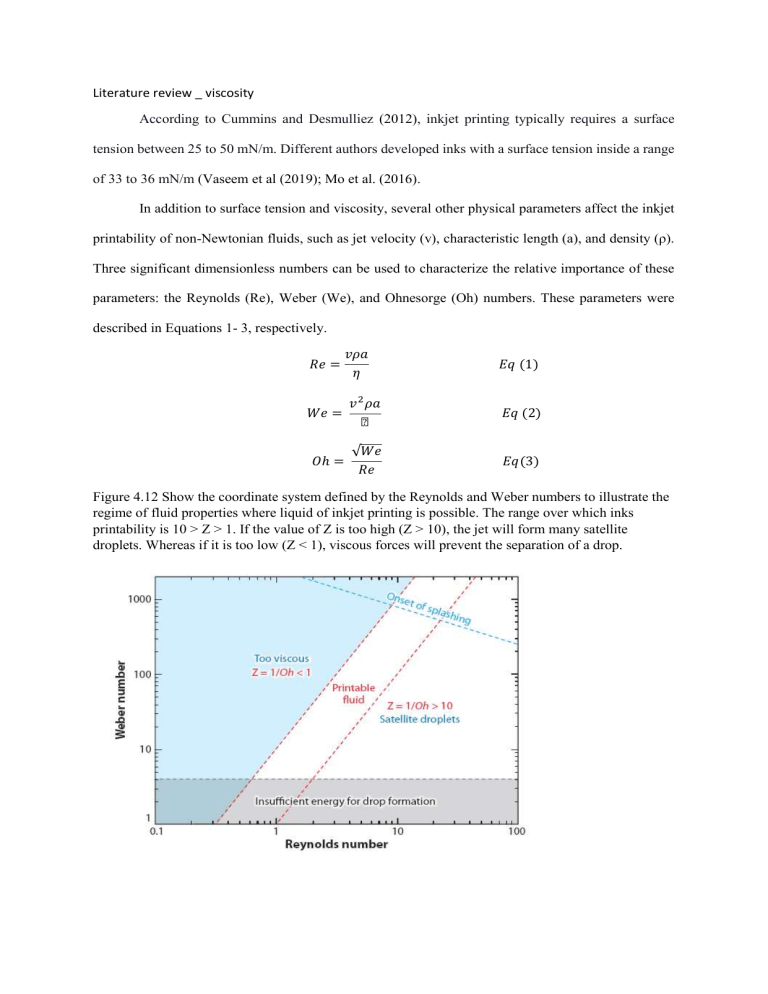

Literature review _ viscosity According to Cummins and Desmulliez (2012), inkjet printing typically requires a surface tension between 25 to 50 mN/m. Different authors developed inks with a surface tension inside a range of 33 to 36 mN/m (Vaseem et al (2019); Mo et al. (2016). In addition to surface tension and viscosity, several other physical parameters affect the inkjet printability of non-Newtonian fluids, such as jet velocity (v), characteristic length (a), and density (ρ). Three significant dimensionless numbers can be used to characterize the relative importance of these parameters: the Reynolds (Re), Weber (We), and Ohnesorge (Oh) numbers. These parameters were described in Equations 1- 3, respectively. 𝑅𝑒 = 𝑣𝜌𝑎 𝜂 𝐸𝑞 (1) 𝑊𝑒 = 𝑣 2 𝜌𝑎 ϒ 𝐸𝑞 (2) 𝑂ℎ = √𝑊𝑒 𝑅𝑒 𝐸𝑞(3) Figure 4.12 Show the coordinate system defined by the Reynolds and Weber numbers to illustrate the regime of fluid properties where liquid of inkjet printing is possible. The range over which inks printability is 10 > Z > 1. If the value of Z is too high (Z > 10), the jet will form many satellite droplets. Whereas if it is too low (Z < 1), viscous forces will prevent the separation of a drop. Figure 4.12: Z = 1/Oh that allows stable printing, can be plotted in a coordinate system defined by the Reynolds and Weber numbers to illustrate the regime of fluid properties where liquid of inkjet printing is possible (Reis & Derby, 2000)