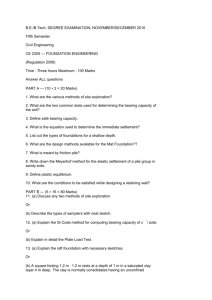

GEOTECHNICAL INVESTIGATION REPORT ON CONSTRUCTION OF OVERHEAD TANK AT HILL CITY, PERNAMITTA, ONGOLE, OF ANDHRA PRADESH. NAME OF THE COMPANY: M/s AUGUST INFRA, VISAKHAPATNAM, ANDHRA PRADESH. CLIENT: M/S PAANYA PROPERTIES Location of Site: HILL CITY, PERNAMITTA, ONGOLE, ANDHRA PRADESH. Soil Investigation By: M/s PRUDHVI CONSULTANTS, GUNTUR-2 1. INTRODUCTION M/s August infra Visakhapatnam, Andhra Pradesh, requested to conduct necessary soil tests on soil samples collected by M/S Prudhvi Consultants and to recommend suitable foundation and bearing capacity of soil for proposed construction of Overhead tank at Hill city, pernamitta, Ongole, District of Andhra Pradesh through Prudhvi Conultants Guntur. The client chose the test location and depth of investigation. Boreholes were subjected to standard penetration tests (SPT). Soil samples from disturbed and undisturbed boreholes were collected for laboratory testing. The index properties and Engineering properties of the soil were performed in the laboratory to determine the safe pressure on the encountered strata. 2. SCOPE OF WORK The following is the scope of work for M/S. Prudhvi Consultants, Guntur. Soil boring at One (1) location Collection of Undisturbed / Disturbed samples from the bore hole Observing the water table, if encountered Conducting standard penetration test (SPT) at 1m /1.50 m depth intervals as per IS Code 2131-1981 The following is the scope of work of M/S Quality Laboratory Services, Soil investigation and testing department Testing of soil sample in the laboratory Preparation of technical report, recommendation of suitable foundations and the Safe Bearing Capacity of soil. 3 SUMMARY The details of the soil investigation conducted along with their results, analysis of the results, recommendations for type of foundation and allowable bearing pressure at founding level thereof has been presented in this report in the form of tabular columns. All the Laboratory tests were conducted as per relevant Indian Standard codes. The geotechnical investigations have indicated that the soil consists of Blackish- Reddish Stiff Clay. Water table was not encountered till the termination depth during the period of field investigation. Subsurface conditions encountered during construction may vary somewhat from the conditions encountered during the site investigation. In case significant variations are encountered during construction, we request to be notified so that our engineers may review the recommendations in this report in light of these variations. Considering the type of structures involved and the subsoil characteristics as determined from the geotechnical investigations, the following are the various options for the choice of foundation. Shallow foundations and Deep foundation in the form of Isolated Square footing Combined footing Raft Foundation Under-reamed pile foundation The actual size of foundations and type of foundations will be based on type of structure, loading conditions, spacing of columns etc. The depth of foundation should satisfy the following requirements. It should rest on ground of adequate bearing capacity and safe from settlement considerations also It should have adequate embedded length so as to resist the overturning moments due to horizontal forces. 4. FIELD INVESTIGATION PROCEDURE The subsoil investigation was carried out to determine: Nature of substratum and engineering properties of soil which may affect the mode of construction of the proposed work. Location of water table and possible effects on foundations. Field investigation procedure The following methods were adopted for sub-soil investigations as per IS: 1892- 1979. Two soil investigation bores of 150 mm diameter up to a depth of 6 meters were proposed and drilled within the proposed structure location. Boring was done using combination of shell and rotary methods with casing pipe to depending upon the type of strata met with in the bore hole location using hand boring machine. Bore holes of 150 mm diameter with casing pipe were drilled to facilitate collection of Undisturbed and Disturbed soil samples and to conduct Standard Penetration Tests. Standard Penetration Tests (SPT) were conducted at every meter intervals within each bore. These tests were conducted as per IS: 2131-1981. Number of disturbed but representative soil samples were collected from the auger cuttings sand bailers for identification and for conducting laboratory tests. Total of 4 bore holes were advanced up to a depth of 6 meters below the existing ground level. A Strata is considered to be hard, when the standard penetration test value, N i.e. the number of blows required for 300 mm penetration of the SPT spoon beyond a seating penetration of 150 mm in the strata is more than 50 ( Clause 3.3.3 of IS: 2131-1981). If the penetration of the spoon is less than 300 mm more than 50 blows, the N value is written as N>50. The depth of water table at the end of boring is observed. All the results obtained from the field operations are shown in the tabular forms 5. LABORATORY TESTS For classification of soil and obtaining engineering properties of soil, the following laboratory tests are conducted as per relevant IS codes of practice detailed below. 1) 2) 3) 4) 5) Grain size analysis ( as per IS 2720 (part-4)-1985) Liquid and plastic limit tests (as per IS 2720 ( part-5)-1985) In- situ density and Natural Moisture content tests Free swell index test (as per IS 2720 ( part-40)-1977) Unconfined Compressive Strength test (as per IS 2720 ( part-10)-1991) 6. REFERENCES IS 6403: Code of practice for Determination of Bearing Capacity of foundation IS 1498: Classification and Identification of soil IS 2911: (part 3), C.O.P for Design and construction of Under-reamed pile foundations. IS 1904: C.O.P for Design and construction of foundations in soils. IS 2720: Code of practice for carrying out various laboratory tests on soils IS 8009: (Part I):1976 Code of practice for calculation of settlements of Shallow foundations IS 8009: (Part II): 1980 Code of practice for calculation of settlement of deep foundations 7. SAFE BEARING CAPACITY Calculation of Safe Bearing capacity Based on shear as per IS 6403 As per clause 5.2.2.1 of IS 6403 Qnu = C*Nc*Sc*Dc*Ic+ Ƴ*Df (Nq-1) Sq Dq Iq + 0.5 B Ƴ NƳ SƳ DƳ IƳ Wʹ Where Qnu is the net ultimate bearing capacity of soil Sc, Sq, SƳ are the shape factors as per Table 2 of IS 6403 Dc, Dq , DƳ are the depth corrections factors as per 5.1.2.2 of IS 6403 Ic, Iq , IƳs are the inclination factors as per 5.1.2.3 of IS 6403 Wʹ is the effect of water table as per 5.1.2.4 of IS 6403 Nc, Nq, NƳ are obtained from the Table1 of IS 6403 Qns = Qnu/ FS SBC is determined for foundation width of 2m and Depth of 3m using a factor of safety of 3.0 against shear failure. Water table correction factor Wʹ is considered as 0.5 to account for ground saturation effect. Calculation Allowable bearing capacity of under-reamed pile as per IS 2911 part-3 1980 Qu= Ap*Nc* Cp+ Aa*Nc* C'a+ Ca'*As' + α*Ca*As Where, Qu is the Ultimate bearing capacity of pile (kN) Ap is Cross-sectional area of pile m2 Nc is the bearing capacity factor (generally taken as 9 for clays) Cp is the Cohesion at the pile tip (kPa) Aa is π/4(Du2-D2) in m2 Ca’ is the Average cohesion of soil around the under-reamed bulbs (kPa) Ca is average cohesion of the soil along the pile stem (kPa) As is the surface area of stem (m2) As’ is the surface area of the cylinder circumscribing the under reamed pile (m2) Qa is the allowable bearing capacity of under-reamed pile (kN). Qa = Qu/ factor of safety As per IS 2911 Part-3 1980 the factor of safety is generally considered as 2.5 in compression and 3 in uplift. SUB SOIL PROFILE INFORMATION BORE HOLE 1 Site Location ONGOLE Bore Hole No 1 Depth of GWT Not Encountered Depth of Bore Hole 6.0 m Date of Drilling 8/07/2022 Type of Boring Rotary Ending of Drilling 09/07/2022 Diameter of Boring 150 mm dia Depth (m) Soil Strata 1.0 to 6.0 Blackish Silty Clay Blackish Silty Clay Reddish Silty Clay Reddish Silty Clay Reddish Silty Clay Reddish Silty Clay Sample Depth (m) Type Penetration 15-30 cm 30-45cm 0-15 cm N 1.0-1.45 SPT 2 2 4 6 2.0-2.45 SPT 3 4 5 9 3.0-3.45 SPT 5 5 6 11 4.0-4.45 SPT 6 8 11 19 5.0-5.45 SPT 4 8 11 19 6.0-6.45 SPT 9 11 15 26 WL (%) WP (%) IP (%) FSI (%) Gravel (%) Sand (%) Silt & Clay Recorded N SPT Ƴd KN/m2 3 NMC (%) SPT Ø 2 Blackish Clay Blackish Clay Reddish Clay UCS KN/m2 SPT ISC Type of Sample 1 VIS Depth below GL (m) ENGINEERING PROPERTIES OF SUBSOIL AT BH-2 LOCATION MH-CH 100 0 44.43 17.9 63 39 24 50 0 2 98 6 MH-CH 100 0 46.97 18.2 65 36 29 50 0 3 97 9 MH-CH 120 0 34.34 17.5 66 32 34 50 1 3 96 11 4 SPT 5 SPT 6 SPT Reddish Clay Reddish Clay Reddish Clay MH-CH 130 0 32.52 19.0 51 30 21 40 1 3 96 19 MI-CI 135 0 27.25 18.8 49 28 21 50 2 4 94 19 MI-CI 160 0 19.62 19.0 43 24 19 50 2 6 92 26 9. RECOMMENDATIONS AND KEY POINTS The foundation soil at the proposed location of construction of Overhead tank at Ongole, Andhra Pradesh represented by 1 bore holes i.e., BH- 1 consisted of Reddish Clay with stiff consistency. No ground water table encountered within the depth of exploration. Considering the prevailing sub soil conditions at the proposed location of construction of the structures, the following recommendations and key points are made for foundation design. 1. The recommended depth of foundation is 3.0m from the ground level in case of isolated square foundation. 2. The recommended allowable bearing pressure at a depth of 2.0 m & 3.0m from the ground level is 80 kN/m2 &110 kN/m2 respectively. 3. Under-reamed pile foundation is also recommended for this soil location and structure. 4. The recommended capacity of under-reamed pile foundations are tabulated below Dia of Dia of Length of pile Safe load for double Safe load increase per 0.3 stem (m) Bulb (m) below cap (m) under-reamed pile (kN) m length (m) (kN) 0.3 0.375 0.4 0.45 0.5 0.75 0.94 1.00 1.125 1.25 3.5 3.75 4 4.5 5 179.65 311.47 382.82 488.41 546.56 5.09 6.26 8.14 9.89 11.18 KEY POINTS 1. The foundation soil should be well compacted prior to foundation laying and the foundation are to be laid on 100 to 200 mm thick lean concrete (1:4:8) in case of shallow foundation. 2. Sufficient spacing must be provided between footings to avoid over stress in adjacent footing. 3. The above recommendations are based on the field and laboratory tests conducted on the soil and our experience in this regard. If the actual subsoil conditions during excavation for the foundation differ from the observations reported here, the design experts/consultants should be referred for suggestion, further investigations. 4. A proper drainage should be provided with suitable finished surface slope, drains and out falls in order to maintain a low and stable water regime in the site. 5. Back filling shall be done in a layers of thickness, and compacted thoroughly. this can be achieved with suitable compaction equipment’s and the excavated soil is not suitable for the back filling purpose. (Back filling of the foundation should be done with the selected soil having Plasticity Index, PI < 6 and Cu > 2, preferably gravel which will be composed of well graded, coarse siliceous grains sharp and gritty touch and free from direct and other deleterious matter.) 6. The entire depth of foundation should not be excavated at a time and should be excavated in stages with proper supports to avoid collapsing the soil. 7. When soil needs to be excavated for footings proper protection measures need to be taken to prevent damage to the adjacent structure. 8. Soil samples received for testing, water table conditions and other site details furnished by the M/s Quality Laboratory Services. Laboratory is only responsible for the results obtained by testing on given soil samples and the Safe Bearing Capacity recommend as well. Prepared By For Quality Laboratory Services CH V S Chirajneevi Authorized Signatory (M.Tech Geotech)