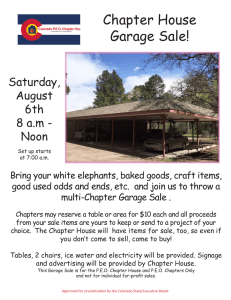

BINDURA UNIVERSITY OF SCIENCE EDUCATION FACULTY OF AGRICULTURE AND ENVIRONMENTAL SCIENCE DEPARTMENT OF ENVIRONMENTAL SCIENCE NAME MAPANZURE EVINA S REG NO. B192204B PROGRAMME BES. SHEM 4.1 COURSE SAFETY HEALTH AND RISK MANAGEMENT COURSE CODE LECTURER’S NAME ESM 402 MR NHOKOVEDZO 1 (a) (i) Explain why risk assessment for exposure of workers to Diesel Engine Exhaust Emissions (DEE) is important at Kunaishe Mine workshop garage which is enclosed garage as shown in the appendix (5) Risk assessments help in identifying, recognizing and describing the risks that might prevent Kunashe Diesel Exhaust Engine Emission achieving the appropriate air circulation through the metal concertina door which moves the outdoor air into the garage which helps in diluting the pollutants originating from the diesel emissions in the garage then the air bricks lets in the cooler air in and hot air rises and exit through the vent on the top part of the garage door. When there is hot air in the garage, it then rises up and helps in setting the turbines in motion thereby letting out air. It also helps in identifying the measures that can be put in place to prevent land pollution from oil spillages and also prevent the skin contact with the hazardous substances, the eye irritation and breathing difficulties caused by the fumes in the garage, if trapped, fatal injuries from smoke inhalation/burns, burns from contact with battery acid while charging, exploding of batteries if is overcharged and electrical shocks or burns from faulty electrical equipment or on installation, Analysing the nature of the risks at Kunashe Mine Workshop Garage and their characteristics including, where appropriate the level of the risks by considering the uncertainties, risk sources, consequences, likelihood, events, scenarios, controls and their effectiveness can also be achieved by doing risk assessments. Risk assessment helps in risk evaluation which helps in support decisions of controlling the hazards which include air pollution by oil spillage. This can be done through comparing the results of the risk analysis with the established risk criteria. Risk assessment plays a vital role in selecting the most appropriate risk treatment options at Kunashe Mine Workshop Garage so that there will not be the reoccurrence of the same risks at the garage . (ii) What should be considered when making a suitable and sufficient risk assessment exposure of workers at the Garage to DEE (20). Firstly, the methods and procedures used in the processing, handling or storage of the substances should be considered when making a suitable and sufficient risk assessment. Supervisor to start keeping a check that gloves are being used, the risks from dermatitis and skin cancer to be explained to worker, the manager to arrange training on use of extinguishers for all workers, annual fire drill to be carried out, brief workers on safe working with petrol. Refer to HSE’s, manager to assess suitability of replacing 240 V tools with air-powered or 110 V alternatives, brief workers on safe handling of air bags, manager to arrange manual handling training for the workers in the store and also, briefing workers on handling tires, refer to HSE publication and detailed assessment must be done using HSE publication. In addition to that, a risk assessment to sufficient and effective, the actual and the potential exposure of the workers for example how many workers may be exposed, what the exposure limit is, what the exposure will be and how often will they be exposed must be considered. The exposures which must be included at Kunashe can include, skin contact with the hazardous substances over a long period can lead to severe dermatitis and skin cancer, the fumes may cause eye irritation and breathing difficulties, if trapped, workers and customers could suffer fatal injuries from smoke inhalation/burns, workers could suffer burns from contact with battery acid while charging, particularly if battery is overcharged and explodes, workers could get electrical shocks or burns from faulty electrical equipment or on installation, electrical faults can also lead to fires workers suffer serious injury from unguarded moving parts of machinery, workers can also get cut on sharp edges or scald themselves on hot parts and failure of a car lift, jack or other lifting equipment may cause severe crush injuries to an employee. The measures and procedures necessary to control the hazards at Kunashe which is by means of engineering controls, work practices, and hygiene practices and facilities must also be included in making a risk assessment sufficient and effective. At Kunashe Company, extinguishers provided and inspected under contract, special fire exits not needed as all work areas have immediate access to outside, fuel retriever used to empty vehicle fuel tanks outside, spillages cleared immediately Component cleaning in recirculating paraffin system, not petrol, LPG fueled vehicles parked in safe places, workers trained in hazards of LPG, fire risk assessment done and necessary action taken, proprietary charger, installed by electrician, is used in accordance with instructions, acid-resistant gloves and goggles supplied and used, lowvoltage 24 V hand lamps used, residual current device (RCD) built into main switchboard. A few 240 V tools are used, all have industrial plugs and leads, testing carried out annually on all portable 240 V tools and workers are trained to carry out pre-use visual checks and report defects. How a person would react in a particular situation for example, what could be the most common reaction by a person if the machine failed or has malfunctioned? The duration of the frequency of the task that is how long and how often a task is done at Kunashe Mine The location of the task that is being done The machinery, tools, materials and items which are being used at the garage in the operation and how they are used for example, the physical state of a chemical, or lifting heavy loads for a distance should not be left out when doing a suitable and effective risk assessment of Kunashe Mine Workshop Garage. Any possible interactions with other activities in area and if the task could affect others like the cleaners and the visitors must be considered when making a risk assessment at Kunashe Mine Workshop Garage. The lifecycle of the product, process or the service which include the design, construction, used, decommissioning. Education and training the workers have been received for it is crucial for Kunashe development and success. Training is fruitful to both the employers and the employees of an organization. When trained, an employee will become more efficient and productive if trained well. B (i) Describe how the air movements provide ventilation in the diagram shown below (10) The door, windows move outdoor air into the garage, and distributes the air within the garage. Its purpose is to provide healthy air for breathing by both diluting the pollutants originating from the diesel emissions in the building and removing the pollutants from it. The bricks vents are installed bottom sides of the garage, to act as the intake vent which lets in cooler outside air. The hot air rises and exits through the vent on the top part of the garage door. Hot air is lighter than cold air and it rises up and this upward movement of hot air within a garage, is enough to set the roof turbines in motion. Any wind will further increase the effectiveness of the Roof Wind Turbine. The fan sucks the air inside the garage and passes it to the outside via a ducting through the wall. Passive roof vents use the natural movement of air. The warm air moves out of the garage to the exteriors. It is replaced by cold air from the garage wall vents or the garage door. The fan blade curves are designed such that the roof vent acts like a one way valve. Air can go out but cannot come in. b (ii)Consider how ventilation in Appendix affects the exposure of workers to DEE (5) Ventilation system in appendix 1 affects the exposure of workers at Kunashe Garage to the diesel Exhaust Emissions to a greater extend. The mechanism of the garage gives the allowance of polluted air to circulate in the garage because there are no exhaust pipes that helps in the letting of the exhaust out of the building at the moment they are being exhausted. Also, the bottom air bricks are not enough, the garage was supposed to have the bottom to let in the cold air and the upper air bricks to let out the hot air. There is one window at the garage which is not enough for air circulation. C(i)Describe the features of the ventilation system shown in appendix There is a portable exhaust pipe which is attached to the car exhaust to exhaust fan which is an engineering control which directly control a hazard or a risk directly from the source. These pipes are attached to the car exhaust pipe to the filters and then to roof fans and chimney to be vented out. The pipes collect air direct from the exhaust pipe before it gets into the garage assisted by the pressure from the engine to the chimneys and exhaust fans and disposed to the air. The door and windows move outdoor air into the garage, and distributes the air within the garage. Its purpose is to provide healthy air for breathing by both diluting the pollutants originating from the diesel emissions in the building and removing the pollutants from it. The bricks vents are installed bottom sides of the garage, to act as the intake vent which lets in cooler outside air. The hot air rises and exits through the vent on the top part of the garage door The fan sucks the polluted air inside the garage and passes it to the outside via a ducting through the wall. (ii)Outline the arrangements the mine would need to out in place for this type of ventilation system to maintain effectiveness (5) Eliminating the potential hazards at Kunashe by keeping the workshop garage free from recognized physical and chemical hazards and make sure it is in compliance with OSHA standards, rules, and regulations. To achieve this, the use your digital signage systems to remind employees about proper body mechanics, safe backing, what PPE is necessary, and ways they can avoid hazards. Workers at Kunashe should be encouraged to identify and report potential problems and safety violations and take immediate steps to have those issues resolved. Making sure all workers are properly trained Kunashe Company must provide all workers with safety training using language they can understand. The training should be given to all new employed workers, with refresher courses offered for existing workers or when workers change jobs within the garage and to use electronic message boards to reinforce safety training, serving it up in bite-sized messages. Making sure workers have proper equipment Make sure Kunashe Company employees have and use safe tools and equipment and properly maintain this equipment they will be using in servicing the cars at the garage. Inspections There must be some on job inspections at Kunashe Mine Workshop Garage to help prevent risk and when you carrying out a workplace inspection, you are critically examining the workplace to identify and report potential hazards that can be removed or avoided. Maintenance schedule Having a maintenance plan is directly related to higher productivity, which is linked to achieving the objectives set by the company’s management. And for this equation to deliver favorable results, reliability is a decisive factor because it provides the conditions to seek optimization of operations, bringing together human talent, optimization of processes and assets, and management strategies to achieve the proposed goals. Planned job observation Purposes of Planned Job Observation helps Kunashe Garage to pinpoint practices that could cause accidents, injuries, damage, inefficiency and waste, determine specific needs for coaching and training, learn more about work habits of your people and check adequacy of existing job/task method sand procedures. Bench marking Benchmarking helps in making continuous improvements and implement changes in business products, methods and services, therefore, benchmarking practices provide a better understanding of customer wishes and expectations. This is because the customers are the most important data source at every stage of comparison. Brain storming Brainstorming allows people to think more freely, without fear of the judgment. It also encourages open and ongoing collaboration to solve problems and generate innovative ideas and helps teams generate a large number of ideas quickly, which can be refined and merged to create the ideal solution. REFERENCES Fundamentals of Industrial Hygiene. 5th Ed. Plog, Barbara and Patricia Quinlain. Chicago, IL: National Safety Council, 2001. Hathaway, Gloria J., Nick H. Proctor, and James P. Hughes. Proctor and Hughes' Chemical Hazards in the Workplace. 4th Ed. New York, NY: Van Nostrand Reinhold, 2006. The Occupational Environment Its Evaluation and Control. 2nd Ed. Dinardi, Salvatore. Fairfax, VA: American Industrial Hygiene Association, 2003. Occupational Medicine. 3rd Ed. Zenz, Carl, O. Bruce Dickerson, Edward P. Horvath. Milwaukee, Wisconsin: Mosby, 2014. Provides information on occupational medicine principles and practice as well as on specific hazards and agents. Physical and Biological Hazards in the Workplace. Wald, Peter and Gregg M. Stave. New York, NY: Van Nostrand Reinhold, 2001. On the Practice of Safety. Manuele, Fred A. 3rd Ed. New York, NY: Wiley-Interscience, 2003. Discusses basic principles and aspects of safety as an evolving discipline. Patty's Industrial Hygiene. 5th Ed. New York, NY: John Wiley and Sons Inc., 2000. set.