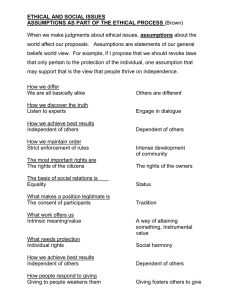

EEB4073 ENGINEERS IN SOCIETY PRODUCTION OF ACRYLIC ACID FROM CRUDE GLYCEROL VIA TWO STEP OXYDEHYDRATION PROCESS GROUP 15 SIVWANI SIVARAM BALNISHA KAUR BAHJAN SINGH ADAM AMINUDIN ASRAJJIT KAUR ASMA' ABU BAKAR 17005061 17004200 17006770 17001700 17001088 SUPERVISOR DR. LAM MAN KEE CHEMICAL ENGINEERING DEPARTMENT UNIVERSITI TEKNOLOGI PETRONAS JANUARY 2022 TABLE OF CONTENT CHAPTER 1 INTRODUCTION 3 CHAPTER 2 DISCUSSION ON THE TOPIC 5 2.1. Discharge/Emission Produced 5 2.2. Ethical and Environmental Issues Related to the Discharge/Emission 7 2.3. Importance of Treating these Discharge/Emissions 8 2.4. Regulations Related to the Emission and Discharges 9 2.5. Improvement of Current Situation 9 CHAPTER 3 REASONS OF FAILURE 11 3.1. Technical Reasons for Failures 11 3.2. Reasons of Technical Failures and Lessons Learned 12 3.3. Ethical Reasons for Failure 13 CHAPTER 4 RECOMMENDATIONS 16 4.1. Recommendation to prevent similar failure in future 16 CHAPTER 5 CONCLUSION 19 REFERENCES 21 2 CHAPTER 1 INTRODUCTION This project report's objective is to evaluate the project failure in terms of technical and ethical methodology or process. In addition, the team must make recommendations to address how, when, and where for appropriate mitigating measures to take place. The case study that has been selected is based on Plant Design Project that outlines the waste treatment for acrylic acid production from crude glycerol through the oxy-dehydration process. From this two-step process, the wastes produced are divided into three constituents: solid wastes, wastewater effluent and gases. It is important to address this issue now since wastewater and air pollution are of global concerns. It's a good reminder to do a complete environmental impact analysis, chemical safety, HAZOP, particularly in waste discharge to the environment in the form of solid, liquid, or gas, before starting any development. If pre-emptive and effective efforts are made, the lives of innocent people may be saved from future accidents. Fault exposure and warning signals must detect early on, so that responsible parties including the engineers are able to mitigate and take preventive steps. Despite that, there have been major incidents in the past regarding ethical concerns particularly, the 2019 Kim Kim River toxic pollution which is caused due to illegal chemical waste dumping. The site location is also proposed to be in Pasir Gudang, Johor, with many surrounding inhabitants and past environmental issues. Public health related issues are also raised by the frequent occurrence of uncontrolled discharge in open spaces in these regions, thus, it is more important that waste is mitigated at source. The primary environmental effects include visual effects, air contamination, scents, greenhouse gas emissions, and disease vectors. Moreover, what will be more detrimental to the environment in the long term is the notorious greenhouse gas, CO2; trapping heat and warming the planet at an alarming rate that stops the Earth from cooling, causing global temperatures to rise. The climate crisis continues to leave an array of impact to the ecosystem, food and water supply, weather patterns, sea levels and other health effects. Nevertheless, this can be undertaken by installing an adsorption column with activated carbon filters to filter out aforementioned pollutants. The technical breakdown of secondary auxiliary systems and their components have been the root cause of majority of the accidents that had occurred in the past, which will also be discussed in this report. 3 In its most recent assessment, the Intergovernmental Panel on Climate Change (IPCC) issued a code red warning as per shown in Figure 1 that there is an urgent risk of reaching 1.5°C warming in the short future if emissions continue at their current rates. The obvious evidence indicates that present efforts fall well short of what is necessary, and that continuing on the current path would impose enormous costs on the global economy and human wellbeing for future generations. It is more than ever that the rate of decarbonisation is needed to be pushed by industrial leaders to achieve a 1.5°C aligned net zero world by 2050, as well as what businesses and governments must do. Figure 1: Greenhouse Gas (GHG) Emissions from IPCC 2022 Report This project's goal is to identify the ethical and technical choices made as a result of current laws. As part of the responsibilities of an engineer, recommendation and consequences are detailed in this report to prevent future mishaps. 4 CHAPTER 2 DISCUSSION ON THE TOPIC 2.1. Discharge/Emission Produced According to the Environmental Quality Act 1974, every industry must accept responsibility for the waste discharged during the manufacturing process, as these discharges may have negative consequences. The discharge from our proposed acrylic acid production plant can be classified into three categories which is solid, liquid and gas emissions. Below is the waste identified according to each category. • Solid Waste o Waste Catalyst produced in dehydration process, silicotungstic acid on alumina supported by zirconia. Table 2.1.1: Solid Waste Catalysts from Dehydration Process Active component Contents (%) Assume 1 kg Total amount per catalyst weight year in 3353.82 kg of (kg) catalyst (kg) Alumina, Al2O3 20% 0.2 670.76 Sillicotungstic acid, HSiW 30% 0.3 1006.15 Zirconia, ZrO2 50% 0.5 1676.91 Coke (Carbon) on Spent 10% of catalyst Catalyst weight - 167.69 Total weight (kg) o 3521.51 Waste Catalyst produced in oxidation process; vanadium molybdenum oxide supported by silica. 5 Table 2.1.2: Solid Catalysts Waste from Oxidation Process Active Contents Assume 1 kg catalyst Total amount per year in Components (%) weight 1619.14 kg of catalyst (kg) V2O5 7.25 0.0725 117.388 MoO3 42.75 0.4275 692.182 SiC 50 0.5 809.57 Total Weight • 1619.14 kg Liquid Waste o Wastewater containing volatile organic compounds, VOCs Table 2.1.3: Wastewater Components from Plant Type of major waste Water Molecular Formula H2O Phase Mol Fraction Liquid 0.989 Mass Flowrate (kg/hr) 102023 Acrylic Acid C3H4O2 Liquid 0.0011 455.152 Allyl Alcohol C3H6O Liquid 0.0009 304.811 Acetone C3H6O Liquid 0.0003 83.8123 Acrolein C3H4O Liquid 0.0003 83.9552 • Gas Waste o Carbon dioxide, nitrogen, and argon gas Table 2.1.4: Pollutants detected from Plant Type of major waste gas Carbon dioxide Molecular Formula CO2 Phase Mol Fraction Gas 0.001 Mass Flowrate (kg/hr) 75.20 Nitrogen N2 Gas 0.69 497417 Argon Ar Gas 0.01 8839.10 6 2.2. Ethical and Environmental Issues Related to the Discharge/Emission Waste management is essential, and all industries must comply to the provided discharge specifications. Failure to comply may result in catastrophic pollution issues and a loss to the company as they would have to bear with the fine issued by the Department of Environment, DoE for failing to comply with the specified regulations. Industrial waste can be managed in several ways which includes recycling of the waste and applying appropriate treatment process for the waste produced before disposing it. From our production process, there are two main solid waste produced which are the spent catalyst from the oxidation and dehydration process. This spent catalyst can be recycled as it contains precious materials such as alumina, vanadium and molybdenum which can be reused for other purposes. The new waste management paradigm prioritizes on reducing and recycling materials instead of disposing it as the number of landfills available are depleting. Between 2007 and now, the number of available landfills has decreased by approximately 50 percent, from 291 to 141. Recycling this waste catalyst can also help to save energy and natural resources. The materials in the spent catalyst can be retrieved by using treatment methods such as leaching. Next, for the wastewater containing volatile organic compounds, VOCs, it must be treated before the water is discharged into water bodies. All effluents must meet the specified standard A or B regulation limits before being discharged. The effluent will have to undergo a wastewater treatment process to remove the VOCs content and there are several treatment strategies such as biological treatment processes or physical treatment processes. In biological treatment, microbes are used to consume the organic matter which is then converted into sludge and the sludge will then be further disposed in landfills. This method is not recommended as it is a destructive method, and it increases the amount of waste disposed in landfills. Whereas physical treatment method such as adsorption or air stripping is a non-destructive method which can be used to retrieve the VOCs and these VOCs can be then used for other purposes. Moreover, for the gas emission, carbon dioxide, nitrogen and hydrogen are the main gas emitted in our proposed plant. These gases must be removed from the air before being discharged into the environment as it causes severe impacts towards the environment such as air pollution. These gases can be removed by treatment methods such as absorption or adsorption which uses activated carbon filters. These gases can also be recovered and reused in other ways. 7 2.3. Importance of Treating these Discharge/Emissions All industrial waste must meet the specified regulation limit before it is safely disposed into the environment as it can have a few negative effects on the environment and human health. The spent catalyst which can be treated by recycling it or disposing it into landfills can cause harm if it is not handled and treated appropriately. If the spent solid catalyst is not treated before it is disposed into the landfill, it can cause groundwater contamination as the harmful toxics from the solid waste would seep into the ground and further contaminate the water bodies. This will then result in water pollution, affecting aquatic life and further depleting our water resources. Moreover, VOCs contained in the wastewater produced can also cause severe harm if it is not removed. VOCs can easily evaporate and vaporize into air, and it then produces smog and fine particulates in the atmosphere. This then causes the surrounding air quality to deteriorate resulting in air pollution. These then contributes to the deterioration of human health as exposure to VOCs may cause respiratory problems and severe health issues such as cancer. Furthermore, the gas emission which contain carbon dioxide, nitrogen, and hydrogen can also pose severe consequences if it does not undergo appropriate treatments. Carbon dioxide is one of the major greenhouse gases and its presence in the atmosphere causes the earth’s temperature to rise which then leads to global warming. This then causes changes in the weather patterns. Too much of carbon dioxide in the atmosphere can also impact the human health as it causes dizziness and elevated blood pressure and increased heart rate. Next, nitrogen gas will be emitted into the environment as nitrogen dioxide and this gas also poses detrimental impacts towards the environment. Elevated levels of nitrogen dioxide in the atmosphere causes acid rain and it causes humans to suffer with respiratory infections and asthma. Finally, hydrogen is considered as an indirect greenhouse gas as its presences causes an increase in other greenhouse gases such as methane and ozone, resulting in global warming. As a result, it is reasonable to conclude that improper waste management and a lack of appropriate treatment can result in a variety of pollutions that have a direct impact on the quality of life. 8 2.4. Regulations Related to the Emission and Discharges Through the enforcement of law and regulations the management of industrial waste has been continuously monitored and improved over time. The Environmental Quality Act 1974, serves to preserve, protect, and control the quality of the environment, as well as to control pollution. Environmental laws are established to limit air, water, and soil pollution and to avoid environmental issues such as global warming, ozone depletion, and acid rain. All industrial effluents must abide to the specified discharge limits according to the Standard A or Standard B regulations. Whereas all solid waste is classified as scheduled waste and must be treated according to the guidelines provided by the Department of Environment, DoE. A few examples of legislations that are related to industrial waste is as listed: - Environmental Quality Act 1974 - Solid Waste and Public Cleansing Management Act 2007 - Environmental Quality (Industrial and Sewage Effluents) Regulations 1979 - Environmental Quality (Prescribed Premises) (Schedule Waste Treatment and Disposal Facilities) Regulations 1989 - Environmental Quality (Scheduled Waste) Regulations 2005 2.5. Improvement of Current Situation Reducing the amount of waste produced is one way to improve the current situation of environmental issues related to emissions. The sustainable waste management approach prioritizes waste reduction, followed by reuse and recycling, and finally safe landfill disposal. This approach can be depicted in the latest hierarchy of waste management as shown in Figure 2. There will be fewer environmental issues if the amount of waste produced is reduced. This is because lesser waste reduces the requirement to harvest new raw materials since the waste produced is reused or recycled for other processes. In addition to this, energy consumption is reduced, as are greenhouse gas emissions, which contribute to climate change. 9 Figure 2: Hierarchy of Waste Management Industrial waste reduction can be done by redesigning the industrial process with the purpose of reducing the number of materials used and the amount of waste produced. This can also be done by reducing the amount of packaging materials. Furthermore, the products produced should be made to last longer, easy to repair, reusable and recyclable. This is to ensure there are lesser waste that are disposed to the landfills. Following that, industrial waste reduction can be accomplished by recycling and reusing waste generated for other purposes. Metals from spent catalysts, for example, can be extracted and used as raw materials in various processes. Moreover, the current situation of environmental issues related to emissions can also be improved by establishing cradle to grave waste management principle. According to the cradle to grave principle, the waste generator is responsible for its waste from generation to disposal. We can ensure that all waste produced is properly managed and disposed of safely by holding the waste generator accountable for the waste produced, because the waste generator will have to consider the public's and the environment's safety. Failure to comply will cause the company to face legal liabilities which then increases the cost and tarnishing the company’s reputation. 10 CHAPTER 3 REASONS OF FAILURE 3.1. Technical Reasons for Failures A study of past accidents within the activity industry (CPI) has been disbursed. It's found that the bulk (73%) of the accidents were caused by technical and engineering failures. The foremost frequent explanation for accidents within the Failure Knowledge Database is the piping system failures (16% from 364 cases). Accidents associated with the piping systems involved loss of containments or leakages that ends up in toxic dispersion, fire, and explosion. From the analysis, typical problems related to the piping system are poor layout, wrong specification, dead end or no flow arrangement, poor installation and finishing work, inadequate hot bolting, and blockage. Technically, the piping system is complex thanks to multiple interactions between process equipment. The demand for higher process flexibility increases the complexity of the system. The likelihood of the piping failure may be a function of failure rate of its components. If the amount of the components increases, the probability of the system failure will increase. Thus, designing a less complicated piping system is that the best thanks to prevent accidents within the natural action industry. The second largest reason behind accidents is contamination of the method stream with 36 cases (10%). during this category, impurities, by-product and in-direct or external contaminations also are considered. the fundamental problem of the contaminations is said to insufficient process hazard analysis at the method development and plant design. Contaminations also occur thanks to incomplete draining/cleaning/purging, reverse flow, pressure difference, blockage, leakages, and condensation thanks to weather changes. In chemistry term, the contaminant changes the standard of process stream and creates plenty of operational problems like increase the corrosion rate, partial/full flow blockage, wall sticking, depositing, or scaling, disturbed/delayed chemical reactions, etc. If unstable or reactive material presents and therefore the conditions are right (temperature and concentration), an unwanted reaction (i.e., polymerization and decomposition) may occur, resulting unwanted events like fire and explosion. 11 Furthermore, heat transfer is awfully a usual contributor of manufactory accidents, causing 20 accidents. Loss of cooling, wrong heating method, hot spots, and scaling within the piping system and process equipment are among the issues related to heat transfer related accidents. Special attention should tend to thermal expansion phenomena and therefore the reactivity hazard of warmth transfer media to the method fluid. Inappropriate selection of construction material (29 cases or 8%) is that the third contributor of accidents in CPI. this can be a design related error and normally connected to the physical and mechanical problems of process equipment like cracking, corrosion, erosion, creep, fatigue, and shock. for instance, selecting mechanically robust construction material also as increasing the wall thickness of process equipment can eliminate wall failures. Meanwhile selecting a chemically resistant construction material like chrome steel or Teflon can minimize the corrosion issue. regarding our carboxylic acid production plant, it's essential to make sure the correct process of storing and preserving carboxylic acid since it's flammable properties. At the planning temperature, the strength of design for components must not surpass the specified design strength for the needed components. The building materials are stainless-steel, carbon steel or fiber reinforced polymer (FRP) based. which might encounter all the challenges associated with storing carboxylic acid in terms of environmental and health risks, flammability, and unexpected polymerization. At least two main storage tanks are required in this plant design to hold acrylic acid in the form of its glacial and technical grade standards. Meanwhile other storage tanks could be constructed to store other by-products such as acrolein and acetol for at least seven days. 3.2. Reasons of Technical Failures and Lessons Learned From the accident cases reported in Failure Knowledge Database, several similarities appear. These will be summarized as following: • Majority of the accidents are caused by failure of auxiliary systems and its components, not the most equipment. Typical example is piping system. The integrity and reliability of the piping system depend upon many factors including design, complexity, and management. The integrity and reliability of the piping system will be achieved by selecting robust material of construction and thru simpler design. Well-structured pipes inspection and replacement may be a good element of piping management system. 12 • Almost 1/2 accidents occur during normal operations and are directly associated with the look error. Typical samples of design error within the chemical change industry are unsuitable construction material for equipment, incorrect design capacity and style specification and poor layout. Proper process analysis is required especially on identification of inherent physical and chemical properties of drugs, stability, and incompatibility of process fluids with construction material, and runaway reaction hazards. additionally, detail risk analysis supported worst-case scenario should be conducted and also the result should be wont to design the equipment’s protective and mitigation system. • Lack of process analysis in regard to chemical reactivity and incompatibility. Identification of hazards related to reactive materials and also the potential of the method contamination yet as material accumulation in process stream should be made referred to as early as possible, for instance in research and development stage. the info may be used as criteria for stuff selection during process screening or process concept development. Selection of safer and compatible stuff can eliminate or reduce the general risk of the action plant operations. 3.3. Ethical Reasons for Failure The complexity and therefore the automation of a mill industry (CPI) have impacted human life profoundly by producing many essential products, utilizing a spread of latest chemicals. In many aspects, the increased application of chemical products has not only improved the standard of human life but also increased dependence of humans on these chemicals. However, chemicals pose potential threats to human life and therefore the environment due to their flammability, reactivity, and toxicity. These properties can cause fire outbreaks and explosions and exert deleterious effects on human health. In the context of environment, it's the utmost responsibility to confirm all kinds of discharge or effluents are treated before releasing into the environment. Solid, gas and liquid harmful discharges from propenoic acid production plants should be a priority to make sure protection of the environment. The steps within the management of carboxylic acid plant 13 effluents should be followed effectively. For example, a minority of the agents involved in management knew the method but failed to put this information into practice would clearly display ethical reason of failure. This might be explained by the ignorance of the engineers or by the ignorance of the health and environmental risks linked to the mismanagement of effluents. The shortage of training, monitoring, and reference documents on the management of plant effluents are also factors of ethical failures. The management of effluents may be a important issue in petrochemical and chemical production plants. The effluents produced by the chemical plants should meet the legal standards and if it's not, it's considered an ethical reason of failure for the responsibility organization. These effluents discharged without prior treatment into surface water could constitute a source of dissemination of doubtless pathogenic germs. It's therefore important to develop methods for treating these effluents before they're released into the natural environment. For effective implementation of effluent management practices, a periodic awareness and continuing education program is mandatory to boost knowledge and practices of waste management among engineers in our society. This kind of ethical failure was often caused by ignoring warnings and continuous add hazardous situations still as misapplication of an honest rule. Ethical failure results in a chemical accident thanks to incorrect and inappropriate information about chemicals yet as lack of experience within the process. Additionally, some accidents were analyzed within which workers weren't acquainted with the method control and were unable to handle treacherous situations. To prevent this sort of accident, preparation of procedures for abnormal and emergency scenarios, knowledge and understanding of chemical processes, and organizational learning are necessary. For a scientific approach toward preventing these chemical accidents, chemical manufacturers must convey the proper information about the potential hazards and therefore the correct safety precautions to users. Additionally, operators, designers, and safety managers should be properly trained to grasp the hazards of materials and reduce human failure of workers. A code of ethics for engineers may be a set of guiding principles that establish standards of behavior and moral guidelines for engineers in their line of duty. Every state engineering board requires professional engineers to follow their code of ethics to safeguard the general public and ensure engineers perform their services in an ethical and honest manner. The first 14 purpose of codes of ethics in engineering professions is to safeguard the general public and uphold professional standards. The NSPE (National Society of Professional Engineers) has created a document called “Ethics” which outlines conduct expected from someone taking on the profession of engineering. Therefore, these kinds of accidents are often avoided if the code of ethics had been followed: 1. Hold paramount the protection, health, and welfare of the general public and protect the environment in performance of professional duties. 2. Formally advise employers or clients (and consider further disclosure, if warranted) if they perceive that a consequence of their duties will adversely affect the current or future health or safety of their colleagues or the general public. 3. Public safety is predominant, we must take the time necessary to fabricate the morally justified possibility. 4. Accept responsibility for your actions, seek and heed critical review of their work and offer objective criticism of the work of others as communication is key. 5. Anticipation of risk can mean mitigation of risk. Other ethical reason for plant failure includes proximity of high-occupancy structures (control rooms) to hazardous operation, inadequate separation between buildings, and crowded process equipment. To sum it all, it's the utmost responsibility of each engineer to achieve knowledge and education on the hazard of reactive chemicals which might prevent similar accidents within the future. Decisions that impact the integrity of a design or its construction usually come from the highest down. Lapses in leadership can result in these types of engineering failures thanks to ethics. That’s why it’s essential to own leaders trained in both ethical decision-making and technical decision-making. By following the moral codes, engineers can create and impact sustainable development safety for society. 15 CHAPTER 4 RECOMMENDATIONS 4.1. Recommendation to prevent similar failure in future As already discussed in the previous chapter on possible reasons of plant failure which include technical and ethical aspects, effective strategies are needed to be study and implement to prevent similar failures in future. One of the way to ensure a smooth and safe working condition for both plant personnel and community surrounding is inherently safer design (ISD) principles must be upheld by any manufacture company. ISD provides more reliable risk management and can simplify and reduce the cost of chemical processing technologies by removing the need for pricey safety systems and processes (Hendershot, 2011). Instead of relying on control systems, complicated operating instructions, or intricate processes, plant that implement this philosophy leverages the reduction of dangers to prevent accidents. Inherently safer plants are simpler, easier to operate, more reliable, error-tolerant and cost - effective. The principles include minimize, substitute, moderate and simplify. The minimize strategy means to use minimum number of materials, length, and sizing of equipment. This strategy can be done by minimizing hazardous materials inventory, reducing the length of pipeline and diameter of pipeline that contain hazardous materials which will ease the control of hazardous material during operation and incident in case of any failure. The substitute strategy entails replacing the hazardous materials with less hazardous materials. It can also be done by substituting the chemical process that produce hazardous intermediate product with process that did not. As the founder of inherent safety, Trevor Kletz has said, “what you do not have, cannot leak”, by eliminating the hazardous material will ultimately eliminate the harms that it will come with. The moderate strategy requires providing less dangerous conditions when handling hazardous material. For example, by using the material under lower temperature and lower pressure or diluting it into lower concentration. Lastly, the simplify strategy entails eliminating unnecessary complexity of the process. This strategy can be done by avoiding confusing control system layouts and equipment labelling which can avoid unnecessary and silly mistake or human error. Based on the failures that has been discussed in the previous chapter, some of ISD principles can be implemented to prevent them. Minimize strategy for example by reducing the length of pipeline can reduce the frequency of leakage, poor layout, wrong specification, dead 16 end or no flow arrangement, poor installation and finishing work, inadequate hot bolting, and blockage which are the common accidents related to piping system failure. Besides, by implementing simplify, for example by reducing number of flanges along the pipeline will minimize the possibility of leakage due to poor installment. When ISD principles are being implement during development stage of plant design will provide fewer error opportunities due to design failures and malfunction during operation such as wrong material selection. Figure 3 taken from Kidam et al. (2016) shows the design paradox and ISD implementation potential throughout process lifecycle where the major improvement of ISD implementation is the greatest between development and detailed engineering phase. Figure 3: The design paradox and ISD implementation potential throughout process lifecycle Another way to prevent similar failure in future is use hierarchy of management systems which from the top to bottom are ISD, passive, active and procedural respectively. A passive safeguard minimizes frequency of failure without the active functioning of device. For example, do passivation process along the pipeline system to reduce deterioration of metal or corrosion that may lead to contamination in the materials which will possibly lead to unwanted runaway reaction that will fire and explosion. Active safeguards require engineering control and human intervention such as alarms, pressure relief valves, safety instrumented systems and 17 flares. Lastly, procedural safeguards, often called administrative safeguards, are based on an established or official way of doing something. Example of procedural safeguards include standard operating procedures, safety rules and procedures, operator training, emergency response procedures and management system. Procedural safeguards if strictly monitor able reduce ethical reason of failure. Failure caused by human error as mentioned in the previous chapter can be influence by many reasons. It is undeniable that personnel working behavior and productivity aside from personal reason are influence by organizational and social factor, assigned task characteristic and operating environment (Embrey, 2000). Management committee plays big role in building the ethical behavior of the staffs. First of all, appropriate and detailed process hazard analysis and job hazard analysis that follow the regulation required by the government must be first completed by the upper authorities in the company. Additionally, standard operating procedure that is finalized, easy to understand and updated must be provided for operators’ reference. Management committee also has to ensure the operators are well trained before assigning the task. Well – monitored routine maintenance, troubleshooting and housekeeping are importance to ensure all equipment are well maintained and always ready to operate. Finally, to have an effective safety culture to develop responsibility among personnel to work safely all the time. Previous chapter also discussed auxiliary systems’ failure as one of the technical reason of failure. Defects in systems must be found and diagnosed to prevent sudden system failure, inefficient operation, and potential health and environmental dangers. The application of fault detection and diagnosis practices has been common to processes and plant equipment to prevent worse accident from happening. Traditionally, process and equipment monitoring is performed by two separate departments, process engineers and mechanical engineers. To ensure more effective diagnosis, current technology able to relate the condition of process and equipment with each other which gives wider overview for the engineers to figure out the reasons for the faulty behavior (Cecilio et al., n.d.). 18 CHAPTER 5 CONCLUSION The objective of this study is to evaluate the project failure of the focus area, which is the waste treatment facility of acrylic acid production plant. The project failure was evaluated in terms of technical and ethical failures and recommendations to prevent the possible failures was also extensively discussed. It is extremely crucial to discuss this issue currently since waste management is a global concern that affects the environment and public health at large which will be severely affected due to failure of this waste treatment plant. The waste produced in the acrylic acid plant is divided into three constituents: solid wastes, wastewater effluent and gases. The solid waste mainly produced from the acrylic acid production plant is the spent catalyst from the 2-step acrylic acid production process which are oxidation and dehydration process. The spent catalyst should be treated before it is disposed into landfills as these metals can cause groundwater contamination. Besides that, volatile organic compounds (VOCs) present in wastewater from the the acrylic acid plant can easily evaporate and vaporize into air, and produce smog and fine particulates in the atmosphere. Exposure to VOCs may also cause respiratory problems and severe health issues such as cancer. In terms of gas emissions from the plant, carbon dioxide emission causes the earth’s temperature to rise which then leads to global warming. Similarly, hydrogen is considered as an indirect greenhouse gas as its presences causes an increase in other greenhouse gases such as methane and ozone. Unchecked emission of nitrogen gas on the other hand will cause acid rain, respiratory infections and asthma. All in all, these waste effluents should be treated before they are being emitted not just to obey environmental regulations imposed under the Environmental Quality Act 1974 but also for the ethical responsibility that engineers have towards the society at large to protect the environment. From the technical standpoint, majority of the accidents are caused by failure of auxiliary systems and its components, such as the piping system instead of the equipment itself. One in two accidents that occur during normal operations are also associated with the look error which is a design error which involves unsuitable construction material for equipment, incorrect design capacity, style specification and poor layout. Lack of process analysis in regard to chemical reactivity and incompatibility is also a possible cause of technical failure. These technical failures can be prevented by minimizing hazardous materials inventory, reducing the 19 length of pipeline and diameter of pipeline that contain hazardous materials which will ease the control of hazardous material during operation and incident in case of any failure. In addition, the substitute strategy entails replacing the hazardous materials with less hazardous materials. Another way to prevent technical failure in future is the use hierarchy of management systems which from the top to bottom are ISD, passive, active and procedural system which will dynamically prevent failures from the development stage of the plant itself. Ethical failures, on the other hand are mainly caused by the ignorance of the engineers towards the health and environmental risks linked to the mismanagement of effluents, the shortage of training, monitoring, and reference documents on the management of plant effluents. Procedural safeguards if strictly monitored is able to mitigate the ethical reasons of failure. The management committee plays big role in building the ethical behavior of the staff mainly to instill the responsibility among personnel to work safely all the time. The detailed process hazard analysis and job hazard analysis according to the regulations must also be completed by the management committee. Additionally, standard operating procedure that is finalized, easy to understand and updated must be provided for operators’ reference. Management committee also has to ensure the operators are well trained before assigning the task. Well –monitored routine maintenance, troubleshooting and housekeeping culture are also important to ensure all equipment are well maintained and always ready to operate. Ultimately, engineers have an ethical responsibility towards the community in preserving the environment. Engineers have to accept responsibility in making engineering decisions consistent with the safety, health, and welfare of the public, and to disclose promptly factors that might endanger the public or the environment. Hence, this study in identifying the possible technical and ethical reasons for failure and their respective preventative measures is crucial in ensuring that the waste treatment facility of the acrylic acid plant runs without failure, fulfilling the ethical responsibility towards the community in preserving the environment. 20 REFERENCES Aja, O. C., Oseghale, S. D., & Al-Kayiem, H. (2014). Review and evaluation of municipal solid waste management practices in Malaysia. The Journal of Solid Waste Technology and Management, 40(3), 215-232. Cecilio, I., Chen, S., & Thornhill, N. Importance of Auxiliary Systems for Process Fault Detection and Diagnosis, 1-6. El Haggar, S. (2010). Sustainable industrial design and waste management: cradle-to-cradle for sustainable development. Academic Press. Embrey, D. (2000). Performance Influencing Factors (PIFs) [Ebook] (pp. 1-5). Human Reliability Associates Ltd. Retrieved from https://www.humanreliability.com/downloads/Introduction-to-PerformanceInfluencing-Factors.pdf. Hendershot, D. (2011). Inherently Safer Designs: An Overview of Key Elements [Ebook] (pp. 48-55). Retrieve from https://aeasseincludes.assp.org/professionalsafety/pastissues/056/02/048_055_F2Hend ershot_0211Z.pdf. Ishak, M. B. (2002). The law of industrial waste management in Malaysia (Vol. 56). WIT Press. Khan, F. I., & Ghoshal, A. K. (2000). Removal of volatile organic compounds from polluted air. Journal of loss prevention in the process industries, 13(6), 527-545. Kidam, K., Sahak, H., Hassim, M., Shahlan, S., & Hurme, M. (2016). Inherently safer design review and their timing during chemical process development and design. Journal Of Loss Prevention In The Process Industries, 42, 47-58. https://doi.org/10.1016/j.jlp.2015.09.016 Metts, T. A., & Batterman, S. A. (2006). Effect of VOC loading on the ozone removal efficiency of activated carbon filters. Chemosphere, 62(1), 34-44. Zhao, Z., Guo, M., & Zhang, M. (2015). Extraction of molybdenum and vanadium from the spent diesel exhaust catalyst by ammonia leaching method. Journal of Hazardous Materials, 286, 402-409. 21