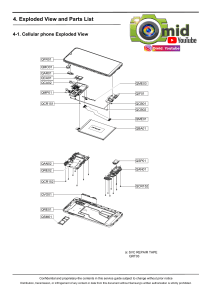

REPAIR PROCEDURE DJ 1220C REVISIONS STATUS ER:AMF Rev Revision Description A Creation of document B Code for Localized printer NVRAM reset Date 23 Mar 00 20 Jun 00 Initials Delphine Sourdin Delphine Sourdin DISTRIBUTION LIST Department Function Super crescent repair line Crescent repair line Management Management APPROVAL Function Business Engineer Rev: B Edition date: Name Didier MONBEIG 2-Dec-22 Date 20/06/00 Signature DMo HP CONFIDENTIAL Document No: A-5969-3685-6 Page: 1 H TABLE OF CONTENTS 1. OBJECTIVE ....................................................................................................................................................................... 3 2. CONCERNED PRODUCT ................................................................................................................................................ 3 3. PRODUCT OVERVIEW ................................................................................................................................................... 3 3.1 GENERAL FEATURES............................................................................................................................................................. 3 3.2 BASIC OPERATION ................................................................................................................................................................ 4 3.3 BASIC LIGHT OPERATION...................................................................................................................................................... 5 4. MATERIAL AND EQUIPMENT REQUIRED FOR REPAIR...................................................................................... 6 4.1 TOOLING LIST ....................................................................................................................................................................... 6 4.2 CALIBRATION TOOL: ............................................................................................................................................................. 6 4.3 MATERIAL AVAILABLE ON BENCH:........................................................................................................................................ 6 5. OVERALL REPAIR FLOWCHART ............................................................................................................................... 8 6. TROUBLESHOOTING ..................................................................................................................................................... 9 6.1 ERROR LIGHT ........................................................................................................................................................................ 9 6.2 AUTOALIGMENT ................................................................................................................................................................. 12 6.3 DIAGNOSTIC PAGE .............................................................................................................................................................. 13 6.4 SELF TEST .......................................................................................................................................................................... 13 6.5 NOZZLE PATTERN TEST ...................................................................................................................................................... 14 6.6 PEN RECOVERY ROUTING ................................................................................................................................................... 14 6.7 NTF TEST........................................................................................................................................................................... 15 6.7.1 Identify Error code .................................................................................................................................................... 15 6.7.2 Continuous H Test ..................................................................................................................................................... 15 6.7.3 Carriage Test ............................................................................................................................................................. 16 6.7.4 Service station test ..................................................................................................................................................... 16 6.8 COMMUNICATION TEST ...................................................................................................................................................... 17 6.9 AUTO PPS ADJUSTMENT TEST ........................................................................................................................................... 18 6.10 FINAL TEST....................................................................................................................................................................... 19 7. SPECIFIC OPERATION ................................................................................................................................................. 22 7.1 CALIBRATION PROCEDURE .................................................................................................................................................. 22 7.2 CLEANING RECOMMENDATIONS ......................................................................................................................................... 24 7.3 DISASSEMBLY RECOMMENDATIONS .................................................................................................................................. 24 7.4 LUBRICATION PROCEDURE ............................................................................................................................................... 25 7.5 SHIPPING INSTRUCTIONS .................................................................................................................................................... 25 7.6 CARTRIDGE RETURN INSTRUCTIONS ................................................................................................................................... 25 8. UPDATE ............................................................................................................................................................................ 26 8.1 FIRMWARE FLASH ............................................................................................................................................................... 26 8.2 NVRAM RESET .................................................................................................................................................................. 26 9. EXPLODED VIEW .......................................................................................................................................................... 27 10. APPENDIX: ERROR CODE........................................................................................................................................... 33 Rev: B Edition date: 2-Dec-22 HP CONFIDENTIAL Document No: A-5969-3685-6 Page: 2 H 1. OBJECTIVE The purpose of this procedure is to describe and to document the repair process to follow, the tooling to use, and the specific operations to do in order to mend the DJ1220C printer. 2. CONCERNED PRODUCT Product Number C2693A Part-Numbers C2693-69055 C2693-69055R Descriptions DJ1220C Professional printer – Exchange program DJ1220C Professional printer – Repair & Return program 3. PRODUCT OVERVIEW 3.1 GENERAL FEATURES DJ1220C is the 4th wide-format (A3) printer from DJ1000 Series, following on DJ1120C. The market position of Escher is in the versatile business with A3 format to 105x148.5mm cards printing performance, print quality and speed. DJ1220C delivers HP's latest PhotoREt III at a speed of 10~11 ppm for black and 8~9 ppm for color. DJ1220C comes with a comprehensive built-in connectivity solution targeted at Wintel as well as Apple customers. It has both the parallel and USB hardware interfaces. Optional network supports are available through HP JetDirect external print servers. The internal mechanism (carriage assembly, service station) is based on Dj970C printer, and the picking system has been improved and redesign from Dj1120C. Rev: B Edition date: 2-Dec-22 HP CONFIDENTIAL Document No: A-5969-3685-6 Page: 3 H 3.2 BASIC OPERATION 1. 2. 3. 4. 5. 6. 7. 8. 9. 10. 11. 12. 13. 14. 15. 16. Rev: Output tray –Collects the printed pages. Paper guides –Guides the paper into the printer. Access cover –Gives access to the print cartridges and jamed paper. Bypass stopper –Lifts for inserting paper into the alternative top media feed. Cartridge LED –Blinks when the access cover is open or a cartridge error occurs. Cancel button –Cancels the current print job. Resume button –Blinks while waiting for a printed page to dry.Press it if you do not want to wait. Power button –Turns the power off and on. Postcard guide –Extends to guide short media into the printer. Main paper tray –Holds the standard paper. USB port –Jack for the Universal Serial Bus cable. Parallel port –Jack for the parallel cable. Rear media feed –Feeds thicker paper that requires a straight paper path. Removable panel knob –Turns counterclockwise for removing the rear panel,or clockwise to lock it. Removable panel –Alternate access to jammed paper. Power input –Connector for the power cable. B Edition date: 2-Dec-22 HP CONFIDENTIAL Document No: A-5969-3685-6 Page: 4 H 3.3 BASIC LIGHT OPERATION The following table describes how the LEDs appear during normal printing. Rev: B Edition date: 2-Dec-22 HP CONFIDENTIAL Document No: A-5969-3685-6 Page: 5 H 4. MATERIAL AND EQUIPMENT REQUIRED FOR REPAIR 4.1 TOOLING LIST The following tools are required to disassemble the printer, to debug it, to calibrate it, to clean it and to lubricate it: Tool Repair Level Tissue 1 Clean Lint-free cloth 1 Large and small Flat Blade 2 Screwdrivers T-8-10-20 Torx Screwdriver 2 Needle Nose Pliers 2 ESD protection 2 ESD PCA bag 2 Pentium Computer 90Mhz 2 Running Windows 95, with a Wordpad application IEEE-1284 Interface cable 2 Calibration tool (see details below) 3 A3 Paper 1 Purpose To clean Cartridge Contacts Cleaning the printer carriage and case parts Assembly / Disassembly tool Removing parts and Assy Removing small parts Protect electronic parts, ensure static free area PCA protection Running the online service manual, printer utilities, diagnostics tests Connecting printers to a computer for performing diagnostic tests and adjustment. Calibrate the pen to paper spacing to ensure optimum print quality, avoid paper jam, paper skew, and print smear. Three tools may be used, see note below. Test A3 picking 4.2 CALIBRATION TOOL: Three calibration tools may be used to calibrate Pen to Paper spacing on Dj1220C: 1. DJ1100/1120C tool: DJ11xx PPS adjustement tool DJ11xx PPS Calibration stand Procedure A-5967-0259-7 for tool maintenance and calibration 2. New DJ1220C tool: Not yet available 3. LVDT Calibration tool LVDT tool Readout controller 4.3 MATERIAL AVAILABLE ON BENCH: To be available on each bench: - The Repair flowchart - The quality code list Rev: B Edition date: 2-Dec-22 HP CONFIDENTIAL Document No: A-5969-3685-6 Page: 6 H At least one copy available on the repair line and easy of access for all technicians: - The service manual - The repair procedure Rev: B Edition date: 2-Dec-22 HP CONFIDENTIAL Document No: A-5969-3685-6 Page: 7 H 5. OVERALL REPAIR FLOWCHART In order to help understanding the repair process and the procedure, please follow this flowchart during repair to assure a correct repair process. See the Update procedure to check if any update has to be done before, during or after repairing the printer. Place - 2 sheets on Upper tray Repair Step How? Documentation Receiving Localize printer product number Receiving Procedure Autoalignment Insert paper and cartridge in printer Then power ON the printer Repair procedure : Troubleshooting - a stack of sheets on lower tray Make Failure Diagnostic 1/ Print Diagnostic Test 2/ Print Self-Test 3/ Nozzle pattern Test Repair procedure : Troubleshooting Test OK? Yes NO Fail Run NTF test Trouble shooting 1. Check Last Error code 2. Continuous H Test on A3+A4 3. Service station test 4. Carriage Test Change defective part Use: - Customer CSO complaint - printer ERROR Light - Pen recovery routing - Alignment routing - Repair procedure : Troubleshooting - Service manual guide Localize part description on exploded view and find part# on PUMA Material list - Service manual Guide - repair procedure: Exploded view Is the part level 3? NO Yes Pass Calibration is required Carry out Pen To Paper calibration Test Communication Toolbox / printer service If printer is NTF or if you have removed left support assy or the drive roller: Make the Auto PPS adjustment test > If PCA is changed: check Firmware version. > if PCA is changed and for all Exchange unit Reset the NVRAM Final Test - Repair procedure: Calibration Run Auto PPS adjustment test - Repair procedure : Troubleshooting Use Print diagnostic test. If FW < 10.3, then flash FW - Repair procedure: Update Run test from Diagnostic Software print on A4 and A3 Paper - Repair procedure : Troubleshooting Carry out cleaning and lubrication Repair procedure: Specific operations NO Final test OK? Yes Cleaning and final inspection Quality data Rev: B Edition date: 2-Dec-22 HP CONFIDENTIAL Document No: A-5969-3685-6 Page: 8 H 6. TROUBLESHOOTING 6.1 ERROR LIGHT 6.1.1 Basic Error light Rev: B Edition date: 2-Dec-22 HP CONFIDENTIAL Document No: A-5969-3685-6 Page: 9 H 6.1.2 Advanced Error light Note: The Page numbers indicated refer to the service manual guide Rev: B Edition date: 2-Dec-22 HP CONFIDENTIAL Document No: A-5969-3685-6 Page: 10 H Rev: B Edition date: 2-Dec-22 HP CONFIDENTIAL Document No: A-5969-3685-6 Page: 11 H 6.2 AUTOALIGMENT This test calibrates the print cartridges by aligning the cartridges, as well as optimizing the turn-on energy for the color print cartridge. WHEN 1/ Automatically at first power on (due to cartridge installation) HOW Hold down the Power Button while pressing the Resume Button 3 times. 2/ For Troubleshooting: if print cartridge alignment is incorrect CHECK Alignment Verification: All the bands should be line up evenly along the top and bottom edges No white gap between color band Alignment Verification Rev: B Edition date: 2-Dec-22 HP CONFIDENTIAL Document No: A-5969-3685-6 Page: 12 H 6.3 DIAGNOSTIC PAGE WHEN For failure diagnostic HOW Press and hold the Power Button and press the Resume Button four times. CHECK - check general printer operation - Use Last error code if NTF unit - Check firmware revision (see the 3 last numbers) HOW - Press the Resume Button and release it when the Resume Light turns off. CHECK - check general printer operation - Printing quality - Paper picking and output - Unusual noise 6.4 SELF TEST WHEN For failure diagnostic Rev: B Edition date: 2-Dec-22 HP CONFIDENTIAL Document No: A-5969-3685-6 Page: 13 H 6.5 NOZZLE PATTERN TEST This test prints a pattern to determine which nozzles, if any, are clogged or not firing. WHEN For failure diagnostic HOW Hold down the Power Button while pressing the Cancel Button 8 times and the Resume Button 4 times. CHECK Look for gaps in the test pattern, these indicate faulty nozzles. If faulty nozzles, perform a pen recovery routing (see below) 6.6 PEN RECOVERY ROUTING WHEN For Troubleshooting: If printouts have incomplete text or graphics that are not corrected by cleaning the print cartridges HOW Level 1 “light cleaning”: Hold CHECK After cleaning routing, print a down the Power Button while Nozzle pattern test, go the pressing the Cancel Button twice. upper level if gaps remain. Level 2 “intermediate cleaning” : Hold down the Power Button while pressing the Cancel Button twice and the Resume Button once. Level 3 “intensive cleaning” : Hold down the Power Button while pressing the Cancel Button twice and the Resume Button twice. Rev: B Edition date: 2-Dec-22 HP CONFIDENTIAL Document No: A-5969-3685-6 Page: 14 H 6.7 NTF TEST 6.7.1 Identify Error code Where: 8 digit code on the Diagnostic Page (see6.3) Use the error code only when the first digit is different from 0 or 1. Ex: C 002 01 30 2nd set 3rd set 4th set -2nd set correspond to the ASSERT_COMPONENT ID -3rd set correspond to the ASSERT_PRODUCT_TYPE (do not matter about this one) -4th set correspond to the ERROR CODE Refer to appendix at the end of this procedure for list of ASSERT_COMPONENT ID, and ERROR CODE. Rev: 6.7.2 Continuous H Test WHEN For NTF unit - on ~10 A4 sheets - and ~10 A3 sheets HOW Press and hold the Power Button while pressing the Resume Button 8 times. B Edition date: HP CONFIDENTIAL Document No: A-5969-3685-6 2-Dec-22 CHECK Look for paper picking issue, paper jam, paper skew, ink smearing Page: 15 H 6.7.3 Carriage Test WHEN For NTF unit HOW Use Diagnostic software CHECK Look for carriage stall, unsusual operation, unusual noise, carriage friction HOW Use Diagnostic software CHECK Look for service station unusual operation 6.7.4 Service station test WHEN For NTF unit Rev: B Edition date: 2-Dec-22 HP CONFIDENTIAL Document No: A-5969-3685-6 Page: 16 H 6.8 COMMUNICATION TEST WHEN Before final test Rev: B Edition date: HOW Use Toolbox 2-Dec-22 HP CONFIDENTIAL Document No: A-5969-3685-6 CHECK Test OK Page: 17 H 6.9 AUTO PPS ADJUSTMENT TEST For NTF unit and each time you have removed the Left Support assy or the drive Roller, Perform this test to ensure that the AutoPPS adjustement system works properly. WHEN HOW For NTF unit and each - Open a Wordpad document time you have removed (or any other application the Left Support assy or that can use the dj1220 the drive Roller driver) - in Properties/Setup/Type select Thick plain paper - send the print job Rev: B Edition date: 2-Dec-22 HP CONFIDENTIAL Document No: A-5969-3685-6 CHECK Ensure the printer perform following operations: - carriage move to the left position - drive roller turn backward, then forward - pivot tilt down then up - The pivot is now on thick media position (it is difficult to see, but the pivot should be lightly lower than the normal position) - After the print job, the carriage move again to the left position - drive roller turn backward, then forward - pivot tilt down then up The pivot is now on normal position Page: 18 H 6.10 FINAL TEST WHEN HOW For all unit at the end of Use Diagnostic software repair process CHECK Pen To Pen Alignment Smear Test Skew Black and color pen Addressing BiDirectional Alignment Track Mark Rev: B Edition date: 2-Dec-22 HP CONFIDENTIAL Document No: A-5969-3685-6 Page: 19 H Skew Test Marks Skew test marks help you to verify that the top skew, side skew and feed skew are within specifications. To check printer top skew, 1. Fold along the short (top) edge 2. Make sure the side edges are flush against each other. 3. Look at the fold through a light source.. 4. The top skew test is considered a failure, if the boxes do not touch each other. To check printer side skew, 1. Fold along the long (side) edge 2. Make sure the side edges are flush against each other. 3. Look at the fold through a light source. 4. The side skew test is considered a failure if the boxes do not touch each other. If the printer consistently displays skewed print, verify that: paper is correctly installed. Input Tray is completely installed to the printer. Paper Separator is present. pressure plate on the Input Tray is not warped and that it contains cork. OOPS flag does not drag excessively on the paper or stick. there are no missing pinch rollers, and that pinch rollers are properly installed and seated. all components of the paper path system are present and installed correctly. the width adjuster and paper stopper are not applying too much or too little pressure to the paper. driver rollers are not defective. pick roller is in the correct position Smear Test Make sure that the lines in the gray boxes do not cross each other or smear into thicker lines. Black Pen and Color Pen Addressing This printout shows a series of “ladders” of black and color print. These ladders represent addresses that relate directly to one of the nozzles on the black cartridge or one of the nozzles on the color print cartridge. If one of the blocks or a rung of the ladder is missing, an inter-connect problem exists. Clean or replace a cartridge and try again. If the problem still exists, replace the Carriage PCA. Bi-directional Alignment There are three sets of seven bi-directional alignment patterns. Each bi-directional pattern contains 4 lines. Check that in every set, the pattern that is aligned is within the 5 centered pattern. Bi-directional alignment problems could be caused by the carriage not locating properly. To solve this problem, check the following: Check that the Encoder Strip is properly routed through Carriage PCA. Check that the Encoder Strip is properly seated. Check if the Carriage PCA is loose, or if any of its parts have come loose. Check that the Carriage does not have too much friction Check that the Carriage Motor is not defective Rev: B Edition date: 2-Dec-22 HP CONFIDENTIAL Document No: A-5969-3685-6 Page: 20 H Check that the Carriage Motor screws are properly seated Check that the Encoder Spring is present and not damaged Track Mark This is to test if the star-wheels leave tracks on the test page. While viewing the test page from 18 inches away, check that there are no noticeable track marks in the white space at the bottom of the page after the black horizontal line. Pen to Pen Alignment This is to test if the black pen and the color pen are properly aligned. The test is considered successful if there is a gap between the black bands and the colored one in each pattern. Rev: B Edition date: 2-Dec-22 HP CONFIDENTIAL Document No: A-5969-3685-6 Page: 21 H 7. SPECIFIC OPERATION 7.1 CALIBRATION PROCEDURE The only calibration the HP 1220C printer requires is the pen-to-paper spacing.When properly calibrated, the printer provides optimum print quality without compromising media handling capabilities. Print quality improves as the print cartridges move closer to the media. However, if the cartridges are too close to the media, paper jams, print skew or print smear may occur. WHEN: To maintain accurate pen-to-paper spacing, you must calibrate the printer whenever on of the following printer parts is removed or replace: Carriage Assembly/Carriage Rod/ Belt / Flex cable / Carriage PCA Backbone Assembly Upper Paper Guide Assembly Drive Roller Assembly / Pivot / Pivot guide Trough-1 Assembly / Pick separator assembly Right Support Assembly Left Support Assembly / Index sensor Base Plate assembly Prepration: Ensure the Pivot is fully raised; this is its normal position. Locate the gear on the right side of the Service Station to unlock the Carriage. Remove the black and color print cartridges. 7.1.1 Using DJ1220C Calibration Tool TIJ2.5 C6471A: 1. Pull out the latch (1a) on the PPS Calibration Tool; this will retract the tool’s probe tip (1b) and prevent damage to the tool and the printer. 2. Insert the PPS Calibration Tool into the color cartridge cradle and close the print cartridge latches. Make sure the Carriage can move freely. 3. Move the Carriage to align the ESD clip on the color cartridge cradle with the fifth cockle rib to the left of the pivot. The Carriage will now be near the left end of the Carriage Rod. 4. Gently push the latch on the PPS Calibration Tool to release the probe and measure the pen-topaper spacing. It should read 55 +/- 10 mils. 5. To adjust PPS, loosen the three silver screws that secure the Upper Rail to the Backbone Assembly. Insert a flathead screwdriver into the slot on the Upper Rail that is closest to the Carriage. Turn the screwdriver until the tool reads 55 +/- 10 mils. 6. Raise the PPS Tool latch and move the Carriage to align the ESD clip on the color cartridge cradle with the third cockle rib to the right of the pivot.The Carriage will now be near the right end of the Carriage Rod. 7. Repeat steps four and five. 8. Recheck your first measurement near the left end of the Carriage Rod; adjusting the right end of the Carriage Rod can affect the left side. Read-just the left end if necessary. 9. Tighten the silver screws. Rev: B Edition date: 2-Dec-22 HP CONFIDENTIAL Document No: A-5969-3685-6 Page: 22 H 7.1.2 Using old Dj1100/1120 Calibration Tool: Use same procedure as above. The calibration value correspond to the green zone of the tool. Adjust the upper rail until the pointer points close to the midpoint of the green zone. Rev: B Edition date: 2-Dec-22 HP CONFIDENTIAL Document No: A-5969-3685-6 Page: 23 H 7.1.3 Using LVDT Calibration Tool: 1. Move the Carriage to align the ESD clip on the black cartridge cradle with the fifth cockle rib to the left of the pivot. The Carriage will now be near the left end of the Carriage Rod. 2. Insert the LVDT Calibration Tool into the black cartridge cradle and close the print cartridge latches. 3. Ensure the probe tip of the tool is resting on the cockle rib and check the PPS measurement. The MP1000 should read 55 mil +- 10. 4. To adjust PPS, loosen the three silver screws that secure the Upper Rail to the Backbone Assembly. Insert a flathead screwdriver into the slot on the Upper Rail that is closest to the Carriage. Turn the screwdriver until the MP - 1000 reads 55 mil +- 10. 5. Lift the trigger on the LVDT Tool and move the Carriage to align the ESD clip on the black cartridge cradle with the third cockle rib to the right of the pivot. The Carriage will now be near the right end of the Carriage Rod. 6. Repeat steps two through four. 7. Recheck your first measurement near the left end of the Carriage Rod; adjusting the right end of the Carriage Rod can affect the left side. Read-just the left end if necessary. 8. Tighten the silver screws. 7.2 CLEANING RECOMMENDATIONS Rod: Cleaning the rod is not recommended, if extremely dirty, wipe with a clean lint-free cloth. Do not use water or solvent Backbone, Pivot Assembly, Print cartridge contact: Use water on a a clean lint-free cloth and dry carefully Encoder strip: Wipe left to right with a clean lint-free cloth. Do not pull hard Drive roller: Use water on a a clean lint-free cloth and dry carefully, Do not use solvent Sponge and wiper of service station: Replace when too dirty 7.3 DISASSEMBLY RECOMMENDATIONS ESD: Electrostatic discharge from your body can damage the Printer Circuit Assemblies (PCAs). Before removing any PCA, ensure that your work area is static-free; wear ESD dissipative straps, use an ESD mat, or work at an ESD protected workstation. Ensure the cleanout trough is in place for testing Starwheel: Do not rest Starwheel assy on Starwheel, they could be damaged by th weight. Encoder disk: When you remove the encoder disk, always replace it with a new one. Upper Paper guide: If you need to move the Auto PPS bearing, take a mark of its location, and replace the bearing at the same location after Paper guide assembly. AutoPPS Bearing Rev: B Edition date: 2-Dec-22 HP CONFIDENTIAL Document No: A-5969-3685-6 Screw hole for Paper guide Page: 24 H 7.4 LUBRICATION PROCEDURE Lubrification oil in containned in carriage bearings. Slide the carriage along the rod to lubricate it. 7.5 SHIPPING INSTRUCTIONS 1/ Always shut down the printer with Power button (not by unplugging power cord) in order to ensure carriage lock. 2/ Printer should not come with output tray. If a customer let is output Tray on a Repair&Return program unit, pack it with bull pack and place it in the box. 3/ Place tape on the printer as shown on photo below. Tape on access door is EXTREMELY IMPORTANT to avoid damage/unclipping during transport. 7.6 CARTRIDGE RETURN INSTRUCTIONS Express Exchange / Unit Exchange: Do not include any cartridge with repaired printer. Express Pick Up and Delivery / (Retrieve,) Repair and Return: If customer has not let his cartridge: Do not include any cartridge with repaired printer. If customer has let his cartridge : - If cartridge is good: Return it to customer using millboard. - If cartridge is defective: Give a new one to customer (let it in the cartridge packaging) Rev: B Edition date: 2-Dec-22 HP CONFIDENTIAL Document No: A-5969-3685-6 Page: 25 H 8. UPDATE 8.1 FIRMWARE FLASH Any time you change the PCA, perform following actions: 1. Print a diagnostic test: POWER + 4x RESUME 2. Check firmware revision (ex EF410103) If last three number are below 103 , then flash firmware: 1) Power off the printer 2) Make sure that you have the printer connected directly to the PC, power up the by pressing the POWER button while holding down the CANCEL and RESUME button. Ensure all three LED lights up. This put the printer in flash mode. 3) From the dos command of the PC , type: copy /b EF410103Intl.bhx lpt1: 4) You should be able to see the three led lights flashing. 5) Upon completion the printer will go into the ready state. 6) Do the 4click test again to verify that the firmware is updated to revision 103. 8.2 NVRAM RESET Any time you change the PCA and for all Exchange unit, reset NVRAM value via Diagnostic Software. Warning: Type “ OK” for generic printer and “PJ” for localised printer at the end of the serial number. Rev: B Edition date: 2-Dec-22 HP CONFIDENTIAL Document No: A-5969-3685-6 Page: 26 H 9. EXPLODED VIEW Rev: B Edition date: 2-Dec-22 HP CONFIDENTIAL Document No: A-5969-3685-6 Page: 27 H Rev: B Edition date: 2-Dec-22 HP CONFIDENTIAL Document No: A-5969-3685-6 Page: 28 H Rev: B Edition date: 2-Dec-22 HP CONFIDENTIAL Document No: A-5969-3685-6 Page: 29 H Rev: B Edition date: 2-Dec-22 HP CONFIDENTIAL Document No: A-5969-3685-6 Page: 30 H Rev: B Edition date: 2-Dec-22 HP CONFIDENTIAL Document No: A-5969-3685-6 Page: 31 H Description Assy Door Access SVC Assy End Cap Left SVC Assy End Cap Right SVC Assy Stopper SVC Assy Input Tray SVC Assy Output Tray SVC Assy Carriage SVC Cable Flex -Head/Drive SVC Assy Strip Encoder SVC Belt Carriage SVC Assy Carriage Motor SVC PCA Linefeed/Encoder SVC Guide - Encoder SVC Assy Output Ramp Motor SVC Cover Rail SVC Assy Starwheels SVC Assy Output Mech. SVC Assy Backbone SVC Assy Upper Paper Guide SVC Assy Cleanout Trough SVC Assy Pick Roller SVC Belt Output SVC Assy Trough 1 SVC Assy Left Support SVC Assy Right Support SVC Assy Service Station Mech SVC Assy Drive Roller SVC Assy Encoder Disc SVC Assy Harness Logic Main SVC Assy Base Plate SVC Hand Grab Stopper Guide Harness Power Switch SVC PCA Keypanel SVC Assy Power Supply SVC Assy Logic PCA SVC Insulator Power SVC Assy Spot Sensor SVC Main Back Panel SVC Assy Service station Motor SVC Assy Wiper SVC Sponge SVC Assy Harness Power Supply SVC PCA Carriage SVC Pivot SVC Guide-Pivot SVC Assy Separator Pick SVC Index Sensor SVC Hardness Index Sensor SVC Assy Cable, Spot Snsr SVC Cover ESD SVC Low Usage Kit 2 Rev: B Edition date: 2-Dec-22 MFG PRO ID 1 2 3 4 5 6 7 8 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25 26 27 28 29 30 31 32,33 34 35 37 38 39 42 43 A2 C1 C2 C5 D1 E3 F1 F2 G4 H1 H2 K2 K3 B1,B2,E4,E5,G1,G2,G3,J2 HP CONFIDENTIAL Document No: A-5969-3685-6 Page: 32 H 10.APPENDIX: ERROR CODE ASSERT_COMPONENT ID ASSERT_ID_STACK_CHECK ASSERT_ID_MECH ASSERT_ID_PEN ASSERT_ID_CARRIAGE ASSERT_ID_PAPER ASSERT_ID_SS ASSERT_ID_UDW ASSERT_ID_PROCESSOR ASSERT_ID_SWEEP_MGR ASSERT_ID_REPORTS ASSERT_ID_PCL ASSERT_ID_PORTSEL ASSERT_ID_P1284 ASSERT_ID_CBIO 0x01 0x02 0x03 0x04 0x05 0x06 0x07 0x08 0x09 0x0A 0x0B 0x0C 0x0D 0x0E ERROR CODE Carriage errors ERROR_CARRIAGE__SHUTDOWN_WHILE_MOVING Cbio errors ERROR_CBIO__A2D_READ_FAILED ERROR_CBIO__CARRIAGE_BOARD_NOT_RESPONDING ERROR_CBIO__DUDLEY_CALIBRATION_VALUE_INVALID ERROR_CBIO__DUDLEY_CALIBRATION_PWM_OUT_OF_RANGE Processor errors ERROR_PROCESSOR__ACCESS_ERROR ERROR_PROCESSOR__ADDRESS_ERROR ERROR_PROCESSOR__ILLEGAL_INSTRUCTION ERROR_PROCESSOR__PRIVELEGE_VIOLATION ERROR_PROCESSOR__UNIMPLEMENTED_A_OPCDE ERROR_PROCESSOR__UNIMPLEMENTED_F_OPCODE ERROR_PROCESSOR__FORMAT_ERROR ERROR_PROCESSOR__UNINITIALIZED_INTERRUPT Generic Firmware Errors ERROR__FIRM_TABLE_SIZE_MISMATCH ERROR__FIRM_TABLE_NAME_TOO_LONG ERROR__BAD_PROVIDED_IFC_INDEX ERROR__BAD_REQUIRED_IFC_INDEX ERROR__BAD_MESSAGE_SEND ERROR__UNKNOWN_COMMAND ERROR__UNEXPECTED_COMMAND ERROR__UNIMPLEMENTED_COMMAND ERROR__OUT_OF_ROOM ERROR__PARM_OUT_OF_RANGE ERROR__PARM_VALUE_TOO_SMALL ERROR__PARM_VALUE_TOO_LARGE ERROR__PARM_MISMATCH ERROR__UNEXPECTED_VALUE ERROR__UNEXPECTED_NULL_PTR Rev: B Edition date: 2-Dec-22 HP CONFIDENTIAL Document No: A-5969-3685-6 0x01 0x01 0x02 0x03 0x04 0x08 0x09 0x0A 0x0B 0x0C 0x0D 0x0E 0x0F 0x7F 0x80 0x81 0x82 0x83 0x84 0x85 0x86 0x87 0x88 0x89 0x8A 0x8B 0x8C 0x8D Page: 33 H ERROR__EXPECTED_NULL_PTR ERROR__LESS_THAN_ZERO ERROR__DIVIDE_BY_ZERO Mechanism Errors ERROR_MECH_MEDIA_JAM ERROR_MECH_PAPER_STALL ERROR_MECH_CARRIAGE_STALL ERROR_MECH_LESS_THAN_ZERO_TIMER_UNIT ERROR_MECH_UNEXPECTED_TIMER_UNIT ERROR_MECH_UNEXPECTED_TIMER_STATE ERROR_MECH_NOT_MODIFIER_TIMER ERROR_MECH_UNKNOWN_TIMER_COMMAND ERROR_MECH_TIMERS_NOT_ACTIVE ERROR_MECH_BAD_STARTUP ERROR_MECH_UNKNOWN_TIMER_UNITS ERROR_MECH_IN_JOB_TOLD_TO_START_JOB ERROR_MECH_NOT_IN_JOB_TOLD_TO_END ERROR_MECH_NO_CARRIAGE_BOARD ERROR_MECH_CARRIAGE_BOARD_OFF ERROR_MECH_CAL_NO_GAIN_FOUND ERROR_MECH_CAL_BAD_A2D_MIN ERROR_MECH_CAL_CANT_GENERATE_A_GAIN ERROR_MECH_CAL_CANT_GENERATE_A_OFFSET ERROR_MECH_CAL_CANT_GENERATE_B_GAIN ERROR_MECH_CAL_CANT_GENERATE_B_OFFSET ERROR_MECH_CAL_BAD_CROSSPOINTS Pen Errors ERROR_PEN__BAD_TRIDENT_PARITY ERROR_PEN__TRIDENT_A2D_INCOMPLETE ERROR_PEN__REGULATOR_FAILURE ERROR_PEN__NOT_MANUAL_IO_MODE ERROR_PEN__NOT_PRINTING_IO_MODE ERROR_PEN__NOT_AUTOSTROBING_IO_MODE ERROR_PEN__BAD_PEN_WORD_OUT_PARM ERROR_PEN__CARRIAGE_BOARD_OFF Portsel Errors ERROR_PORTSEL_RESERVED_CHARACTER ERROR_REPORTS Sweep Manager Errors SWEEP_MGR_INVALID_NOZZLE SWEEP_MGR_NO_DATA_PRESENT SWEEP_MGR_NOT_IN_DD SWEEP_MGR_INVALID_CAR_SP SWEEP_MGR_INVALID_DIR SWEEP_MGR_DATA_BUF_FULL SWEEP_MGR_NEG_MOVE SWEEP_MGR_INVALID_RES SWEEP_MGR_TOO_MANY_SWEEPS SWEEP_MGR_NO_DATA_FOUND SWEEP_MGR_INVALID_RSPEED SWEEP_MGR_INVALID_FIRE_RES SWEEP_MGR_MISMATCH_KCMY_POS 0x8E 0x8F 0x90 0x01 0x02 0x03 0x04 0x05 0x06 0x07 0x08 0x09 0x0a 0x0b 0x0c 0x0d 0x2f 0x30 0x40 0x41 0x42 0x43 0x44 0x45 0x46 0x01 0x02 0x03 0x04 0x05 0x06 0x29 0x30 0x01 0x00 0x00 0x01 0x02 0x03 0x04 0x05 0x06 0x07 0x08 0x09 0x0a 0x0b 0x0c END OF PROCEDURE Rev: B Edition date: 2-Dec-22 HP CONFIDENTIAL Document No: A-5969-3685-6 Page: 34 H