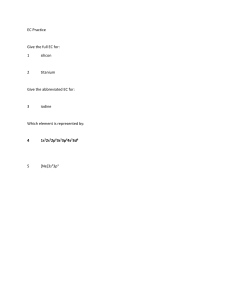

Microelectromechanical Systems

(MEMS/NEMS) MEMS: A

Technology from Lilliput

An introduction

"Innovation distinguishes between a

leader and a follower." --Steve Jobs

https://www.youtu

be.com/watch?v=

0EokkhdppgE

What are MEMS?

(Micro-electromechanical Systems)

• Fabricated using micromachining technology

• Used for sensing, actuation or are passive

micro-structures

• Usually integrated with electronic circuitry

for control and/or information processing

Introduction, Continued

Image Courtesy of Sandia National Laboratories, SUMMiTTM Technologies,

www.mems.sandia.gov

Figure 5.3: Spider mite with legs on a mirror drive assembly.

Brief History

1962

1967

1967

1972

1979

1982

1982

1983

1983

1983

1985

1987

1993

1994

1999

Silicon Integrated piezo actuators BY O.N. Tufte et al.

Anisotropic deep silicon etching H.A. Waggener

The resonant gate transistor by H. Nathanson, et.al

National Semiconductor - Pressure Sensor

Thermal inkjet technology is invented at HP laboratories

“Silicon as a Mechanical Material” K. Peterson

Liga Process (KFIK, Germany)

“Infinitesimal Machinery” R. Feynman

Silicon Micromechanical devices – J.B.Angel etc.

Integrated Pressure Sensor – Honeywell

Airbag Crash Sensor

Dr. Hornbeck Digital Micromirror Device or DMD (DLP by Texas Instruments)

Later in 1990s micromachining begins leveraging microelectronics industry

Accelerometer integrated with electronics Analog devices

DRIE Etching (Bosch process is patented)

Optical network switch - Lucent

3-D Micromachined Structures

Linear Rack Gear Reduction Drive

Triple-Piston Microsteam Engine

Photos from Sandia National Lab. Website: http://mems.sandia.gov

Applications: Passive Structures

Inkjet Printer Nozzle

https://www.youtube.com/watch?v=9yeZSaig

Bj4&feature=youtu.be

https://www.youtube.com/watch?v=

qPwlgL91-Q4

On Chip Inductor

A surface-micromachined

parallel-plate variable

capacitor

Different

implementations of a

surface-micromachined

parallel-plate variable

capacitor:

(a) perspective view of

the basic concept

showing a stationary

plate and a moveable

plate suspended by

springs;

(b) top view of a

capacitor using straight

beams as springs;

(c) top view using Tshaped springs [8];

(d) top view using Lshaped springs [5]; and

(e) top view with

center anchor [7].

Applications: Sensors

Pressure sensor:

• Piezoresistive sensing

• Capacitive sensing

• Resonant sensing

Application examples:

• Manifold absolute pressure (MAP) sensor

• Disposable blood pressure sensor (Novasensor)

Piezoresistive Pressure Sensors

Pressure

Piezoresistive elements

SiO2

p+ Si

<100> Si

substrate

Piezoresistive Pressure Sensors

Wheatstone Bridge configuration

Illustration from “An Introduction to MEMS Engineering”, N. Maluf

Applications: Sensors

Inertial sensors

•

Acceleration

– Air bag crash sensing

– Seat belt tension

– Automobile suspension control

– Human activity for pacemaker control

•

Vibration

– Engine management

– Security devices

– Monitoring of seismic activity

•

Angle of inclination

– Vehicle stability and roll

Accelerometers

Accelerometer parameters

• acceleration range (G) (1G=9.81 m/s2)

• sensitivity (V/G)

• resolution (G)

• bandwidth (Hz)

• cross axis sensitivity

Application

Range

Bandwidth

Air Bag Deployment

± 50 G

~ 1 kHz

Engine vibration

±1G

> 10 kHz

Cardiac Pacemaker control

±2G

< 50 Hz

Comment

resolve small accelerations (< 1 micro G)

multiaxis, ultra-low power consumption

https://www.youtube.com/watch?v=eqZgxR6eRjo&t=509s

https://www.youtube.com/watch?v=4kfzqZpttTA

https://www.youtube.com/watch?v=XsjvaYAFN1M

Capacitive Accelerometers

Anchor to substrate

Spring

Displacement

Inertial Mass

Stationary Polysilicon fingers

Based on ADXL accelerometers, Analog Devices, Inc.

Applications: Actuators

Texas Instruments Digital Micromirror DeviceTM

• Invented by Texas Instruments in 1986

• Array of up to 1.3 million mirrors

• Each mirror is 16 mm on a side with a pitch of 17 mm

• Resolutions: 800x600 pixels (SVGA) and 1280x1024 pixels (SXGA)

For an animated demo of this device, go to http://www.dlp.com/dlp_technology/

Digital Micromirror Device

From “An Introduction to Microelectromechanical Systems Engineering” by Nadim Maluf

Digital Micromirror Device

• Mirror is moved by electrostatic actuation (24 V applied to bias electrode)

• Projection system consists of the DMD, electronics, light source and projection optics

• Switching time: 16 µs (about 1000 times faster than the response time of the eye)

=> Acheive grey scale by adjusting the duration of pulse

• Placing a filter wheel with the primary colors between light source and the micromirrors

=> Achieve full color by timing the reflected light to pass the wheel at the right color

From “An Introduction to Microelectromechanical Systems Engineering” by Nadim Maluf

Some future applications

• Biological applications:

– Microfluidics

– Lab-on-a-Chip

– Micropumps

– Resonant microbalances

– Micro Total Analysis systems

• Mobile communications:

– Micromechanical resonator for resonant circuits and filters

• Optical communications:

– Optical switching

Microfluidics / DNA Analysis

In the future, a complete DNA sequencing systems should include:

•Amplification (PCR)

•Detection (electrophoresis)

•Fluid preparation and handling (pumps, valves, filters, mixing and rinsing)

MEMS !

MEMS Fabrication

“You can’t see it, but it’s everywhere

you go.”

—Bridget Booher, journalist, on

silicon

Materials for MEMS

• If we view micromachining technology as a set of generic tools,

then there is no reason to limit its use to one material. Indeed,

micromachining has been demonstrated using silicon, glass,

ceramics, polymers, and compound semiconductors made of

group III and V elements, as well as a variety of metals

including titanium and tungsten.

• Silicon, however, remains the material of choice for

microelectromechanical

systems.

Unquestionably,

this

popularity arises from the large momentum of the electronic

integrated circuit industry and the derived economic benefits,

not least of which is the extensive industrial infrastructure.

Silicon-Compatible Material

System

• The silicon-compatible material system

encompasses, in addition to silicon itself, a

host of materials commonly used in the

semiconductor integrated circuit industry.

• Normally deposited as thin films, they

include silicon oxides, silicon nitrides, and

silicon carbides, metals such as aluminum,

titanium, tungsten, and copper, and

polymers such as photoresist and polyimide.

Why Silicon

• Silicon is one of very few materials that is economically manufactured in

single crystal substrates. This crystalline nature provides significant

electrical and mechanical advantages.

• The precise modulation of silicon’s electrical conductivity using

impurity doping lies at the very core of the operation of electronic

semiconductor devices.

• Mechanically, silicon is an elastic and robust material whose

characteristics have been very well studied and documented.

• The tremendous wealth of information accumulated on silicon and its

compounds over the last few decades has made it possible to innovate

and explore new areas of application.

• It becomes evident that silicon is a suitable material platform on which

electronic, mechanical, thermal, optical, and even fluid-flow functions

can be integrated.

• Ultrapure, electronic-grade silicon wafers available for the integrated

circuit industry are common today in MEMS.

• The relatively low cost of these substrates (approximately $10 for a 100mm-diameter wafer and $15 for a 150-mm wafer) makes them attractive

for the fabrication of micromechanical components and systems.

Forms of silicon

• Silicon as an element exists with three different microstructures:

• crystalline, polycrystalline, amorphous.

• Polycrystalline, or simply “polysilicon,” and amorphous silicon are

usually deposited as thin films with typical thicknesses below 5 µm.

• Crystalline silicon substrates are commercially available as circular

wafers with 100-mm (4-in) and 150-mm (6-in) diameters. Largerdiameter (200-mm and

• 300-mm) wafers, used by the integrated circuit industry, are currently

economically unjustified for MEMS. Standard 100-mm wafers are

nominally 525 µm thick, and 150-mm wafers are typically 650 µm

thick.

• Double-side-polished wafers commonly used for micromachining on

both sides of the wafer are approximately 100 µm thin-ner than

standard thickness substrates.

• Polysilicon is an important material in the integrated

circuit industry and has been extensively studied.

• Polysilicon is an equally important and attractive material

for MEMS.

• It has been successfully used to make micromechanical

structures and to integrate electrical interconnects,

thermocouples, p-n junction diodes, and many other

electrical devices with micromechanical structures.

• The most notable example is the acceleration sensor

available from Analog Devices, Inc., of Norwood,

Massachusetts, for automotive airbag safety systems.

• The mechanical properties of polycrystalline and amorphous silicon vary with

deposition conditions, but, by and large, they are similar to that of single crystal

silicon. Both normally have relatively high levels of intrinsic stress (hundreds of

MPa) after deposition, which requires annealing at elevated temperatures (>900ºC).

• Beam structures made of polycrystalline or amorphous silicon that have not been

subjected to a careful stress annealing step can curl under the effect of intrinsic

stress.

• Silicon is a very good thermal conductor with a thermal conductivity greater than

that of many metals and approximately 100 times larger than that of glass. In

complex integrated systems, the silicon substrate can be used as an efficient heat

sink.

• Unfortunately, silicon is not an active optical material—silicon-based lasers do not

exist. Because of the particular interactions between the crystal atoms and the

conduction electrons, silicon is effective only in detecting light; emission of light is

very difficult to achieve.

• The surface of silicon oxidizes immediately upon exposure to the oxygen in air

(referred to as native oxide). The oxide thickness self-limits at a few nanometers at

room temperature. As silicon dioxide is very inert, it acts as a protective layer that

prevents chemical reactions with the underlying silicon.

Silicon Oxide and Nitride

• It is often argued that silicon is such a successful material because it has a stable

oxide that is electrically insulating—unlike germanium, whose oxide is soluble in

water, or gallium arsenide, whose oxide cannot be grown appreciably.

• Various forms of silicon oxides (SiO2, SiOx, silicate glass) are widely used in

micromachining due to their excellent electrical and thermal insulating properties.

• They are also used as sacrificial layers in surface micromachining processes

because they can be preferentially etched in hydrofluoric acid (HF) with high

selectivity to silicon.

• Silicon dioxide (SiO2) is thermally grown by oxidizing silicon at temperatures

above 800°C, whereas the other forms of oxides and glass are deposited by

chemical vapor deposition, sputtering, or even spin-on (the various deposition

methods will be described in the next chapter).

• Silicon oxides and glass layers are known to soften and flow when

subjected to temperatures above 700°C. A drawback of silicon

oxides is their relatively large intrinsic stresses, which are difficult

to control. This has limited their use as materials for large

suspended beams or membranes.

• Silicon nitride (SixNy) is also a widely used insulating thin film

and is effective as a barrier against mobile ion diffusion—in

particular, sodium and potassium ions found in biological

environments. Its Young’s modulus is higher than that of silicon

and its intrinsic stress can be controlled by the specifics of the

deposition process.

• Silicon nitride is an effective masking material in many alkaline

etch solutions.

Thin Metal Film

• The choice of a thin metal film depends greatly on the nature of the final

application.

• Thin metal films are normally deposited either by sputtering, evaporation,

or chemical vapor deposition; gold, nickel, and Permalloy™ (NixFey),

and a few other metals can also be electroplated.

• For basic electrical interconnections, aluminum (usually with a few

percent silicon and perhaps copper) is most common and is relatively easy

to deposit by sputtering, but its operation is limited to noncorrosive

environments and to temperatures below 300ºC.

• For higher temperatures and harsher environments, gold, titanium, and

tungsten are substitutes.

• Aluminum tends to anneal over time and with temperature, causing

changes in its intrinsic stresses. As a result, it is typically located away

from stress- or strain-sensing elements.

• Aluminum is a good light reflector in the visible, and gold excels in the

infrared. Platinum and palladium are two very stable materials for

electrochemistry, though their fabrication entails some added

complexity.

• Gold, platinum, and iridium are good choices for microelectrodes, used

in electrochemistry and in sensing biopotentials. Silver is also useful in

electrochemistry.

• Chromium, titanium, and titanium-tungsten are frequently used as very

thin (5–20 nm) adhesion layers for metals that have poor adhesion to

silicon, silicon dioxide, and silicon nitride.

• Metal bilayers consisting of an adhesion layer (e.g., chromium) and an

intermediate nickel or platinum layer are normally used to solder with

silver-tin or tin-lead alloys. For applications requiring transparent

electrodes, such as liquid crystal displays, indium-tin-oxide (ITO)

meets the requirements.

• Finally, Permalloy™ has been explored as a material for thin magnetic

cores.

Polymers

• Polymers, in the form of polyimides or photoresist,

can be deposited with varying thicknesses from a

few nanometers to hundreds of microns.

• Spin-on organic polymers are generally limited in

their application as a permanent part of MEMS

devices because they shrink substantially as the

solvent evaporates, and because they cannot sustain

temperatures above 200°C.

• Because of their unique absorption and adsorption

properties, polymers have gained acceptance in the

sensing of chemical gases and humidity [7].

Glass and Fused Quartz Substrates

• Micromachining of glass and fused quartz (amorphous silicon

dioxide) substrates is practical in special applications, such as when

an optically transparent or an electrically insulating substrate is

required.

• Crystalline quartz (as opposed to fused quartz) also has the distinct

property of being piezoelectric and is used for some MEMS

devices. However, micromachining of glass or quartz is limited in

scope relative to silicon. Etching in HF or ultrasonic drilling

typically yields coarsely defined features with poor edge control.

Thin metal films can be readily deposited on glass or quartz

substrates and defined using standard lithographic techniques.

• Channels microfabricated in glass substrates with thin metal

microelectrodes have been useful in making capillaries for

miniaturized biochemical analysis systems.

Silicon Carbide and Diamond

• Silicon carbide and diamond continue to captivate the

imagination of many in the micromachining community.

• Both materials offer significant advantages, in particular

hardness, high stiffness (high Young’s modulus), resistance to

harsh chemical environments, mechanical stability at high

temperature, wide bandgap, and very high thermal conductivity.

• An important feature of both silicon carbide and diamond is that

they exhibit piezoresistive properties.

• High temperature pressure sensors in silicon carbide substrates

have been developed with stable operation up to about 500°C.

What Is Micromachining?

• Micromachining is the set of design and fabrication

tools that precisely machine and form structures and

elements at a scale well below the limits of our human

perceptive faculties—the microscale.

• Micromachining is the underlying foundation of

MEMS fabrication; it is the toolbox of MEMS.

Basic microfabrication technologies

• Deposition

– Chemical vapor deposition (CVD/PECVD/LPCVD)

– Epitaxy

– Oxidation

– Evaporation

– Sputtering

– Spin-on methods

• Etching

– Wet chemical etching

• Istropic

• Anisotropic

– Dry etching

• Plasma etch

• Reactive Ion etch (RIE, DRIE)

• Patterning

– Photolithography

– X-ray lithography

• Epitaxy,

sputtering,

evaporation,

chemical-vapor

deposition, and spin-on methods are common techniques

used to deposit uniform layers of semiconductors,

metals, insulators, and polymers.

• Lithography is a photographic process for printing

images onto a layer of photosensitive polymer

(photoresist) that is subsequently used as a protective mask

against etching.

• Wet and dry etching, including deep reactive ion etching,

form the essential process base to selectively remove

material.

Types:

• Isotropic etchants etch uniformly in all directions, resulting in

rounded cross sectional features.

• Anisotropic etchants etch in some directions preferentially

over others, resulting in trenches or cavities delineated by flat

and well defined surfaces, which need not be perpendicular to

the surface of the wafer.

.

The etch medium (wet versus dry) plays a role in selecting a

suitable etch method.

Wet etchants in aqueous solution offer the advantage of lowcost batch fabrication—25 to 50 100-mm-diameter wafers can

be etched simultaneously—and can be either of the isotropic or

anisotropic type.

Dry etching involves the use of reactant gases, usually in a lowpressure plasma, but non plasma gas-phase etching is also used

to a small degree. It can be isotropic or vertical.

The equipment for dry etching is specialized and requires the

plumbing of ultra-clean pipes to bring high purity reactant

gases into the vacuum chamber

Three Techniques of

Micromachining

• Surface Micromachining

• Bulk Micromachining

• LIGA

Bulk micromachining

Anisotropic etch of {100} Si

111

a

0.707a

54.74º

Surface Micromachining

substrate

Important issues:

• selectivity of structural, sacrificial and substrate materials

• stress of structural material

• stiction

Surface Micromachining

Most commonly used materials for surface micromachining:

• substrate:

silicon

• sacrificial material:

SiO2 or phosphosilicate glass (PSG)

• structural material:

polysilicon

Alternative materials

Substrates

Sacrificial

Structural

Glass

Plastic

metals

Polymer

Metals

silicon nitride

Thin film silicon (a-Si:H, c-Si)

silicon nitrides

Silicon carbide

Metals

polymers

bilayer composites

LIGA – X-ray Lithography,

Electroplating (Galvanoformung), Molding (Abformung)

Remove mold

Immerse in chemical bath and

electroplate the metal

Expose and develop photoresist

Deposit photoresist

Deposit plating base

LIGA

Photos from MCNC – MEMS group

MEMS Resources

Reference Books

• Nadim Maluf, An Introduction to Microelectromechanical Engineering (Artech House,

Boston,2000)

• M. Elewenspoek and R. Wiegerink, Mechanical Microsensors (Springer-Verlag, 2001)

• Héctor J. De Los Santos, Introduction to Microelectromechanical (MEM) Microwave

Systems (Artech House, Boston, 1999)

Websites

• Sandia National Lab: http://mems.sandia.gov

• Berkeley Sensors and Actuators Center: http://www-bsac.eecs.berkeley.edu

• MEMS Clearinghouse: http://www.memsnet.org/

Some companies with MEMS products

• Accelerometers – Analog Devices:

http://www.analog.com/technology/mems/index.html

• Digital Light Processing Projector- Texas Instruments: http://www.dlp.com

• Micro-electrophoresis chip – Caliper Technologies: http://www.calipertech.com

NEMS and Nanotechnology

• Nanotechnology

– manipulation of matter

at the nanometer scale.

• Nanomaterials

– Started with carbon.

– Behavior depends on

morphology.

Figure: Eight allotropes of carbon:

Diamond, graphite, lonsdaleite, C60, C540, C70,

amorphous carbon and carbon nanotube

Micro and Nanotechnologies for Sensors

Quantum dots are just as

awesome as we’d hoped

•

•

A new way to measure the efficiency of quantum dots could get them into

things like solar cells and electronics faster.

BY TAYLOR KUBOTA-STANFORD APR 11, 2019

Quantum Dots

• Quantum dots—tiny, easy-to-produce particles—may soon

take the place of more expensive single crystal

semiconductors in advanced electronics found in solar

panels, camera sensors, and medical imaging tools.

• Although quantum dots have begun to break into the

consumer market—in the form of quantum dot TVs—longstanding uncertainties about their quality have hampered their

adoption.

• “Traditional semiconductors are single crystals, grown in

vacuum under special conditions. These we can make in

large numbers, in flask, in a lab and we’ve shown they are as

good as the best single crystals,” says co-lead author David

Hanifi, a graduate student in chemistry at Stanford University.

NEMS and Nanotechnology,

Continued

• Quantum dots

• Nanowires

• Quantum films

https://www.youtu

be.com/watch?v=

0EokkhdppgE

Figure: Quantum Dots.

‘Giant leap’

• The measurement technique could lead to the development of

new technologies and materials that require knowing the

efficiency of our semiconductors to a painstaking degree, says

Paul Alivisatos, professor of nanoscience and nanotechnology

at the University of California, Berkeley.

• “We want to measure emission efficiencies in the realm of 99.9

to 99.999 percent…”

• “These materials are so efficient that existing measurements

were not capable of quantifying just how good they are. This is

a giant leap forward,” says Alivisatos.

• “It may someday enable applications that require materials with

luminescence efficiency well above 99 percent, most of which

haven’t been invented yet.”

Quantum dots from coal are a

promising antioxidant

• Quantum dots could make a great

antioxidant to treat people who've had brain

injuries, heart attacks, or strokes.

Quantum dots from coal are a

promising antioxidant

• Graphene quantum dots drawn from common coal may be

the basis for an effective antioxidant for treating traumatic

brain injuries, strokes, or heart attacks.

• Quantum dots are semiconducting materials small enough

to exhibit quantum mechanical properties that only appear

at the nanoscale.

• The Tour lab first extracted quantum dots from coal in

2013 and reported on their potential for medical imaging,

sensing, electronic, and photovoltaic applications. A

subsequent study showed how they can be engineered for

specific semiconducting properties.