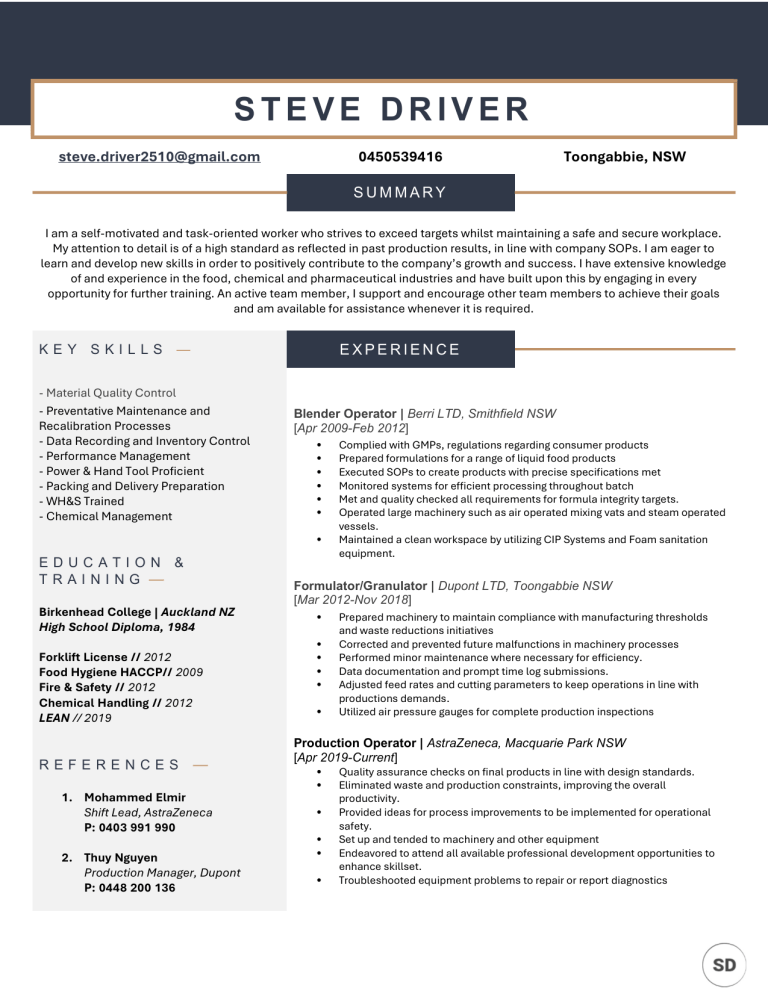

STEVE DRIVER steve.driver2510@gmail.com 0450539416 Toongabbie, NSW SUMMARY I am a self-motivated and task-oriented worker who strives to exceed targets whilst maintaining a safe and secure workplace. My attention to detail is of a high standard as reflected in past production results, in line with company SOPs. I am eager to learn and develop new skills in order to positively contribute to the company’s growth and success. I have extensive knowledge of and experience in the food, chemical and pharmaceutical industries and have built upon this by engaging in every opportunity for further training. An active team member, I support and encourage other team members to achieve their goals and am available for assistance whenever it is required. KEY SKILLS EXPERIENCE — - Material Quality Control - Preventative Maintenance and Recalibration Processes - Data Recording and Inventory Control - Performance Management - Power & Hand Tool Proficient - Packing and Delivery Preparation - WH&S Trained - Chemical Management Blender Operator | Berri LTD, Smithfield NSW [Apr 2009-Feb 2012] • • • • • • • EDUCATION & TRAINING — Formulator/Granulator | Dupont LTD, Toongabbie NSW [Mar 2012-Nov 2018] Birkenhead College | Auckland NZ High School Diploma, 1984 Forklift License // 2012 Food Hygiene HACCP// 2009 Fire & Safety // 2012 Chemical Handling // 2012 LEAN // 2019 REFERENCES Complied with GMPs, regulations regarding consumer products Prepared formulations for a range of liquid food products Executed SOPs to create products with precise specifications met Monitored systems for efficient processing throughout batch Met and quality checked all requirements for formula integrity targets. Operated large machinery such as air operated mixing vats and steam operated vessels. Maintained a clean workspace by utilizing CIP Systems and Foam sanitation equipment. — 1. Mohammed Elmir Shift Lead, AstraZeneca P: 0403 991 990 2. Thuy Nguyen Production Manager, Dupont P: 0448 200 136 • • • • • • Prepared machinery to maintain compliance with manufacturing thresholds and waste reductions initiatives Corrected and prevented future malfunctions in machinery processes Performed minor maintenance where necessary for efficiency. Data documentation and prompt time log submissions. Adjusted feed rates and cutting parameters to keep operations in line with productions demands. Utilized air pressure gauges for complete production inspections Production Operator | AstraZeneca, Macquarie Park NSW [Apr 2019-Current] • • • • • • Quality assurance checks on final products in line with design standards. Eliminated waste and production constraints, improving the overall productivity. Provided ideas for process improvements to be implemented for operational safety. Set up and tended to machinery and other equipment Endeavored to attend all available professional development opportunities to enhance skillset. Troubleshooted equipment problems to repair or report diagnostics