Flowline Wall Thickness Criteria - Weco & Chiksan

advertisement

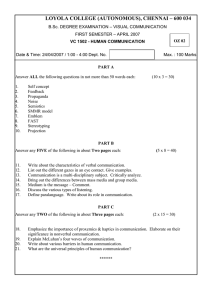

Doc No: RPT50001989 Rev: E Page 1 of 9 REPORT, ENGINEERING BULLETIN, FOR CUSTOMER USE, FLOWLINE, WALL THICKNESS MEASURMENT CRITERIA FOR WECO AND CHIKSAN PRODUCTS Rev ECN No. Date Reviewed By Approved By Status E 5053301 18-NOV-2020 Bedwell2, Cody Soltau, James RELEASED Summary: This document provides wall thickness measurement criteria for the Flowline equipment. This document along with RPT50002000 also replaces Engineering Bulletin 102C. This document and all the information contained herein are the confidential and exclusive property of TechnipFMC, and may not be reproduced, disclosed, or made public in any manner prior to express written authorization by TechnipFMC. Doc No: RPT50001989 Rev: E Page 2 of 9 Engineering Bulletin 1.0 Scope The purpose of this document is to provide inspection personnel with minimum pressure boundary wall thickness criteria for Weco® and Chiksan® (hereafter referred to a "Flowline") products. For guidance on routine maintenance and other inspection criteria, the end user should consult product specific operating manuals and Integrated Services procedures. CAUTION 2.0 Due to variability of service conditions, the service life of life of oilfield temporary piping can vary widely. In order to maximize the useful life of Chiksan and Weco products, the end user must institute appropriate inspection procedures with due consideration of all service conditions. Background Oil well pumping services such as hydraulic fracturing involve the movement of slurries with abrasive solids at high flow rates. Over time, temporary piping equipment can experience significant loss of pressure boundary wall thickness. The minimum wall thickness values in the tables of this document are a result of a consistent application of pressure boundary calculations per ASME Boiler and Pressure Vessel Code Section VIII Division 2, and acceptance criteria in accordance with API 6A for non-standard materials. WARNING 3.0 Never take TechnipFMC Flowline equipment above its rated working pressure. The minimum wall thickness criteria in this document assume that rated working pressure is never exceeded during operation, pre-job testing or recertification for service. Use of this Document This document only provides wall thickness acceptance criteria. Actual inspection methodology requirements such as inspection frequency, inspection scope and acceptable measurement techniques are beyond the scope of this document. All This document and all the information contained herein are the confidential and exclusive property of TechnipFMC, and may not be reproduced, disclosed, or made public in any manner prior to express written authorization by TechnipFMC. Doc No: RPT50001989 Rev: E Page 3 of 9 such inspection activity on Flowline products should be carried out in accordance with Integrated Services procedures or other procedures approved by TechnipFMC. When wall thickness measurements are taken, they must be compared with the minimum allowable thickness for the product and feature per the applicable table(s) within this document. If any inspected wall thickness falls at or below the specified minimum allowable thickness, the component or product must be replaced. It is highly recommended that the rate of erosion wear be analyzed to ensure that the minimum wall thickness is not violated prior to the next scheduled inspection. Use of temporary piping equipment with wall thickness in any area below that specified in this document can result in death, severe injury and significant property damage. WARNING 4.0 Minimum Wall Thickness Tables Tables 4.1 through 4.4 on the following pages contain minimum wall thickness criteria for Flowline products. These values apply to products manufactured specifically by TechnipFMC. This document and all the information contained herein are the confidential and exclusive property of TechnipFMC, and may not be reproduced, disclosed, or made public in any manner prior to express written authorization by TechnipFMC. Doc No: RPT50001989 Rev: E Page 4 of 9 Table 4.1: Minimum Eroded Wall Thickness for Various Swivel Joints/ Longsweep Elbows in Bend and Straight Areas (Not at Swivel or Male Sub End) Nominal Size 1" Model(s) Minimum Thickness (inches) LS10, LS15, LSG10 0.178 LS10, LS15 0.243 2" LS10, LS15, LSG10 LS20, LSG15 0.309 0.386 3" HP (602) LS7, LS10 TSi-10, TS10 LS15, LSG10 TSi-15, TS15, TSI+15 LS20, LSG15 TSi-20 0.292 0.299 0.280 0.434 0.403 0.721 0.662 4" FS4 (4000 CWP) HP6 HPX LS10 XHTL, LSG10 TSi-10 TSi-15 0.310 0.381 0.419 0.390 0.562 0.359 0.517 1-1/2" This document and all the information contained herein are the confidential and exclusive property of TechnipFMC, and may not be reproduced, disclosed, or made public in any manner prior to express written authorization by TechnipFMC. Doc No: RPT50001989 Rev: E Page 5 of 9 Table 4.2: Minimum Eroded Wall Thickness Under Male Ball Race for Swivel Joints Nominal Size Model(s) Minimum Thickness (inches) 1" LS10, LS15 LSG10* 0.104 0.075 1-1/2" LS10, LS15 0.145 2" LS10, LS15 LSG10* LS20 LSG15* 0.188 0.142 0.259 0.221 3" HP (602) LS7, LS10 LS15 LSG10* LS20 LSG15* TSi-10, TSi-15, TSI+15 TSi-20 0.212 0.176 0.271 0.205 0.476 0.395 0.268 0.430 4" FS4 (4000 CWP) HP6 HPX LS10 XHTL LSG10* TSi-10 TSi-15 0.176 0.231 0.306 0.224 0.346 0.255 0.211 0.312 * Minimum wall for sour gas swivels are with snap-in races removed This document and all the information contained herein are the confidential and exclusive property of TechnipFMC, and may not be reproduced, disclosed, or made public in any manner prior to express written authorization by TechnipFMC. Doc No: RPT50001989 Rev: E Page 6 of 9 Table 4.3: Minimum Eroded Wall Thickness for Detachable Wing Union behind Male Sub Shoulder Nominal Figure Size Number Standard Service Minimum (Inches) Sour Gas Service Minimum (inches) 1" 1502 0.228 0.171 1-1/2" 1502 0.325 0.244 2" 602 0.131 0.248 1002 0.212 0.191 1502 0.316 0.283 2002 0.396 ---- 2202 ---- 0.364 602 0.196 0.411 1002 0.332 0.314 1502 0.474 0.407 1505 0.591 ---- 2002 0.821 ---- 2202 ---- 0.754 3" 4" 602 (All except 4" HP6) 0.313 0.502 602 (4" HP6, only) 0.452 ---- 0.422 0.349 1002 1502 (All except 4" XHTL) 0.592 0.534 1502 (4" XHTL, only) 0.648 ---- 602 to 2202 1505 This document and all the information contained herein are the confidential and exclusive property of TechnipFMC, and may not be reproduced, disclosed, or made public in any manner prior to express written authorization by TechnipFMC. Doc No: RPT50001989 Rev: E Page 7 of 9 Table 4.4: Minimum Eroded Wall Thickness for Pup Joints in Tubular Area Nominal Size Figure Number Standard Service Minimum (Inches) Sour Gas Service Minimum (Inches) Non-Pressure Seal Thread Pup Joints: 1" (1.375" OD) 1" (1.315" OD) 1502 1502 0.153 0.146 0.126 0.120 1 1/2" 1502 0.222 0.182 2" 602 1002 1502 0.114 0.184 0.246 0.136 ---0.217 3" 602 1002 1502 0.168 0.270 0.361 0.200 0.246 0.319 4" 602 1002 1502 1502 0.200 0.323 0.499 0.473 0.256 0.315 0.409 ---- 4" (4.50" OD) 4" (4.75" OD) Integral Pup Joints and Swivel Joint Hose Straight Pieces 1" 1502 0.212 0.175 1 1/2" 1502 0.289 0.238 2" (3.00" OD) 602 1002 1502 0.159 0.255 0.364 0.189 ---0.300 2" (2.75" OD) 602 1002 1502 0.146 0.233 0.332 0.173 ---0.274 2" (2.50" OD) 602 1002 1502 0.134 0.215 0.306 0.159 ---0.252 This document and all the information contained herein are the confidential and exclusive property of TechnipFMC, and may not be reproduced, disclosed, or made public in any manner prior to express written authorization by TechnipFMC. Doc No: RPT50001989 Rev: E Page 8 of 9 Table 4.4: Minimum Eroded Wall Thickness for Pup Joints in Tubular Area (Continued) Nominal Size Figure Number Standard Service Minimum (Inches) Sour Gas Service Minimum (Inches) Integral Pup Joints and Swivel Joint Hose Straight Pieces (Continued) 2" (2.38" OD) 602 1002 1502 2002 2202 0.115 0.184 0.246 0.366 ---- 0.136 ---0.217 ---0.336 3" (4.12" OD) 602 1002 1502 1505 0.219 0.350 0.500 0.500 0.259 0.319 0.412 0.412 3" (3.75" OD) 602 1002 1502 1505 0.193 0.309 0.442 0.442 0.252 0.263 0.341 0.341 3" (5.41" OD) 2002 2202 0.824 ---- ---0.757 3" (5.25" OD) 2002 2202 0.736 ---- ---0.704 4" (5.00" OD) 602 1002 0.240 0.386 0.285 0.350 4" (5.25" OD) 1502 0.578 0.475 2" 2002 2202 0.348 ---- ---0.336 3" 2002 2202 0.783 ---- ---0.757 Fabricated Pup Joints: This document and all the information contained herein are the confidential and exclusive property of TechnipFMC, and may not be reproduced, disclosed, or made public in any manner prior to express written authorization by TechnipFMC. Doc No: RPT50001989 Rev: E Page 9 of 9 Table 4.4: Minimum Eroded Wall Thickness for Pup Joints in Tubular Area (Continued) Nominal Size Figure Number Pressure Rating (psi) Standard Service Minimum (Inches) Line Pipe Thread Swivel Joint Hoses: 1" 602 1502 6,000 10,000 0.146 0.107 1 1/2" 602 1502 6,000 10,000 0.096 0.155 2" 602 1502 6,000 10,000 0.114 0.184 3" 602 1502 6,000 7,500 0.156 0.207 This document and all the information contained herein are the confidential and exclusive property of TechnipFMC, and may not be reproduced, disclosed, or made public in any manner prior to express written authorization by TechnipFMC.