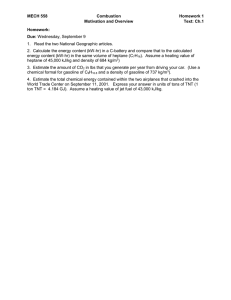

Chemical Engineering Journal 268 (2015) 116–124 Contents lists available at ScienceDirect Chemical Engineering Journal journal homepage: www.elsevier.com/locate/cej Droplet size distribution and droplet size correlation of chloroaluminate ionic liquid–heptane dispersion in a stirred vessel Lu Qi a, Xianghai Meng a, Rui Zhang a, Haiyan Liu a, Chunming Xu a, Zhichang Liu a,⇑, Peter A.A. Klusener b,⇑ a b State Key Laboratory of Heavy Oil Processing, China University of Petroleum, Beijing 102249, China Shell Technology Centre Amsterdam, Shell Global Solutions International B.V., Grasweg 31, 1031 HW Amsterdam, The Netherlands h i g h l i g h t s g r a p h i c a l a b s t r a c t Ionic liquid–heptane dispersion was studied as model system for ionic liquid alkylation process. FBRM and PVM were successfully used to determine the phase inversion and droplet size distribution respectively. The phase inversion point was close to the heptane holdup of 0.5. Self-similar droplet size distribution of IL-continuous dispersion was found. A semi-empirical correlation is proposed to predict the Sauter diameter of the heptane droplets. a r t i c l e i n f o Article history: Received 26 September 2014 Received in revised form 2 January 2015 Accepted 3 January 2015 Available online 17 January 2015 Keywords: Ionic liquid Heptane Liquid–liquid dispersion Droplet size distribution a b s t r a c t Droplet size distribution (DSD) and mean droplet size of chloroaluminate ionic liquid (IL)–heptane dispersion in a stirred vessel were investigated as a model system for the composite ionic liquid/hydrocarbon system applied in the commercial isobutane alkylation process. Focused beam reflectance measurement was used to identify the phase inversion, and particle video microscope (PVM) was employed to measure the DSD of IL-continuous dispersions. The effects of agitation speed and dispersed phase holdup on the DSD and mean droplet size were investigated. Phase inversion was found at a heptane hold-up of just above 0.5. The observed DSDs could be described well by logarithmic normal distributions in spite of variable operating conditions. The DSDs appeared to be more or less independent of the dispersed phase holdup (/heptane P 0.3) at the same agitation speed. A semi-empirical correlation based on Shinnar theory was proposed to predict the droplet mean size in the impeller region for the IL-continuous dispersion, and the predicted value agreed well with the experimental data. This work will be a good basis to predict the dispersion behavior under process conditions. Ó 2015 Elsevier B.V. All rights reserved. 1. Introduction ⇑ Corresponding authors at: State Key Laboratory of Heavy Oil Processing, China University of Petroleum, Changping District, Beijing 102249, China. Tel.: +86 10 8973 1252 (Office); fax: +86 10 6972 4721 (Z.C. Liu). Tel.: +31 206302743 (P.A.A. Klusener). E-mail addresses: lzch@cup.edu.cn (Z.C. Liu), peter.klusener@shell.com (P.A.A. Klusener). http://dx.doi.org/10.1016/j.cej.2015.01.009 1385-8947/Ó 2015 Elsevier B.V. All rights reserved. Alkylation of isobutane with light olefins is an important process in petroleum industry to produce high-quality gasoline. Concentrated sulfuric acid (H2SO4) and hydrofluoric acid (HF) are the commercial catalysts. However, these liquid catalysts exhibit disadvantages such as severe corrosion, safety and environmental L. Qi et al. / Chemical Engineering Journal 268 (2015) 116–124 117 Nomenclature a specific interfacial area (m2) b0, b1, b2 constant values in the correlation of d32 (-) C impeller clearance off the tank bottom (m) C1, C2, C3, C4 empirical constants in population balance equation (-) d, d0 diameter of a droplet (m) d32 Sauter mean diameter (m) d99 diameter related to the cumulative percentage of 99% in DSD (m) D diameter of impeller (m) g(d) breakage frequency of droplet (1/s) h(d, d0 ) collision between droplets with diameter d and d0 (1/s) Lk Kolmogoroff length (m) n(d), n(d0 ) number of droplets with d or d0 (-) N agitation speed (rpm, 1/min) Np power number of impeller (-) P power input of impeller, (W) Reimp impeller Reynolds number, (¼ qc ND2 =lc ), (-) T internal diameter of vessel (m) X independent variable in logarithmic normal function (m) issues, hard disposal of spent catalyst and high operating cost. Acidic ionic liquids (ILs) are promising substitutes for H2SO4 and HF as alkylation catalysts because of their safer operation, low consumption and good catalytic performance [1,2]. The composite ionic liquid developed by China University of Petroleum shows a high selectivity to high octane alkylate and has been demonstrated in industrial application [3]. Liquid acid catalyzed isobutane alkylation is a heterogeneous system wherein the reactions occur in or near the interface between the catalyst and hydrocarbon phases [4]. The intrinsic reaction rate is extremely fast, which is explained by the highly reactive carbonium intermediate in the generally accepted mechanism [5]. In H2SO4-catalyzed isobutane alkylation, the alkylate quality can be enhanced with increased mixing intensity [6]. Mixing largely determines the interfacial mass transfer and reaction performance [7]. The interfacial mass transfer rate is proportional to the interfacial area. In practice, the interfacial area is controlled by the mixing intensity, geometry of mixer and reactor, dispersed phase holdup and physicochemical properties of fluid phases [8–10]. In industrial isobutane alkylation, liquid H2SO4 or HF is applied in more than 50 vol% to form the acid-continuous dispersion in the reactor. As reported by Am Ende [11], the interfacial area reached a maximum at the dispersed isooctane holdup of 0.25. The interfacial area increased furthermore with increasing acid soluble oil content, which was attributed to the decreased interfacial tension. Liquid HF has lower viscosity and density compared to H2SO4, and continuous HF dispersion is found to have much larger interfacial area under vigorous agitation, resulting in a faster reaction rate. On the other hand, continuous HF dispersion produces more undesirable by-products in case of too long contact times [12]. Thus, hydrodynamics influences the selectivity in the current systems. In the actual ILA process, the IL catalyst is expected to be the continuous phase in the reactor, comparable to the isobutane alkylation processes using liquid H2SO4 or HF. The physical properties of the recently developed IL-catalyzed alkylation (ILA) are different from those of liquid H2SO4 and HF-catalyzed systems, and the interfacial area being one of the controlling factors in X Weimp median of the logarithmic normal function (m) impeller Weber number, (¼ qc N2 D3 =c), (-) Greek letters c interfacial tension (N/m) e energy dissipation rate (m2/s3) e average energy dissipation rate (m2/s3) eimp energy dissipation rate at impeller region (m2/s3) r standard deviation of distribution function (m) f (d, d0 ) coalescence rate between droplets with diameter d and d0 (1/s) k (d, d0 ) coalescence efficiency between droplets with diameter d and d0 (1/s) qc, qd densities of the continuous and dispersed phases (kg/m3) qm average density of the dispersion (kg/m3) lc viscosity of the continuous phase (Pa s) / holdup (volume fraction) of the dispersed phase (-) determining the apparent reaction rate is still unknown. In a recent study of the intrinsic kinetics of ILA, the reaction rate was found to be extremely fast and consequently the reaction was found to be limited by mass transfer of light olefins to the IL phase [13]. Similar finding was reported by Schilder et al. [14] who demonstrated that the apparent reaction rate of ILA increased pronouncedly with a decrease in IL droplet size, and the reaction was predicted to be completed in approximately 0.1 s when the IL mean droplet size decreased to 10 lm. In addition, ILA experiments at a short contact time by our research group showed that an IL/hydrocarbon volume ratio of P1 and sufficient mixing were critical to obtain a highquality alkylate [15]. Thus, like in the current systems, mass transfer affects reaction selectivity in ILA. Determining the effect of hydrodynamics (mixing conditions and geometry) and phase volume ratio on the interfacial area generated in the IL/hydrocarbon system is desirable for the design of the ILA reactor. Therefore, quantifying the local interfacial area to understand the mass transfer is crucial. ) can be derived from the Sauter The local interfacial area (a diameter (d32) and the holdup (volume fraction) of the dispersed phase (/), using Eq. (1) [16]: ¼ 6/=d32 a ð1Þ wherein d32 is determined as defined in Eq. (2) [17]: R dmax d d32 ¼ R dmin max dmin 3 d pðdÞdd 2 d pðdÞdd ð2Þ wherein dmax and dmin denote the maximum and the minimum droplet size, respectively, and p(d) is the probability density function of the droplet size. The local interfacial area and how to be influenced can be determined by measuring the droplet distribution and hold-up at different operating conditions. Dispersion behavior and the corresponding DSD are dynamically controlled by the breakage and coalescence events [18–20]. To date, liquid–liquid mixing and dispersion behaviors are still not thoroughly understood because of the highly complex phenomena of drop breakage and coalescence [21–23]. The main factors influencing liquid–liquid dispersion include local flow 118 L. Qi et al. / Chemical Engineering Journal 268 (2015) 116–124 patterns, energy dissipation distribution, physical properties of both dispersed and continuous phases, droplet breakage, and coalescence characteristics [24]. Stirred vessels are the typical configurations to investigate the liquid–liquid dispersion under specific operating conditions [9,25–27] and numerous experimental and theoretical studies have been performed on stirred vessels [28]. Experimental investigations have largely been focused on the effect of physical properties of dispersed phase and/or continuous phase [23,29–32], phase holdup of the dispersion [25,33–36], and the impeller types on steady DSD and mean droplet size [37]. Theoretical studies have been performed to investigate both the steady and the dynamic DSD with the population balance equation (PBE) solely [18,20,26,36,38] or in combination with computational fluid dynamics [19,39]. This study is motivated by the promising ILA technology and the lack of knowledge concerning the dispersion behavior of the IL-hydrocarbon system, particularly the effect of mixing intensity and dispersed phase holdup on the dispersion characteristics. The DSD, mean droplet size of our IL-hydrocarbon dispersion and the influence of agitation speed and hydrocarbon holdup on DSD were investigated applying focused beam reflectance measurement (FBRM) and particle video microscope (PVM) techniques. A chloroaluminate IL–heptane mixture was used as model system. n-Heptane was chosen as model compound for our isoparaffinic hydrocarbon mixture because its density and viscosity are close to that of the hydrocarbon mixture and it is more stable than i-heptane when contacted with acidic ionic liquids. Moreover, mixing experiments of n-heptane and IL are much convenient to perform as they can be carried out at atmosphere pressure. 2. Experimental 2.1. Materials Triethylamine hydrochloride (Et3NHCl, 99%) and AlCl3 (99%) were purchased from Aladdin. The n-heptane (95%) was obtained from Beijing Reagent Company. Unless otherwise stated, all chemicals were used directly without further treatment. 2.2. Chloroaluminate IL synthesis Chloroaluminate IL with AlCl3 mole fraction of 0.64 was synthesized from Et3NHCl and AlCl3 under nitrogen protection according to the literature [40]. The sample pretreatment for the interfacial tension testing, as well as the density and viscosity measurement, was also performed under nitrogen protection. 2.3. Physical properties of chloroaluminate IL and n-heptane The physical properties of chloroaluminate IL and n-heptane are summarized in Table 1. 2.4. Experimental setup The schematic diagram of the experimental apparatus is shown in Fig. 1. Liquid–liquid dispersion measurements were conducted in a stirred tank (b). The internal diameter of the vessel (T) was 0.092 m, and the total height was 0.146 m. The liquid height of dispersion was fixed at 0.092 m for all experiments. The impeller (d) was a Rushton disk turbine with a diameter (D) of 0.045 m, and its dimensions are shown in Fig. 2. The D/T ratio was 0.5 for the present tank geometry. The off-bottom clearance of impeller (C) was 0.030 m (0.33T) in all experiments. Four vertical baffles (c) with a width of 0.009 m (0.1T) were mounted equally-spaced on the vessel wall. The total volume of the vessel was 608 mL. The vessel was equipped with probes of two on-line particle size characterization systems: an FBRM probe (e) and a PVM probe (f) (both FBRM and PVM systems were manufactured by Mettler-Toledo Co., Switzerland). The FBRM and PVM probes were positioned at opposite sides and inserted into the vessel with a slope angle of 45° (see Fig. 1). The tips of the two probes were oriented 0.048 m above the bottom and 0.036 m toward the impeller shaft centerline. The top view of the orientation of impeller, baffles and probes is shown in Fig. 3. 2.5. Experimental conditions and procedure Table 1 Physical properties of chloroaluminate IL and n-heptane at 293.15 K. * Fluid Density (kg/m3) Viscosity (Pa s) Interfacial tension (N/m) IL n-Heptane* 1.31 103 6.84 102 2.81 102 4.11 104 1.28 102 Data taken from NIST Database [59]. The holdup of n-heptane (/) in IL–heptane mixtures varied from 0.1 to 0.8 with intervals of 0.1 per experiment. Additional experiments at 0.55 were performed. A specific amount of chloroaluminate IL was placed into the vessel under nitrogen protection and then the remaining part of the vessel was filled with n-heptane up to 0.092 m. The vessel was closed and placed in a water bath at 293.15 K. For each holdup, the agitation speed (N) was changed from 500 rpm to 900 rpm at 100 rpm intervals. Fig. 1. Experimental setup. (a) electric motor; (b) stirred vessel; (c) baffle; (d) Rushton disc turbine impeller; (e) FBRM probe; (f) PVM probe; (g) signal processing unit; (h) laptops; (i) valve; (j) heptane storage tank; and (k) nitrogen cylinder. 119 L. Qi et al. / Chemical Engineering Journal 268 (2015) 116–124 3. Results and discussion 3.1. Identification of the phase inversion Fig. 2. Geometrical details of Rushton disc turbine impeller. The phase inversion behavior of n-heptane and IL model system was identified by the mean chord length (sqr-wt) of droplets measured with FBRM [44]. The measured mean chord lengths (CL) as a function of /heptane at different agitation speeds are shown in Fig. 4. The mean CL showed a marked change between /heptane values of 0.5 and 0.6, indicating that the phase inversion took place between these conditions. Phase inversion was also confirmed by PVM images demonstrated for the agitation speed of 500 rpm in Fig. 5. The images for the other experiments at agitation speed above 500 rpm are provided in the supporting information (Table S1 therein). Thus, the heptane holdup should be 0.5 or less to ensure the presence of a continuous IL phase. This phenomenon is consistent with our earlier observations that for a high-quality alkylate the IL/hydrocarbon volume ratio should be not less than 1. It furthermore supports that n-heptane is an acceptable model compound for the isoparaffinic hydrocarbon mixture under alkylation conditions. 3.2. Effect of agitation speed on DSD The DSD can be represented by the single probability density function or combined functions [27]. The linear normal distribution [30,31], logarithmic normal distribution [32,45] and Schwartz–Bezemer equation [46] are commonly applied to fit experimental DSD data. The DSD dispersion with dominant droplets breakage has been described by a logarithmic normal distribution assuming binary breakage, which agreed well with the large amount of experimental data [17,45]. Our IL/hydrocarbon system, being a viscous dispersion with low interfacial tension, most likely matches the characteristics of the breakage dominated system. Thus, the logarithmic normal distribution in Eq. (3) was used: 2 1 ðlnðX=XÞÞ f d ðXÞ ¼ pffiffiffiffiffiffiffi exp 2r2 2prX Fig. 3. Top view of impeller, baffles, and probes in the vessel. 2.6. CLD and DSD measurement Chord length distribution (CLD) was measured by FBRM D600L system. The CLD was then analyzed by the iC FBRMÒ using two weighting functions, namely, ‘‘no weight’’ (no-wt) and ‘‘square weight’’ (sqr-wt), which emphasize the size change of large and small droplets, respectively [41]. FBRM was mainly used in this study to monitor the phase inversion. The V819-version PVM probe was used to obtain digital images with a field view of 1075 lm 825 lm identifying droplets larger than 2 lm [42]. The depth of field of the PVM probe used was approximately 400 lm. The PVM image of fluid particles for each experimental condition (/ and N) was recorded when a steady CLD was monitored with the FBRM probe. The DSD was determined from PVM image processing according to Maab [43] et al. as following. A threshold was set on the gray value of the pixels to detect the droplet edges in the image. Subsequently, four hundred-count of droplets was manually performed to obtain a statistically reliable DSD result. ! ð3Þ wherein X is the droplet size (equivalent diameter), r is the stan is the median of distribution. The coefficients dard deviation and X of each distribution were obtained by nonlinear fitting. Normalized experimental DSDs with fitted distributions at various agitation speeds are shown in Fig. 6. The regressed parameters of the size distribution function are listed in Table 2. The DSD plots show that increased agitation speed leads to smaller droplet sizes and narrower size distributions. This observation was also Fig. 4. Mean CL (sqr-wt) as a function of /heptane at different agitation speeds. 120 L. Qi et al. / Chemical Engineering Journal 268 (2015) 116–124 Fig. 5. PVM images of IL-heptane dispersion at N = 500 rpm for (a) /heptane = 0.5 and (b) /heptane = 0.55. Fig. 6. DSD of IL-continuous dispersion (/heptane = 0.1) at various agitation speeds. Table 2 Fitted parameters of lognormal distribution functions (/heptane = 0.1). Agitation speed (rpm) 500 600 700 800 900 (lm) Median droplet size X Standard deviation r (lm) R2 of fit 93.02 0.20 0.975 86.01 0.19 0.981 66.14 0.19 0.981 57.85 0.18 0.982 46.81 0.16 0.989 confirmed by the corresponding decrease in the median of the DSD. Thus, the intensified mixing increased the breakage frequency of droplet and local homogeneity of dispersion [47]. The fitted logarithmic normal distributions agreed well with the experimental DSD. The small discrepancies between experimental DSD and fitted distribution at N = 500 rpm might be due to local inhomogeneity of the dispersions. Applying the correlation of circulation time of fluid proposed by Wichterle [48], the circulation time at N = 500 rpm and 700 rpm was calculated to be 23 s and 19 s, respectively. Therefore, localized inhomogeneity of the dispersion at N = 500 rpm could be induced by the relatively slow circulation of fluid in the viscous liquid agitated. 3.3. Effect of dispersed phase holdup on DSD The effect of dispersed phase holdup on the DSD mainly depends on the physical properties, hydrodynamics and the breakage and coalescence behavior of liquid–liquid systems [23,25,31,49]. The influence of dispersed phase holdup on the DSD was studied by PVM image statistics. The results at agitation speeds of 500 and 900 rpm and the data fitting are shown in Fig. 7. DSDs measured at different heptane holdups showed lognormal distribution as evidenced by the function fitting. The characteristic parameters Fig. 7. Measured DSD and fitted DSD of IL-continuous dispersions with different heptane holdups and two agitation speeds. of fitted distribution functions are given in the supporting information (Table S2 therein). At the agitation speed of 500 rpm, the DSD shifted to larger droplet size and broadened when the heptane holdup increased from 0.3 to 0.5. No pronounced trend of DSD shift could be observed, and nearly identical distributions were formed for either the holdup ranges of 0.1–0.2 or 0.3–0.5. The dispersion behavior showed a step change at dispersed phase holdup between 0.2 and 0.3. With increased agitation speed, a similar trend in DSD was observed, whereby the step change occurred at a lower heptane holdup. An example at an agitation speed of 900 rpm is shown in Fig. 7. The step change was lowered to a holdup of between 0.1 and 0.2. Self-similarity of DSD is often present in concentrated dispersions or emulsions. Kraume et al. reported that the toluene/water 121 L. Qi et al. / Chemical Engineering Journal 268 (2015) 116–124 dispersed phase holdup, and C1 and C2 are empirical constants. The coalescence rate f(d, d0 ) is expressed as the product of collision frequency h(d, d0 ) and coalescence efficiency k(d, d0 ), which can be expressed by Eqs. (5) and (6): 0 hðd; d Þ ¼ 1 2 2 2 1 0 0 0 C 3 e3 ðd þ d Þ d3 þ d 3 nðdÞnðd Þ 1þ/ 0 kðd; d Þ ¼ exp C 4 qc lc e c2 ð1 þ /Þ3 0 dd 0 dþd ð5Þ 4 ! ð6Þ wherein d and d0 are the diameters of two coalescing droplets, n(d) and n(d0 ) denote the number of droplets, qc is the density of continuous phase, and C3 and C4 are empirical constants. In the heptane holdup range of /heptane: 0.1 ? 0.2, the breakage rate was reduced because of the damping effect of increasing dispersed phase holdup on the local turbulence energy [Eq. (4)] [51,52]. In addition, the increase in number of droplet enhanced the collision frequency [Eq. (5)], and compensated the negative effect of dispersed phase holdup on coalescence efficiency [Eq. (6)] [53]. Therefore, the coalescence rate increased in proportion to the dispersed phase holdup, and balanced with the breakage rate. The resulting DSD shifted to larger droplet size and broadened. In the heptane holdup range /heptane: 0.3 ? 0.5, the reduction in the breakage rate was limited because of the fast coalescence rate at high /heptane. Dynamic equilibrium was quickly achieved, leading to the slight shift in the DSD and corresponding self-similarity of size distribution. 3.4. Correlation of Sauter diameter Fig. 8. Volume-based cumulative DSD as a function of dimensionless droplet size. dispersion (/toluene = 0.05–0.5) had strongly self-similar linear normal distribution under such conditions (pH and ionic strength) that coalescence rate of toluene droplets was high [31]. Boxall et al. [50] demonstrated that the holdup of the dispersed water phase within the range of 0.1–0.35 had no significant effect on the DSD of water/crude oil dispersion. Considering the effect of continuous-phase viscosity, the behavior of IL-heptane dispersion at higher heptane holdup is comparable to the system studied by Boxall et al. To further elucidate the DSD characteristics of our IL-continuous dispersion, the cumulative volume distributions as a function of dimensionless droplet size were examined [31]. As can be seen in Fig. 8, at an agitation speed of 500 rpm, similar distributions appeared at two holdup regions (0.1–0.2 and 0.3–0.5). When the agitation speed was 900 rpm, approximately identical distributions were found when the heptane holdup was either 0.1 or 0.2 and above. A possible explanation of the self-similarity of DSDs is given as follows. The DSDs of dispersions are determined by the dynamic equilibrium between droplet breakage and coalescence. In viscous dispersions with low interfacial tension, the rate of droplet breakage is faster than that of coalescence before the dynamic equilibrium is reached. PBE is used to describe the dynamic breakage and coalescence. Based on the framework of PBE [18,22], the breakage rate g(d) is given by Eq. (4): gðdÞ ¼ C 1 e1=3 2=3 ð1 þ /Þd exp C 2 cð1 þ /Þ2 qd e2=3 d5=3 ! ð4Þ wherein e is the energy dissipation rate, d is the droplet size, c is the interfacial tension, qd is the density of dispersed phase, / is the In comparison to other droplet size parameters, the Sauter diameter d32 related to interfacial area is most convenient to study the transfer phenomena of a dispersed system [16]. Droplet size scaling laws based on the isotropic turbulence theory are extensively used to predict the d32 in turbulent liquid– liquid mixing [25,35]. The isotropic turbulence can be characterized by energy cascades from large to small-scale eddies, and the smallest eddy size is the so-called ‘‘Kolmogoroff length’’ (Lk) [54]. The flow ‘‘subregion’’ of isotropic turbulence can be classified according to the dominant stress for droplet disruption, which requires different droplet size scaling laws [54]. The subregion can be identified indirectly based on Lk relative to the maximum stable droplet size (dmax) [55]. Therefore, the appropriate droplet size scaling law was selected by comparing Lk with dmax. Droplet size scaling laws have been developed to describe dmax rather than d32. However, the d32 of our IL-continuous dispersion was linearly proportional to dmax (d32 = 0.64dmax), as shown in the supporting information (see Fig. S1 therein). This result was supported by findings from other studies [29,34,56]. Thus, correlating d32 using one of droplet size scaling laws developed by Shinnar is feasible and can be determined by analyzing Lk. The Lk can be related to the energy dissipation rate as described in Eq. (7) [21]: Lk ððlc =qc Þ3 =eÞ 1=4 ð7Þ wherein e is the specific energy dissipation rate, lc and qc are the viscosity and density for the continuous phase, respectively. The PVM probe tip was located at the impeller region to measure the DSD in the experiment. Thus, the energy dissipation rate at the impeller region was used to estimate Lk. Okamoto et al. [57] investigated the influence of different D/T ratios on e in the Rushton turbine stirred tank. It was found that at the identical average energy dissipation rate e, the e increased 122 L. Qi et al. / Chemical Engineering Journal 268 (2015) 116–124 with the decreased D/T ratio. They finally correlated the e=e and D/T ratio at the impeller region and circulation region respectively, and the correlation can be applied to predict approximately the e in the stirred tank. Zhou et al. [58] studied the effect of tank geometry on the maximum energy dissipation rate in the stirred tank driven by four types of impellers. With constant e, the maximum energy dissipation rate enhanced with the decreased D/T ratio. Their investigation shows the same effect of D/T on e compared with the work of Okamoto. According to the work of Okamoto [57], the energy dissipation rate at the impeller region of a stirred vessel can be estimated through the average energy dissipation rate using the following empirical equations: eimp =e ¼ 7:8ðD=TÞ1:38 expð2:46D=TÞ ð0:25 6 D=T 6 0:70Þ ð8Þ e ¼ P=ðqm V t Þ ð9Þ P ¼ Np qm N 3 D5 Fig. 9. d32/D versus (ReWe)1/3 at different values of /heptane. ð10Þ wherein eimp is the energy dissipation rate at the impeller region, e is the average energy dissipation rate or specific power input, P is the input power, Np is the power number of impeller (5.0 was used for the Rushton impeller), qm is the average density of dispersion, and D is the diameter of impeller. The calculated specific power input is listed in Table 3. The maximum droplet size (d99) acquired by the PVM statistic is compared with Lk for the IL-continuous dispersion with /heptane = 0.5 in Table 3, showing that at each agitation speed Lk was larger than d99. Furthermore, Lk and d99 were of the same order of magnitude, indicating that both inertial stress and viscous stress are important to the disruption of droplets [21]. The above analysis led to selection of the following Shinnar model for droplet size correlation [55]: dmax =D ¼ b0 ðReimp Weimp Þ1=3 ð11Þ Fig. 10. Dimensionless term (d32/D)(ReWe)1/3 as a function of heptane holdup at various agitation speeds. wherein Reimp is the impeller Reynolds number being expressed as qc ND2 =lc , and Weimp is the impeller Weber number being expressed as qc N2 D3 =c. The original Shinnar model was applied to predict the droplet size of diluted dispersions. For our concentrated IL-heptane dispersion, the model needs to be modified to include the effect of dispersed phase holdup. Here, we propose a semi-empirical correlation to predict the d32 of a IL-continuous dispersion as Eq. (12): d32 =D ¼ f ð/ÞðReimp Weimp Þ1=3 ð12Þ 1=3 A plot of d32/D versus ðReimp Weimp Þ shown in Fig. 9 illustrates clearly a linear relationship for the systems of different values of /heptane. The slope of the fitted lines slightly increased from 0.22 to 0.25 at /heptane increasing from 0.1 to 0.5. This result indicates that the dispersion is dominated by droplet breakage [34,35]. The independent variable (d32/D)(ReWe)1/3 as a function of /heptane was investigated to describe the functional expression of f(/). The linearity between these two variables is demonstrated in Fig. 10. Thus, a linear term can be introduced for f(/) into Eq. (12), reflecting the effect of heptane holdup on d32. Thus, a modified correlation is proposed for concentrated IL-continuous dispersion as shown in Eq. (13): d32 =D ¼ b1 ð1 þ b2 /ÞðReimp Weimp Þ1=3 ð13Þ Parameters b1 and b2 were fitted using least-square iteration program. The optimized b1 and b2 were 0.168 and 0.348, respectively. The experimental and calculated data for d32 are shown in Fig. 11. The calculated d32 agreed well with the experimental data, with the average relative error of 4.18% (R2 = 0.997). Table 3 Comparison between the Lk and dmax (d99) for /heptane = 0.5. Agitation speed (rpm) 500 600 700 800 900 e (m2/s3) Lk (lm) d99 (lm) 0.9 204.9 178.3 1.6 178.7 145.5 2.6 159.2 117.1 3.8 144.1 107.2 5.4 131.8 79.3 Fig. 11. Calculated d32 and experimental data for IL-continuous dispersion. L. Qi et al. / Chemical Engineering Journal 268 (2015) 116–124 4. Conclusions Chloroaluminate IL-heptane dispersion in a stirred vessel was studied experimentally using FBRM and PVM techniques. The phase inversion was identified experimentally through the pronounced increase in chord length before and after the transition point, indicating that an IL-continuous dispersion was obtained when the heptane holdup was below 0.5. The DSD of IL-continuous dispersion was logarithmic normal distributed, indicating the breakup-dominated dispersion. With increasing heptane holdup, the DSD shifted to a larger droplet size, which reflected the damping effect of the dispersed phase on turbulence. In addition, self-similarity of DSD occurred approximately with the independence of dispersed phase holdup when the heptane holdup was above 0.3. A semi-theoretical correlation for the Sauter mean diameter based on Shinnar theory was proposed; the predicted values agreed well with the experimental data. This work elucidates the dispersion behavior of IL-hydrocarbon system, which knowledge can be applied for the design of the ILA reactor. In particular, the semi-theoretical correlation is suitable to be applied in the impeller region for the stirred-tank reactor configuration. The identification of phase inversion through PVM images at different agitation speeds was presented. The functional relation between d32 and dmax was determined. In addition, the fitted parameters of lognormal distribution functions were given. Acknowledgments The authors gratefully acknowledge the financial support provided by Shell Global Solutions International B.V., The Netherlands, the Natural Science Foundation of China (Nos. 21425626, 21436001, 21276275, 21206193 and 21036008), the National Science and Technology Support Program of China (2014BAE13B01), and the Program for New Century Excellent Talents in the University of China (No. NCET-12-0970). Appendix A. Supplementary data Supplementary data associated with this article can be found, in the online version, at http://dx.doi.org/10.1016/j.cej.2015.01.009. References [1] K. Yoo, V.V. Namboodiri, R.S. Varma, P.G. Smirniotis, Ionic liquid-catalyzed alkylation of isobutane with 2-butene, J. Catal. 222 (2004) 511–519. [2] J. Zhang, C.P. Huang, B.H. Chen, P.J. Ren, M. Pu, Isobutane/2-butene alkylation catalyzed by chloroaluminate ionic liquids in the presence of aromatic additives, J. Catal. 249 (2007) 261–268. [3] Z.C. Liu, R. Zhang, C.M. Xu, R.A. Xia, Ionic liquid alkylation process produces high-quality gasoline, Oil Gas J. 104 (2006) 52–56. [4] L.F. Albright, R.E. Eckert, Formation and separation of sulfuric acid/n-heptane dispersions: applications to alkylation, Ind. Eng. Chem. Res. 40 (2001) 4032– 4039. [5] L. Schmerling, The mechanism of the alkylation of paraffins, J. Am. Chem. Soc. 67 (1945) 1778–1783. [6] K.W. Li, R.E. Eckert, L.F. Albright, Alkylation of isobutane with light olefins using sulfuric acid. Operating variables affecting physical phenomena only, Ind. Eng. Chem. Process Des. Dev. 9 (1970) 434–440. [7] F.B. Sprow, Role of interfacial area in sulfuric acid alkylation, Ind. Eng. Chem. Process Des. Dev. 8 (1969) 254–257. [8] C.A. Coulaloglou, L.L. Tavlarides, Drop size distributions and coalescence frequencies of liquid–liquid dispersions in flow vessels, AIChE J. 22 (1976) 289–297. [9] R.E. Eckert, C.M. McLaughlin, J.H. Rushton, Liquid–liquid interfacial areas formed by turbine impellers in baffled, cylindrical mixing tanks, AIChE J. 31 (1985) 1811–1820. [10] H.T. Chen, S. Middleman, Drop size distribution in agitated liquid–liquid systems, AIChE J. 13 (1967) 989–995. [11] D.J. am Ende, R.E. Eckert, L.F. Albright, Interfacial area of dispersions of sulfuric acid and hydrocarbons, Ind. Eng. Chem. Res. 34 (1995) 4343–4350. 123 [12] L.F. Albright, Alkylation of isobutane with C3–C5 olefins to produce highquality gasolines: Physicochemical sequence of events, Ind. Eng. Chem. Res. 42 (2003) 4283–4289. [13] S.J. Aschauer, A. Jess, Effective and intrinsic kinetics of the two-phase alkylation of i-paraffins with olefins using chloroaluminate ionic liquids as catalyst, Ind. Eng. Chem. Res. 51 (2012) 16288–16298. [14] L. Schilder, S. Maass, A. Jess, Effective and intrinsic kinetics of liquid-phase isobutane/2-butene alkylation catalyzed by chloroaluminate ionic liquids, Ind. Eng. Chem. Res. 52 (2013) 1877–1885. [15] Z.C. Liu, X.H. Meng, R. Zhang, C.M. Xu, H. Dong, Y.F. Hu, Reaction performance of isobutane alkylation catalyzed by a composite ionic liquid at a short contact time, AIChE J. 60 (2014) 2244–2253. [16] K.K. Singh, S.M. Mahajani, K.T. Shenoy, S.K. Ghosh, Representative drop sizes and drop size distributions in A/O dispersions in continuous flow stirred tank, Hydrometallurgy 90 (2008) 121–136. [17] A. Pacek, C. Man, A. Nienow, On the Sauter mean diameter and size distributions in turbulent liquid/liquid dispersions in a stirred vessel, Chem. Eng. Sci. 53 (1998) 2005–2011. [18] C.A. Coulaloglou, L.L. Tavlarides, Description of interaction processes in agitated liquid–liquid dispersions, Chem. Eng. Sci. 32 (1977) 1289–1297. [19] V. Alopaeus, J. Koskinen, K.I. Keskinen, J. Majander, Simulation of the population balances for liquid–liquid systems in a nonideal stirred tank. Part 2—parameter fitting and the use of the multiblock model for dense dispersions, Chem. Eng. Sci. 57 (2002) 1815–1825. [20] E.G. Chatzi, C. Kiparissides, Dynamic simulation of bimodal drop size distributions in low-coalescence batch dispersion systems, Chem. Eng. Sci. 47 (1992) 445–456. [21] R. Shinnar, On the behaviour of liquid dispersions in mixing vessels, J. Fluid Mech. 10 (1961) 259–275. [22] C. Tsouris, L.L. Tavlarides, Breakage and coalescence models for drops in turbulent dispersions, AIChE J. 40 (1994) 395–406. [23] M. Stamatoudis, L. Tavlarides, The effect of continuous-phase viscosity on the unsteady state behavior of liquid–liquid agitated dispersions, Chem. Eng. J. 35 (1987) 137–143. [24] D.E. Leng, R.V. Calabrese, Immiscible liquid–liquid systems, in: E.L. Paul, V.A. Atiemo-Obeng, S.M. Kresta (Eds.), Handbook of Industrial Mixing: Science and Practice, John Wiley & Sons, New York, 2004, pp. 639–753. [25] C. Desnoyer, O. Masbernat, C. Gourdon, Experimental study of drop size distributions at high phase ratio in liquid–liquid dispersions, Chem. Eng. Sci. 58 (2003) 1353–1363. [26] S. Maaß, F. Metz, T. Rehm, M. Kraume, Prediction of drop sizes for liquid–liquid systems in stirred slim reactors—Part I: Single stage impellers, Chem. Eng. J. 162 (2010) 792–801. [27] G.W. Zhou, S.M. Kresta, Evolution of drop size distribution in liquid–liquid dispersions for various impellers, Chem. Eng. Sci. 53 (1998) 2099–2113. [28] Y. Zhao, X. Li, J. Cheng, C. Yang, Z.-S. Mao, Experimental study on liquid–liquid macromixing in a stirred tank, Ind. Eng. Chem. Res. 50 (2011) 5952–5958. [29] R.V. Calabrese, T. Chang, P. Dang, Drop breakup in turbulent stirred-tank contactors. Part I: effect of dispersed-phase viscosity, AIChE J. 32 (1986) 657–666. [30] C.Y. Wang, R.V. Calabrese, Drop breakup in turbulent stirred-tank contactors. Part II: relative influence of viscosity and interfacial tension, AIChE J. 32 (1986) 667–676. [31] M. Kraume, A. Gäbler, K. Schulze, Influence of physical properties on drop size distribution of stirred liquid–liquid dispersions, Chem. Eng. Technol. 27 (2004) 330–334. [32] J.A. Boxall, C.A. Koh, E.D. Sloan, A.K. Sum, D.T. Wu, Measurement and calibration of droplet size distributions in water-in-oil emulsions by particle video microscope and a focused beam reflectance method, Ind. Eng. Chem. Res. 49 (2010) 1412–1418. [33] E.G. Chatzi, C. Kiparssides, Steady-state drop-size distributions in high holdup fraction dispersion systems, AIChE J. 41 (1995) 1640–1652. [34] M. Zerfa, B. Brooks, Prediction of vinyl chloride drop sizes in stabilised liquidliquid agitated dispersion, Chem. Eng. Sci. 51 (1996) 3223–3233. [35] C.W. Angle, H.A. Hamza, Predicting the sizes of toluene-diluted heavy oil emulsions in turbulent flow. Part 2: Hinze–Kolmogorov based model adapted for increased oil fractions and energy dissipation in a stirred tank, Chem. Eng. Sci. 61 (2006) 7325–7335. [36] S. Maaß, N. Paul, M. Kraume, Influence of the dispersed phase fraction on experimental and predicted drop size distributions in breakage dominated stirred systems, Chem. Eng. Sci. 76 (2012) 140–153. [37] A. Pacek, S. Chamsart, A. Nienow, A. Bakker, The influence of impeller type on mean drop size and drop size distribution in an agitated vessel, Chem. Eng. Sci. 54 (1999) 4211–4222. [38] M. Laso, L. Steiner, S. Hartland, Dynamic simulation of liquid-liquid agitated dispersions—I. Derivation of a simplified model, Chem. Eng. Sci. 42 (1987) 2429–2436. [39] P.J. Becker, F. Puel, A. Dubbelboer, J. Janssen, N. Sheibat-Othman, Coupled population balance-CFD simulation of droplet breakup in a high pressure homogenizer, Comput. Chem. Eng. 68 (2014) 140–150. [40] C.P. Huang, Z.C. Liu, C.M. Xu, B.H. Chen, Y.F. Liu, Effects of additives on the properties of chloroaluminate ionic liquids catalyst for alkylation of isobutane and butene, Appl. Catal. A: Gen. 277 (2004) 41–43. [41] S. Less, R. Vilagines, Light beam reflectance measurement of droplets diameter distribution in crude oil emulsions, Fuel 109 (2013) 542–550. [42] Mettler-Toledo ParticleTrack PVMÒ Product Group, PVMÒ V819 System Manual, Mettler-Toledo AutoChem Inc., Columbia, MD, 2009. 124 L. Qi et al. / Chemical Engineering Journal 268 (2015) 116–124 [43] S. Maaß, J. Rojahn, R. Hänsch, M. Kraume, Automated drop detection using image analysis for online particle size monitoring in multiphase systems, Comput. Chem. Eng. 45 (2012) 27–37. [44] W. Wang, J. Liu, P.Y. Wang, J.M. Duan, J. Gong, Evolution of dispersed drops during the mixing of mineral oil and water phases in a stirring tank, Chem. Eng. Sci. 91 (2013) 173–179. [45] L.L. Tavlarides, M. Stamatoudis, The analysis of interphase reactions and mass transfer in liquid–liquid dispersions, in: G.R.C.J.W.H. Thomas B. Drew, V. Theodore (Eds.), Advances in Chemical Engineering, Academic Press, 1981, pp. 199–273. [46] F.B. Sprow, Distribution of drop sizes produced in turbulent liquid–liquid dispersion, Chem. Eng. Sci. 22 (1967) 435–442. [47] M.M.M. Ribeiro, M.M.L. Guimarães, C.M.N. Madureira, J.J.C. Cruz, Pinto, Noninvasive system and procedures for the characterization of liquid–liquid dispersions, Chem. Eng. J. 97 (2004) 173–182. [48] K. Wichterle, Drop breakup by impellers, Chem. Eng. Sci. 50 (1995) 3581–3586. [49] J. Lovick, A. Mouza, S. Paras, G. Lye, P. Angeli, Drop size distribution in highly concentrated liquid–liquid dispersions using a light back scattering method, J. Chem. Technol. Biotechnol. 80 (2005) 545–552. [50] J.A. Boxall, C.A. Koh, E.D. Sloan, A.K. Sum, D.T. Wu, Droplet size scaling of water-in-oil emulsions under turbulent flow, Langmuir 28 (2011) 104–110. [51] M.S. Doulah, An effect of hold-up on drop sizes in liquid–liquid dispersions, Ind. Eng. Chem. Fundam. 14 (1975) 137–138. [52] Z.-C. Liu, R. Zhang, C.-M. Xu, R. Xia, Ionic liquid alkylation process produces high-quality gasoline, Oil Gas J. 104 (2006) 52–56. [53] W. Wang, W. Cheng, J.M. Duan, J. Gong, B. Hu, P. Angeli, Effect of dispersed holdup on drop size distribution in oil–water dispersions: experimental observations and population balance modeling, Chem. Eng. Sci. 105 (2014) 22– 31. [54] R. Shinnar, J.M. Church, Statistical theories of turbulence in predicting particle size in agitated dispersions, Ind. Eng. Chem. 52 (1960) 253–256. [55] P.E. Rueger, R.V. Calabrese, Dispersion of water into oil in a rotor–stator mixer. Part 1: drop breakup in dilute systems, Chem. Eng. Res. Des. 91 (2013) 2122– 2133. [56] D.E. Brown, K. Pitt, Drop size distribution of stirred non-coalescing liquid– liquid system, Chem. Eng. Sci. 27 (1972) 577–583. [57] Y. Okamoto, M. Nishikawa, K. Hashimoto, Energy dissipation rate in mixing vessels and its effects on liquid–liquid dispersion and solid–liquid mass transfer, Int. Chem. Eng. 21 (1981) 88–94. [58] G. Zhou, S.M. Kresta, Impact of tank geometry on the maximum turbulence energy dissipation rate for impellers, AIChE J. 42 (1996) 2476–2490. [59] Isothermal Properties for Heptane.