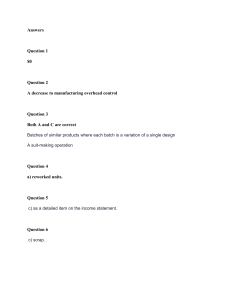

COST ACCOUNTING AND COST MANAGEMENT 1 CHAPTER 3 – ACCOUNTING FOR MATERIALS COST ACCOUNTING FOR MATERIALS COST Production costs are incurred based on expected output. Expected output is based on expected volume. Expected volume is based on sales forecast considering competition, changes in the economy and management’s policies on pricing, credit and sales promotions. Effective control of the elements of production cost requires - - Adoption of procedures geared towards maximum efficiency in the use of funds invested in the manufacturing resources and their recovery upon collection from customers within the shortest period after their conversion into finished goods. The time lag between procurement of materials and labor and start of production, the time period for processing, and the time lag between completion of goods and their delivery to customers are minimized considering changes in the incidental costs. CONTROL OF PRODUCTION COST - Refers to seeing to it that the different elements incurred (materials, labor and factory overhead), in total and per unit, are in accordance with plans and Adopting prompt remedial measures in case there are deviations It requires effective control systems for the different elements of production costs. Benefits of having an effective control of the Elements of Production cost a. Maximizes manufacturing efficiency b. Reduces unit cost c. Enables management to attain desired inventory levels CONTROL OF MATERIALS COST Requirements for control of materials cost Estimates of materials cost, in total and per unit. - Requires engineering, planning and routing. Products are designed and manufacturing processes are carefully planned. o Used as basis in determining materials requirements ( in terms of quantity per unit and quality) Production budget - Shows the budgeted production volumes, monthly or quarterly o Used as a basis in computing budgeted materials usage o Used as guides in timing materials procurement and estimating incidental costs involved and the desired inventory level of materials Purchase requisition - Informs the purchasing agent that materials as indicated therein are needed by the issuing party Purchase order - Issued to suppliers stating the specifications, quantities and unit prices for the different items being purchased and all the desired delivery date or dates Receiving report - Certifies the quantity of items received and may state the results of inspection and of quality tests Materials requisition - Notifies the storeroom or warehouse that materials as specified therein are needed by the issuing party and may state the date the materials are needed Page | 1 COST ACCOUNTING AND COST MANAGEMENT 1 CHAPTER 3 – ACCOUNTING FOR MATERIALS COST Materials ledger cards - The perpetual inventory records for materials showing receipts and issuances for each class thereof and the resulting balances. A card is maintained for each item of materials Returned materials report - Shows the materials previously issued and are being returned to the storeroom Scrap report - Shows the quantity of scrap materials removed from the factory Return shipping order - shows the materials returned or being returned to suppliers in some companies, they also use delivery receipt ( a form used to evidence that goods are brought out from the company compound) SAMPLE FORMS Silver Corporation Purchase Requisition No. 0211 To: Purchasing Department Date: _____________ Deliver To: ________________________ Date Required: __________ Job No./ Dept No. ________ Suggested Supplier: _______________ PLEASE ORDER THE ITEMS LISTED BELOW: Quantity Item Description Unit No. Price Silver Corporation Receiving and Inspection Report No. 532 RECEIVED FROM: ___________________ DATE: _________ PER INVOICE/ DELIVERY RECEIPT NO. ________ PURCHASE ORDER NO. _______ Quantity Description Item No. Amount Items Not Accepted: BUDGET CONTROL Allowance for the period P ______ Balance available ______ This purchase ______ Remaining balance ______ Ordered by ___________________ Silver Corporation Store Requisition No. 876 SUPPLIER: _______________________________ DATE: __________ Per Pur. Req. No. _______ Prepared b__________________ Posted by: __________________ Approved by ____________________ Silver Corporation Purchase Order Please deliver the items listed below: Quantity Description ___________________________________________________ Received by: Inspected by: _________________________ ______________________ Item No. Unit Price Approved by _________________________ TO: STORES DEPARTMENT FROM: ______________________________ REQUESTED BY: ______________________ CHARGE TO __________________________ Please issue the following items: Quantity Description Item No. No. 154 Date: ___________ Unit Cost Amount Received the above items. Approved by: ______________________ _____________________ Signature Date: _________________ Posted by _________________ Code: ______________________ Page | 2 COST ACCOUNTING AND COST MANAGEMENT 1 CHAPTER 3 – ACCOUNTING FOR MATERIALS COST PURCHASE OF, AND PAYMENT FOR MATERIALS a. When did the stores clerk or department head issues a purchase requisition? - When the balance of an item that is carried in stock reaches the critical level or When a department requisitions items that are not yet carried in stock b. Purchase requisition is sent to the accounting department for the corresponding account number before it is sent to the purchasing department. c. Purchasing department canvasses prices among suppliers and issues a purchase order to the chosen supplier so that delivery may be effected. d. A copy of the purchase order is forwarded to the receiving and inspection department to inform them of what deliveries are to be expected. e. The supplier delivers the goods to the company thru the latter’s receiving and inspection department and provides it with a copy of his invoice. f. The receiving and inspection department issues a receiving and inspection report after checking whether the goods so received are in accordance with specifications per purchase order. g. A copy of the receiving and inspection report goes with the materials received to the materials or stores department so that the storekeeper may know how many and what kind of materials have been received and whether they tally with what he actually receives. h. The original copy of the receiving and inspection report and the advance copy of the supplier’s invoice are forwarded to the accounting department so that they can be matched with the purchase order in processing payment. i. Another copy of the receiving and inspection report is sent to the purchasing department (to inform them of the A deliveries made by the supplier.) - this copy is subsequently forwarded to the stores or materials ledger clerk in the accounting department for posting to stock cards. j. The supplier, upon receipt of payment, surrenders the original copies of his invoice and of the purchase order. - these are attached to the voucher, stamped as already paid and are then filed. * in some companies, they require original copies of the vendor’s invoice and of the purchase order before payment is processed. Contracts for Repairs, Subscriptions and Purchase of Supplies – the procedure describe earlier for purchase of materials is also observed in acquiring other items. - These may be supplies for the offices, sales department, engineering department, cafeteria, and medical and dental clinics. Page | 3 COST ACCOUNTING AND COST MANAGEMENT 1 CHAPTER 3 – ACCOUNTING FOR MATERIALS COST - Annual contracts for repairs and subscriptions for journals and periodicals are to be covered by requisitions also. In case of short-notice or emergency repairs, the purchasing department may issue a blanket purchase order without specifying the amount. o Upon receipt of the bill, the amount thereof is verified with the head of the department in which repairs were made. ISSUANCE OF MATERIALS AND SUBSEQUENT RETURNS Issuance of materials – covered by stores( or materials ) requisition. - It is both a request for issuance and receipt for items so issued because an acknowledgement blank is provided therein. The form should clearly state the department or job to be charged and is accomplished in quadruplicate providing: o two copies for the accounting department – for the bookkeeper and the materials ledger clerk who enters the contents thereof to the ledger cards. o the storeroom and o a file copy for the requisitioning department. Recording requisitions - Inasmuch as many requisitions are made every month, it would be impractical to make a journal entry for each. Instead, they may be summarized monthly so that only one journal entry is made each month for requisitions. Another alternative – use of a special journal – the requisitions journal. ( illustrated below) Requisitions summary may have the same columns with the exception of the post reference column for the sundry accounts. o If a requisitions journal is used, it is part of the books of accounts and must be registered with the Bureau of Internal Revenue. REQUISITIONS JOURNAL Date Req. No. Job or Account No. Description Credit Materials Debit Work in Process Factory Overhead Control Selling Expenses Control General and Adm. Exp. Control Sundries Account Post Amount Title Ref. Page | 4 COST ACCOUNTING AND COST MANAGEMENT 1 CHAPTER 3 – ACCOUNTING FOR MATERIALS COST ISSUANCE OF MATERIALS: REQUISITIONS JOURNAL AND FLOW OF WORK Date Req. No. Description Credit Materia ls Work in Proces s Debit FOHC – Indirect Materials Sundries F Amount Material – X Received 1997 D May 5 9 15 20 27 28 551 552 553 554 555 556 557 Job No. 225 Job No. 223 For Machine Shop Job No. 226 Job No. 224 Shipping Supplies Factory office supplies Total for the month 7,000 4,500 1,200 6,800 3,500 2,500 800 7,000 4,500 Issued Am t. D 1,200 6,800 3,500 26,300 21,800 1,200 (15) (14) (21) Materials 15 May 31 Purchases May 31 Req. V.R. 31,000 Jr. 26,300 STORES REQUISITION For : Carpentry Dept. Date: 5/5 For Job 225 Materials X Material Y Q Q 5/5 Selling Expenses – Shipping supplies FOH – Factory Off. Supplies 31 21 2,500 800 Material – Y Received D Q Amt. 3,300 Work in Process Balance Amt. 4,200 Issued D Q Amt. 5/5 2,800 D Q Amt. 5/1 6,000 5/5 1,800 Balance D Q 5/1 5/5 Amt. 4,500 1,700 14 May 31 Req. Jr. 21,800 Job Order Cost Sheet No. 551 Job No. 225 For Stock – 20 computer tables Started : 5/4 4,200 2,800 7,000 Direct Cost 5/5 Materials Direct Cost Labor Factory Overhead 7,000 GENERAL LEDGER ACCOUNTS AND SUBSIDIARY RECORD ENTRIES - - Based on the procedure given for acquisitions, issuances and returns, the transactions are analyzed as to their effects on general ledger accounts and the corresponding subsidiary records per illustration below. In the given illustration, the stores account instead of the materials account is used so that acquisitions of items that go to the storeroom are debited to the account. Accounts Payable may also be used despite the use of vouchers in processing payment if said account appears in the chart of accounts. STORES LEDGER CARDS AND BIN CARDS Stores Ledger Cards - The perpetual records of the different items in the storeroom. Items received and issued for each class are posted to the corresponding card and the resulting balance must be equal to the inventory for said item. The total of all balances per stores ledger cards must therefore be equal to the inventory in the storeroom as of the same date. o To be assured of this, the balances per stores ledger cards are compared with the physical inventory on chosen dates during the accounting period. ▪ if there is a difference between the balance per books and the inventory per physical count, the possible cause thereof is determined. ▪ If a difference still exists after eliminating significant causes, the balance per books is adjusted by a corresponding debit or credit to factory overhead (inventory adjustment) Page | 5 COST ACCOUNTING AND COST MANAGEMENT 1 CHAPTER 3 – ACCOUNTING FOR MATERIALS COST Bin cards or bin tags - Those attached to storage bins, shelves, racks or other containers of items in the storeroom showing the movement of stock in said containers. Not part of the accounting records but are useful in controlling flow of materials. Balances per bin cards must be equal to the balances per materials or stores ledger cards. BIN TAG STOCK NO. ________ MAXIMUM ____ LOCATION ________ MINIMUM ____ DESCRIPTION ____________________________ Date Received Issued Balance Remarks COSTING METHODS FOR REQUISITIONS These methods are related to the flow of costs and not necessarily to the actual flow of materials or finished goods. If only the materials were acquired at the same cost all year round, then valuation of materials inventory end, will not be a problem because the value can be computed by simply multiplying the units on hand and the unit cost. The same can be said for the finished because if the units were produced at the same cost all year round, the value at the end of the period can be computed by multiplying the finished goods on hand by the cost to produce each unit. The different methods are used because the materials are acquired at different costs during the year. Average cost for: Perpetual inventory system refers to moving average Periodic inventory system refers to weighted average FIFO method • Based on the assumption that cost should be charged to manufacturing cost or cost of goods sold in the order in which incurred • Inventories are stated in terms of the most recent costs and • Expense is charged with the earliest costs incurred ▪ Average method – discussed in detail in financial accounting • Weighted average method o Based on the assumption that units issued should be charged at an average cost, such average being influenced or weighted by the number of units acquired at each price. o Inventory at the end is computed by multiplying the weighted average cost per unit by the units on hand. • Moving average method o When a perpetual inventory system is used, a new weighted average unit cost is calculated after each new purchase, and this amount is used to cost each subsequent issuance until another purchase is made. The FIFO method is used in illustrating the use of the 5-column stock card and the average method is used in emphasizing adjustments to average unit costs brought about by returns on the next page. ▪ o Page | 6 COST ACCOUNTING AND COST MANAGEMENT 1 CHAPTER 3 – ACCOUNTING FOR MATERIALS COST Inventory adjustment When inventory per physical count is different from balances per materials ledger cards (the total of w/c must be equal to the balance per general ledger), the latter are adjusted to make the balances equal to the former. - An addition is shown either in the “received” column or in the “issued” column but negative and vice-versa. In making the entry, the corresponding debit or credit is to factory overhead – inventory adjustment - - THE FIVE-COLUMN STOCK CARD - In the five-column stock card, the columns ordered and reserved are added to facilitate materials management. o These additional columns do not affect the balance but are reminders that some units have already been ordered although not yet received and that some have been reserved but not yet issued. - To illustrate the use of the five-column stock card, the following data are given on Silver Corporation’s raw material item 605, one-inch concrete nail, (with minimum and maximum balances of 150 and 400 kilos respectively, reorder quantity of 200 kls. And located in bin no. 455) for March, 2014. 2014 March 1 Inventory: 80 kgs. @ P 5 120 kgs. @ 6 3 Purchase order no. 653 for 200 kgs. at P 4.50 4 Reservation for 90 kgs. for job 786 per requisition no. 850. 5 Received 50 kgs. (P.O 653) per receiving and inspection report 026. 7 Issued 70 kgs. for job 786 per requisition 850. 9 Ordered 200 kgs. per P.O. No. 659 at P 5.70. 14 Issued the 20 kgs. reserved for job 786 per requisition 850. 19 Receiving and inspection report 035: balance ordered per P.O. 653. 22 Returned 20 kgs. to supplier for P.O. 653 per return shipping order 081. 25 Received 10 kgs. returned from job 786 per returned materials report 017. 27 Received 80 kgs. (P.O. 659) per receiving report No. 042. 30 Reserved 100 kgs. for job 75 per requisition no. 895. 31 Issued 125 kgs. for job 797 per requisition 910. Page | 7 COST ACCOUNTING AND COST MANAGEMENT 1 CHAPTER 3 – ACCOUNTING FOR MATERIALS COST Returns. - Returns to suppliers are shown in the received column as negative and at the unit cost at which they were recorded upon purchase. - Returns to storeroom are shown in the issued column as negative and at the unit cost used upon their issuance. Practices differ in extending the latter to the balance column. They may be shown is such a way that they are the first to be issued depending on the assumed flow of cost. This means that under FIFO, the returns are to be shown ahead of the others while under LIFO, they are to be shown as the last. AVERAGE COSTING METHOD: ADJUSTMENT ARISING FROM RETURNS - When the average costing method is in use and there are returns to suppliers, the average unit cost may be different from the acquisition cost of the materials being returned. o The difference is treated as a debit or credit to factory overhead (inventory adjustement). o Per illustration on the previous page, the return of 20 units on March 22 is posted to the stock card at the average unit cost P 4.9542. However, the purchase unit cost was P 4.50 only so that the P. 4542 difference gives rise to a debit to factory overhead of P 9.00 (or 20 units x P .4542) as shown in the following entry. Vouchers Payable ( 20 units x P 450) P 90 Factory Overhead (Inventory Adjustment) 9 Materials P 99 - Returns to storeroom of previously issued materials may give rise to adjustment in average unit cost. In the given example, the return to storeroom of 10 units on March 25 is posted at the assigned unit cost of P 5.38. The adjusted average unit cost is computed as follows: Balance, March 22 ( 290 units @ P 4.9542) P 1,437 Add: Return to storeroom, March 25 ( 10 x P 5.38) 54 Total P 1,491 Divide by 300 units Adjusted average unit cost P 4.97 / 4.8684 to be exact. Page | 8 COST ACCOUNTING AND COST MANAGEMENT 1 CHAPTER 3 – ACCOUNTING FOR MATERIALS COST SUMMARY OF MATERIALS ACCOUNTING UNDER A COST SYSTEM General Ledger Transactions Subsidiary Records Debit Credit Purchase of materials for stock Stores Accounts Payable Purchase of materials for immediate need in a job Work in Process Purchase of indirect materials Stores Accounts Payable Accounts Payable Purchase of supplies for factory, and the sales and administrative offices Issuance of direct materials Stores Issuance of indirect materials Factory Overhead Control Issuance of supplies for factory, and the sales and administrative offices Return of materials to suppliers Accounts Payable Work in Process Stores Stores Factory Overhead Control Selling Expenses Control Gen. And Adm. Stores Exp. Control Return of indirect materials to storeroom Accounts payable subsidiary ledgers Stores Ledger cards: Received section Accounts payable subsidiary ledgers Stores Ledger cards: Received section Accounts payable subsidiary ledgers Stores Ledger cards: Received section Accounts payable subsidiary ledgers Cost sheet or production report: Materials cost section Stores ledger cards: Issued section Factory overhead analysis sheet Stores ledger cards: Issued section Factory overhead analysis sheet Selling expenses analysis sheet General and adm.exp. analysis sheet Stores ledger cards: Issued section Accounts payable subsidiary ledgers Accounts Payable Stores Return of materials from factory to storeroom Stores Ledger cards: Received section Stores Work in Process Stores Factory Overhead Control Stores ledger cards: Received section (negative) Stores ledger cards: Issued section (negative) Cost sheet or production report: Materials cost section Stores ledger cards: Issued section (negative) Factory overhead analysis sheet (negative for indirect materials) Forms Used as Basis for Entry on Subsidiary Records Invoice, receiving and inspection report, purchase order Voucher Receiving and inspection report or voucher Voucher Receiving and inspection report or voucher Voucher Receiving and inspection report or voucher Voucher Stores Requisition Stores Requisition Stores Requisition Stores Requisition Stores Requisition Stores Requisition Stores Requisition Stores Requisition Return shipping order/ delivery receipt Return shipping order/ delivery receipt Returned materials report Returned materials report Returned materials report Returned materials report Page | 9 COST ACCOUNTING AND COST MANAGEMENT 1 CHAPTER 3 – ACCOUNTING FOR MATERIALS COST PURCHASE DISCOUNTS Trade discounts - Generally given in terms of percentage (15%, 10%, 5%) and are used to convert single price list into a series of price lists for different types of middleman. Not recorded on the books because purchases are recorded on the books net of the discount Example: Windy Corporation bys all of its materials and supplies from the Oregon Company and is allowed a trade discount of 10%. Purchases during the month were P 400,000 before the discount. Entry: Materials 360,000 Accounts Payable (400,000*90%) 360,0000 Quantity discounts - Represent cost savings for volume purchases. Not given explicit accounting recognition in the books Cash discounts - Deductions from the invoice price when payment is made within the discount period. Purpose: to encourage prompt payment Recorded as purchase discount by the buyer and sales discount by the seller Purchase discount - Deducted from purchases to arrive at net purchases Illustration: - The list price of a merchandise purchased is P 500,000 less 20% and 10%, with credit terms of 5/10, n/30. This means that trade discounts are 20% and 10%, and the cash discount is 5% if payment is made in 10 days. The full amount of the invoice is paid if the payment is made after 10 days and within the credit period of 30 days. List price First trade discount (20% x P 500,000) Second trade discount (10% x P 400,000) Invoice price Cash discount (5% x 360,000) Payment within the discount period The journal entry to record the purchase is: Purchases Accounts Payable o o 500,000 (100,000) 400,000 (40,000) 360,000 (18,000) 342,000 360,000 360,000 Note that the trade discounts are not recorded. The journal entry to record the payment of the invoice within the discount period is: Accounts payable Cash Purchase discount 360,000 342,000 18,000 Methods of recording purchases 1. Gross method – purchases and accounts payable are recorded at gros 2. Net method - purchases and accounts payable are recorded at net Illustration – Gross method 1. Purchases on account, P 200,000, 2/10, n/30. Purchases 200,000 Accounts payable 200,000 Page | 10 COST ACCOUNTING AND COST MANAGEMENT 1 CHAPTER 3 – ACCOUNTING FOR MATERIALS COST 2. Assume payment is made within the discount period. Accounts payable 200,000 Cash Purchase discount 3. Assume payment is made beyond the discount period. Accounts payable 200,000 Cash 196,000 4,000 200,000 Illustration – Net Method 1. Purchases on account, P 200,000, 2/10, n/30. Purchases 196,000 Accounts payable 196,000 2. Assume payment is made within the discount period. Accounts payable 196,000 Cash 196,000 3. Assume payment is made beyond the discount period. Accounts payable 196,000 Purchase discount lost (other expense) 4,000 Cash 200,000 4. Assume it is the end of accounting period, no payment is made and the discount period has expired. Purchase discount lose 4,000 Accounts Payable 4,000 Gross method vs. Net method In practice, most entities record purchases at gross invoice amount. Technically, the gross method violates the matching principle because discounts are recorded only when taken or when cash is paid rather than when purchases that give rise to the discounts are made. Moreover, this procedure does not allocate discounts taken between goods sold and goods on hand. Despite its theoretical shortcomings, the gross method is supported on practical grounds. The gross method is more convenient than the net method from a bookkeeping standpoint. FREIGHT IN - Freight cost for purchases may be treated as: A. ADDITION TO PURCHASE COST – specific freight charges ma either be • directly added to purchase cost - Example: Freight cost of P 600 is incurred on 10,000 units of material ABC bought for P.55 The purchase of material ABC is posted to the stock cards at the unit cost of P.61 considering the addition of freight cost per unit of P .06 (or P600/10,000 units) as shown below. Invoice price (10,000 units x P.55) P 5,500 Freight In 600 Total P 6,100 Divide by 10,000 units Unit cost P .61 • - The entry to record the acquisition would be: Materials P 6,100 Accounts Payable P 6,100 accumulated in the Freight In account and applied to purchases at a predetermined rate. Example: Freight cost of P 600 is incurred on 10,000 units of material ABC bought for P.55 Assume that purchases consist of P 6,000 units of material ABC @ P .20 and 2,400 units of mate rial DEF @ P .70 with total weights of 300 and 200 pounds, respectively. Page | 11 COST ACCOUNTING AND COST MANAGEMENT 1 CHAPTER 3 – ACCOUNTING FOR MATERIALS COST The allocation based on relative weights, would be as follows: Allocated Freight In Material ABC (300/500 lbs.) x P 600 360 Material DEF (200/500 lbs.) x P 600 240 Freight In Per unit P .06 .10 Unit Cost P .26 .80 Freight bills are not based solely on weights but also on peso values because of insurance coverage so that if there is a great disparity in relative weights and the bill is significant in amount, allocation of freight cost may be revised to consider both factors. - Freight cost may also be charged to purchases at a predetermined rate based on estimated freight costs and the corresponding estimated purchases in terms of peso value, weight or volume. o Freight costs are charged to Freight In and applied to the corresponding debit for materials purchased (such as Materials, Work in Process, and Factory Overhead Control). ▪ Any year-end balance is treated in a similar manner as that accorded to factory overhead variance, that is: • It is closed to cost of goods sold or to income and expense summary • If the balance is significant, it is prorated to cost of goods sold and the inventories of materials, work in process and finished goods. B. FACTORY OVERHEAD - this treatment requires the inclusion of estimated freight in cost in the computation for predetermined factory overhead rate so that it is automatically included in production cost upon recording the applied amount. - Freight in for supplies purchased for the sales and administrative departments are charged to the corresponding expense accounts. - MATERIALS HANDLING ACCOUNTS Materials Handling Costs - Refers to those incurred incidental to acquisition and storage of materials. These are the costs incurred in: o Ordering (purchasing department) o Receiving (receiving and inspection department) o Processing payment (accounting department) and in o Handling and storing materials ( materials department) - They are treated either as factory overhead or as an additional cost of materials. o As Factory Overhead ▪ Estimated materials handling costs are included in the computation for predetermined overhead rate and the actual figures are charged to factory overhead control. o As Additional Cost of Materials ▪ Materials handling costs are charged to Materials upon purchase at a predetermined rate. ▪ Costs incurred are charged to Materials Handling Cost Control and the variance, if any, is closed to Cost of Goods Sold. • If the variance is significant, it is allocated between cost of goods sold and the inventories of materials, work in process and finished goods. o Materials handling costs may be charged to cost of purchases using a single rate only or a rate for each of the departments involved. ▪ One predetermined rate used. Materials handling rate = Estimated materials handling costs Estimated materials purchases o Illustrative Problem. The budget of Cavite Mfg. Co. for 2014, its books of accounts and analysis sheets show the following: Page | 12 COST ACCOUNTING AND COST MANAGEMENT 1 CHAPTER 3 – ACCOUNTING FOR MATERIALS COST Peso Value Number of units Number of orders Departmental costs: Purchasing dept Receiving and inspection dept Materials dept Accounting dept (portion applicable to processing of payment) Per Budget P 5,000,000 25,000 units 20x Actual P 5,500,000 30,000 units 22x P 120,000 70,000 50,000 30,000 P 132,000 80,000 56,000 37,000 P 270,000 P 305,000 In using one predetermined rate, the computations and entries would be as follows: Materials handling cost rate: P 270,000/ 5,000,000 = 5.4% Materials handling cost variance: Actual P305,000 Applied (P 5,500,000 * 5.4%) 297,000 Materials handling cost variances – underapplied P 8,000 Entries: Upon purchase: Materials (P 5,500,000 + 297,000) Accounts Payable Applied Materials Handling Cost P 5,797,000 P 5,500,000 297,000 Actual materials handling cost: Materials Handling Cost Control Cash and other credits 305,000 To set up the variance: Applied Materials Handling Cost Materials Handling Cost Variance Materials Handling Cost Control 297,000 8,000 305,000 305,000 To close the variance: Cost of Goods Sold Materials Handling Cost Variance 8,000 8,000 Departmental Rates Used. A materials handling cost rate may be computed for each of the departments involved as follows: For purchasing department: Estimated purchasing department cost Estimated no. of purchases or amount of purchases = Rate per purchase or per peso of purchases For receiving department: Estimated receiving department cost Estimated number of units to be received = Rate per unit = Rate per unit or cubic foot For the materials department: Estimated materials department cost Estimated number of units or cubic feet of items to be purchased Page | 13 COST ACCOUNTING AND COST MANAGEMENT 1 CHAPTER 3 – ACCOUNTING FOR MATERIALS COST For the accounting department: Estimated applicable accounting department cost = Rate per transaction Estimated number of transactions The departmental rates based on the illustrative problem would be as follows: Purchasing dept.: P 120,000/ 20 orders = P 6,000 per order Receiving and inspection dept.: P 70,000/ 25,000 u. = P 2.80 per unit Materials dept.: P 50,000/ 25,000 u. = P 2.00 per unit Accounting dept.: P 30,000/ 20 orders = P 1,500 per transaction The materials handling cost variance is computed as follows: Applied: Purchasing dept.: P 6,000 x 22 orders = Receiving and inspection dept.: P 2.80 x 30,000 units = Materials dept.: P 2.00 x 30,000 units = Accounting dept.: P 1,500 x 22 transactions = Applied materials handling cost Actual Overapplied materials handling cost P 132,000 84,000 60,000 33,000 P 309,000 305,000 P 4,000 The entries may be similar to those made when using only one rate. If there is departmentalization of expenses in the company, departmental applied accounts are used as shown in the following entry upon purchase of materials: Materials ( P 5,500,000 + 309,000) P 5,809,000 Accounts Payable Applied Purchasing Dept. Expenses Applied Receiving and Inspection Dept. Expenses Applied Materials Dept. Expenses Applied Accounting Dept. Expenses P 5,500,000 132,000 84,000 60,000 33,000 The actual expenses related to materials purchases may be charged to the applied accounts so that the total of the resulting balances shall be equal to the variance. SCRAP MATERIALS Scrap - Refers to pieces or fragments of materials or something to be discarded. - Examples: o pieces of cloth resulting from cutting the material into the required shapes and sizes in the manufacture of t-shirts o fragments of iron bars resulting from cutting them into the desired lengths in a construction company. - Although it cannot be avoided, they should be minimized and should be reported and controlled. - A scrap report is prepared regularly so that unusual quantities and value may be noted for the adoption of prompt corrective measures. - When the value of scrap is significant and readily determinable, an entry is made upon transfer thereof to storeroom, otherwise, an entry is made only upon sale. - Regardless of whether an entry is made or not upon transfer of scrap, it is preferable to maintain a ledger to control the quantity of scrap. It its value can be reasonably estimated, the corresponding value may also be indicated thereon. - The treatment for scrap is summarized on the next page. Page | 14 COST ACCOUNTING AND COST MANAGEMENT 1 CHAPTER 3 – ACCOUNTING FOR MATERIALS COST - o Entry is made only upon sale ▪ the credit may be to factory overhead (if not traceable to any specific job or process), to income and expense summary ( as other income) or to work in process ( if traceable to a specific job or process). o Entry is made upon gathering of scrap. ▪ Debit “Scrap Materials” crediting factory overhead or work in process. ▪ Upon sale, the difference between assigned value and selling price is treated as an adjustment to factory overhead or work in process depending on which account was credited when the scrap was recorded. Example: Scrap materials with estimated value of P P 4,800 are transferred to the storeroom. They are subsequently sold for P 5,000 cash. A. Entry is made upon sale only. 1. Scrap sales treated as other income Cash P 5,000 Scrap Sales P 5,000 To close a year-end: Scrap Sales 5,000 Income and Expense Summary 5,000 2. Scrap sales treated as adjustment to factory overhead ( if not traceable to specific job or process): Cash 5,000 Factory Overhead 5,000 3. Scrap sales treated as adjustment of production cost of a job or process: Cash 5,000 Work in Process 5,000 B. Scrap materials are taken up upon gathering them. Scrap Materials 4,800 Factory Overhead (or Work in Process) 4,800 Upon Sale: Cash 5,000 Scrap Materials 4,800 Factory Overhead (or Work in Process) 200 - When sales of scrap are recurring and significant in amount, they may be accumulated first in “ Scrap Sales” and subsequently closed to factory overhead or work in process (as the case may be) to facilitate analysis and for more effective control) Page | 15 COST ACCOUNTING AND COST MANAGEMENT 1 CHAPTER 3 – ACCOUNTING FOR MATERIALS COST SPOILED GOODS - Those that have developed imperfections and are disposed of as such. The difference between selling price and accumulated cost is treated either as a a. Charge to factory overhead (loss on spoiled goods) - charged when spoilage is normal or inherent in the manufacture of standard jobs. ▪ This practice has the effect of charging the cost item to all regular jobs inasmuch as charges to factory overhead are prorated among all jobs upon the application of the factory overhead rate. • this implies that in computing for factory overhead rate, sufficient provision for spoilage is included in the estimated amount of factory overhead. • In making the entry, the cost of the spoiled units is removed from work in process and spoiled goods are taken up at their estimated market value with the loss in value debited to factory overhead. b. Left with work in process as additional cost of the remaining good units in a job. ▪ When spoilage is due to the special nature of a job or due to strict specifications or difficult processing involved, the loss is treated as part of the cost of the particular job or is left with work in process. ▪ In making the entry, only the estimated cost recovery is removed from work in process so that whatever loss is incurred from spoilage is left with work in process as part of the cost of the remaining good units in the particular job. - Example: The prime cost per unit for 100 beds are as follows: Direct materials P 450 Direct labor 300 Factory overhead is P 250 per unit and includes a P 10 provision for normal spoilage. Upon final inspection of the beds, two units are considered imperfect and can be sold for P 600 each. o Loss from Spoilage Charged to Factory Overhead ▪ If the spoilage is considered normal so that it must be charged to total prod uction, the overhead rate used is P250 per unit so that cost per unit of the 100 beds must be P 1,000. The production costs are tabulated as follows: Original Cost of 2 beds Cost of 98 beds Direct materials P 45,000 ( 2%) P 900 P 44,100 Direct labor 30,000 600 29,400 Factory overhead @ P 250 25,000 500 24,500 P100,000 P 2,000 P 98,000 Unit cost P 1,000 P 1,000 P 1,000 The entries would be as follows: To charge the original cost to production: Work in Process – Direct Materials Work in Process – Direct Labor Work In Process – Factory Overhead Materials Payroll Applied Factory Overhead To take up the spoiled goods: Spoiled Goods Factory Overhead Control Work in Process – Direct Materials Work in Process – Direct Labor Work In Process – Factory Overhead To take up the completion of the remaining 98 beds: P 45,000 30,000 25,000 P 45,000 30,000 25,000 1, 200 800 900 600 500 Page | 16 COST ACCOUNTING AND COST MANAGEMENT 1 CHAPTER 3 – ACCOUNTING FOR MATERIALS COST Finished Goods Work in Process – Direct Materials Work in Process – Direct Labor Work in Process – Factory Overhead 98,000 44,100 29,400 24,500 It may be noted that the cost per unit of the 98 remaining good beds remains at P 1,000 (or P 98,000/ 1,000 beds). o Loss from Spoilage Charged to a Particular Job ▪ Assume that the production order is a special one because of strict specifications. The overhead rate used excludes the P 10 provision for normal spoilage so that the original cost per bed must be P 990 (direct materials – P 450, direct labor – P 300, and factory overhead – P 240). Direct materials Direct labor Factory overhead @ P 240 Unit cost Original P 45,000 30,000 24,000 P 99,000 P 990 Estimated cost recovery P 545 364 291 P 1,200 The estimated cost recovery per element of cost is computed as follows: Direct materials [(P 450/P 990) x P 1,200] Direct labor [(P 300/P 990) x P 1,200] Factory Overhead [(P 240/P 990) x P 1,200] Estimated Cost Recovery The entries would be as follows: To charge the original cost to production: Work in Process – Direct Materials Work in Process – Direct Labor Work In Process – Factory Overhead Materials Payroll Applied Factory Overhead = = = Cost of 98 beds P 44,455 29,636 23,709 P 97,800 P 998 P 545 364 291 P 1,200 P 45,000 30,000 24,000 P 45,000 30,000 24,000 To take up the spoiled goods: Spoiled Goods Work in Process – Direct Materials [(P 450/P 990) x P 1,200] Work in Process – Direct Labor [(P 300/P 990) x P 1,200] Work In Process – Factory Overhead [(P 240/P 990) x P 1,200] To take up the completion of the remaining 98 beds: Finished Goods Work in Process – Direct Materials (P 45,000 – 545) Work in Process – Direct Labor (P 30,000 – 364) Work in Process – Factory Overhead (P 24,000 – 291) 1, 200 545 364 291 97,800 44,455 29,636 23,709 With loss from spoilage treated as part of work in process (or left with the cost of the particular job) , unit cost of the 98 remaining good units becomes P 998 (P 97,800/98 units). This means that the spoilage results in an adjustment in unit cost of P 8 which may also be arrived at as follows: Loss from spoilage (P 2,000 – 1,200) P 800.00 Divide by remaining good units 98 units Adjustment in unit cost P 8 Page | 17 COST ACCOUNTING AND COST MANAGEMENT 1 CHAPTER 3 – ACCOUNTING FOR MATERIALS COST - From the foregoing illustration, the following comparison may be emphasized: When loss from spoilage is treated as factory overhead, the overhead rates includes the provision for normal spoilage and the cost of the spoiled units is removed from work in process. When loss is charged to a particular job, the overhead rate excludes the provision for normal spoilage and it is the estimated cost recovery that is removed from work in process. DEFECTIVE GOODS - Those that have developed imperfections and are reprocessed so that they can be sold as regular finished goods. Advisability of correcting imperfections depends on whether the expected benefit therefrom (that is, increase in sales value) exceeds the incremental cost arising from the reprocessing. - Cost of reprocessing defective work may be charged (debited) to: o Factory overhead – when imperfections are normal or expected in standard jobs ▪ Has the effect of prorating said cost among all jobs and requires the inclusion of sufficient provision therefor in computing for the factory overhead rate. o Work in process/ particular job – when imperfections are due to the special nature of the job. - Example: A job order for 30 kitchen cabinets entails the following prime costs: Direct materials P 18,000 Direct labor 12,000 Factory overhead rate of 80% of direct labor cost includes 3% provision for reprocessing cost of defective work. Five of the cabinets are found to have imperfections and are reprocessed. Prime cost incurred in reprocessing them amounts to P 2,000 ( Direct materials - P 800, direct labor – P 1,200). o Reprocessing cost treated as Factory Overhead if the job is a standard or regular one and imperfections are considered normal, the reprocessing cost is charged to factory overhead so that the overhead rate to be used is P 80%. The original cost of the job must therefore be equal to P 39,600 or at P 1,320 per unit arrived at as follows: Per Unit Direct materials P 18,000 P 600 Direct labor 12,000 400 Factory overhead (80% of P 12,000) 9,600 320 P 39,600 P 1,320 The entries are given below. To take up the original cost of the job Work in Process – Direct Materials P 18,000 Work in Process – Direct Labor 12,000 Work In Process – Factory Overhead 9,600 Materials P 18,000 Payroll 12,000 Applied Factory Overhead 9,600 ▪ To take up the reprocessing cost: Factory Overhead Control (Defective work) Materials Payroll Applied Factory Overhead (80% x P 1,200) 2,960 800 1,200 960 To take up the completion of the Finished Goods 39,600 Work in Process – Direct Materials 18,000 Work in Process – Direct Labor 12,000 Work in Process – Factory Overhead 9,600 It may be noted that the unit cost of the 30 units remains at their original figure of P 1,320 inasmuch as the reprocessing cost is charged to factory overhead. Page | 18 COST ACCOUNTING AND COST MANAGEMENT 1 CHAPTER 3 – ACCOUNTING FOR MATERIALS COST o Reprocessing Cost Charged to a Particular Job. When defective work is due to the special nature of a job as when it requires difficult processing or the specifications are very strict, cost of reprocessing is charged to the job. ▪ Factory overhead rate should therefore exclude the provision for normal imperfection. ▪ Based on the given example, the original production costs of 30 kitchen cabinets in total and per unit would be as follows: Per Unit Direct materials P 18,000 P 600 Direct labor 12,000 400 Factory overhead (77% of P 12,000) 9,240 308 P 39,240 P 1,308 The entries are given below. To take up the original production costs: Work in Process – Direct Materials P 18,000 Work in Process – Direct Labor 12,000 Work In Process – Factory Overhead 9,240 Materials P 18,000 Payroll 12,000 Applied Factory Overhead 9,240 ▪ To take up the reprocessing cost: Work in Process – Direct Materials Work in Process – Direct Labor Work in Process – Factory Overhead Materials Payroll Applied Factory Overhead 800 1,200 924 800 1,200 924 (77% x P 1,200) To take up the completion of the job Finished Goods Work in Process – Direct Materials Work in Process – Direct Labor Work in Process – Factory Overhead P 42,164 18,800 13,200 10,164 In charging the reprocessing cost to the job, unit cost goes up to P 1,405.47 (that is, P 42,164/30 units) or there is an adjustment for defective work of P 97.47 ( P 2,924/30 units). LOSS FROM SPOILAGE AND REPROCESSING COST AS PERIOD COST Loss from spoilage and reprocessing cost - when treated as given in the preceding paragraph (as factory overhead or as cost of a particular job), are product cost. - Treated as period cost when imperfections are due to extraordinary factors beyond the control of production men and the amount involved is significant. o Examples: those caused by fortuitous events such as flood and earthquake. o For spoiled goods, the entry upon recognition of the spoiled goods would be Spoiled goods (at market value) Loss from Flood Work in Process – Direct Materials Work in Process – Direct Labor Work in Process – Factory Overhead o o P xxx xxx Pxxx xxx xxx For defective work, the reprocessing cost is taken up as follows: Loss from Flood xxx Materials xxx Payroll xxx Applied Factory Overhead xxx It may be emphasized that normal loss is treated as product cost and abnormal loss, as period cost. Page | 19 COST ACCOUNTING AND COST MANAGEMENT 1 CHAPTER 3 – ACCOUNTING FOR MATERIALS COST TREATMENT FOR LOSS FROM SPOILAGE AND REPROCESSING COST COMPARED Although entries for loss from spoilage and reprocessing cost differ, there may be one set of guidelines in their treatment. These are briefly stated as follows: Imperfections Reprocessing Cost or Loss from Spoilage treated as Normal or inherent in the regular manufacturing process Normal in particular jobs or due to strict specifications Due to extraordinary causes Factory overhead Additional cost of the job (or work in process) Charge to specific loss account - Although the above treatment are observed for both defective work and spoiled goods, it should be borne in mind that: o In the case of the former, the entry is to take up the additional cost incurred to correct the imperfection. o In the case of spoiled goods, the entry is to remove said goods from work in process and any difference between accumulated cost of the spoiled goods and their estimated market value is accorded the corresponding treatment as given above. - Factory overhead rate – when reprocessing costs (in the case of defective work) and loss from spoilage in the case of spoiled goods) are treated as factory overhead, the proration automatically occurs upon inclusion of their estimated figures in estimated total factory overhead in computing for the predetermined overhead rate. o Illustrative Problem: Accounting for Defective Goods and Spoiled Goods Prime costs charged to job 324 (for 10,000 units of a product) are the following: Per Unit Direct materials P 20,000 P 2.00 Direct labor cost 10,000 1.00 Factory overhead is charged to production at 80% of direct labor cost. This rate excludes provision for normal imperfections. Five hundred units develop imperfections. What entries are to be made under each of the following assumptions? A. The five hundred units that have developed imperfections are reprocessed requiring prime costs of P 800 (direct materials, P 500 and direct labor cost, P 300). 1. The imperfections are considered normal or expected in all the regular jobs. Factory overhead rate is to include an additional 10% to provide for the defective work. 2. The imperfections are considered due to the special nature of the particular job. B. The goods with imperfections are to be sold at P 1.50 per unit. Observe the different assumptions as given above. The entries as given are presented in comparative form and three work in process accounts are used to emphasize the difference between accounting for defective goods and spoiled goods. A-1: Defective Work Normal in all Regular Jobs. The reprocessing cost is charged to factory overhead and the cost of the job is affected by the corresponding increase in factory overhead rate. The unit cost of the finished units is P 3.90 (or P 39,000/10,000 units) broken down as follows: Direct materials P 2.00 Direct labor 1.00 Factory overhead .90 P 3.90 Without any provision for normal imperfection, the unit cost ought to be P 3.80 with factory overhead per unit at P .80. Thus, even if the reprocessing cost is charged to factory overhead, the cost of the given job is affected by the inclusion of the provision for normal defective work in the computation for factory overhead rate. Page | 20 COST ACCOUNTING AND COST MANAGEMENT 1 CHAPTER 3 – ACCOUNTING FOR MATERIALS COST A-2: Defective Work Normal Only in the Special Job. The reprocessing cost is treated as additional cost of the special job so that the overhead rate used is 80%, that is, without including any provision for defective work that is considered normal in all regular jobs. Without the defective work, unit cost is P 3.80 only (direct materials – P 2; direct labor – P 1 and factory overhead – P .80). With the additional debit to work in process of P 1,040 (reprocessing cost), unit cost of the finished units becomes P 3.904 (P 39,040/10,000 units) or higher by P 1.04 when compared with the original unit cost of P 3.80. B-1: Loss from Spoilage Normal in all Regular Jobs. The difference between accumulated cost of the spoiled units of P 1, 950 and their estimated market value of P 750 is charged to factory overhead. The overhead rate used is 90% and includes the 10% provision for spoilage normal in all regular jobs. The unit cost of the remaining good units remains at P 3.90 (or P 37,050/9,500 units). B-2: Spoiled Goods Normal in the Particular Job. Factory overhead rate used is 80%, that is, disregarding the provision for normal spoilage in all regular jobs. The loss from spoiled goods of P 1,150 (see computation below) remains in work in process so that only the estimated market value of the spoiled units is credited to the cost of the job. The cost recovery is allocated among the three cost elements in the ratio that each bears to the total. Consequently, the unit cost of the remaining good units goes up to P 3.921 (or P 37,250/ 9,500 units) with the adjustment for loss from spoilage arrived at as follows: Cost of spoiled units (500 x P 3.80) P 1,900 Cost recovery (500 x 1.50) (750) Loss from Spoilage P 1,150 Divide by remaining good units 9,500 units Adjustment in unit cost for spoilage P .121 Page | 21 COST ACCOUNTING AND COST MANAGEMENT 1 CHAPTER 3 – ACCOUNTING FOR MATERIALS COST EXERCISES Problem 1 The following information is to be used in costing inventory on August 31. August 1 Beginning balance 1,600 units at P 6.00 5 Purchased 400 units at P 7.00 9 Purchased 400 units at P 8.00 16 Issued 800 units 24 Purchased 600 units at P 9.00 27 Issued 1,000 units Required: The cost of materials used and the cost assigned to the August 31 inventory by each of these perpetual inventory costing methods. 1. First-in, first-out 2. Average Problem 2 The Heaven & Earth Company made the following purchases and issues during January: January 1 Balance on hand, 1,000 units at P 4.00 each 3 Issued 250 units 5 Received 500 units at P 4.50 each 6 Issued 150 units 10 Issued 110 uunits 11 Factory returned 10 units to the store room that were issued on the 10th 15 Received 500 units at P 5.00 each 20 Returned 300 units to vendor from May 15th purchase 26 Issued 100 units Required: Cost of materials used and inventory, end using: 1. First-in, first out 2. Average Problem 3 – Materials Cost – Accounting for Scrap Scrap materials with estimated value of P 6,000 are gathered and separated from work in process. They are subsequently sold for P 6,200. Make the entries under each of the following assumptions: a. Revenue from sale of scrap is recognized only upon sale as (1) other income (2) as adjustment to factory overhead (3) as reduction in the cost of a particular job b. Scrap is recognized upon separation thereof from work in process and revenues is treated as (1) as adjustment to factory overhead (2) as reduction in the cost of a particular job Problem 4 - Materials Cost – Accounting for Spoiled Goods Sunny Corp. manufactures portable beds and chairs made of round steel bars and woven plastic strips (similar to woven rattan strips). The steel bars are cut, heated and bent before they are connected by bolts and nuts to form the desired structures. The woven plastic strips are subsequently attached per specifications. For 2014, estimated factory overhead (without the corresponding provision for any imperfection) is P 60,000 based on estimated direct labor cost of P 120,000. Per estimates, a 5% spoilage may be expected with unrecovered cost of P 3,000. For January, 2014, the company processed an order for 10 portable rocking chairs (job no. 027). The prime costs are as follows: Direct materials P 10,000 Direct labor 5,000 Upon final inspection, two rocking chairs are found below standard. Estimated cost recovery is P 1,000 per chair. Page | 22 COST ACCOUNTING AND COST MANAGEMENT 1 CHAPTER 3 – ACCOUNTING FOR MATERIALS COST Questions: a. Assuming that the job is a regular or standard one, (1) what factory overhead rate must be used? (2) what must be the unit cost for the remaining eight rocking chairs upon completion? (3) what are the entries to take up the original production cost, spoilage and completion of the remaining units? b. Assuming that the job is a special one, what would be your answers for the questions given above? Problem 5 – Materials Cost – Accounting for Defective Work A job order for 1,000 pairs of carved wooden bookends is processed and prime costs are as follows: Direct materials P 30,000 Direct labor 20,000 Factory overhead rate of 50% of direct labor cost excludes a 2% provision for defective work. Prior to transfer to stockroom, 50 pairs are found defective and are reprocessed. Prime costs in reprocessing amount to P 800 (direct materials of P 200 and direct labor of P 600). Questions: a. Assuming that the job is a regular or standard one, (1) what factory overhead rate must be used? (2) what must be the unit cost for the 1,000 pairs of bookends upon completion? (3) what are the entries to take up the original production cost, spoilage and completion of the job? b. Assuming that the job is a special one, what would be your answers for the questions given above? Multiple Choice 1. According to the net method, which of the following items should be included in the cost of inventory? Freight cost Purchase discounts not taken a. Yes No b. Yes Yes c. No Yes d. No No 2. The weighted average for the year inventory cost flow method is applicable to which of the following inventory system? Periodic Perpetual a. Yes Yes b. Yes No c. No Yes d. No No 3. During June, Delta Co. experienced scrap, normal spoilage, and abnormal spoilage in its manufacturing process. The cost of units produced includes a. Scrap, but not spoilage b. Normal spoilage, but neither scrap nor abnormal spoilage c. Scrap and normal spoilage, but not abnormal spoilage d. None of the items mentioned 4. March Company had 150 units of product on hand at January1 costing P 21.00 each. Purchasing of product A during the month of January were as follows: Units Unit cost January 10 200 P 22.00 18 250 23.00 28 100 24.00 Physical count on January 31 shows 250 units of product A on hand. The cost of the inventory at January 31, under the FIFO method is: a. P 5,850 b. P 5,550 c. P 5,350 d. P 5,250 Page | 23 COST ACCOUNTING AND COST MANAGEMENT 1 CHAPTER 3 – ACCOUNTING FOR MATERIALS COST Harper Company’s Job 301 for the manufacture of 2,200 coats was completed during August, 2014 at the following unit costs: Direct materials P 20.00 Direct labor 18.00 Factory overhead (includes an allowance of P 1 for spoiled work) 18.00 Final inspection of Job 301 discloses 200 spoiled costs which were sold to a jobber for P 6,000. 5. Assume that spoilage loss is charged to all production during August. What would be the unit cost of the good units produced on Job 301? a. P 53.00 b. P 55.00 c. P 56.00 d. P 58.00 6. Assume instead, that the spoilage loss is attributable to exacting specification of Job 301 and is charged to this specific job. What would be the unit cost of the good coats produced on Job 301? a. P 55.00 b. P 57.50 c. P 58.60 d. P 61.60 7. Palmer Corporation is a manufacturing concern that uses a perpetual inventory system. Te following data on the material inventory account is provided for 2014. Material balance P 275,000 Other debits to the materials account during the year 825,000 Increase of ending over beginning inventory 55,000 How much is the cost of materials issued to production? a. P 1,045,000 b. P 770,000 c. P 880,000 d. P 430,000 8. Job 75 incurred the following costs for the manufacture of 200 units of motors: Original cost accumulation Direct materials P 13,200 Direct labor 16,000 Factory overhead (150% of direct labor) 24,000 Direct costs of reworked 10 units Direct materials 2,000 Direct labor 3,200 The total rework costs were attributable to exacting specifications of Job 75 and the full rework costs were charged to the specific job. The cost of Job 75 was a. P 316 b. P 266 c. P 280 d. P 292 9. The following data on materials purchases and issues during the month of April were reported: April 1 Beginning balance 400 units at P 6 5 Received 100 units at P 7 11 Received 100 units at P 8 13 Issued 400 units 15 Received 200 units at P 6 22 Issued 250 units 27 Returned from factory 50 units 30 received 300 units at P 9 Assuming that the company used a perpetual inventory system (FIFO method), the total quantity and cost of materials purchased for the month of April should be: a. 700 units at P 5,800 c. 700 units at P 5,400 b. 700 units at P 5,810 d. 700 units at P 6,200 10. Euphorbia Company produces and sells a single item of product. Inventory at the beginning of September was 400 units valued at P 1.80 per unit. Further receipts and sales during the month were as follows Units Cost per unit September 8 Receipts 600 P 2.10 20 Receipts 50 ? 25 Sales 1,250 4.00 The inventory uses the FIFO method of stock valuation. Gross margin for September was P 2,500. What was the cost per unit of the 500 units received on September 20? a. P 1.04 b. P 1.94 c. P 2.00 d. P 2.08 Page | 24 COST ACCOUNTING AND COST MANAGEMENT 1 CHAPTER 3 – ACCOUNTING FOR MATERIALS COST During March, March Company incurred the following costs on Job 209 for the 200 motors: Original cost accumulation: Direct materials P 660 Direct labor 800 Factory overhead 1,200 P 2,660 Direct costs of reworking 10 units: Direct materials P 100 Direct labor 160 P 260 Method A – The rework cost were attributable to the exacting specifications of Job 209, and the full rework costs were charged to this specific job. Method B – The defective units fall within the normal range and the rework is not related to a specific job, or the rework is common to all the jobs. 11. The cost per finished unit of Job 209 using Method A us: a. P 15.60 b. P 15.80 c. P 13.30 d. P 13.50 12. The cost per finished unit of Job 209 using method B is: a. P 13.30 b. P 15.80 c. P 15.30 d. P 13.60 13. Tools Company manufactured electric drills to the exacting specifications of various customers. During February 2008, Job 403 for the production of 1,100 drills was completed at the following cost per unit Direct materials P 100 Direct labor 80 Factory overhead 120 Total P 300 Final inspection of Job 403 disclosed 50 defective units and 100 units of normal spoilage. The defective drills were reworked at a total cost of P 5,000 and the spoiled drills were sold to a jobber for P 15,000. The unit cost of the good units produced on Job 403 was: a. P 330 b. P 320 c. P 300 d. P 290 14. Arko Manufacturing Co. purchased 10,500 lbs. Of materials XY at P 2 per lb. and incurred freight cost of P 1,050. A cash discount of 2% is granted on payments within ten days. Freight in is treated as an additional cost of materials purchased. What unit cost must be entered on the stock card for material XY assuming that the allowance method is used in accounting for discount? a. P 2.06 b. P 1.96 c. P 2.00 d. P 2.058 REFERENCES USED FOR THE 3RD MODULE – ACCOUNTING FOR MATERIALS COST Cost accounting by Nenita Mejorada, 3rd Edition. Cost accounting by Guillermo M. De Leon Jr. And Norma D. De Leon. Page | 25