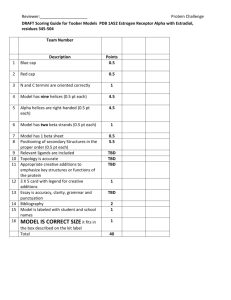

Duct Static Pressure Transmitter Detail (EPD or EPU) 2-Wire Current Output DPT# ZERO DPT# ZERO 7 0 1 On Off RMT ZERO Rotary Dial Settings 6 2 5 4 3 RMT ZERO 6 1 2 3 4 5 6 7 8 Hi Lo TBx:## TBx:## TBx:## UI# RET X#N X#H Hi Lo CtrlrName StPr TB-PA TB-PA TBx:## UI# RET Y1Y1+ TBx:## DIP Switch Settings Switch 1 2 3 4 5 6 7 8 2 5 4 3 PWR mA RTN V+/PWR V-/GND Vout 1 2 3 4 5 6 7 8 7 0 1 On Off Switch 0 1 2 3 4 5 6 7 0-25 Pa 0-50 Pa 0-100 Pa 0-250 Pa 0-2.5 m/s 0-5.0 m/s 0-10.0 m/s 0-15.0 m/s 05 Models (Pressure Mode) Switch Range 0 0-0.1 in. WC 0-25 Pa 1 0-0.25 in. WC 0-50 Pa 2 0-0.5 in. WC 0-100 Pa 3 0-1.0 in. WC 0-250 Pa 4 0-2.5 in. WC 0-500 Pa 5 0-5.0 in. WC 0-1000 Pa 6 0-10.0 in. WC 0-2500 Pa 7 0-10.0 in. WC 0-2500 Pa 02 Models Range 0-1.0 in. WC 0-2.5 in. WC 0-5.0 in. WC 0-10.0 in. WC 0-3000 ft/min 0-4000 ft/min 0-5000 ft/min 0-6000 ft/min VFD 0-250 Pa 0-500 Pa 0-1000 Pa 0-2500 Pa 0-15.0 m/s 0-20.0 m/s 0-25.0 m/s 0-30.0 m/s 05 Models (Velocity Mode) Switch Range 0 0-500 ft/min 0-2.5 m/s 1 0-1000 ft/min 0-5.0 m/s 2 0-2000 ft/min 0-10.0 m/s 3 0-3000 ft/min 0-15.0 m/s 4 0-4000 ft/min 0-20.0 m/s 5 0-5000 ft/min 0-25.0 m/s 6 0-6000 ft/min 0-30.0 m/s 7 0-7000 ft/min 0-35.0 m/s +- TBD TBD UO# RET Spd CtrlrName Speed Feedback TBD TBD UI# RET VfdFbk CtrlrName Start/Stop Command TBD TBD DO# X#N Cmd CtrlrName ORG YEL WHT/BLU FR# WHT/YEL Safety Interlock TBD TBD Not Used TBD TBD Fault TBD TBD TBD UI# RET VfdFlt CtrlrName Running TBD TBD TBD UI# RET VfdSts CtrlrName + GND BACnet MSTP 7.4" TBD TBD TBD From: See Network Architecture To: See Network Architecture Tubing to Duct Probe EPD### Note: For duct mounted applications, thread the probe into the back of the device housing as shown in the dimensional drawing. Configure the internal tubing for the selected installation method as described below. A) Connect the right-side tube to the rear brass bard marked as “-“ on the underside of the device housing. B) Connect the left-side tube to the back of the device housing. AFMS-ELECTRA-flo/S5 xxDpr - DprPos,Fbk 1.6.# 8.3" 6.0" 1.9.1 Duct Humidity 4-20 mA 10.9" 10.3" 0-10 VDC On Off 10.8" On Off 1 2 3 4 5 6 7 8 5 5 UI# RET Y1Y1+ 4.3" 6 6 4. 1/2" conduit analog output/network opening for connection 5. Two (2) 1/2" NPT liquid tight cord grips 6. Two (2) 1/2" conduit openings with knockouts Field 1 2 3 4 5 6 7 8 CtrlrName xxRh TB-PA TB-PA UI# RET X#N X#H CtrlrName xxRh TB-PA TB-PA NOTE: For optimal readings, follow these tips: • The sensor should be mounted in the middle of the duct where air circulation is well mixed (no stratification), and not blocked by obstructions. Strati?fication and obstructions can cause sensing errors. An example is downstream from a heating or cooling coil. • Duct probe should be placed (3) to (4) duct segments down from any bend or obstructions and away from 90° bends. • Mount the sensor on the top or sides of duct work; mounting on the bottom risks damage due to moisture. XXVlvPos Ø 0.875" (22.23 mm) 5 DA Dip switches provided for selection of direct or reverse acting control mode and control signal type Torque 35 lb-in 60 lb-in 133 lb-in 0-10 V 0-5 V 5-10 V 2-10 V 4-20 mA RA 3.80" (96.56 mm) 4.30" (109.22 mm) Model Number VA @ 60 Hz M333A0# 2.8 VA Replace # and ‘xx’ in detail box Delete note when done 5 = Chw I 6 = Hw I 6 = Stm I 7 = RhtVlv | 8 = HumVlv Replace # and ‘xx’ in detail box Delete note when done 1 = Oa I 2 = Ra I 3 = Ea I 4 = Moa I 11 = Byp 6 Model Number VA @ 60 Hz MS40-7043 5.6 VA MS41-7073 5.8 VA MS41-7153 9.7 VA DC IN 4 R 24 VAC COM 3 L 24VAC Power Only TB-PA X#H TB-PA X#N CtrlrName COM VlvPos AO# 2 GRN/ yel Switch provided for selection of direct or reverse acting control mode 1 Clockwise or counterclockwise spring return is determined by actuator mounting position HOT COM COM AI AO GND = Switch ON OFF X#H X#N COM AO# RET UI# Speed Command FR#-1 = Cap unused wires CtrlrName DprFbk Field SE Panel VFD Board Replace # in detail box. Delete note when done. 1 = Sa | 2 = Ra | 3 = Oa | 4 = Moa TB-PA TB-PA CtrlrName DprPos Replace # and ‘xx’ in detail box Delete note when done 1 = Sa | 2 = Ra | 3 = Ea | 4 = Hrw | 4 = Erw 0.3" 8.5" 4.9" 6.0" INPUT POWER 3.5" Warning: Do not connect shield 24 VAC, 16-90 VA, varies based on # of sensors (1-32 sensors) drains to the “G” terminal 24 VDC, 16-50 W, varies based on # of sensors (1-32 sensors) 1. Transceiver: 2-wire, half-duplex (1/3 unit load) ELCTRA-flo/S5 2. Baud Rate(s): 9600, 19200, 38400, 7.8" 7.4" 6.9" TBPA X#H L 56700, 76800, 115200 (Default: 10.5" 38400) unless specified by the end TBPA X#N N 24 AC/DC user G 3. MS/TP MAC Address (“Address” in menu) range: 1 – 255. Starts at 1, CtrlrName UI# Out1 + Flow Vel / 1 incremented for each transmitter in the Velocity Pres XaFl RET Com system, unless specified by the end Out2 + user Temperature Com 4. BACnet Device ID (“ID” in menu) 2 range: 0 – 4,194,303. Same as the N.C. Device Address, unless specified by Com Alarm the end user N.O. 2.3" 5. Max Masters: 1 – 127 (Default: 127) 6.4" unless specified by the end user 4 3 D+ 6. Termination: 120 Ohms or none See Network Architecture D(Default: None) BACnet / 1. Two (2) 0.188" mounting slots 7. Biasing: 549 Ohms or none Modbus G 2. 1/2" conduit field power opening for connection See Network Architecture (Default: None) Sh 3. Two (2) Mini-DIN connectors for probe 8. Flow control: None 1.6.# xxFanVfd-Cmd,Spd,Shd,Sts,Flt,Fbk Mounting and Configuration DIP Switch Settings Function On Off Scale Pascal (m/s) In WC (ft/min) Mode Velocity Pressure Direction Unidirectional Bidirectional Response Slow Fast Output 4-20 mA Voltage Volt Scale 0-5 Vdc 0-10 Vdc Unused NA NA Unused NA NA 1.11.# CtrlrName StPr TB-PA TB-PA Switch 0 1 2 3 4 5 6 7 1.#.2 01 Models Range 0-0.1 in. WC 0-0.25 in. WC 0-0.5 in. WC 0-1.0 in. WC 0-500 ft/min 0-1000 ft/min 0-2000 ft/min 0-3000 ft/min 4-20mA VIN COM OUT 3-Wire Voltage Output 4-20mA VIN COM OUT 1.8.1 Torque 220 lbf 1.90" (48.28 mm) 2.12" (53.72mm) 7.94" (201.60mm) Ø 0.75" (19.05 mm)