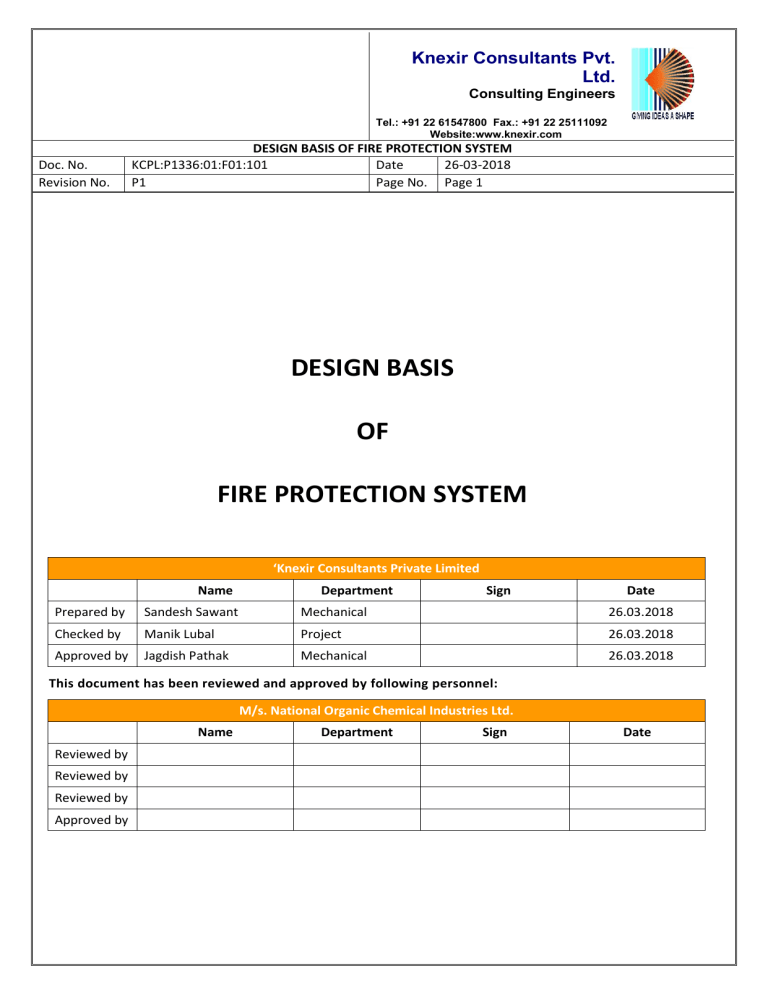

Knexir Consultants Pvt. Ltd. Consulting Engineers Tel.: +91 22 61547800 Fax.: +91 22 25111092 Website:www.knexir.com Doc. No. Revision No. DESIGN BASIS OF FIRE PROTECTION SYSTEM KCPL:P1336:01:F01:101 Date 26-03-2018 P1 Page No. Page 1 DESIGN BASIS OF FIRE PROTECTION SYSTEM ‘Knexir Consultants Private Limited Name Department Sign Date Prepared by Sandesh Sawant Mechanical 26.03.2018 Checked by Manik Lubal Project 26.03.2018 Approved by Jagdish Pathak Mechanical 26.03.2018 This document has been reviewed and approved by following personnel: M/s. National Organic Chemical Industries Ltd. Name Reviewed by Reviewed by Reviewed by Approved by Department Sign Date Knexir Consultants Pvt. Ltd. Consulting Engineers Tel.: +91 22 61547800 Fax.: +91 22 25111092 Website:www.knexir.com Doc. No. Revision No. DESIGN BASIS OF FIRE PROTECTION SYSTEM KCPL:P1336:01:F01:101 Date 26-03-2018 P1 Page No. Page 2 Table of Contents 1 PROJECT INFORMATION................................................................................................................... 3 2 INTRODUCTION ............................................................................................................................... 4 3 WATER SPRAY SYSTEM (MVWS) ....................................................................................................... 5 4 HYDRANT SYSTEM ........................................................................................................................... 8 5 PUMP HOUSE ................................................................................................................................ 12 6 RESERVOIR –.................................................................................................................................. 13 7 PORTABLE FIRE EXTINGUISHERS ..................................................................................................... 14 8 ABBREVIATIONS: ........................................................................................................................... 16 Knexir Consultants Pvt. Ltd. Consulting Engineers Tel.: +91 22 61547800 Fax.: +91 22 25111092 Website:www.knexir.com Doc. No. Revision No. DESIGN BASIS OF FIRE PROTECTION SYSTEM KCPL:P1336:01:F01:101 Date 26-03-2018 P1 Page No. Page 3 1 PROJECT INFORMATION 1.0 Client : M/s National Organic Chemical Industries Ltd (NOCIL) 2.0 Plant location : PLOT NO. 12/A/1 & 13/A/1, G.I.D.C, BHARUCH, GUJRAT. 3.0 Project : Rubber chemical plant 4.0 Site data Ambient data : Other data 5.0 Access to Site DBT (0C) WBT (0C) RH (%) Summer 41°C 31°C 53% Monsoon 33°C 30°C 82% Winter 12°C 7.5°C 48% Altitude By Road : Ahmedabad-Mumbai Highway Railway Station : Bharuch Nearest Airport : Vadodara 4-5 m (from sea level) Knexir Consultants Pvt. Ltd. Consulting Engineers Tel.: +91 22 61547800 Fax.: +91 22 25111092 Website:www.knexir.com Doc. No. Revision No. DESIGN BASIS OF FIRE PROTECTION SYSTEM KCPL:P1336:01:F01:101 Date 26-03-2018 P1 Page No. Page 4 2 INTRODUCTION This report describes the overall design brief for the structures and the systems to be proposed and installed for the facility. The purpose of this Design Basis Report is to describe in brief the requirement of Fire protection. During detail design phase, changes are anticipated. The FPS Package consists of the following Systems: Water spray system (MVWS) Hydrant System Pump House Portable Extinguisher BASIS OF DESIGN Following points are considered while designing the various systems: Secure & safe working conditions. The fire & Safety guidelines & industry specific requirement practice & guidelines which will meet regulatory norms. All the systems designed are time tested so that the business operations are uninterrupted due to unlikely event of fire. REFERENCE STANDARDS National Building Code of India (NBC) Bureau of Indian Standards (BIS) Codes Recommended practices of Equipment suppliers Knexir Consultants Pvt. Ltd. Consulting Engineers Tel.: +91 22 61547800 Fax.: +91 22 25111092 Website:www.knexir.com Doc. No. Revision No. DESIGN BASIS OF FIRE PROTECTION SYSTEM KCPL:P1336:01:F01:101 Date 26-03-2018 P1 Page No. Page 5 3 WATER SPRAY SYSTEM (MVWS) OBJECTIVE This report describes the overall design basis for the proposed water spray systems to be installed at site. The designs of the proposed Systems are based on statutory requirement ensuring protection of people & property. This covers the design basis and the design requirements of water spray system to tanks containing solvents which is having flash point below 65 degree C. The liquids (TBA, CHA) stored in tanks in tank farm area- 2 and liquids (CS2) stored in tanks in CS2 tankfarm area are having flash point below 650C. Also as Autoclave area and chlorine shed are high hazard area, total water flooding of these areas through spray system has been considered. The fire protection system is being designed to meet the largest fire water demand in the plant. The system is provided with deluge valve actuated with Quartzoid bulb sprinklers and additional actuation through manual release on the deluge valve and solenoid valve. Sprayers direct water over the whole surface preventing dangerous temperature rise and distortion resulting in further explosions REFERENCE STANDARDS IS 15325 NFPA 15 Tariff Advisory Committee (TAC) SYSTEM DESCRIPTION As per IS 15325/TAC guidelines for liquids having flash point below 65 degree Celsius shall need to have medium velocity water spray system. Sprinklers shall be used as detectors. The system shall have a deluge valve which gets operated on the pressure drop of the air in the detection system. After the operation of the deluge valve water is admitted into the system and sprayed using the sprayers which are located around the tank. Detection System Sprinklers shall be used for detection system. Sprinklers shall be installed in horizontal rows supported on the spray network. The no of detectors rings shall be equal to no of spray rings. Knexir Consultants Pvt. Ltd. Consulting Engineers Tel.: +91 22 61547800 Fax.: +91 22 25111092 Website:www.knexir.com Doc. No. Revision No. DESIGN BASIS OF FIRE PROTECTION SYSTEM KCPL:P1336:01:F01:101 Date 26-03-2018 P1 Page No. Page 6 The detectors shall be located not more than 1m. System Design Medium velocity water shall be applied at a minimum density of 10.2 lpm/m2 of the exposed area. The supporting legs and the product pipes within the bund area shall also receive water at the same density. The network shall be hydraulically so designed as to provide a minimum running pressure of 1.4 bar at the hydraulically most unfavorable sprayer and not more than 3.5 bars at the hydraulically most favorable sprayer in the network. The velocity in the feeder pipes shall not exceed 4.5m/s when sprayers discharge at their normal rates. Distribution of Sprayers Sprayers shall be spaced at not more than 2.5m in the rings when measured along the curved surface of the vessels. There shall be a ring for every 3.5m height of the shell. Sprayers in each successive ring will be staggered. Sprayers shall be installed at not less than 550mm or more than 650mm from the surface. Flow Demand 1. Tankfarm 2 Area: Sr. No Tank Sr no Tank Capacity Solvent stored 1 2 TF-301 TF-401 50 KL 50 KL TBA CHA Dia (m) Height (m) 3.85 4.85 3.85 4.85 Total Surface Area Total SA (sq .m) 70 70 140 2. CS2 Tankfarm Area: Sr. No Tank Sr no Tank Capacity Solvent stored 1 2 TF-202 TF-203 25 KL 25 KL CS2 CS2 Dia (m) Height (m) 3.0 4.05 3.0 4.05 Total Surface Area Total SA (sq .m) 46 46 92 Knexir Consultants Pvt. Ltd. Consulting Engineers Tel.: +91 22 61547800 Fax.: +91 22 25111092 Website:www.knexir.com DESIGN BASIS OF FIRE PROTECTION SYSTEM KCPL:P1336:01:F01:101 Date 26-03-2018 P1 Page No. Page 7 Doc. No. Revision No. 3. Autoclave area: Entire plan area of Autoclave is considered for calculating water demand for this area; Sr. No Floor Level Length 1 2 3 Ground Floor First Floor Second Floor 11 11 11 Width 7.8 2.5 7.8 Total floor Area Total SA (sq .m) 85.8 27.5 85.8 199.1 4. Chlorine Shed: Entire plan area of Chlorine Shed is considered for calculating water demand for this area; Sr. No Floor Level Length 1 Ground Floor 18.3 Width 9.6 Total floor Area Total SA (sq .m) 175.68 175.68 Amongst the tables provided above, Auto clave is having the maximum area hence water demand will be maximum for this area. Hence, calculations for maximum water demand of MVWS System area as follows; Note- The surface areas of tanks and plan areas of Rooms have been calculated approximately considering the drawing given. Exact surface area will be calculated during detailed engineering. The pump capacity has been designed not considering the future tanks of Tank farm. Theoretical Water required for medium velocity spray system: i) ii) iii) iv) v) vi) vii) viii) Total Surface Area - 199.1 sq.m Design Density - 10.2 Lpm/m2 Water required - 2030.8 LPM 10% Design Margin - 2233.9 LPM Hydrant requirement - 1700 LPM Pump capacity - 2233.9 + 1700 = 3934.9 LPM= 236m3/hr Pump Selected - 273 m3/hr @ required head Water storage tank requirement = 273 X 1.5 = 409.5 Say 450 M3 Note: By using this system the fire may not be extinguished completely. The objective of this application is to control the rate of burning, prevent dangerous increase of pressure in vessels exposed to the fire and protect adjacent plot and buildings. Knexir Consultants Pvt. Ltd. Consulting Engineers Tel.: +91 22 61547800 Fax.: +91 22 25111092 Website:www.knexir.com Doc. No. Revision No. DESIGN BASIS OF FIRE PROTECTION SYSTEM KCPL:P1336:01:F01:101 Date 26-03-2018 P1 Page No. Page 8 4 HYDRANT SYSTEM 4.1 OBJECTIVE The firefighting system is provided for the purpose of fire extinguishing, fire intensity control, and /or fire exposure protection. Hydrant system is the backbone of fire protection system. 4.2 REFERENCE STANDARDS National Building Code – 2016 Indian Standards (IS) – 3844 – Internal Hydrant System Indian Standards (IS) – 13039 – External Hydrant System Indian Standards (IS) – 12469 – Pumps for Fire Fighting System NFPA 14 4.3 SYSTEM DESCRIPTION Design Pressure Design pressure of the equipment and materials used in the fire water network and the water firefighting system shall not be less than the sum of maximum suction pressure and shut off pressure of the fire water pump. Design temperature The design temperature for the equipment and material shall be: 55 oC for those subject to direct sun 45 oC for those not subject to direct sun HYDRANT SYSTEM: Hazard As per NBC/IS 3844/IS 13039/ NOC Ordinary Hazard (for Proposed Building Structures) IS 13039 Annexure B (Clause 3) CLAUSE IS 3844 Table 1 (Clauses - 4.1.1,4.1.2,5.1.1,5.2.1, 5.3.1, 5.4.1 and 7.2) NBC 2016 Table 7 (Clauses-3.1.1, 3.1.8, 3.2.2.2, 3.4.6.2, 4.5.2, 6.7.1.1) Knexir Consultants Pvt. Ltd. Consulting Engineers Tel.: +91 22 61547800 Fax.: +91 22 25111092 Website:www.knexir.com Doc. No. Revision No. DESIGN BASIS OF FIRE PROTECTION SYSTEM KCPL:P1336:01:F01:101 Date 26-03-2018 P1 Page No. Page 9 4.4 BASIC SYSTEMS DESIGN & OPERATION The proposed buildings are provided with the following type of fire protection systems: External Fire Hydrant system. Internal Fire Hydrant system. 4.5 EXTERNAL FIRE HYDRANT SYSTEM The hydrants are spaced as per Ordinary hazard at 45 m spacing. The entire plant is protected with hydrants. The exact quantity of hydrants shall be worked out during detailed engineering by the firefighting vendor as per IS guidelines. The vetting of the entire firefighting system from IS (Local CFO) accredited professional agency and getting approval shall be the responsibility of the firefighting vendor. The hydrant system is designed to protect the buildings and equipment’s by providing hydrants around the area as mentioned above. The water monitors shall be provided at strategic locations especially near tank farm areas. The system mains run above ground and shall be provided required number isolation valves to facilitate the maintenance. The installation is to provide with adequate number of isolation valves at suitable locations for the purpose of isolation during the event of fire or during emergencies. The External hydrants shall be provided around the plant building. The ring main has been proposed around the building. The riser for internal hydrant shall be tapped to this ring. Maximum spacing between two external hydrants shall not be more than 45mtrs as per requirements of NBC and IS 13039. Each External hydrant station shall consist of one no. single headed hydrant valve along with two no’s of hoses with one branch nozzle. An isolation valve shall be provided after every four external hydrants for ease of maintenance. The hydrant station shall be located within 2 meters to 15 meters from external wall of Building, in compliance with NBC and IS 13039. During detail engineering will decide the water cum foam monitor/double hydrant or single hydrant requirement for tank farm area. Knexir Consultants Pvt. Ltd. Consulting Engineers Tel.: +91 22 61547800 Fax.: +91 22 25111092 Website:www.knexir.com Doc. No. Revision No. DESIGN BASIS OF FIRE PROTECTION SYSTEM KCPL:P1336:01:F01:101 Date 26-03-2018 P1 Page No. Page 10 4.6 INTERNAL FIRE HYDRANT SYSTEM The water to the Internal Hydrant system shall be fed through vertical risers as shown in respective floor drawings. This riser shall be further connected to the delivery headers in the pump room. In compliance with NBC and IS 3844, the hydrant system shall be designed with a Hydrant and First aid Hose Reel System. The Hydrant Stations with Fire Hose Reel shall be provided preferably at Main landing of all stairs wherever possible and to meet requirements of Local Fire authorities. In the fire escape staircases, the location of fire hydrant station shall be inside the staircase so that it will be easily accessible / available to the fireman without entering into the affected area (Floor area) as per consultation with Architects. Refer Floor layout drawings for locations of Fire Hydrant Cabinets. System shall be hydraulically designed to provide water flow at minimum residual pressure of 3.5 Kg/cm2 at outlet of most remote hydrant valve, with 2 nearest & one farthest in operation. The maximum pressure in the riser at any point at any time shall not exceed 12.1 bar (12.3 Kg/cm2). However, to avoid high pressure at outlet of fire hydrant valves, near to pump room, (restricted up to 7 Bars), orifice plates shall be designed. Hose connection and hose station shall be unobstructed and shall be located not less than 0.9 meters or more than 1.2 meters from finished floor level. 4 way fire brigade inlets for pumping water into main internal hydrant risers shall be provided through ring-main. Fire brigade inlet shall be located and arranged so that hose lines can be readily and conveniently attached to the inlets without external interference. Isolation valve shall be of OS and Y type with rising spindle. The hydrant risers shall be terminated with air release valve at the highest points to release the trapped air in the pipe work along with necessary accessories. Each internal hydrant station shall consist of single headed hydrant valve with one hose cabinet and a wall mounted hose reel complete with shut off nozzle & clamps, Hose cabinet consist of 2 Nos of RRL canvas type ‘B’ hoses complete with 1 no branch nozzle The Hydrant cabinets shall be provided in all areas as shown in drawing. The hydrant cabinets shall be provided at designated locations shown in the drawing. The cabinets shall be in the form of doors (where niche and the cavity) is provided and it shall be in the form of boxes where no such provision is made. The size of the door cabinets shall be as such to accommodate all the accessories mentioned above. Knexir Consultants Pvt. Ltd. Consulting Engineers Tel.: +91 22 61547800 Fax.: +91 22 25111092 Website:www.knexir.com Doc. No. Revision No. DESIGN BASIS OF FIRE PROTECTION SYSTEM KCPL:P1336:01:F01:101 Date 26-03-2018 P1 Page No. Page 11 4.7 HYDRANT SYSTEM OPERATION Maximum operating pressure required at the remotest point is – 3.5 kg/cm2. All above pump sets are to be installed in the Fire Water pump house. Depending on the location of pumps, the hydrostatic head at base of facility will be worked out. 4.8 EXISTING HYDRANTS DETAILS Single Hydrant stand points Double Hydrant stand points Fire Escape Hydrant points Foam-water monitors Water Monitors - 37 - 00 - 31 - 04 = 8 Hydrants - 12 = 24 hydrants Additional tentative new points for proposed hydrant system: (Actual qty may vary during detail engineering and change in layout) External Single Hydrant stand points - 10 Fire Escape Hydrant points - 17 So considering proposed hydrants total number of hydrants will be @ 127 nos 4.9 Pump Capacity Selection As per NBC 2016 & IS 12469, if total no of Hydrants in a plant exceeds – 100 nos. then 2 sets of Pumps of capacity 273 m3/hr shall be selected. But as per NFPA 14, clause 7.10.1.1.3 and 7.10.1.2.3, single pump of 273 m3/hr is sufficient for all hydrant points. As per NFPA 14 the Pump capacity for hydrant system is 273 m3/hr @ required head is sufficient though hydrants exceeding 100nos. But same has to be confirmed with local CFO because as per NBC 2016 & IS 12469 will require additional set of pump of 273 m3/hr for number of hydrants exceeding 100. We can conclude the requirement of additional pump sets as per provisional NOC (CFO recommendation). *Note : Hydraulic Calculations shall be submitted for Head calculations. Knexir Consultants Pvt. Ltd. Consulting Engineers Tel.: +91 22 61547800 Fax.: +91 22 25111092 Website:www.knexir.com Doc. No. Revision No. DESIGN BASIS OF FIRE PROTECTION SYSTEM KCPL:P1336:01:F01:101 Date 26-03-2018 P1 Page No. Page 12 5 PUMP HOUSE Existing Pumps details (as per Site Data received) Sr. No. 1 2 3 Pump Main Electrical Pump Diesel Engine Driven Pump Jockey pump Capacity 273 m3/hr 273 m3/hr 16.8 m3/hr Head 88 M 88 M 88 M Pump Capacity calculated for different Fire Systems is as follows; MVWS + Hose allowance Hydrant System = 236 m3/hr = 273 m3/hr Proposed pumps set if demanded by CFO as per below table If required additional pump set as per provisional NOC (CFO recommendation) then below is the list of proposed pump sets. Sr. No. Pump Type Demand 1 Main electrical pump for Hydrant & MVWS system Jockey Pump for Hydrant & MVWS system Dedicated Common Standby Diesel Engine Pump for Hydrant & MVWS system 273 m3/ hr 2 5 10.8 cum /hrs Same as Main Pump Capacity Pump Capacity Provided 273 m3/ hr @ reqd mtrs head 10.8 hr @ reqd mtrs head 273 m3/ hr @ reqd mtrs head Note: 1. Fire System for External warehouse is not considered in the current scope. 2. There will be separate Fire systems for External Warehouse. 3. For existing pumps, we will verify the pump head requirement by hydraulic calculation during detail engineering. Knexir Consultants Pvt. Ltd. Consulting Engineers Tel.: +91 22 61547800 Fax.: +91 22 25111092 Website:www.knexir.com Doc. No. Revision No. DESIGN BASIS OF FIRE PROTECTION SYSTEM KCPL:P1336:01:F01:101 Date 26-03-2018 P1 Page No. Page 13 6 RESERVOIR – Hence Tank capacity selected for single set of pump = 273 m3/hr X 2hr = 546 say 550 m3. If additional pump set is recommended by CFO then fire storage tank capacity shall be = 273 m3/hr X 2 X 2hr = 1092 say 1100 m3. Existing fire water tank capacity available at site is 1800 cum. Hence same can be utilized for proposed fire system water requirement. Knexir Consultants Pvt. Ltd. Consulting Engineers Tel.: +91 22 61547800 Fax.: +91 22 25111092 Website:www.knexir.com Doc. No. Revision No. DESIGN BASIS OF FIRE PROTECTION SYSTEM KCPL:P1336:01:F01:101 Date 26-03-2018 P1 Page No. Page 14 7 PORTABLE FIRE EXTINGUISHERS 7.1 OBJECTIVE The objective is to protect the entire premises with suitable Fire Extinguishers approved and certified for particular application. The extinguishers shall form as a first aid action against small and incipient fire so as to extinguish fire even before it develops into a major hazard. 7.2 REFERENCE STANDARD Relevant IS Standard:- IS 2190:2010 7.3 TYPE OF FIRES: a. Class A Fire: Fires involving solid combustible materials of organic nature such as wood, paper, rubber, plastics, etc, where the cooling effect of water is essential for extinction of fires. b. Class B Fire: Fires involving flammable liquids or liquefiable solids or the like where a blanketing effect is essential. c. Class C Fire: Fires involving flammable gases under pressure including liquefied gases, where it is necessary to inhibit the burning gas at fast rate with an inert gas, powder or vaporizing liquid for extinguishment. d. Class D Fire: Fires involving combustible metals, such as magnesium, aluminium zinc, sodium, potassium, etc, when the burning metals are reactive to water and water containing agents and in certain cases carbon dioxide, halogenated hydrocarbons and ordinary dry powders. These fires require special media and techniques to extinguish. 7.4 SYSTEM DESCRIPTION The Extinguishers proposed is to protect all the equipment, areas with relevant type of suitable Fire Extinguishers. Carbon-di-oxide Extinguishers are proposed as it is an inert gas with no residue, is electrically nonconductive and ideal for all electrical protection application. ABC type Extinguishers are proposed for Type ‘A’ class fire, which is stored, pressured type and is used as protection against fires caused from solids like powders, tables, furniture, curtains, etc. Water/ Foam Type Extinguishers are proposed for protection against fire causing from fires caused due to class B fire. FE 36 type Clean Agent fire extinguishers are proposed for critical rooms like server, hub rooms etc. Carbon-di-oxide of 4.5 kg and ABC Type 2/4/6 Kg capacity shall be provided as first aid fire extinguishing appliances for electrical fire. Knexir Consultants Pvt. Ltd. Consulting Engineers Tel.: +91 22 61547800 Fax.: +91 22 25111092 Website:www.knexir.com Doc. No. Revision No. DESIGN BASIS OF FIRE PROTECTION SYSTEM KCPL:P1336:01:F01:101 Date 26-03-2018 P1 Page No. Page 15 The appliances shall be so distributed over the entire floor area so that a person has to travel not more than 15 m to reach the nearest appliance. These shall be placed or hanged on wall in a group on several suitable places. The number and capacity of extinguishers shall be calculated as per IS 2190 during detail engineering. Approved Makes: SUPREMEX / BHARATI FIRE / KANEX IS 2190 - Table 3 - Suitability of Different types of Fire Extinguishers for Different Classes of Fire Sr. No. Type of Extinguisher Type of Fire A B C 1 Water type (gas cartridge), IS 940 and IS 13385 S NS NS 2 Water type (Stored Pressure), IS 6234 S NS NS 3 Mechanical Foam type (gas cartridge), IS 10204 and IS S S NS 13386 4 Mechanical Foam type (Stored Pressure), IS 14951 and IS S S NS 15397 5 Dry Powder type (Stored Pressure), IS 13849 S S S 6 Dry Powder type (gas cartridge), IS 2171 and IS 10658 S S S 7 Dry Powder type for Metal Fires, IS 11833 NS NS NS 8 Carbon Dioxide type, IS2878 and IS 8149 NS S S 9 Clean Agent Gas type, IS 15683 S S S 10 Halon 1211 type, IS 4862 (Part-I) and IS 11108 S S S Note: S - Suitable NS - Not Suitable D NS NS NS NS NS NS S NS NS NS Knexir Consultants Pvt. Ltd. Consulting Engineers Tel.: +91 22 61547800 Fax.: +91 22 25111092 Website:www.knexir.com Doc. No. Revision No. DESIGN BASIS OF FIRE PROTECTION SYSTEM KCPL:P1336:01:F01:101 Date 26-03-2018 P1 Page No. Page 16 8 ABBREVIATIONS: SHORT FORM DESCRIPTION Ft. Feet m Meter Sqft Square Feet Sqm Square Meter AHU Air handling unit m/s Meter per Second 0 C Degree Celsius mm Millimeter Cu m Cubic Meter Hrs. Hours MWC Meter of Water Column M² Square Meter LPM Liter Per Minute Kg/cm² Kilogram per Square centimeter No. Number DG Diesel Generator UPS Un-Interrupted power supply VESDA Very early smoke detection apparatus FRLS Fire retardant low smoke BMS Building Management System Ph Phase STP Sewage Treatment Plant F&S Fire & Safety NBC National Building Code UL Underwriters Laboratories (Safety Consulting) Knexir Consultants Pvt. Ltd. Consulting Engineers Tel.: +91 22 61547800 Fax.: +91 22 25111092 Website:www.knexir.com Doc. No. Revision No. DESIGN BASIS OF FIRE PROTECTION SYSTEM KCPL:P1336:01:F01:101 Date 26-03-2018 P1 Page No. Page 17 SHORT FORM DESCRIPTION GI Galvanized Iron SS Stainless steel ERW Electric Resistance Welded Bar Pressure Unit PESCO/CCOE Petroleum and Explosive Safety Organization/Chief Controller of Explosives OEM Original Equipment Manufacture LPCB Loss prevention council board FMRC Factory mutual research corporation AHJ Authority having jurisdiction CFO Chief fire officer DOT Department of transportation EN European standards AMAO Assumed Maximum Area Of Operation NFPA National Fire Protection Association ------------------ End of Document ------------------