Recycling of waste HDPE and PP plastic in preparation of plastic brick and its mechanical properties

advertisement

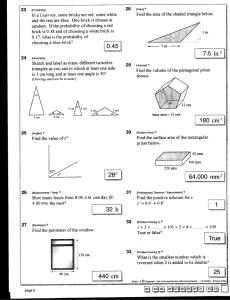

Cleaner Materials 5 (2022) 100113 Contents lists available at ScienceDirect Cleaner Materials journal homepage: www.journals.elsevier.com/cleaner-materials Recycling of waste HDPE and PP plastic in preparation of plastic brick and its mechanical properties Prathik Kulkarni a, *, Vikas Ravekar a, P. Rama Rao b, Sahil Waigokar a, Sanket Hingankar a a b Department of Civil Engineering, Bajaj Institute of Technology, Wardha, India Research Scholar, Pondicherry Technological University, Puducherry, India A R T I C L E I N F O A B S T R A C T Keywords: Plastic brick Thermoplastic Physical recycling HDPE and PP Plastic brick wall Brick is a primary building material that is often utilized in the construction of masonry. Conventionally, brick is made up of dried clay and recently many studies have focused on the use of waste materials as an alternate material to a conventional brick. In the present study thermoplastics like High-Density Polyethylene (HDPE) and Polypropylene (PP) are used to manufacture the plastic brick using the physical recycling method. Here, waste plastic from Maharashtra Industrial Development Corporation (MIDC) is collected, segregated, cleaned, and melted to manufacture a 190 × 90 × 90 mm modular sized HDPE and PP brick according to IS 1077:1992. In the first phase of work, standard tests are performed to study the physical, mechanical and thermal properties of the plastic brick. In the next phase, a 500 × 110 × 500 mm wall is constructed and the results of the plastic brick wall are compared with a conventional brick wall. The wall was tested using a universal testing machine (UTM) as per IS 1905:1987. It was interesting to observe that the HDPE and PP brick gave a compressive strength of 11.19 N/ mm2 and 10.02 N/mm2 which were in good agreement with first-class conventional brick which gave a compressive strength of 10.5 N/mm2. While it is also worth noting that HDPE brick had the highest compressive strength. The ultimate load for the plastic brick wall was 197.50 KN with a shear failure at a 45◦ , while the conventional brick wall experienced a vertical failure at 153.95 KN load. A fire-resistance test on a plastic brick wall and a conventional brick wall was performed to evaluate if the specifications of Nation Building Code (2005): Part 4: Table 1 were met. It was observed that the plastic brick wall even after 30 min of heating at 4 corners and centre, showed a better temperature difference as compared to the conventional brick wall. The study initiates a new line of research in sustainable plastic waste management. 1. Introduction Brick is a vital building material that is widely utilized throughout the world. It is one of the most demanding masonry units. India, along with China and Spain, is the leading brick manufacturing country, with an annual production rate of more than 240 billion bricks (MuheiseAralia and Pavia, 2021). India produces about a 3.5 million tons of waste plastic every year which has almost doubled in the last five years. The production of waste plastic adversely affects our ecosystem and even it is linked with air pollution. Due to this high rate of production, it was brought to investigate and scrutinize the feasibility of using waste plastic as an alternative for manufacturing the brick. As they will be benefiting the environment as well as maintaining the requirements of materials and their standards. As a result, numerous attempts have been made to incorporate waste into the production of bricks, and their physical and mechanical properties have been investigated. In previous research, the replacement and addition have been done in the brick with the direct composition of different raw materials like rice husk or rice husk ash (Sutas et al., 2012), grapevine twig dust and popular dust(Andiç-Çakır et al., 2021), slate tailing, fly ash, and OPC(Wang et al., 2021); fly ash and lime(Çiçek and Çinçin, 2015), cigarettes buds(Kadir and Mohajer­ ani, 2015), crushed glass(Chidiac and Federico, 2007; Demir, 2009), clay, sawdust, marble(Eliche-Quesada et al., 2012), and sugarcane bagasse ash(Faria et al., 2012). In addition to the above-mentioned materials, Plastics are widely employed in the production of bricks. The use of thermoplastic waste in the production of bricks is the most effective alternative for reducing plastic waste, saving raw materials, and enhancing the properties of bricks. Plastics are preferred over other materials due to their light­ weight, low cost, low density, good stability, and durability, ability to be * Corresponding author. E-mail address: prathik.kulkarni@bitwardha.ac.in (P. Kulkarni). https://doi.org/10.1016/j.clema.2022.100113 Received 29 April 2022; Received in revised form 23 June 2022; Accepted 29 June 2022 Available online 2 July 2022 2772-3976/© 2022 The Author(s). Published by Elsevier Ltd. This is an open access article under the CC BY-NC-ND license (http://creativecommons.org/licenses/bync-nd/4.0/). P. Kulkarni et al. Cleaner Materials 5 (2022) 100113 easily molded, good impact resistance, and mechanical properties (Jahidul Islam and Shahjalal, 2021; Banerjee et al., 2014; Ahmad et al., 2017) . M.K. Mondal et al.(Mondal et al., 2019) conducted an experi­ mental study on three batches of blocks composed of polycarbonate (RIC 7), polystyrene (RIC 6), and mixed thermoplastics, sand with fly ash, and OPC. Whereas mixed thermoplastics are 0–10% by weight and sand is 60–70% by weight. The test results suggest that the brick containing 10% waste plastics has a compressive strength of 17 MPa and high thermal resistance. Although these bricks are lightweight, the density is significantly lower. Isaac I. Akinwumi et al.(Akinwumi et al., 2019) manufactured compressed earth brick with the use of stabilized soil and shredded waste plastic varying in percentages and by the size of particles (less than 6.3 mm and more than 9.6 mm). The results showed that compressed earth brick (CEB) incorporating shredded waste plastic (1% by weight and particle size <6.3 mm) resulted in a 50% rise in erosion rate (the lowest among them) and a 244.4% increase in compressive strength compared to brick containing no plastic (0.45 MPa). These earth bricks can be used in residential and commercial buildings. In the construction industry Polyethylene (PET) and Polypropylene (PP) plastics are frequently employed. PET plastic brick in composition with foundry sand(Aneke and Shabangu, 2021)and recycled glass granules(Frank Ikechukwu and Shabangu, 2021) respectively had 2.5 and 3 times higher compressive strength, and the temperature required to manufacture those bricks was approximately 5 times lower than burnt clay brick. The bricks with a higher percentage of PET i.e., 5% gave many effective results when compared with conventional fire clay bricks, but beyond 5% replacement of PET in fire clay bricks, a reduction in compressive strength was observed (Akinyele et al., 2020a,b). Many experimental studies have been undertaken on a brick ma­ sonry wall and masonry prisms of varied constituent materials, bonds, dimensions, and height to thickness (h/t) ratio. The physical and me­ chanical characteristics of brick masonry units, as well as their masonry with lime mortar joints, are determined(Drougkas et al., 2016; Bompa and Elghazouli, 2020). Nassif Nazeer Thaickavil et al.(Thaickavil and Thomas, 2018)proposed a masonry model with two different types of bricks: cement stabilized pressed earth brick (B1) and local burnt clay brick (B2). Cement mortar ratios of different proportions were used to make masonry prisms. They assessed the compressive strength of the masonry prism and recorded the cracking pattern by performing a lab­ oratory test on 192 masonry prism specimens. The model proposed by Thaickavil et al.(Thaickavil and Thomas, 2018) accommodates a wide range of mortar (0.3–52.6 MPa) and masonry unit strength (3.5–127 MPa) in his study. Kumavat et al.(Kumavat, 2016) conducted experi­ mental research on the mechanical properties and compressive strength of clay brick masonry prisms using mortar composed of fine aggregate with clay brick waste (in percentage proposition) as a replacement for sand. In that, the cement mortar of 1:4 and a 20% replacement of clay brick waste gave higher results in compressive strength. They found that due to this replacement compressive strength of the masonry prism was found to be more as compared to standard masonry prism. The compressive strength of brick and mortar is the primary factor influ­ encing the compressive strength of masonry prism, since the strength of masonry increases as the strength of brick and mortar increases (Nau­ man Azhar and Ali Qureshi, 2020; Francis et al., 2017; Singh and Munjal, 2017). Gumaste et al. (2007) conduct experimental research on strength, elastic properties, and failure pattern of brick masonry prism and Wallette under axial compression. The masonry prism is constructed with varying mortar ratios and designed following IS 1905:1987 speci­ fications. Ajith Thamboo and Dhanasekar (2019)compared the behavior of a prism to a cube and found that the prism provides more strength than a cube. Aside from constructing brick and analyzing its mechanical properties, numerical simulation and computerized modeling of brick masonry are also done using a finite element (FE) program (Srinivas and Sasmal, 2016; Furtmüller and Adam, 2011). The cracking pattern, crushing, failure of the wall, deformation by mesh application, and maximum principal strain are all shown in the FE analysis. The results Table 1 Physical and mechanical properties of HDPE and PP (Maddah, 2016; Kusuktham and Teeranachaideekul, 2014). Property HDPE PP Melting point (◦ C) Flashpoint (◦ C) Density (g/cm3) Specific gravity Tensile Strength (MPa) Elongation (%) Water absorption (%) 110–140 greater than 300 0.90–1.00 0.90–1.00 19–39 180–1000 <0.05 160–166 greater than 300 0.91–0.94 0.9–1.00 22–34 3–700 0.01 obtained using FE analysis were compared with the theoretical values and it was observed that FE analysis gave much accurate results. Many researchers have partially replaced waste plastic to improve the mechanical and durability properties of brick, but no study is carried out on the complete (100%) replacement of HDPE and PP plastic in the preparation of brick. As HDPE and PP do not emit harmful gases when melted, so the melting process was carried out to prepare 19 × 9 × 9 cm modular brick. The physical, durability, and mechanical properties of plastic brick and first-class (designation-10) red clay brick which is termed conventional brick are examined. Additionally, an experimental study and comparison of plastic brick walls with the conventional brick wall are conducted in accordance with its compressive strength and fire resistance test. All the tests were performed according to Indian Stan­ dard codes. This research contributes to the use of plastic waste (HDPE and PP) in the manufacture of bricks, which is the most effective method for reducing plastic waste, conserving raw materials, and enhancing the properties of bricks. 2. Materials and methodology 2.1. Materials The thermoplastics, which include High-Density Polyethylene (HDPE) and Polypropylene (PP), were used in this research for manufacturing the plastic bricks. PP plastics are the most often used thermoplastics as they are lightweight and easily mouldable (Maddah, 2016), whilst HDPE is commonly recyclable but decomposition time is too long (almost 100 years (Material Safety Data Sheet: High Density Polyethylene), therefore those plastics were implemented. Furthermore, according to the Material safety data sheet (Material Safety Data Sheet: High Density Polyethylene; Material Safety Data Sheet: Polypropylene (PP) Homopolymer, HDPE and PP have properties such as low toxicity, non-hazardous, and safe use. The physical, durability, and mechanical properties of HDPE and PP are tabulated in Table 1. The reddish-brown local river sand (as fine aggregate) with a particle size of less than 4.75 mm was collected from the Bajaj Institute of Technology in Wardha. Sand has a specific gravity of 2.65, a bulk den­ sity of 1595 kg/m3, and a fineness modulus of 2.88. As a binding ma­ terial, ordinary Portland cement (OPC) of 43 grade is used. Normal tap water with a pH value of 7.0 is used for making masonry mortar. 2.2. Methodology A physical (mechanical) recycling method is involved while manufacturing plastic bricks (Leng et al., 2018). Initially, we collected discarded plastic materials of High-density Polyethylene (HDPE) and Polypropylene (PP) from Maharashtra Industrial Development Corpo­ ration (MIDC) Wardha, Maharashtra, India. However, to make these waste plastics appropriate for brick manufacturing, undesired elements are then removed from the HDPE and PP plastics. The collected plastic materials are then individually chopped into 10–20 mm size using a plastic crusher machine, as shown in Fig. 1(a). Now, this chopped plastic material is placed in a container as shown in Fig. 1(b) and heated to 230 ◦ C (Temperature was measured using an infrared thermometer) 2 P. Kulkarni et al. Cleaner Materials 5 (2022) 100113 Fig. 1. The manufacturing process of Plastic brick. (a) Chopped plastic, (b) Melting, (c) Designed mold, (d) Plastic brick. Fig. 2. (a) Soundness Test (b) Hardness test. Fig. 3. (a) Plastic brick wall (b) Painting on plastic brick wall. which is above the melting point of HDPE and PP individually. Once the plastic has been converted into paste form, it is poured into molds of the standard-modular brick size of dimension 190 × 90 × 90 mm in accordance with IS 1077:1992, as shown in Fig. 1(c). Then the molten plastic paste is properly compacted in the mold during filling to avoid any pores in the brick. After 24 h, the plastic brick is removed from the mold as shown in Fig. 1(d) and tested afterward. properties were conducted on plastic and conventional bricks, Plastic and conventional brick wall was constructed according to IS 1905: 1987 to determine the crack pattern and load-carrying capacity of the plastic brick wall (HDPE) (500 × 110 × 500 mm) with a conventional wall (500 × 110 × 500 mm) as HDPE brick carries more compressive strength than PP brick, fire resistance test of plastic brick wall and a conventional brick wall was carried out according to Table 1 in Part 4 of SP 7: Group 1 (2005): National Building Code. The soundness test and hardness test are as shown in Fig. 2a and 2b. The plastering was a quite challenging job on a plastic brick wall, so grooves were made on all the surfaces of the plastic brick to have a good bond between cement mortar (1:3 (IS 1661 (1972)) and brick as shown in Fig. 3a and b. 2.3. Experimental program In the present study, Physical (Soundness, Efflorescence, Hardness, Impact, and Structure) and mechanical (Compression strength) 3 P. Kulkarni et al. Cleaner Materials 5 (2022) 100113 includes certain physical and durability properties of HDPE, PP, and conventional brick. Table 2 Properties of HDPE and PP brick. Parameters HDPE brick PP brick Conventional brick Weight (kg) Dry density (kg/m3) Specific gravity Water absorption (%) Efflorescence 1.330 864.197 0.866 0.752 Nil 1.350 877.192 0.879 0.370 Nil 2.920 1897.335 1.903 12 Slight 3.2. Compressive strength test on plastic brick and conventional brick HDPE, PP, and conventional brick specimens were tested under the universal testing (AIMIL) machine of capacity 1000 kN. The ultimate load carried by HDPE brick is 191.35 kN at a displacement of 18.40 mm, whereas PP brick carries 171.35 kN at a displacement of 15.30 mm. In addition, the conventional brick carries an ultimate load of 178.95 kN at a displacement of 13.50 mm. The Load vs Displacement graph of brick specimens is obtained through computerized UTM and illustrated in Fig. 4(a). The failure pattern of plastic brick was observed, with bricks forming vertical cracks in the tension zone and splitting the edges. Similarly, conventional brick is crushed completely. However, HDPE brick has better compressive strength than PP brick and is significantly greater than conventional brick (First class) it was used in the prepa­ ration of plastic brick walls. HDPE brick and PP brick have 11.19 N/mm2 and 10.02 N/mm2 compressive strength respectively. Similarly con­ ventional brick has 10.50 N/mm2 compressive strength as shown in Fig. 4(b). 3. Results and discussion 3.1. Physical properties of plastic brick Plastic brick appears to be greyish-black in color and free of cracks. The edges of plastic bricks are not precisely sharp. The weights of HDPE and PP bricks were found to be 1.33 kg and 1.35 kg, respectively. The brick’s density is calculated as a ratio of dry weight to volume (Ornam et al., 2017). A water absorption test had carried out on HDPE and PP plastic bricks according to IS 3495 (Part 2): 2019. We observed that the water absorption capacity of plastic brick is drastically lower than that of conventional brick. After the water absorption test, an efflorescence test is performed on both types of plastic bricks, to find the salt contents available in the HDPE and PP plastic in accordance with IS 3495 (Part 3): 2019. We investigated the surfaces of brick for two evaporation cy­ cles and discovered that there are no perceptible changes on the satu­ rated surface of the brick. The results are tabulated in Table 2, which 3.3. Compressive strength test on plastic brick and conventional brick wall A plastic brick wall is tested on a computerized Universal testing machine (UTM) with a capability of 1000 kN, and a load is applied to the wall. The results revealed that loading up to 16 kN caused no displacement on the specimen. However, the plastic brick wall bears an Fig. 4. (a) Load vs Displacement graph of brick specimens (b) Compressive strength of brick specimens. Fig. 5. (a) Load vs Displacement graph of brick wall specimens and (b) Cracking pattern on the plastic brick wall. 4 P. Kulkarni et al. Cleaner Materials 5 (2022) 100113 masonry is affected by the strength of the brick and mortar used in the brickwork (Venkatesh, 2010). Furthermore, the compressive strength of brick masonry (8.5 MPa) is less than the masonry unit strength (10.5 MPa) (Ludovikus Sugeng Wijanto, 2007). The same graph pattern was even observed in our study, individual bricks carry higher strength than the brick masonry. Table 3 Properties of the brick wall. Parameters Plastic brick wall Conventional brick wall Dimensions: b × t × h (mm) 500 × 110 × 500 mm 47.530 1728.363 3.59 3.48 500 × 110 × 500 mm 104.353 3794.654 2.79 2.70 28.95 25.71 Weight (kg/m) Density (kg/m3) Compressive strength (N/mm2) Corrected Compressive strength: after applying a correction factor of 0.97 (N/ mm2) Masonry efficiency (%) 3.4. Fire resistance test on plastic brick and conventional brick wall The plastic itself is combustible at high temperatures. In the event of a fire, the cement sand mortar with burnt clay bricks may be able to resist the temperature that the plastic brick could not. So, in order to determine the fire resistance of plastic brick and conventional brick walls, we applied continuous heat to the plastered walls’ faces according to Nation Building Code (2005): Part 4: Table 1. The face of the walls has been continuously heated by a torch of gas wielding at a temperature of around 1000–1200 ◦ C and the temperature on both sides of the wall was measured using a digital thermometer (TP101). The test result reveals that after 30 min, the structural integrity of plastic brick increased burning as illustrated in Fig. 6(a). The exact rear unexposed area of the plastic brick wall was at a normal temperature of about 32 ◦ C, which the bare hand could touch, while the edge of this brick wall has a temperature of 78 ◦ C. Cracks form on the face of heataffected surfaces as shown in Fig. 6(b). The conventional brick wall is tested in the same way as the plastic brick wall, with a constant rate of temperature and time as shown in Fig. 7(a). After 30 min of constant heating, the structural integrity of the conventional brick is nearly identical, with a tiny cracks pattern and some roughness in the texture of that exposed surface as shown in Fig. 7 (b). In this case, heat transfers well to the rear side of the wall having a temperature of 113 ◦ C after 30 min. The temperature at the edges of conventional brick was 173 ◦ C. As a result, we observed that using a digital thermometer (TP-101), in the case of a plastic brick wall, bricks burned while heat did not transmit very well through the wall. However, in a conventional brick wall, heat is transferred more evenly throughout ultimate load of 197.5 kN at a displacement of 27.50 mm on the wall, as shown in Fig. 5(a). However, according to IS 1905:1987, the correction factor for the height to thickness (h/t) ratio is multiplied by the exper­ imental compressive strength value obtained. The height to thickness (h/t) ratio is 4.54, and the correction factor for the brickwork specimen according to interpolation is 0.97 and the corrected or normalized compressive strength of the wall is then calculated. The normalized masonry efficiency is also calculated as the ratio of normalized or cor­ rected compressive strength to brick strength (Gumaste et al., 2007). The plastic brick wall fails due to the crushing of bricks and spalling of mortar cover and de-bonding between the bricks. Shear failure was observed in the wall at 45◦ angle as shown in Fig. 5(b). The conventional brick wall took a deflection from 21.80 kN, and the first crack was observed at 98.25 kN loading. The maximum load carried by the wall is 153.95 kN, as shown in Fig. 5(a). The compressive strength of a conventional brick wall was calculated, and the correction factor of 0.97 was multiplied by the experimental compressive strength according to IS 1905:1987. Hence the experimental compressive strength data for the plastic brick wall and the conventional brick wall is given in Table. 3. The wall was deflected by an amount of 18.70 mm with vertical cracks along with their height. Previous research has shown that the compressive strength of brick Fig. 6. Heat on Plastic brick wall. (a) Burning of brick and (b) Crack on the face of a wall. Fig. 7. Heat on Red clay brick wall. (a) Applied heat and (b) Crack and Roughness on the face of a wall. 5 Cleaner Materials 5 (2022) 100113 P. Kulkarni et al. the wall, but no bricks are burnt. Mondal, M.K., Bose, B.P., Bansal, P., 2019. Recycling waste thermoplastic for energy efficient construction materials: an experimental investigation. J. Environ. Manage. 240, 119–125. https://doi.org/10.1016/j.jenvman.2019.03.016. Akinwumi, I.I., Domo-Spiff, A.H., Salami, A., 2019. Marine plastic pollution and affordable housing challenge: Shredded waste plastic stabilized soil for producing compressed earth bricks. Case Stud. Constr. Mater. 11, e00241. https://doi.org/ 10.1016/j.cscm.2019.e00241. ISSN 2214–5095. Aneke, F.I., Shabangu, C., 2021. Green-efficient masonry bricks produced from scrap plastic waste and foundry sand. Case Stud. Constr. Mater. 14, e00515. https://doi. org/10.1016/j.cscm.2021.e00515. ISSN 2214–5095. Frank Ikechukwu, A., Shabangu, C., 2021. Strength and durability performance of masonry bricks produced with crushed glass and melted PET plastics. Case Stud. Constr. Mater. 14, e00542. https://doi.org/10.1016/j.cscm.2021.e00542. Akinyele, J.O., Igba, U.T., Adigun, B.G., 2020a. Effect of waste PET on the structural properties of burnt bricks. Sci. Afr. 7, e00301. https://doi.org/10.1016/j.sciaf.2020. e00301. ISSN 2468–2276. Drougkas, A., Roca, P., Molins, C., 2016. Compressive strength and elasticity of pure lime mortar masonry. Mater. Struct. 49, 983–999. https://doi.org/10.1617/s11527-0150553-2. Bompa, D.V., Elghazouli, A.Y., 2020. Compressive behaviour of fired-clay brick and lime mortar masonry components in dry and wet conditions. Mater. Struct. 53, 60. https://doi.org/10.1617/s11527-020-01493-w. Thaickavil, Nassif Nazeer, Thomas, Job, 2018. Behaviour and strength assessment of masonry prisms. Case Stud. Constr. Mater. 8, 23–38. https://doi.org/10.1016/j. cscm.2017.12.007. Kumavat, H.R., 2016. An experimental investigation of mechanical properties in clay brick masonry by partial replacement of fine aggregate with clay brick waste. J. Inst. Eng. India Ser. A 97, 199–204. https://doi.org/10.1007/s40030-016-0178-7. Nauman Azhar, M., Ali Qureshi, L., 2020. Experimental study of structural behaviour of Chinese bond brick Masonry: a new trend of durable and economical construction in Pakistan. J. King Saud Univers Eng. Sci. https://doi.org/10.1016/j. jksues.2020.09.013. ISSN 1018-3639. A.J. Francis, C.B. Horman, L.E. Jerrems, The effect of joint thickness and other factors on compressive strength of brickwork, Proceedings of 2nd International Brick Masonry Conference, Stroke-on-Trent, 2017, 31-37. Singh, S.B., Munjal, Pankaj, 2017. Bond strength and compressive stress-strain characteristics of brick masonry. J. Build. Eng. 9, 10–16. https://doi.org/10.1016/j. jobe.2016.11.006. ISSN 2352-7102. Gumaste, K.S., Nanjunda Rao, K.S., Venkatarama Reddy, B.V., Jagadish, K.S., 2007. Strength and elasticity of brick masonry prisms and wallettes under compression. Mater. Struct. 40, 241–253. https://doi.org/10.1617/s11527-006-9141-9. Ajith Thamboo, J., Dhanasekar, M., 2019. Correlation between the performance of solid masonry prisms and wallettes under compression. J. Build. Eng. 22, 429–438. https://doi.org/10.1016/j.jobe.2019.01.007. Srinivas, V., Sasmal, S., 2016. Experimental and numerical studies on ultimate load behaviour of brick masonry. J. Inst. Eng. India Ser. A 97, 93–104. https://doi.org/ 10.1007/s40030-016-0152-4. Furtmüller, T., Adam, C., 2011. Numerical modeling of the in-plane behavior of historical brick masonry walls. Acta Mech. 221, 65. https://doi.org/10.1007/ s00707-011-0493-z. Maddah, H.A., 2016. Polypropylene as a promising plastic: a review. Am. J. Polym. Sci. 6 (1), 1–11. Material Safety Data Sheet, High Density Polyethylene Page 1 to 6 Issue No. 01/03/2016 Rev. No. 00/03/2016 PARC/MSDS. Material Safety Data Sheet, Polypropylene (PP) Homopolymer Page 1 to 6 Issue No. 01/ 03/2016 Rev. No. 00/03/2016 PARC/MSDS. Kusuktham, B., Teeranachaideekul, P., 2014. Mechanical properties of high density polyethylene/modified calcium silicate composites. Silicon 6, 179–189. https://doi. org/10.1007/s12633-014-9204-4. Leng, Z., Padhan, R.K., Sreeram, A., 2018. Production of a sustainable paving material through chemical recycling of waste PET into crumb rubber modified asphalt. J. Cleaner Product. 180, 682–688. https://doi.org/10.1016/j.jclepro.2018.01.171. ISSN 0959-6526. Akinyele, J.O., Igba, U.T., Ayorinde, T.O., Jimoh, P.O., 2020b. Structural efficiency of burnt clay bricks containing waste crushed glass and polypropylene granules. Case Stud. Constr. Mater. 13, e00404. https://doi.org/10.1016/j.cscm.2020.e00404. ISSN 2214–5095. Ornam, K., Kimsan, M., Ngkoimani, La Ode, 2017. Santi, Study on Physical and Mechanical Properties with Its Environmental Impact in Konawe - Indonesia upon Utilization of Sago Husk as Filler in Modified Structural Fly Ash - Bricks. Proc. Comput. Sci. 111, 420–426. https://doi.org/10.1016/j.procs.2017.06.043. ISSN 1877-0509. Venkatesh, S.V., 2010. Strength characteristics of brick masonry wall before and after encasing with ferrocement. 8th International Masonry Conference 2010 in Dresden. Ludovikus Sugeng Wijanto, 2007. Seismic Assessment of Unreinforced Masonry Walls. University of Canterbury Christchurch, New Zealand, Department of Cicil Engineering https://doi.org/10.26021/2545’. 4. Conclusion The research and experimental work attempted to reduce the in­ tensity of plastic and its disposal problem by reusing discarded plastic waste to make High-Density Polyethylene (HDPE) and Polypropylene (PP) plastic bricks. These bricks have several advantages over a con­ ventional brick of standard brick. In our study, plastic brick is entirely made from discarded plastic waste without using water, HDPE and PP bricks have a water absorption capacity of 0.75% and 0.37% respec­ tively. Furthermore, because this brick does not absorb water, it can be used in constructions where water leakage is a major issue. The dead weight of bricks in the structure can be reduced by 55% when compared with a conventional brick. The compressive strength of HDPE plastic brick is 14.6% higher than conventional brick. The ultimate load carried by HDPE plastic brick wall is 197.5 kN, while a conventional brick wall of the same dimensions carries 153.95 kN. As a result, we can use the HDPE plastic brick for load-bearing structures. The plastic brick wall has poor bond strength between bricks and mortar, but it can be enhanced by introducing frog or rough texture to the surfaces of the bricks. Plastic brick as a masonry wall will be the ideal choice for civil infrastructure construction or in high-rise buildings since it is light­ weight, has a good load-bearing capacity, and is non-absorbent. As a result, it can minimize the burden of building construction. Declaration of Competing Interest The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper. References Muheise-Aralia, D., Pavia, S., 2021. Properties of unfired, illitic-clay bricks for sustainable construction. Constr. Build. Mater. 268, 121118. https://doi.org/ 10.1016/j.conbuildmat.2020.121118. ISSN 0950–0618. Sutas, J., Mana, A., Pitak, L., 2012. Effect of rice husk and rice husk ash to properties of bricks. Procedia Eng. 32, 1061–1067. Andiç-Çakır, Ö., Son, A.E., Sürmelioğlu, S., Tosun, E., Sarıkanat, M., 2021. Improvement of traditional clay bricks’ thermal insulation characteristics by using waste materials. Case Stud. Constr. Mater. 15, e00560. https://doi.org/10.1016/j.cscm.2021.e00560. ISSN 2214–5095. Wang, Weijin, Gan, Yuxiang, Kang, Xin, 2021. Synthesis and characterization of sustainable eco-friendly unburned bricks from slate tailings. J. Mater. Res. Technol. 14, 1697–1708. https://doi.org/10.1016/j.jmrt.2021.07.071. Çiçek, Tayfun, Çinçin, Yasin, 2015. Use of fly ash in production of light-weight building bricks. Constr. Build. Mater. 94, 521–527. https://doi.org/10.1016/j. conbuildmat.2015.07.029. Kadir, A.A., Mohajerani, A., 2015. Effect of heating rate on gas emissions and properties of fired clay bricks and fired clay bricks incorporated with cigarette butts. Appl. Clay Sci. 104, 269–276. https://doi.org/10.1016/j.clay.2014.12.005. ISSN 0169-1317. Chidiac, S.E., Federico, L.M., 2007. Effects of waste glass additions on the properties and durability of fired clay brick. Can. J. Civ. Eng. 34, 1458–1466. https://doi.org/ 10.1139/L07-120. Demir, I., 2009. Reuse of waste glass in building brick production. Waste Manage. Res. 27, 572–577. https://doi.org/10.1177/0734242X08096528. Eliche-Quesada, D., Corpas-Iglesias, F.A., Pérez-Villarejo, L., Iglesias-Godino, F.J., 2012. Recycling of sawdust, spent earth from oil filtration, compost and marble residues for brick manufacturing. Construct. Build. Mater. 34, 275–284. https://doi.org/ 10.1016/j.conbuildmat.2012.02.079. ISSN 0950-0618. Faria, K.C.P., Gurgel, R.F., Holanda, J.N.F., 2012. Recycling of sugarcane bagasse ash waste in the production of clay bricks. J. Environ. Manage 101, 7–12. https://doi. org/10.1016/j.jenvman.2012.01.032. ISSN 0301-4797. Jahidul Islam, M.d., Shahjalal, M.d., 2021. Effect of polypropylene plastic on concrete properties as a partial replacement of stone and brick aggregate. Case Studies Constr. Mater. 15, e00627. https://doi.org/10.1016/j.cscm.2021.e00627. ISSN 2214–5095. Banerjee, T., Srivastava, R.K., Hung, Y.T., 2014. Plastic Waste Management in India: An Integrated Solid Waste Management Approach. World Scientific Publishing Co., Singapore. Ahmad, A.F., Razali, A.R., Razelan, I.S.M., 2017. Utilization of polyethylene terephthalate (PET) in asphalt pavement: a review. IOP Conf. Ser. Mater. Sci. Eng. 203, 012004 https://doi.org/10.1088/1757-899X/203/1/012004. Further Reading IS 1905 (1987): Code of Practice for Structural use of. Unreinforced Masonry. 6 P. Kulkarni et al. Cleaner Materials 5 (2022) 100113 National Building Code of India, 2005. IS 1661, 1972 IS 1661 (1972): Code of Practice for Application of Cement and CementLime Plaster Finishes. IS 3495, 2019 IS 3495 (2019) Methods of tests of Burnt Clay Building Bricks, Part-2: Determination of Water Absorption, Part-3: Determination of Efflorescence. 7