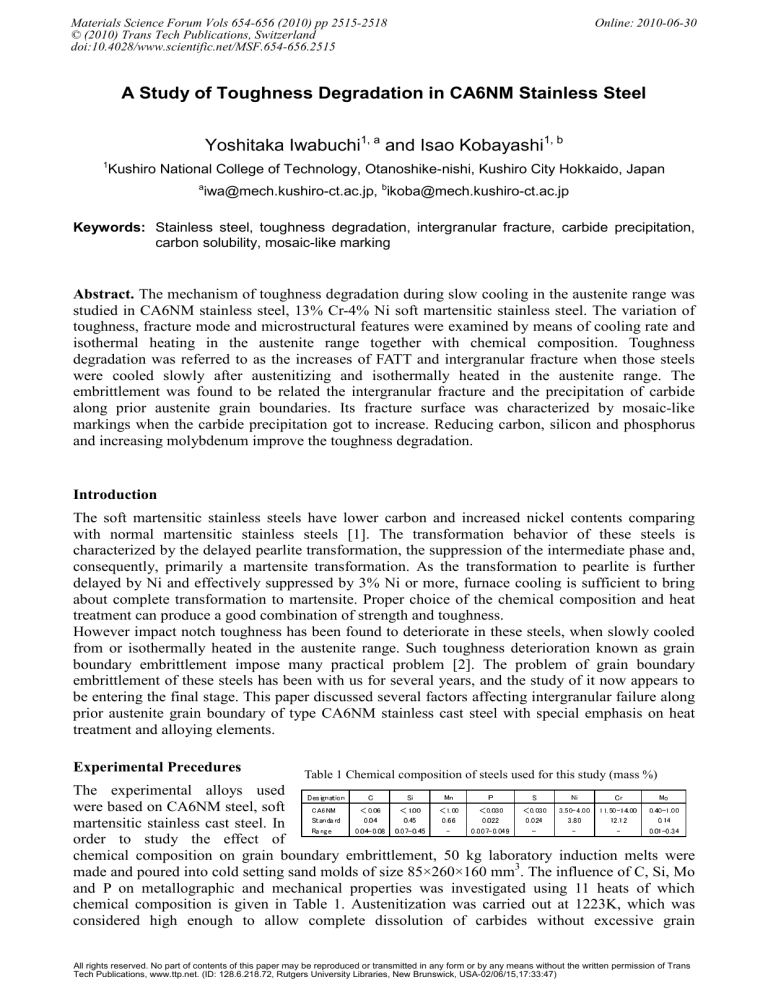

Materials Science Forum Vols 654-656 (2010) pp 2515-2518 © (2010) Trans Tech Publications, Switzerland doi:10.4028/www.scientific.net/MSF.654-656.2515 Online: 2010-06-30 A Study of Toughness Degradation in CA6NM Stainless Steel Yoshitaka Iwabuchi1, a and Isao Kobayashi1, b 1 Kushiro National College of Technology, Otanoshike-nishi, Kushiro City Hokkaido, Japan a iwa@mech.kushiro-ct.ac.jp, bikoba@mech.kushiro-ct.ac.jp Keywords: Stainless steel, toughness degradation, intergranular fracture, carbide precipitation, carbon solubility, mosaic-like marking Abstract. The mechanism of toughness degradation during slow cooling in the austenite range was studied in CA6NM stainless steel, 13% Cr-4% Ni soft martensitic stainless steel. The variation of toughness, fracture mode and microstructural features were examined by means of cooling rate and isothermal heating in the austenite range together with chemical composition. Toughness degradation was referred to as the increases of FATT and intergranular fracture when those steels were cooled slowly after austenitizing and isothermally heated in the austenite range. The embrittlement was found to be related the intergranular fracture and the precipitation of carbide along prior austenite grain boundaries. Its fracture surface was characterized by mosaic-like markings when the carbide precipitation got to increase. Reducing carbon, silicon and phosphorus and increasing molybdenum improve the toughness degradation. Introduction The soft martensitic stainless steels have lower carbon and increased nickel contents comparing with normal martensitic stainless steels [1]. The transformation behavior of these steels is characterized by the delayed pearlite transformation, the suppression of the intermediate phase and, consequently, primarily a martensite transformation. As the transformation to pearlite is further delayed by Ni and effectively suppressed by 3% Ni or more, furnace cooling is sufficient to bring about complete transformation to martensite. Proper choice of the chemical composition and heat treatment can produce a good combination of strength and toughness. However impact notch toughness has been found to deteriorate in these steels, when slowly cooled from or isothermally heated in the austenite range. Such toughness deterioration known as grain boundary embrittlement impose many practical problem [2]. The problem of grain boundary embrittlement of these steels has been with us for several years, and the study of it now appears to be entering the final stage. This paper discussed several factors affecting intergranular failure along prior austenite grain boundary of type CA6NM stainless cast steel with special emphasis on heat treatment and alloying elements. Experimental Precedures Table 1 Chemical composition of steels used for this study (mass %) The experimental alloys used Des ignation C Si Mn P S Ni Cr Mo were based on CA6NM steel, soft CA6NM < 0.06 < 1.00 <1.00 <0.030 <0.030 3.50-4.00 11.50-14.00 0.40-1.00 Standard 0.04 0.45 0.66 0.022 0.024 3.80 12.12 0.14 martensitic stainless cast steel. In Rang e 0.04-0.08 0.07-0.45 0.007-0.049 0.01-0.34 order to study the effect of chemical composition on grain boundary embrittlement, 50 kg laboratory induction melts were made and poured into cold setting sand molds of size 85×260×160 mm3. The influence of C, Si, Mo and P on metallographic and mechanical properties was investigated using 11 heats of which chemical composition is given in Table 1. Austenitization was carried out at 1223K, which was considered high enough to allow complete dissolution of carbides without excessive grain All rights reserved. No part of contents of this paper may be reproduced or transmitted in any form or by any means without the written permission of Trans Tech Publications, www.ttp.net. (ID: 128.6.218.72, Rutgers University Libraries, New Brunswick, USA-02/06/15,17:33:47) 2516 PRICM7 coarsening. A typical heat treatment to obtain the desired properties is austenitizing at 1223K for 28.8ks, followed by air cooling to ambient temperature and tempering for 36ks at 893K. In order to study the embrittlement in the austenite range, some steel were cooled at the various cooling rates of 0.0014 to 0.17 K/s from 1223K, and the others were exposed to an isothermal treatment of holding at 923K for 7.2 to 360ks during cooling from 1223K. Fractured surfaces of Charpy impact specimens were examined with a scanning electron microscope. Charpy V impact tests were carried out at the temperature between 173 and 373K. Results Figure 1 shows the variation of 50% ductile-fracture appearance transition temperature (FATT) as a function of the cooling rate from 1223K. When the cooling rate is increased, FATT is abruptly lowered and then slightly decreased. The effect of C, Si, Mo and P on the toughness is depicted in Fig.2, indicating the shift of FATT to high temperature side with increasing C, Si and P contents. It is noted that lowering C, Si and P contents and adding Mo decrease FATTs. 500 150 solid line : intergranular fracture broken line : intragranular fracture 400 P ]K [ 50 T T A F fo tfi 0 S ] K [ T 300 T A F 200 100 C 100 Si -50 10-3 10-2 Cooling Rate [K/s] 10-1 Fig. 1 Variation of FATT of the steels with cooling rate -100 Mo 0 0.1 0.2 0.3 Increment of Alloying Elements [mass%] 0.4 Fig. 2 Variation of the shift of FATT with alloying elements Figure 3 is the scanning electron fractgraphs of brittle fracture appearance of Charpy impact specimens tested at a temperature corresponding to FATT, indicating the typical mode of intergranular fracture along the austenite grain boundaries. It reveals that the fracture surface is characterized by mosaic-like markings as the cooling rate decrease, although the rapidly cooled specimens show the normal intergranular appearance with the flat and smooth surface. Figure 4 shows the variation in fracture mode of three specimens having 0.007, 0.026 and 0.049%P with isothermal holding time at 923K. It is clear that the intergranular fracture mode is increased with increasing isothermal-heating time and P content. Figure 5 shows the transmission electron micrographs of carbon extraction replicas taken from the intergranular fractured surface and the polished-etched cross section of the specimens with 0.04%C cooled at 1.4K/ks from 1223K and followed by 50μ 50μm tempering at 873K for 36ks. It is noted that the prior austenite grain boundary is Fig. 3 Scanning electron fractographs of brittle fracture covered by carbide precipitates which appearance of impact specimens with 0.06%C Materials Science Forum Vols. 654-656 2517 100 0.049%P ] % [ e r u t c a r F r a l u n a r g r e t In 80 0.026%P 60 40 0.007%P 20 0 104 105 Isothermal Holding Time [s] 1μm 106 Fig. 4 The fraction of intergranular fracture vs. isothermal holding time at 923K were identified as type Cr23C6 carbide. A large amount of intergranular carbide precipitates are unavoidable where the slow cooling and the long-period isothermal heating in the austenite range are performed respectively. From the transmission electron micrographs of carbon replicas of the specimens with different amounts of P, which are isothermally held at 923K for 86.4ks during cooling from 1223K and followed by tempering at 853K, it is noted that with increasing P contents, the carbide precipitates are unambiguously observed along the prior austenite grain boundary. Figure 6 shows the relation between the fraction of intergranular fracture and the corrosion loss after immersing in a boiled 4.4% HNO3 solution. It is noted that the magnitude of intergranular fracture becomes large with increasing corrosion loss. 5μm Fig. 5 Transmission electron micrograph of carbon extraction replicas. 100 ] % [ e r u t c a r F r a l u n a r g r e t n I 80 60 40 20 0 30 40 50 60 2 Corrosion Loss [mg/cm ・d] Fig. 6 The fraction of intergranular fracture vs. weight loss after immersion in 4.4%HNO3 Discussion Extensive studies [3, 4] have been performed on the carbide precipitation at grain boundaries in austenitic stainless steels. The rate determining process of the carbide precipitation has been theoretically discussed by Arai [5] using austenitic stainless steel. Since an only austenite phase exists until a martensite transformation is brought about, it is right to discuss the carbide precipitation in the austenite range for CA6NM steel as well as austenitic stainless steels. The amount of carbide is expressed as eq. (1), where the rate determining process is the rate of carbide reaction. (1) ΔC = (C0-Cs){1-exp(3kt/r0)} where ΔC : amount of C, C0 : initial C content, Cs : C solubility, k : reaction rate constant, t : time, r0 : austenite grain diameter assuming they have a spherical geometry. Area fraction of carbide precipitates, A0 was measured as 0.095%, which was converted into 0.0015% of weight fraction, using that the volume fraction is A0√A0, and the densities of austenite 2518 PRICM7 and (Cr ・ Fe)23C6 are 7.9 and 6.92 g/cm3. A 1100 time-temperature- Δ C (0.0015%) diagram of 0.08%C 13%Cr-4%Ni steel is obtained from eq.(1) as shown in Fig.7. These theoretical curves also 0.06%C 1000 correspond to the critical cooling rate at which the 0.04%C ]K [ mosaic-like marking appeared on the fractured er ut 900 grain boundary surface. ar It is clear that coarse carbides are observed ep me densely on prior austenite grain boundaries in the T specimens of high amounts of P. Banerjee [6] 800 reported that P was substituted for metallic elements and included in M23C6 carbide as 700 (Cr18Fe4P1)C6 leading the reduction of lattice 1 10 100 1000 10000 constant, and consequently it gave the ease of the Time [ks] carbide nucleation. The basic statistical technique employed was multiple regression analysis for the Fig.7 Time-temperature –∆C(0.0015%C) diagram correlation in FATTs with cooling rate, R0 and obtained by theoretical calculation. carbon content. The result of regression analysis gives eq. (2). FATT(K) = 2586×(%C) – 91×log〔R0 (K/s) – 47 …………(2) The regression equation satisfactorily predicts FATT. Although uncertainty exists in the role of carbide concerning the toughness, increasing carbide content and decreasing cooling rate in the austenite range promote the carbide precipitation and also coarsen its size, consequently lower the absorbed energy. The precipitation and growth of M23C6 carbide, which plays the important role on the toughness, has been studied [3] in austenitic stainless steels, and there was parallel relation between the carbide and the matrix. Supposing that 13%Cr-4%Ni steels have the same relation as austenitic stainless steels concerning the carbide precipitation, mosaic-like marking on the grain boundary surface is presumed to be the marks of M23C6 carbide precipitated in parallel to each other. Summary The experimental results obtained in this work lead to the following conclusion. (1) Carbide precipitated in the austenite range causes adverse effect on the toughness and gives the grain boundary embrittlement with mosaic-like marking. (2) Toughness degrades by slow cooling and isothermal heating in the range between 823 and 1023K during cooling from austenitizing temperature. (3) The embrittlement is related to the intergranular fracture and the precipitation of carbides along prior austenite grain boundaries. (4) Susceptibility to the embrittlement is improved by reducing C, Si and P, and adding Mo improves toughness as the result of retarding carbide precipitation along grain boundaries. References [1] [2] [3] [4] [5] [6] Soursny H. and Sauer H: Giesserei, 58(1971), 775 C.Leymonie, M.C.Ottman and R.Risache: PowerIndustry Research, (1982), 17 L.K.Singhal and J.W.Martin: Trans.Metall.Soc.AIME, 242(1968), 814 C.S.Tedmor Jr. and D.A.Vermilyea: Metall. Trans., (1970), 2043 H.Arai: Tetsu-to-Hagane, 56(1970), 44 S.K.Banerjee, CJ.McMahon Jr. and H.C.Feng: Metall. Trans. A, 9(1978), 237 PRICM7 10.4028/www.scientific.net/MSF.654-656 A Study of Toughness Degradation in CA6NM Stainless Steel 10.4028/www.scientific.net/MSF.654-656.2515