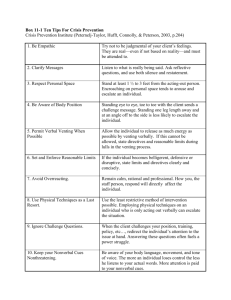

Special Issue Article Numerical simulation of gas dispersion during cold venting of natural gas pipelines Advances in Mechanical Engineering 2018, Vol. 10(2) 1–14 Ó The Author(s) 2018 DOI: 10.1177/1687814018755244 journals.sagepub.com/home/ade Ning Liao1, Kun Huang1, Liqiong Chen1, Zhifang Wang2, Jin Wu3 and Fang Zhang2 Abstract This article analyzes the effects of various factors on gas dispersion during cold venting based on the actual cold venting operations of long-distance natural gas pipelines in China. Under the circumstance that no obstacles existed, unified dispersion model and PHAST software were used to simulate the gas dispersion process of cold venting in order to study the changes of gas concentration along vertical and horizontal directions over time. FLUENT was used to make numerical simulations to analyze the effect of the existence of high obstacles on gas dispersion. The results indicated that (1) with an increase in wind speed, the concentration range in which the gas might explode (5%–15%) decreased along the vertical direction but slightly increased along the horizontal direction; (2) when the initial venting pressure gradually decreased with the proceeding of cold venting, the downwind distance that might trigger danger reduced significantly; and (3) with an increase in atmospheric stability, the dispersion height of vented gas first increased and then decreased continuously. High atmospheric stability could inhibit the gas dispersion height to a larger degree than the wind speed and aerostatic buoyancy could facilitate it. Keywords Natural gas, cold venting, PHAST software, dispersion law, numerical simulation Date received: 17 January 2017; accepted: 1 December 2017 Handling Editor: Oronzio Manca Introduction During the operation management of long-distance natural gas pipelines, in case of a fault or maintenance of auxiliary facilities, the pipe section in question will be cut off by a valve chamber to reduce its pressure and be vented. Such a venting operation is generally achieved using a venting flare or a venting riser. It can be divided into hot venting and cold venting, depending on whether ignition is required. Cold venting is used to directly discharge the high-pressure natural gas into the atmosphere through a venting riser. Along with an increase in the number of natural gas pipelines, the safety hazard associated with cold venting has attracted wide concern. Scholars at home and abroad have conducted a lot of research regarding this issue. H Wei1 derived a formula that could calculate the venting time required by the long-distance, natural gas 1 School of Petroleum Engineering, Southwest Petroleum University, Chengdu, China 2 PetroChina West-East Gas Pipeline Company, Shanghai, China 3 Electromechanical Construction Co., Ltd., China Gezhouba Group, Chengdu, China Corresponding author: Ning Liao, School of Petroleum Engineering, Southwest Petroleum University, 8 Xindu Avenue, Chengdu 610500, Sichuan, China. Email: 995761416@qq.com Creative Commons CC BY: This article is distributed under the terms of the Creative Commons Attribution 4.0 License (http://www.creativecommons.org/licenses/by/4.0/) which permits any use, reproduction and distribution of the work without further permission provided the original work is attributed as specified on the SAGE and Open Access pages (https://us.sagepub.com/en-us/nam/ open-access-at-sage). 2 pipeline. Q Qin et al.2 studied the distance of thermal radiation due to venting of natural gas pipelines and compared it with the calculation result of PHAST software. Kong3 derived a calculation formula that used parameters of an actual pipeline, which could solve the venting time and venting volume of the pipe section. J Qi et al.4 simulated the dispersion process of inflammable gas at the outlet of the venting riser using PHAST software and presented the heat intensity and range in case of accidental burning of the gas. Y Wang and L Wang5 identified the safety distance related to the venting system. J Liang6 identified the dangerous zone subject to burning during small-ignition venting of natural gas and calculated natural gas dispersion law under two working conditions by taking an actual long-distance natural gas pipeline as an example. YD Jo and BJ Ahn7 analyzed the effect of various factors on the scope of danger caused by cracks of high-pressure natural gas pipeline and proposed a simplified correlative equation on that basis. H Montiel et al.8 developed a gas release model applicable to medium and low-pressure relief systems to calculate the venting flow and venting time in case of emergency venting. Although scholars at home and abroad have conducted lots of research on this issue, the research is rare regarding the natural gas dispersion law along the horizontal and vertical directions during cold venting. In this article, first, different factors that may affect gas dispersion during cold venting were analyzed, such as wind speed, atmospheric stability, initial pressure, and outlet diameter of the riser. An analog calculation for gas dispersion during cold venting was performed later using PHAST software, from which the corresponding concentration-distribution cloud charts were obtained. Finally, the effect of different factors on gas dispersion was identified through comparison and analysis. Basic theory Introduction to PHAST software PHAST software is a piece of software independently developed by DNV to perform risk analysis and safety calculation exclusively for petroleum, petrochemical, and natural gas fields. This software has a wide calculation scope and can quickly output various data related to the simulated accident. The calculation result fits well with the experimental data.9 The software could perform analog computations for the consequences of many types of accidents. By checking the result reports and relevant curves, the effect of the pertinent accident on the surrounding environment and personnel can be identified. It could be useful to perform analog computation for leakage and dispersion of pipelines and storage tanks, as well as the severity of corresponding consequences (burning, toxicity, and explosion).10,11 Advances in Mechanical Engineering Mathematical model PHAST software uses the unified dispersion model (UDM) to simulate dispersion of gas when the gas is continuously being released. Dispersion of a gas cloud is affected by various factors and may change significantly during the process. UDM is a complex model that integrates various models to simulate dispersion of gas, such as Gaussian model, BM model, and P-G model.12 It could use the concentration-distribution points of gas being dispersed at a certain moment to portray an isoconcentration line and describe the width of the gas cloud, downwind area, as well as other parameters.13–17 The UDM has the following assumptions: 1. 2. 3. 4. 5. The value of the variable would not change with time. When the gas spreads to the ground, complete reflection occurs, and the ground will not entrain the gas. No chemical reaction will take place during the dispersion. The average wind speed is not less than 1 m/s. The ground is flat without any obstacles. Under stable dispersion, the similar distribution c (x, y, z) of concentration c was obtained from equation (1) ð1Þ cðx, y, zÞ = c0 ð xÞFn ðzÞFh ð yÞ z n y m , Fh ð yÞ = exp Fn ðzÞ = exp Rz Ry where x is the horizontal distance along downwind direction; y is the distance along across-wind direction; c0 is the concentration at the center line; Fv(z) is the distribution of concentration along the vertical direction; Fh(y) is the distribution of concentration along the horizontal direction; z is the distance from horizontal plane to the center line of gas cloud; Rz and Ry are the vertical dispersion factor and lateral wind dispersion factor, respectively; the constants m and n are to be obtained through tests. Operating conditions 1. 2. Composition. The constituent is taken as pure methane during the simulation analysis, as methane takes up over 95% in domestic pipeline natural gas. Initial venting pressure. The design pressure of long-distance natural gas pipelines in our country is normally between 10 and 12 MPa. Considering the depressurization measures taken prior to cold venting and flow regulating as well as the pressure reducing measures taken Liao et al. 3 Figure 1. The obstacle height is significantly less than the height of venting riser. 3. 4. prior to the entrance of gas into the venting riser, the initial pressure of venting is designed as 3–9 MPa. Climate conditions and type of ground surface. The atmospheric temperature is 15°C with a relative humidity of 0.85. Some short crops are growing on the ground surface. There are a few large obstacles with a length–height ratio larger than 20. The surface roughness is taken as 0.1. In order to simulate the effect of different wind speeds on cold venting, the atmospheric stability was set as D. In order to simulate the effect of different atmospheric stabilities on cold venting, the wind speed was set as 5 m/s. In order to simulate the effect of venting pressure and outlet diameter of the riser on cold venting, the atmospheric stability was set as D and the wind speed as 5 m/s. The terrain conditions were assessed by whether or not obstacles exist around the venting area. In the simulation made by the PHAST software, there were no obstacles, or the heights of obstacles were far less than the height of the riser, as shown in Figure 1. Case study Venting of long-distance natural gas pipelines can be categorized into hot venting and cold venting based on whether or not ignition is required. During hot venting, it is necessary to consider the effect of heat radiation and combustion products on the surrounding environment and personnel, as well as the effect of temperature rise on the performance of related venting equipment. In cold venting, it is necessary to consider the dispersion process of natural gas in the air and the possibility of flash burn and other hazards during dispersion of natural gas. Compared to hot venting, cold venting has fewer hazards but is still risky due to flammable and combustible characteristics of high-pressure natural gas. To learn the effects of different influence factors on gas dispersion during cold venting, an analog calculation was performed using PHAST software to understand the dispersion results of the vented gas. For comparison and analysis purposes, corresponding concentration-distribution cloud charts were derived. Input parameters for simulation To study the effects of wind speed and atmospheric stability on cold venting, the venting volume was set as 800,000 m3, the initial venting pressure as 5 MPa, the temperature as 15°C, and the outlet diameter of the venting riser as 300 mm. Different methane concentrations were taken as the minimum monitoring concentrations depending on different situations. The natural gas was made of pure methane. The initial venting pressure was set as 5 MPa and the riser as 20 m high with an outlet diameter of 300 mm. The atmospheric stability was set as D and the wind speed as 5 m/s. Table 1 displays part of the initial data used in the software simulation. Analysis of results Different initial parameters corresponding to different influence factors were inputted into the PHAST software. In the dispersion cloud charts obtained, different colors represent different concentration ranges of natural gas. In the cloud charts made of brown, blue, yellow, and red, brown indicates a concentration of less than 0.5%, blue between 0.5% and 2.5%, yellow between 2.5% and 5% (flash burn range), and red between 5% and 15%. In the cloud charts made of blue, green, yellow, and red, blue indicates a concentration of less than 1%, green between 1% and 2.5%, yellow between 2.5% and 5% (flash burn range), and red between 5% and 15%. Effect of wind speed on gas dispersion. An analysis was made regarding the environmental conditions at the place where the long-distance, natural gas pipeline stations are located. A strake was often mounted on the top of the riser to mitigate the effect of high wind speed on the venting riser itself. In this study, different wind speeds of 2, 4, 6, 8, 10, and 12 m/s were selected for simulation purpose. Part of the dispersion cloud charts 4 Advances in Mechanical Engineering Table 1. Part of the initial data in cold venting simulation. Condition Entry Input data Basic date Composition Venting amount Gas temperature Spraying direction Height of the riser Atmospheric temperature Relative humidity Surface temperature The surface roughness The sun radiation The initial blow-down pressure Outlet diameter Atmospheric stability The initial blow-down pressure Outlet diameter Wind speed Outlet diameter Wind speed Atmospheric stability The initial blow-down pressure Wind speed Atmospheric stability Composition Venting amount Gas temperature Spraying direction Height of the riser Atmospheric temperature Relative humidity Surface temperature The surface roughness The sun radiation The initial blow-down pressure Outlet diameter Atmospheric stability The initial blow-down pressure Outlet diameter Wind speed Outlet diameter Wind speed Atmospheric stability The initial blow-down pressure Wind speed Atmospheric stability Methane 80 3 104m3 15°C Vertical upward 20 m 16°C 0.85 10°C 10 cm 0.5 50 bar 300 mm D 50 bar 300 mm 5 m/s 300 mm 5 m/s D 50 bar 5 m/s D Methane 80 3 104 m3 15°C Vertical upward 20 m 16°C 0.85 10°C 10 cm 0.5 5 MPa 300 mm D 5 MPa 300 mm 5 m/s 300 mm 5 m/s D 5 MPa 5 m/s D Different wind speeds Different atmospheric stabilities Different outlet pressures Different standpipe outlet diameters Basic data Different wind speeds Different atmospheric stabilities Different outlet pressures Different standpipe outlet diameters obtained is shown in Figure 2. The dispersion cloud charts indicated the dispersion conditions within 50 m along the downwind direction. The concentration distribution of the vented gas under different wind speeds is obtained, in which the minus symbol indicates upwind direction. Using these data, the relation curve of wind speed versus dispersion height of methane of 5% concentration and the relation curve of wind speed versus downwind distance were portrayed, which are shown in Figures 3 and 4. The simulation results show that the dispersion height decreases insignificantly with the increasing wind speed, but it has an instability influence on the downwind distance when the wind speed increases. What is more, the scope of the dispersion has narrowed obviously with the increasing wind speed, which is more safe. It can be derived from the simulation results that 1. 2. The duration required for the gas cloud to disperse to a certain distance (to 50 m along downwind direction of the riser) shortened with an increase in wind speed. Under low wind speed, the natural gas mainly disperses upward; with an increase in wind speed, the gas cloud significantly shifts to the horizontal direction. Liao et al. 5 Figure 2. Gas dispersion cloud charts of different wind speeds (2, 6, 10 m/s). 3. 4. With an increase in wind speed, the concentration range in which the gas might explode (5%– 15%) decreased along the vertical direction, but it slightly increased along the horizontal direction. Within the wind speed range used for simulation purposes, the concentration range in which the gas might explode decreased with an increase in 5. wind speed along the vertical direction, which was varied to a relatively large degree. Under the assumption that there is no obstacle under certain conditions (5 MPa and atmospheric stability of D), if there are no combustion sources within 30 m during cold venting, then the probability of combustion or explosion was extremely small. 6 Advances in Mechanical Engineering as shown in Figures 7 and 8. The simulation results show that the dispersion height increases first when the atmospheric stability is between A and D and then decreases. Despite the fact that the downwind distance has a growing tendency as the increase in atmospheric stability, the influence on it is unstable. What is more, the scope of the dispersion has narrowed obviously with the increasing atmospheric stability. It can be derived from the simulation results that 1. 2. Figure 3. The effect of wind speed on the dispersion height (methane concentration is 5%). 3. Figure 4. The effect of wind speed on the downwind dispersion distance (methane concentration is 5%). Effect of atmospheric stability on gas dispersion. Atmospheric stability refers to an air mass in the air rising or falling due to the buoyancy caused by the intensity of the density, temperature, and velocity of the surrounding air, which can be divided into strong unstable, unstable, weakly unstable, neutral, more stable, and stable six atmospheric stabilities, and they are expressed as A, B, C, D, E, and F. Using PHAST software, gas dispersion cloud charts corresponding to atmospheric stabilities A– G were obtained. Part of the cloud charts is presented in Figures 5 and 6, which show the dispersion conditions within 40 m along the downwind direction. The concentration distribution of the vented gas under different atmospheric stabilities is obtained, in which the minus symbol indicates upwind direction. Using these data, some relation curves were portrayed, The duration required for the gas cloud to disperse to a certain distance (to 40 m along the downwind direction of the riser) shortened with an increase in atmospheric stability; With an increase in atmospheric stability, the vented gas dispersed more easily along the horizontal direction. Along the vertical direction, the dispersion height of natural gas first increased, followed by a continuous decrease. Similar to the effect of wind speed, increase in atmospheric stability was also conductive to the gas to disperse along the horizontal direction. Along the vertical direction, the atmospheric stability could inhibit the gas dispersion height to a larger degree than the wind speed could facilitate it. Effect of initial venting pressure on gas dispersion. A survey was performed regarding the operation pressure of long-distance natural gas pipelines during cold venting operations. The initial venting pressure of 3–9 MPa was taken to make the simulation considering the depressurization measures taken prior to cold venting and the pressure reducing effect of the air-release valve. Part of the cloud charts obtained is presented in Figure 9, which shows the dispersion conditions within 50 m along the downwind direction. The concentration distribution of the vented gas under different initial venting pressures is obtained from the simulation results, in which the minus symbol indicates upwind direction. Using these data, some relation curves were portrayed, as shown in Figures 10 and 11. The simulation results show that the dispersion height and downwind distance increase with the increasing initial venting pressure, and the downwind distance has a fluctuant growing tendency. What’s more, the scope of the dispersion does not change obviously with the increasing venting pressure. It can be derived from the simulation results that 1. The duration required for the gas cloud to disperse to a certain distance (to 50 m along the downwind direction of the riser) lengthened with a decrease in initial venting pressure. Liao et al. 7 Figure 5. Gas dispersion cloud charts under different atmospheric stabilities (A and C). 2. 3. 4. Under the conditions that wind speed and other external conditions remained unchanged, with a decrease in the outlet pressure, the gas cloud shifted more toward the horizontal direction. Under the same concentration, the dispersion height upward became smaller. Proceeding with the venting operation, the outlet pressure decreased, and the concentration range in which the gas might explode decreased along both the vertical and horizontal directions. In the areas where obstacles were not considered, during cold venting under certain conditions (wind speed of 5 m/s), if there was no combustion source within 50 m, the probability of explosion was extremely small. Effect of outlet diameter of the riser on gas dispersion. There was an analysis of the statistical data of specifications of venting risers used in the natural gas industry. The outlet diameters of 150, 200, 250, 300, 350, and 400 mm were selected for simulation purposes. Part of the cloud charts obtained is presented in Figure 12, which shows the dispersion conditions within 50 m along the downwind direction. The concentration distribution of the vented gas under different outlet diameters is obtained, in which the minus symbol indicates upwind direction. As shown in Figures 13 and 14, using these data, some relation curves were portrayed. The simulation results show that the dispersion height and downwind distance increase with the increasing riser outlet diameter, and the downwind distance has a fluctuant growing tendency. What is more, the scope of the dispersion becomes larger obviously with the increasing atmospheric stability, which increases the risk of venting process. It can be derived from the simulation results that 1. 2. The duration required for the gas cloud to disperse to a certain distance (to 50 m beyond the outlet of the venting riser) shortened with an increase in the outlet diameter of the riser. Under the conditions that wind speed and other external conditions remained unchanged, along with an increase in the outlet diameter, both the height and horizontal distance of the gas cloud increased, as well as the dispersion range. 8 Advances in Mechanical Engineering Figure 6. Gas dispersion cloud charts under different atmospheric stabilities (E and G). Figure 7. The effect of atmospheric stability on the dispersion height (methane concentration is 5%). 3. When other conditions remained unchanged, with an increase in the venting diameter, the area in which the gas concentration was at the edge of explosion (5%–15%) significantly increased. Figure 8. The effect of atmospheric stability on the downwind dispersion distance (methane concentration is 5%). Changes of various factors. During cold venting, more than one factor may be changed. For a planned cold venting operation, the size and the outlet pressure of the venting riser could be controlled by the initial Liao et al. 9 Figure 9. Gas dispersion cloud charts of different venting pressures (9, 7, and 5 MPa). pipeline pressure and the opening of the air-release valve. However, the external environmental factors, such as wind speed and atmospheric stability, are not controllable. Wind speed, however, could be measured 10 Advances in Mechanical Engineering 2. could trigger danger also significantly decreased. This means that it is necessary to depressurize the pipeline prior to venting. It can be seen from Figure 16 that under the same initial venting pressure, the higher the wind speed, the lower the dispersion height. This trend became more obvious when the initial venting pressure became smaller. Discussion Figure 10. The effect of initial venting pressure on the dispersion height (methane concentration is 5%). Figure 11. The effect of initial venting pressure on the downwind dispersion distance (methane concentration is 5%). simply. The statistical data of concentration distribution under different wind speeds and different initial venting pressures are obtained. The venting volume was 800,000 m3, and the riser is 20 m high with a diameter of 300 mm. The atmospheric stability is D, and the atmospheric temperature is 15°C. The effect of wind speed and initial venting pressure on the dispersion height and downwind distance of methane was derived, as shown in Figures 15 and 16. According to the relationship curves, the following conclusions were derived: 1. Figure 15 demonstrates that when the initial venting pressure decreased gradually during the venting operation, the downwind distance that PHAST software could produce different curves and concentration cloud charts for different heights but could not reflect the effects of obstacles on gas dispersion. For this end, FLUENT was used to perform numerical simulation to analyze the effect of obstacles on gas dispersion. Figures 17 and 18 displayed the case of venting in a mountainous area and a forest area. And Figures 19 and 20 display the dispersion cloud charts that the obstruction exists or not. The dispersion cloud charts at different time points from FLUENT software indicated that during the initial period of venting, the velocity at the outlet of the riser was relatively fast. As a result, the gas cloud soon reached the windward side of the obstacle and formed a concentration accumulation area. Proceeding with cold venting, the velocity at the outlet of the riser decreased. Under the action of wind speed and buoyancy, the concentration of methane was reduced in the front of the obstacle. When the venting operation approached the end, the velocity at the outlet of the riser decreased more. Compared to the case where there is no obstacle, or the obstacle is lower than the venting riser, the case with the large obstacle is different. In the initial period of venting, the gas at the outlet of the riser swelled into a high-speed stream and was sprayed into the air. Pushed by the strong initial kinetic energy, the gas stream moved upward rapidly and turned to the right direction under the action of wind speed after reaching a certain distance. Following that, the velocity component along the vertical direction became smaller. The gas stream reached the windward side of the obstacle, and its speed along the horizontal direction was offset by bumping. Part of the gas cloud still climbed alongside the obstacle under the action of buoyancy. The rest accumulated in the front of the obstacle and formed a high-concentration area. Conclusion PHAST software was used to calculate the effect of wind speed, atmospheric stability, initial venting pressure, and outlet diameter of the riser on the gas dispersion during cold venting. This was based on the actual Liao et al. 11 Figure 12. Gas dispersion cloud chart of different standpipe outlet diameters (200, 300, and 400 mm). conditions of cold venting operation in our country’s long-distance natural gas pipelines. The following conclusions and control measures were obtained after analysis of the charts and tables: 1. The higher the wind speed, the shorter the duration required for the gas to disperse to a certain distance. With higher wind speed, the concentration range in which the gas might explode (5%–15%) 2. decreased along the vertical direction but slightly increased along the horizontal direction. Therefore, to prevent gas from accumulating, the reduction of its dispersion concentration, and to minimize possible hazards, cold venting should be performed under relatively high wind speed in order to accelerate gas dispersion. With an increase in atmospheric stability, the dispersion height of vented gas first increased 12 Figure 13. The effect of riser outlet diameter on the dispersion height (methane concentration is 5%). Advances in Mechanical Engineering Figure 16. Maximum dispersion height under different wind speeds and pressure conditions (methane concentration of 5%). Figure 17. Sketch map of mountain-type obstacle. Figure 14. The effect of riser outlet diameter on the downwind dispersion distance (methane concentration is 5%). Figure 18. Sketch map of forest-type obstacle. 3. Figure 15. Maximum downwind dispersion distance under different wind speeds and pressure conditions (methane concentration of 5%). and then decreased continuously. High atmospheric stability could inhibit the gas dispersion height to a larger degree than the wind speed and aerostatic buoyancy could facilitate it. Hence, it is necessary to choose proper atmospheric stability to facilitate the gas to disperse along the horizontal and vertical directions. The simulation results indicated that the vented gas dispersed quite well when the atmospheric stability was around D. When the initial venting pressure gradually decreased with the proceeding of cold venting, the downwind distance which might trigger danger reduced significantly. Therefore, it was necessary to depressurize the pipeline prior to venting. Liao et al. 13 Figure 19. Gas dispersion cloud chart without obstacles. Figure 20. Gas dispersion cloud chart with obstacles. It could be seen from the relevant charts that when an obstacle existed and reached a certain height, a high-concentration area would be formed in front of the obstacle. Any object that required protection on the windward side of the obstacle would be seriously damaged by the venting. Moreover, PHAST software alone could not reflect the entire situation of actual venting. If there are buildings, forests, or hills with a height higher than the safety height within the safety distance, FLUENT software should be used to further simulate the gas dispersion law. The gas concentration within the accumulation area should be monitored at all times, and all possible fire sources should be excluded to minimize the hazard of fire and explosion. Hot venting may be considered if necessary. Funding Acknowledgements The utilization of facilities and resources of PetroChina West–East Gas Pipeline Company is very much appreciated. The guiding idea of Prof. Huang is also acknowledged. The authors are also very grateful for the support of the national key projects (2016YFC0802100) ‘‘Pipeline and storage facilities inspection evaluation and safety assurance technology’’ in ‘‘13th Five-Year’’ and the consulting research project of Chinese Academy of Engineering (2015-XZ-37) ‘‘The research on the development strategy of oil and gas pipeline network system safety.’’ Declaration of conflicting interests The author(s) declared no potential conflicts of interest with respect to the research, authorship, and/or publication of this article. The author(s) received no financial support for the research, authorship, and/or publication of this article. References 1. Wei H. Discussion of venting time of long-distance natural-gas pipelines. Chem Enterp Manag 2014; 8: L43. 2. Qin Q, Wang W, Zhang L, et al. Discussion on the method of calculating heat radiation distance of venting flare of long-distance natural-gas pipelines. Chem Mach 2009; 6: 566–569. 3. Kong J. Discussion of venting time and venting volume of natural-gas inside the pipeline. Petrochem Ind Appl 2005; 24: 18–20. 4. Qi J, Sun L, Zhang W, et al. Configuration of venting system in the valve chambers along the second west-east natural-gas transmission line. Oil Gas Storage Transp 2009; 9: 63–65. 5. Wang Y and Wang L. Study on safe spacing of venting system for natural-gas pipelines. Chem Eng Equipment 2015; 9: 229–230. 6. Liang J. Study on dispersion rules during flaring of longdistance natural-gas pipelines [J] Contemporary Chemical Engineering 2016; 45: 559–560. 7. Jo YD and Ahn BJ. Analysis of hazard areas associated with high-pressure natural-gas pipelines. J Loss Prevent Proc 2002; 15: 179–188. 8. Montiel H, Vıä lchez JA, Casal J, et al. Mathematical modelling of accidental gas releases. J Hazard Mater 1998; 59: 211–233. 9. Zhu B and Yu X. Study on leakage & dispersion of liquefied natural-gas using PHAST software. Comput Appl Chem 2009; 26: 1418–1422. 10. Wang K. Simulation study on leakage accident of liquefied natural-gas storage tank using PHAST software. Sino-Glob Energy 2016; 21: 87–90. 14 11. Jiang L, Liu F, Gao Z, et al. Application of PHAST software in consequence evaluation of a leakage accident in gas transmission stations. Contemp Chem Ind 2015: 292–294. 12. Yuan L. Analysis on controlling leakage dispersion and risks associated with large-scale air separation storage tank area using PHAST software [D]. East China University of Science and Technology, Shanghai, 2014. 13. Miu C, Zhang S, Wang S, et al. Application of PHAST software in analyzing leakage of LPG. Storage Tanks 2013; 29: 10–13. Advances in Mechanical Engineering 14. Lu Y and Zhao J. Application of PHAST software in quantitative analysis of consequences of butyronitrile reaction still. Ind Safety Environ Prot 2009; 35: 34–37. 15. Hong Z. Environmental noise control engineering. Beijing, China: Higher Education Press, 2002. 16. Lei L. Deformation analysis and structure optimization of plug valve body [D]. Lanzhou University of Technology, Lanzhou, China, 2013. 17. Zhu B, Yu X and Li Y. Study on dispersion process of gas leakage and influence factors thereof. Oil Nat-Gas Chem Ind 2009; 38: 354–358.